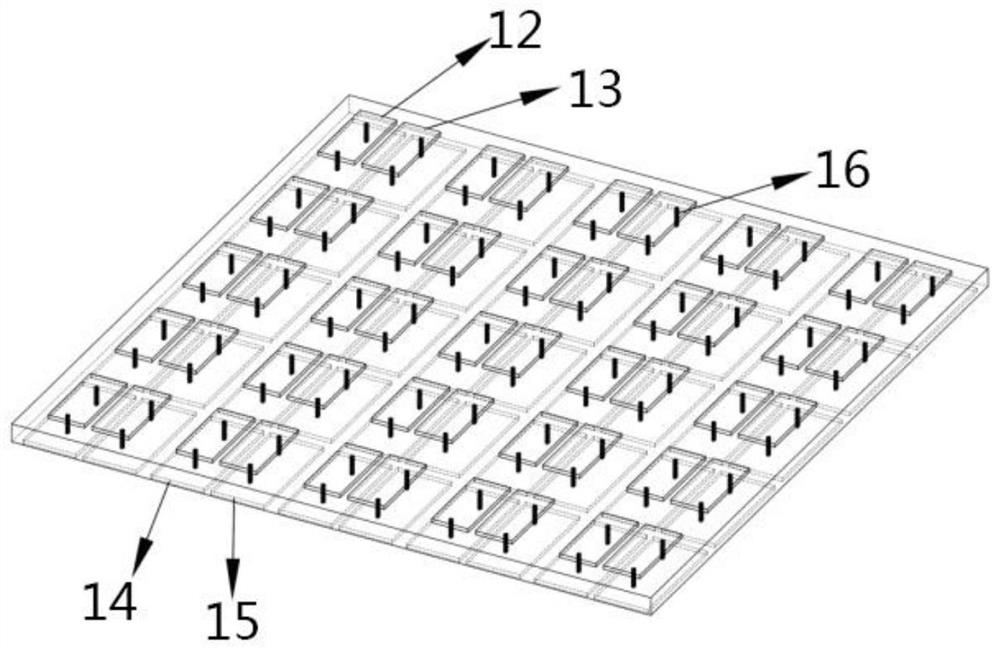

Patents

Literature

41results about How to "Expansion coefficient matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

