High-temperature environment-friendly antibacterial glaze

An antibacterial glaze and environmental protection technology, applied in the direction of fungicides, preservation of human or animal bodies, biocides, etc., can solve the problems of ceramic glaze adding lead, human hazards, etc., to save production costs, high antibacterial rate, and maintain enamel smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is illustrated below with specific examples.

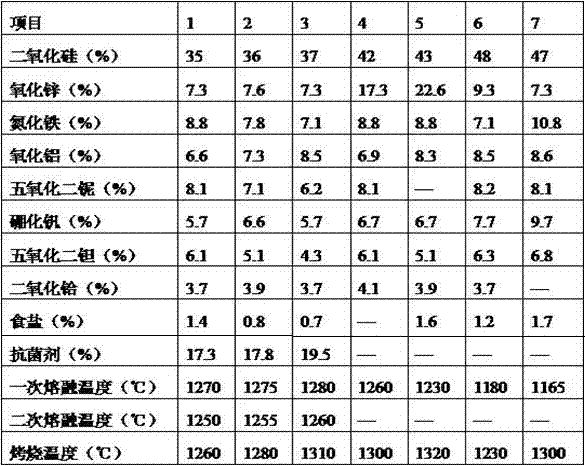

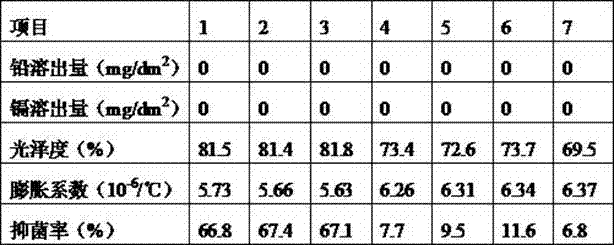

[0021] Examples 1-3 of the high-temperature environment-friendly antibacterial glaze of the present invention, and comparison examples 4-7, the formula (weight percentage) and preparation method thereof are shown in Table 1.

[0022] Table 1: The formula (percentage by weight) and preparation method of the high-temperature environment-friendly antibacterial glaze of the embodiment and the comparative example

[0023]

[0024] Note: "—" means none.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com