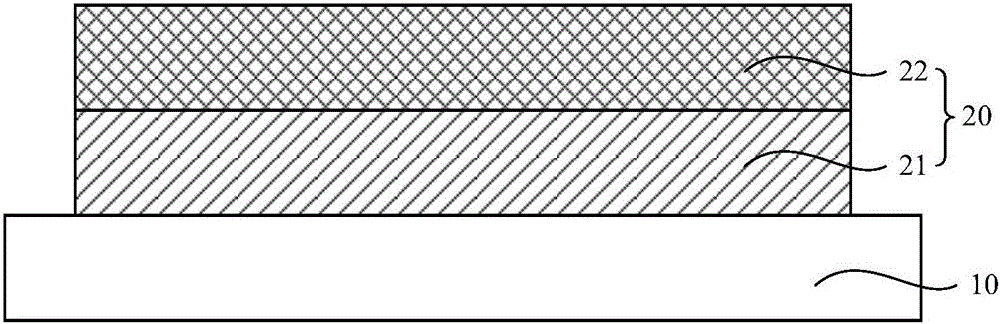

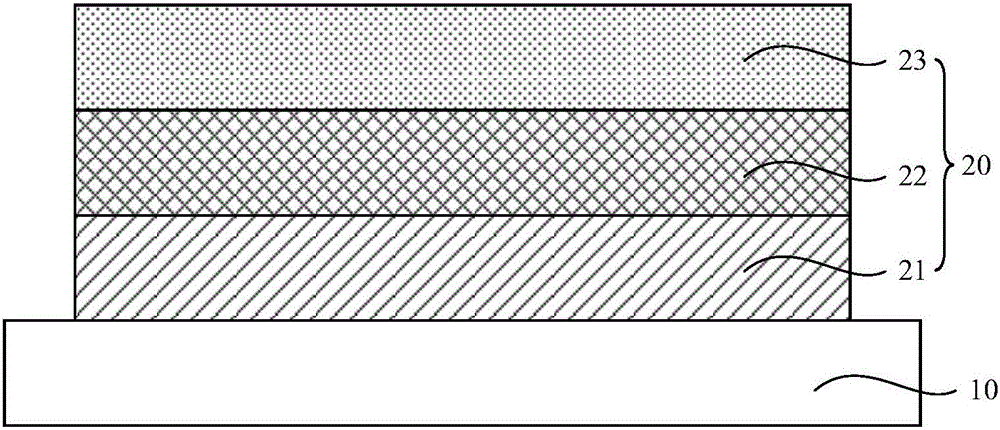

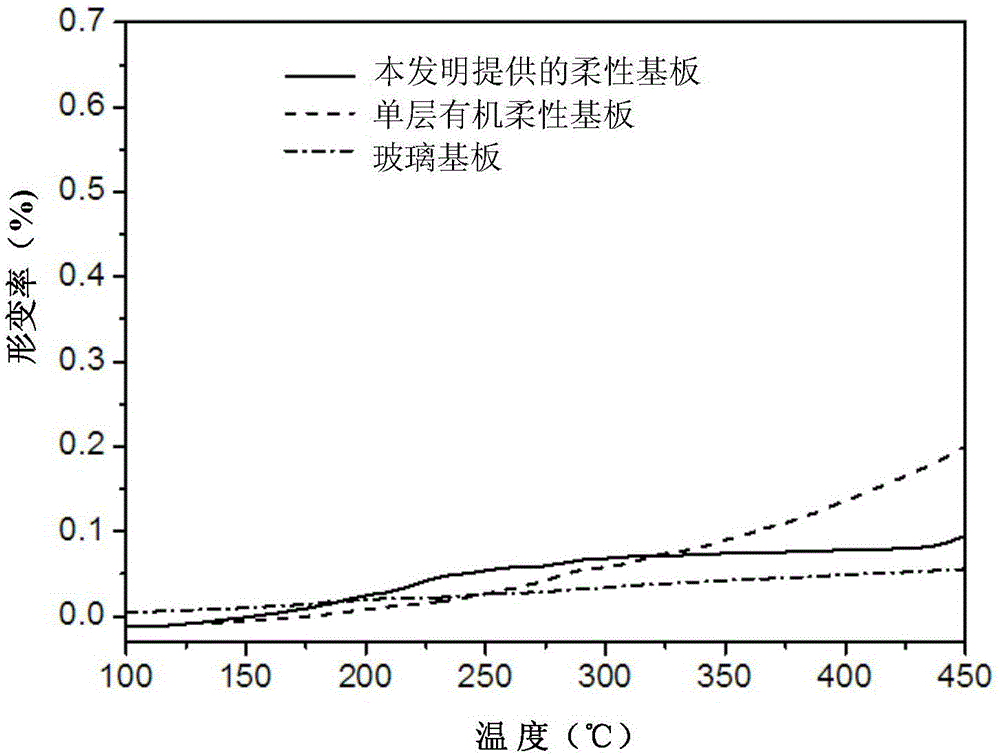

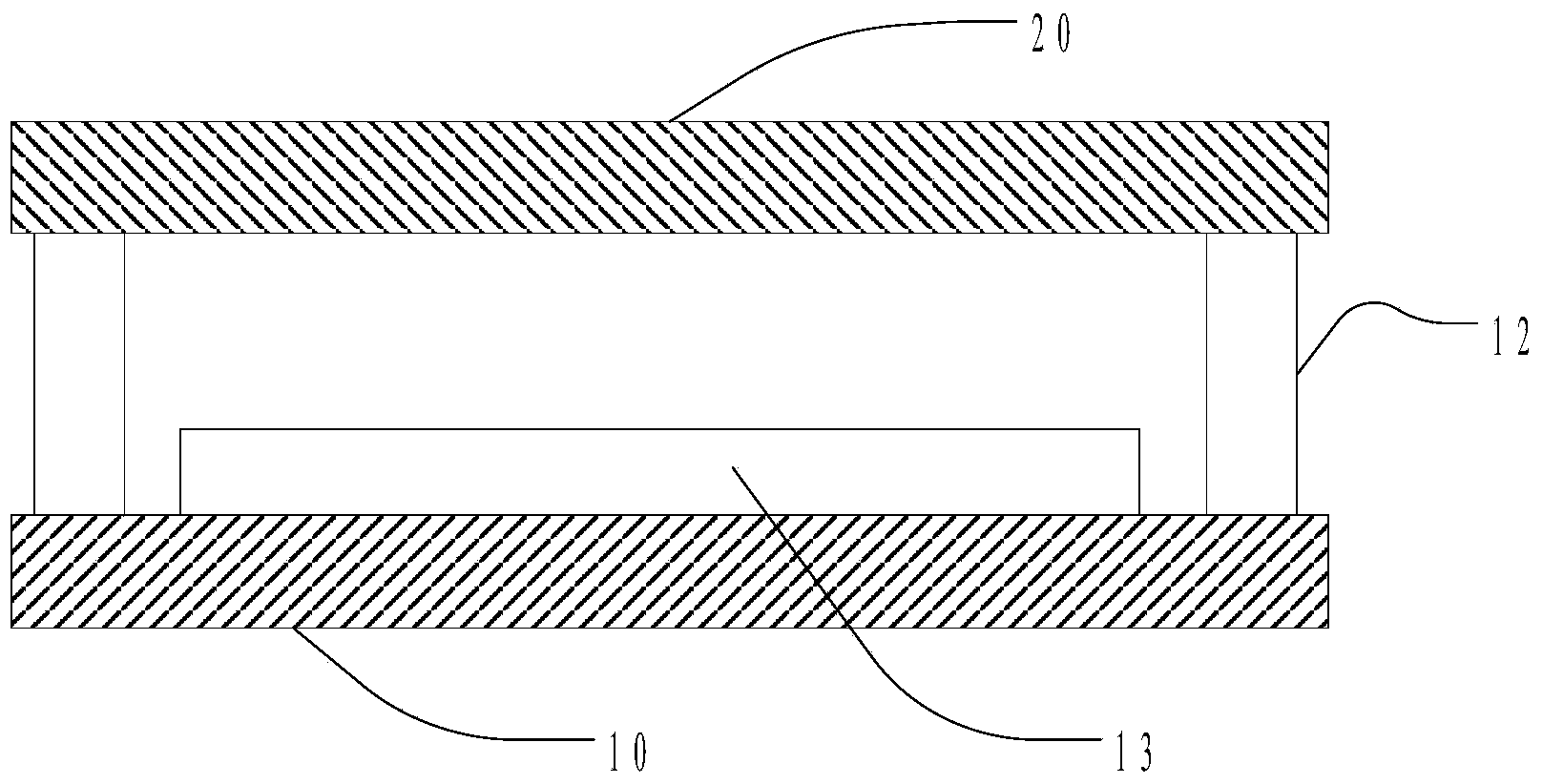

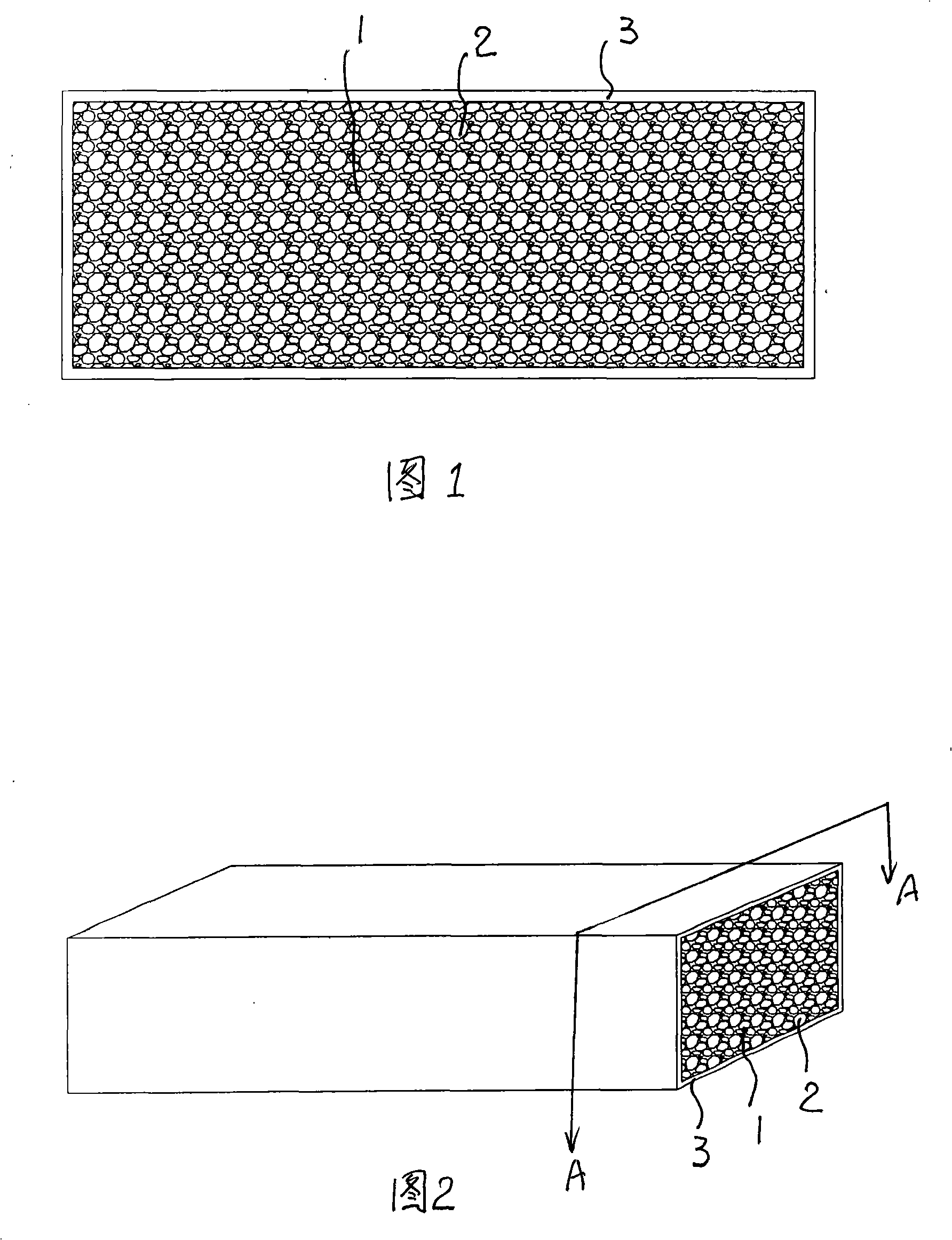

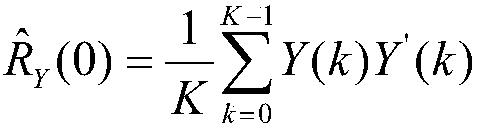

Flexible substrate, preparation method of flexible substrate and flexible display device

PendingCN106206945ASmall expansion coefficientExpansion coefficient matchingMaterial nanotechnologyFinal product manufactureComposite structureOrganic inorganic

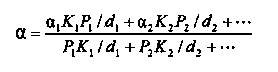

The invention relates to the technical field of display and discloses a flexible substrate, a preparation method of the flexible substrate and a flexible display device to solve the technical problems that as a rigid auxiliary substrate is prone to warping, the process precision is low when a display device is prepared. The flexible substrate comprises a first organic layer and an inorganic buffer layer which are sequentially stacked. An organic-inorganic composite structure is formed by the first organic layer and the inorganic buffer layer. The expansion coefficient of the inorganic buffer layer is smaller than the expansion coefficient of the first organic layer. Under the interaction of the first organic layer and the inorganic buffer layer which form the organic-inorganic composite structure, the expansion coefficient of the flexible substrate is reduced; the expansion coefficient of the flexible substrate is matched with the expansion coefficient of the rigid auxiliary substrate better, the risk that the rigid auxiliary substrate warps is reduced, and the process precision is increased when the display device is prepared. The flexible substrate is applied to the flexible display device.

Owner:BOE TECH GRP CO LTD

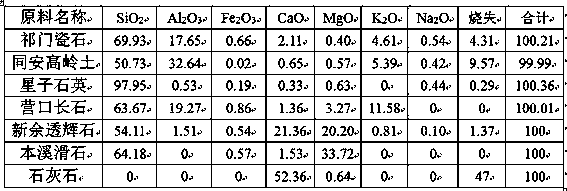

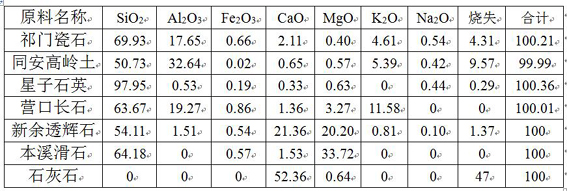

Lead- and zinc-free transparent fritted glaze

A fritted glaze without Pb and Zn for ceramics contains SiO2, Al2O3, CaO, MgO, K2O, Na2O, SrO, Li2O, B2O3, Fe2O3, Bi2O3 and Y2O3 proportionally. Its advantages are high adhesion, smooth and bright surface, and gay color.

Owner:JIANGSU BAIFU TECH CO LTD

Ceramic binding agent for ceramic grinding block and preparation method thereof

ActiveCN103551971AGood gripLower sintering temperatureAbrasion apparatusGrinding devicesPowder metallurgyOxide

The invention discloses a ceramic binding agent for a ceramic grinding block and a preparation method thereof and belongs to the technical field of powder metallurgy materials. The ceramic binding agent aims at achieving the effects that the retention to diamond is good, the expansion coefficient is matched with expansion coefficients of silicon carbide, brown aluminum oxide and the diamond, and the sintering temperature of a finished product is low. The ceramic binding agent is formed by the following powder materials of, by weight, 20 to 55 kilograms of silicon dioxide, 5 to 25 kilograms of aluminum oxide, 0 to 5 kilograms of zinc oxide, 0 to 5 kilograms of titanium dioxide, 0 to 7 kilograms of zirconium oxide, 10 to 20 kilograms of sodium carbonate, 5 to 15 kilograms of lithium carbonate and 8 to 30 kilograms of boric acid. According to the ceramic binding agent for the ceramic grinding block, the ceramic grinding block has the advantages of being low in sintering temperature, good in self-sharpening, good in sharpness, long in service life, low in carbon and environmentally friendly.

Owner:BOSUN TOOLS CO LTD

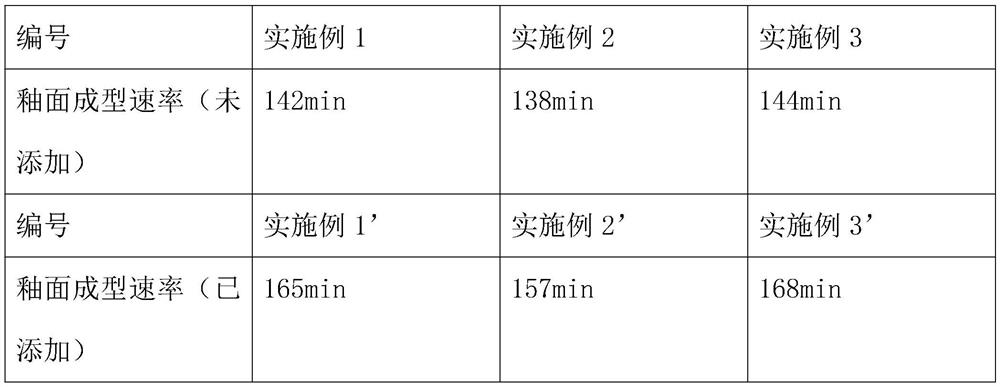

Glazing method for enhancing ceramic durability

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a glazing method for enhancing ceramic durability. The glazing method includes the steps: wet glaze preparation; primary glazing; dry glaze preparation; secondary glazing; firing and drying. The method is simple and convenient to operate, glaze and a green body are closely combined, expansion coefficients are matched, surfaces are smooth and uniform, colors are bright, corrosion resistance is high, the service life is prolonged by 12.4%, and economic income is improved by 26.7%. The glaze is frozen by adding water, grinding is facilitated, anhydrous alcohol is added, the glaze is grinded in a high-temperature dry environment, unfreezing of the glaze is accelerated, and the bright colors are kept. The green body is placed in a high-temperature and high-humidity environment after primary glazing, adsorption of the green body for the glaze is promoted, needle holes and bubbles are decreased, and the service life is prolonged. The sprayed glaze is freeze-dried, the colors of the glaze are kept bright, adsorptivity of the glaze is enhanced, the glaze is applied by dry pressing, so that a glaze layer is smooth and uniform, and durability is improved. The green body is fired at low temperature after the glaze is applied, durability of the green body is improved, environments are protected, and energy is saved by 9.6%.

Owner:福建省德化佳旺达陶瓷有限公司

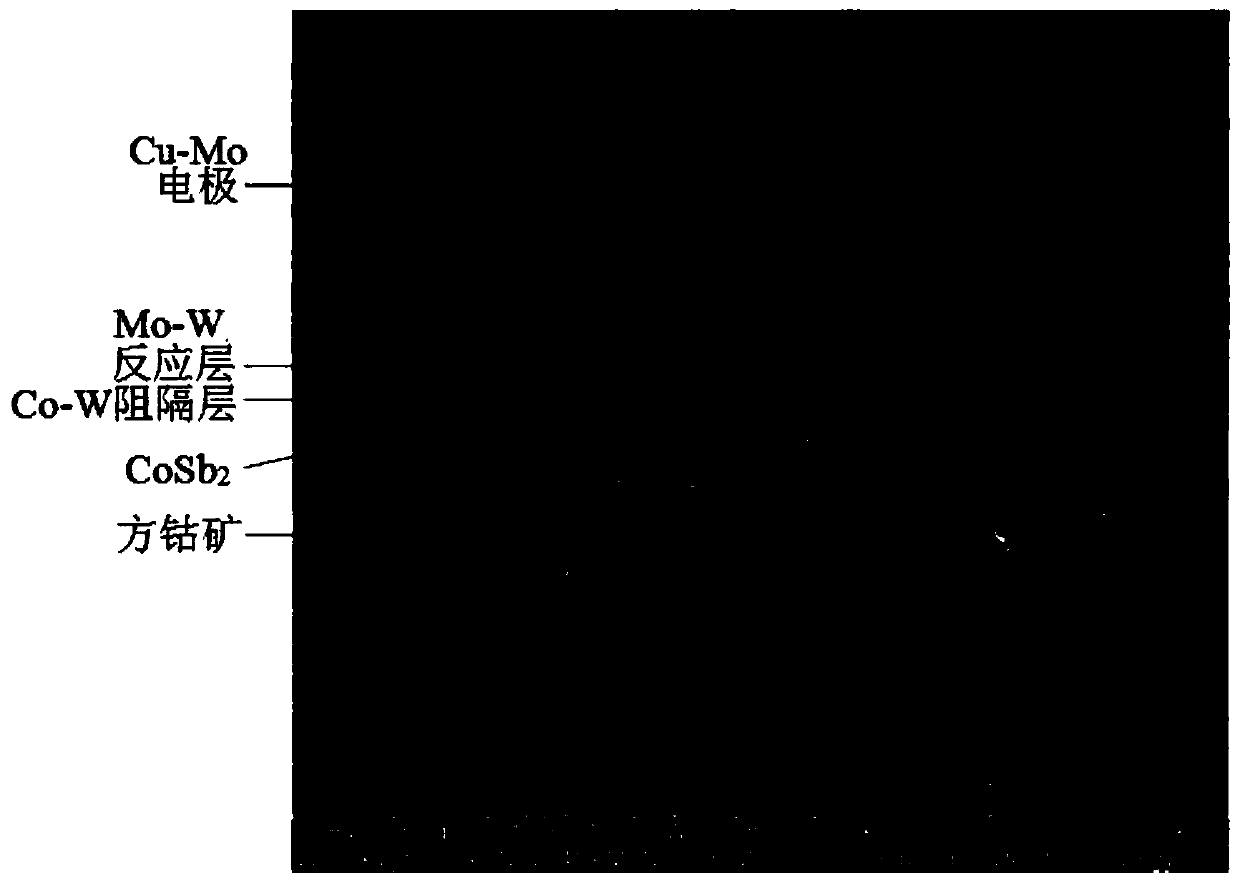

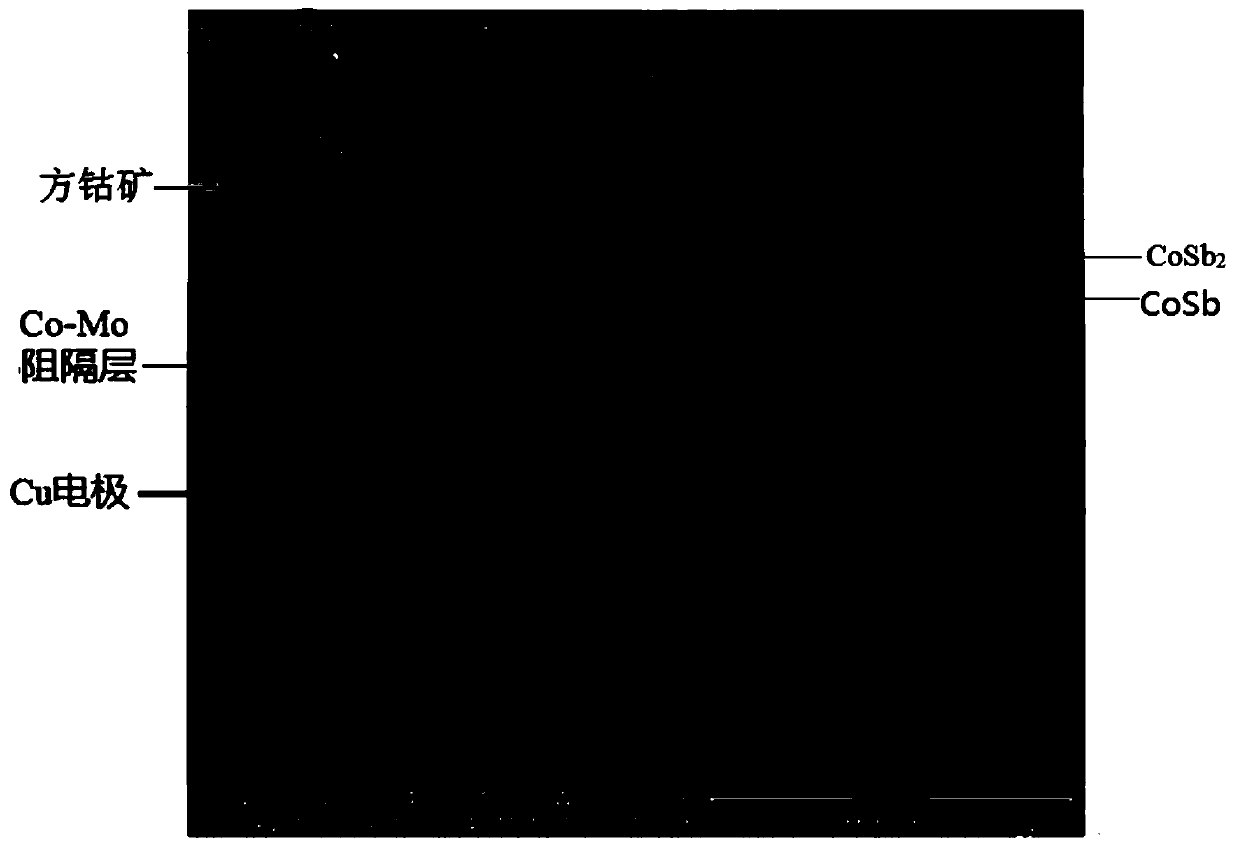

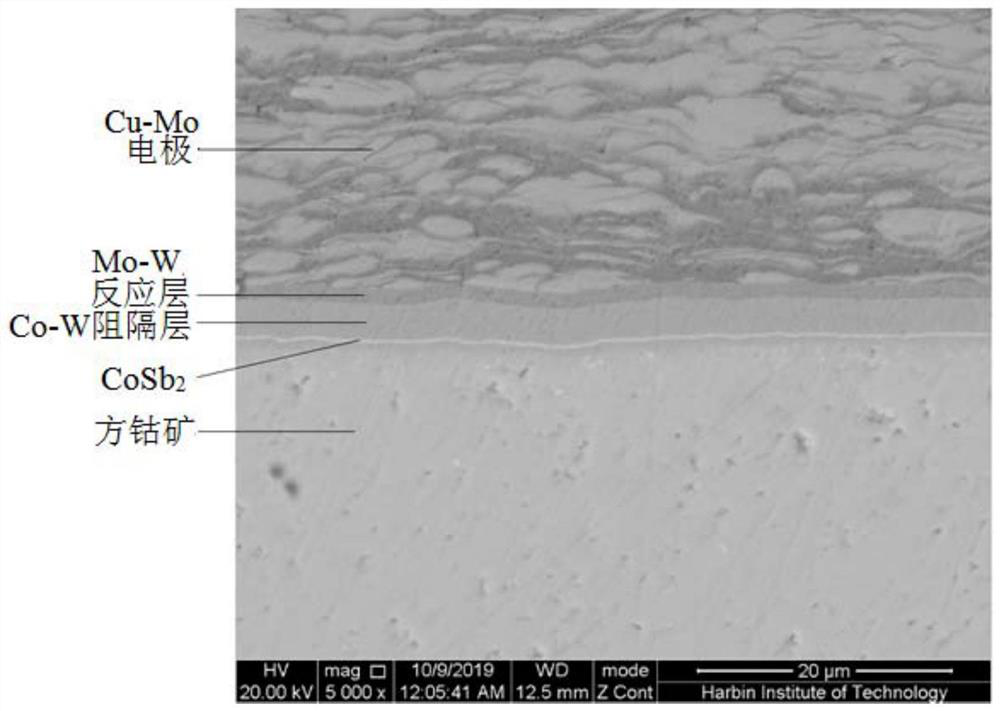

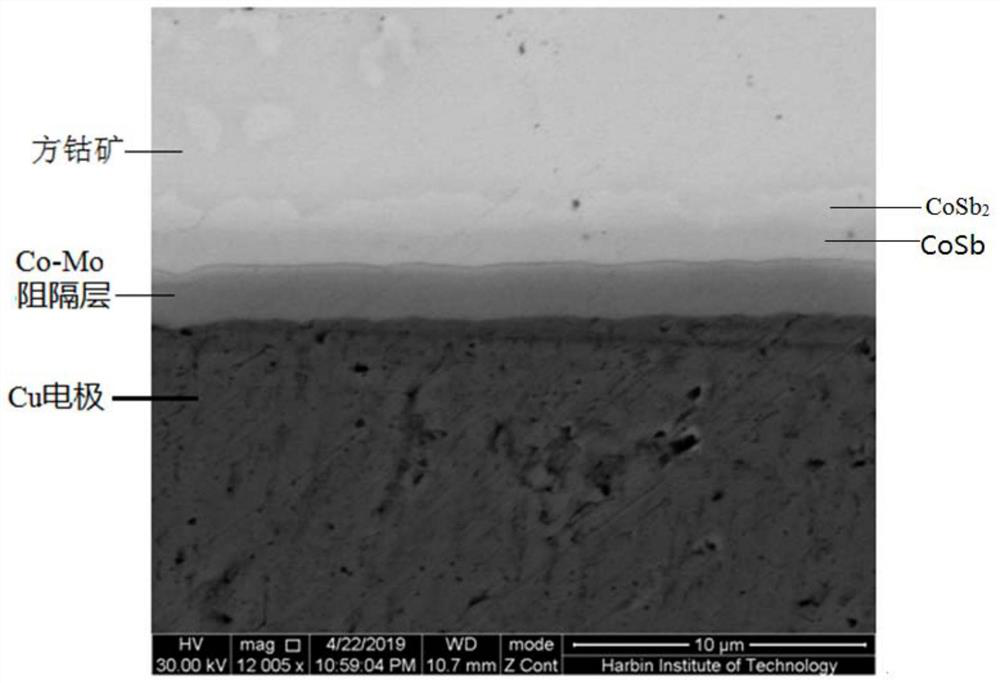

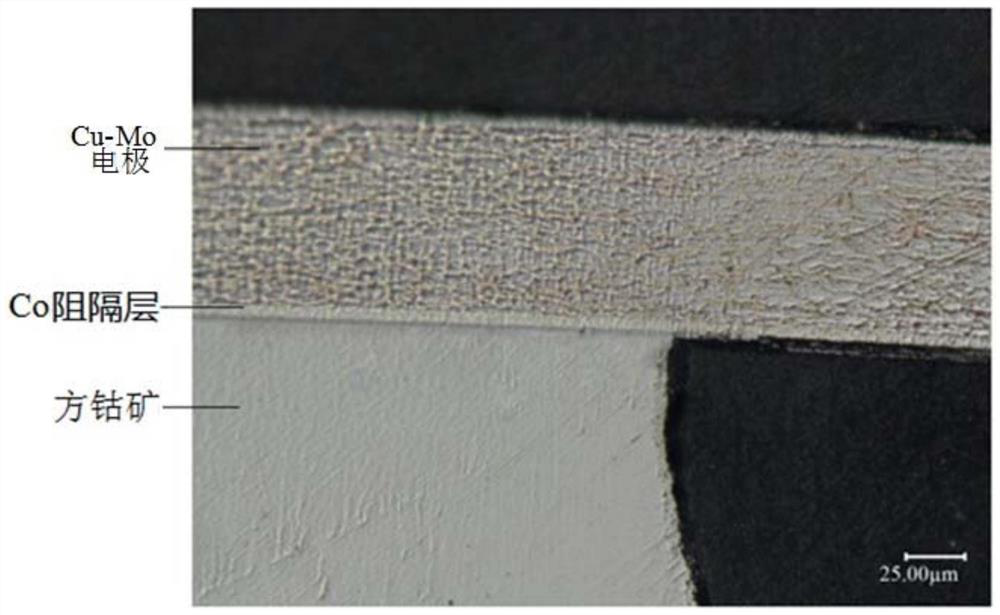

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

Method for decreasing glaze pinholes and bubbles

The invention mainly relates to the technical field of ceramic glaze processing and discloses a method for decreasing glaze pinholes and bubbles; the method comprises: mixing materials, melting for the first time, quenching for the first time, melting for the second time, quenching for the second time, ball-milling and pulverizing, and glazing and firing; the method is simple and convenient to perform, and can decrease glaze pinholes and bubbles by 90.9% and save product cost by 21.2%; the raw materials are crushed, water is added for melting, mixing well the materials is facilitated, sodium nitrate solution is added for quenching, double melting and quenching are performed, emission of the gas from the materials is quickened, the stability, mobility and compactness of the glaze are improved, glaze can be applied evenly, the cost can be saved as low-temperature slow firing is performed, the glaze has bright color and zero pinholes and bubbles, has matching expansion coefficient, and has smooth surface, good corrosion resistance and service life extended by 16.4%.

Owner:界首市伟盛古窑彩陶制作发展有限公司

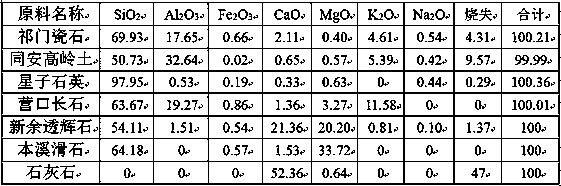

Preparation method of colorful glazed rice-pattern decorated porcelain

The invention relates to a preparation method of colorful glazed rice-pattern decorated porcelain. The preparation method comprises the following steps: 1, selecting a high-temperature porcelain bodypug, and forming a green body; 2, biscuiting the green body prepared in the step 1; 3, preparing a colorful glaze material for ceramic decoration; 4, applying transparent glaze to the inner of the green body, and after drying, applying the prepared colorful glaze material to the outer surface of the green body; 5, carrying out secondary biscuiting on the prepared glazed body; 6, attaching rice-pattern decorated porcelain decorative patterns to the surface of the glazed body prepared in the step 5, and spraying rice-pattern decorated porcelain holes by adopting a sand blasting jet process; 7, preparing rice-pattern decorated porcelain glaze high in high temperature permeability for filling of the rice-pattern decorated porcelain holes; 8, carrying out water washing of the glazed body with the rice-pattern decorated porcelain holes, drying, and applying the rice-pattern decorated porcelain glaze, carrying out glaze firing at a high temperature of 1295 DEG C after glaze washing, and taking an obtained product out of a kiln to obtain the ceramic body decorated by the colorful glaze and the rice-pattern decorated porcelain glaze material. The colorful glaze from Jingdezhen and rice-pattern decorated porcelain are combined, the colorful rice-pattern decorated porcelain is obtained through whole new blank glaze formula and technological parameters, and a promising market prospect is achieved.

Owner:景德镇市望龙陶瓷有限公司

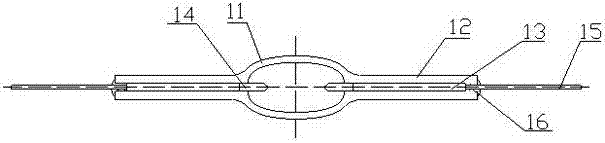

Preparation method of aluminum nitride insulation layer cathode hot wire

ActiveCN105931932ALow equipment requirementsExpansion coefficient matchingElectrolytic coatingsThermionic cathode manufactureElectrophoretic depositionTungsten

The invention belongs to the field of a microwave device and relates to a preparation method of an aluminum nitride insulation layer cathode hot wire formed, with the aluminium nitride materials being as raw materials and through an electrophoretic deposition method, by preparing a layer of compact aluminium nitride ceramic coating on the surface of the cathode hot wire for a travelling wave tube. Aluminum nitride powders are subjected to ultrasonic dispersion through organic solvents of alcohol and the like to obtain a stable suspension liquid; a layer of aluminium nitride film is deposited on the surface of a cleaned tungsten-rhenium wire through electrophoretic deposition; and the cathode hot wire having the compact aluminium nitride insulation layer is obtained after high-temperature sintering. The method is simple in process and low in device requirement; the coating and the tungsten-rhenium wire have better thermal expansion matching; the coating is not easy to crack or shed, and the coating has the advantages of high thermal conductivity and large resistivity; and the prepared coating hot wire is long in service life and high in reliability.

Owner:UNIV OF SCI & TECH BEIJING

Frit composition, frit paste composition and sealing method and electric device

ActiveCN104045236AExpansion coefficient matchingAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingFritLight-emitting diode

The invention discloses a frit composition which comprises a frit base material and filler, wherein the filler comprises a quasi-crystal material which accounts for 5-45wt% of the total weight of the filler. The frit composition, and the frit paste composition have negative thermal expansion coefficients, the thermal expansion coefficient of the frit can be reduced very well, so that the expansion coefficients of the frit and the base plate are further matched. Furthermore, a channel for discharging gross blow holes is provided and the compactness and adhesive strength of the frit composition are improved, so that the packaging yield is further improved and the OLED (Organic Light Emitting Diode) packaging stability is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Heat-resistant and environmentally friendly glaze for tableware

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a heat-resistant and environmentally friendly glaze for tableware, which is made of the following raw materials: silicon dioxide, zinc oxide, iron nitride, graphene, aluminum oxide, di Niobium, vanadium boride, cobalt oxide, white carbon black, salt, antibacterial agent; rich in raw materials, enhance the heat resistance and wear resistance of the glaze, the resistance to rapid change in cold and heat reaches 193.1K, and the biaxial bending strength increases by 58.1%. Prevent the glaze layer from falling off after bumping, prolong the service life, and the antibacterial time can be as long as 10 years in normal use; adding salt and antibacterial agent can reduce air bubbles, increase the fineness, density and fluidity of the enamel, and match the expansion coefficient. Keep the enamel smooth, the antibacterial rate reaches 66.1%, after short-term high-temperature firing, maintain the original color of ceramic products, strong stability, corrosion resistance, save production costs by 17.8%, safe and environmentally friendly, green and healthy, free of lead and cadmium dissolution, Health and Environmental Protection.

Owner:界首市伟盛古窑彩陶制作发展有限公司

Preparation method of colorful rice-pattern decorated porcelain

The invention relates to a preparation method of colorful rice-pattern decorated porcelain. The preparation method comprises the following steps: 1, selecting a high-temperature porcelain body pug, and forming a green body by grouting or rolling; 2, biscuiting the green body prepared in the step 1; 3, attaching rice-pattern decorated porcelain decorative patterns to the surface of a glazed body prepared in the step 2, and spraying rice-pattern decorated porcelain holes by adopting a sand blasting jet process; 4, preparing a colorful rice-pattern decorated porcelain glaze material for ceramic decoration; 5, washing the green body sprayed with the rice-pattern decorated porcelain holes in the step 3 with water, drying, applying the colorful rice-pattern decorated porcelain glaze material tothe interiors of the rice-pattern decorated porcelain holes, and cleaning the colorful rice-pattern decorated porcelain glaze material remaining on the surface of the green body; and 6, applying transparent glaze to the inner and outer surfaces of the green body prepared in the step 5, carrying out glaze firing at a high temperature of 1295 DEG C, and taking out of the kiln to obtain the ceramic body decorated by the colorful rice-pattern decorated porcelain glaze material. The colorful rice-pattern decorated porcelain is obtained by designing a brand-new body glaze formula and technological parameters, so that the colorful rice-pattern decorated porcelain has a wide market space.

Owner:景德镇市望龙陶瓷有限公司

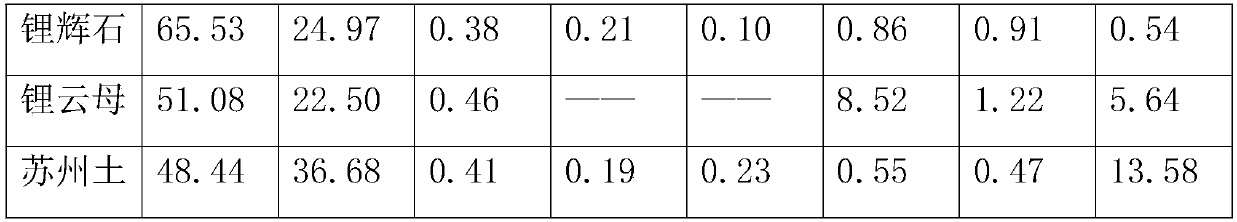

Lead-free transparent frit for preparing ceramics

The invention discloses lead-free transparent frit for preparing ceramics, and particularly relates to the field of ceramic preparation. The lead-free transparent frit comprises main ingredients and accessory ingredients, wherein the main ingredients mainly comprise SiO2, B2O2, Al2O3, ZnO, Li2O, Na2O, MgO, K2O and CaO, and the accessory ingredients mainly comprise SrO, Bi2O3, Re, nitrate, titaniumpowder and vanadium pentoxide. Firing is conducted by using a lithium-containing compound or mineral spodumene and Suzhou soil as raw materials, a chemical substances formed through firing replaces PbO in lead-containing glaze, and the minimum eutectic mixture is formed together, and therefore, lead oxide is replaced. A low glaze firing temperature and a wide firing range are ensued, the glaze glossiness can be ensured, and matching of the expansion coefficient can be ensured. Li2O is an oxide with a strong melting function, the expansion coefficient of the glaze can be significantly reduced,and the durability is improved; when the Li2O is added into the frit, the lead-free transparent frit which is high in elasticity and high in glossiness can be obtained at a low glaze firing temperature, B2O2 can obviously reduce the melting temperature and the viscosity of the frit, and the B2O2 can be used as a strong fluxing agent.

Owner:江西省千陶新型材料有限公司

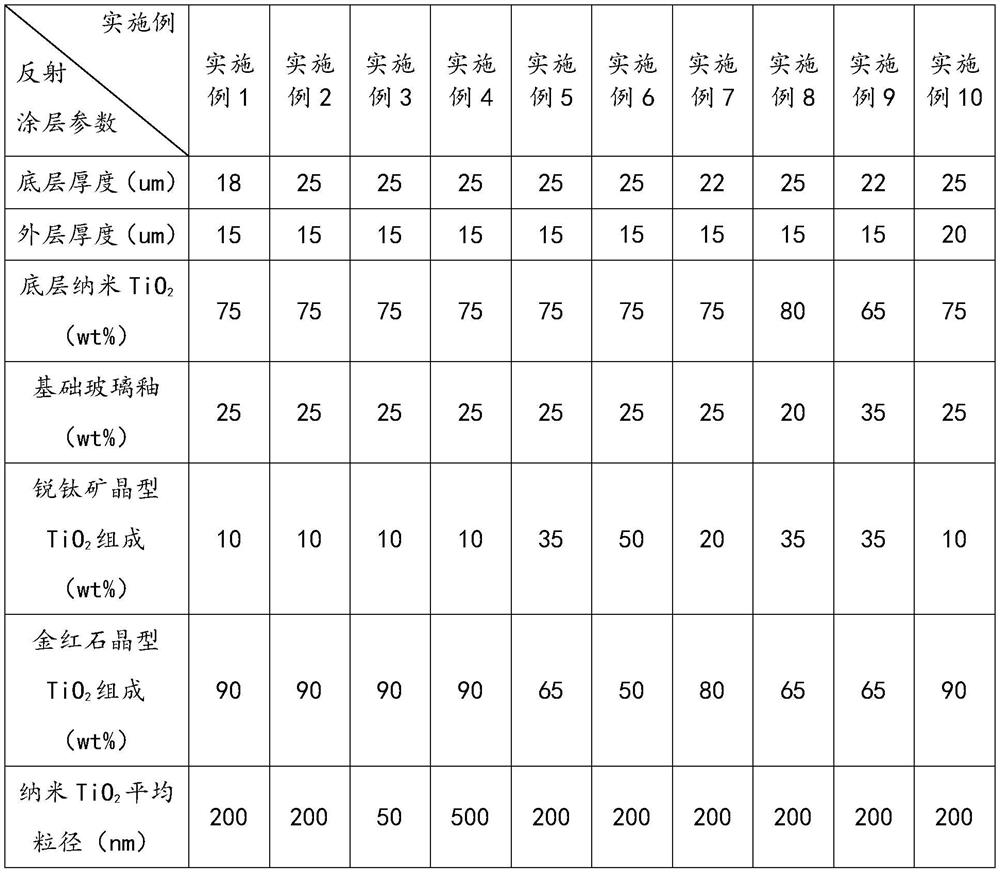

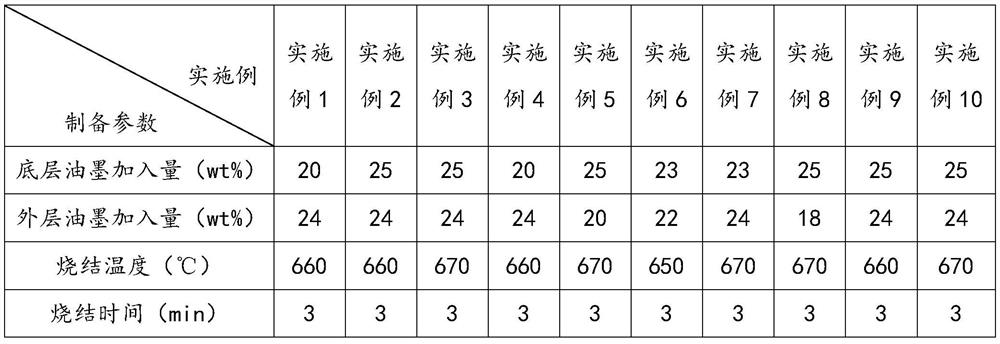

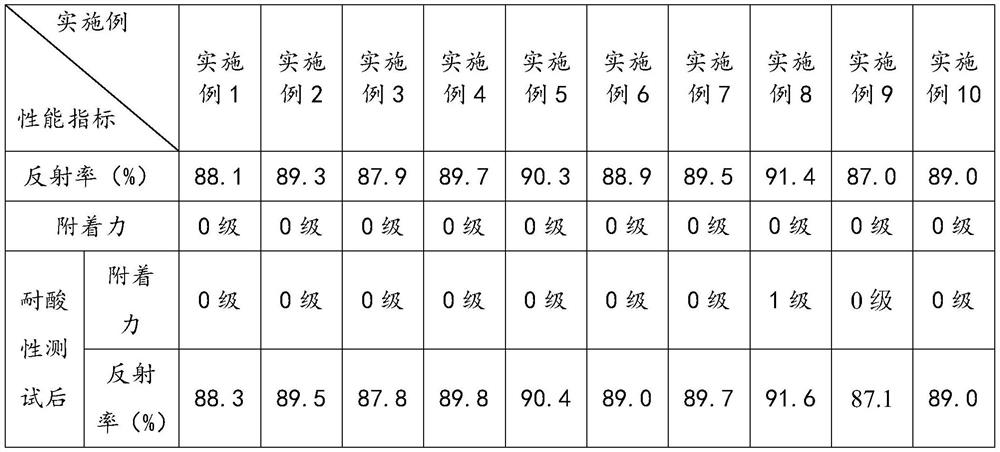

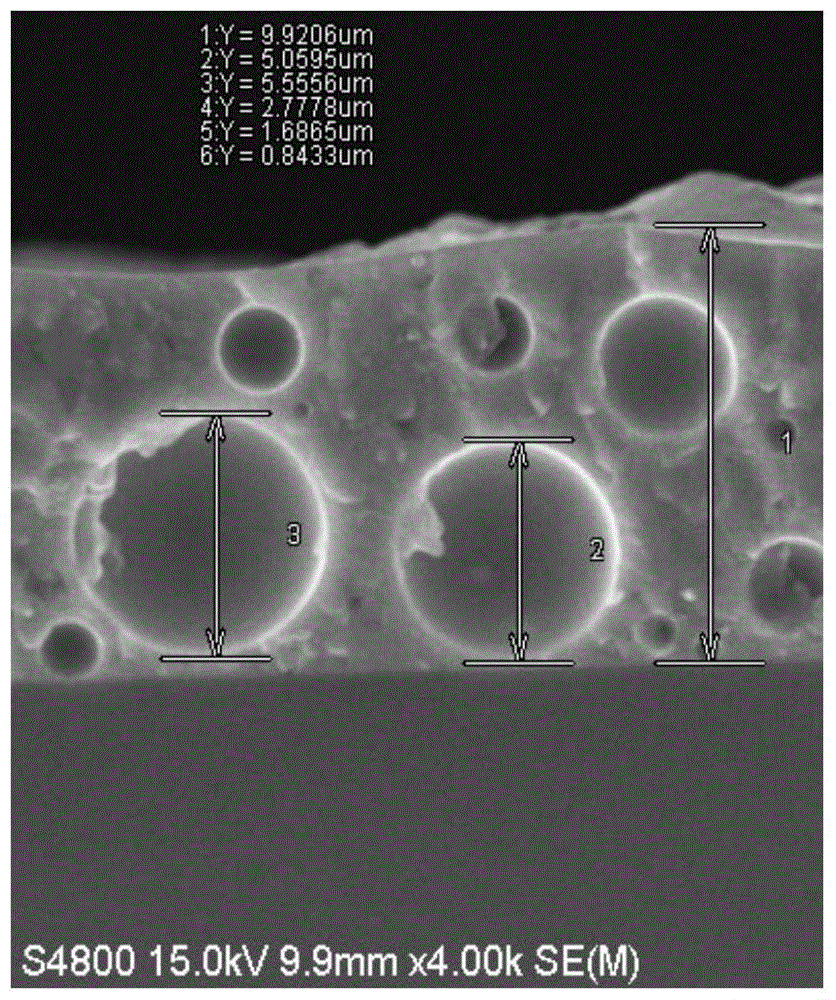

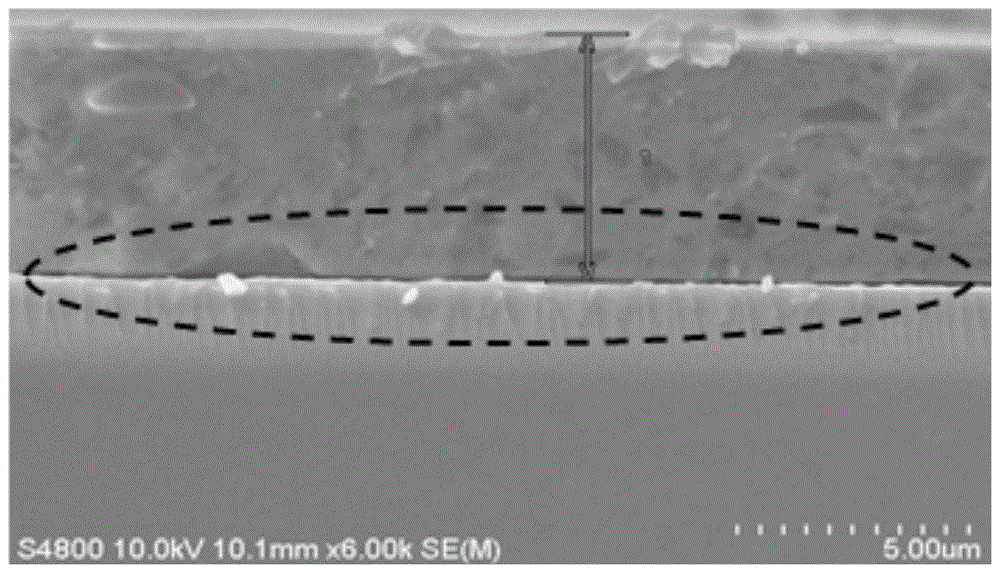

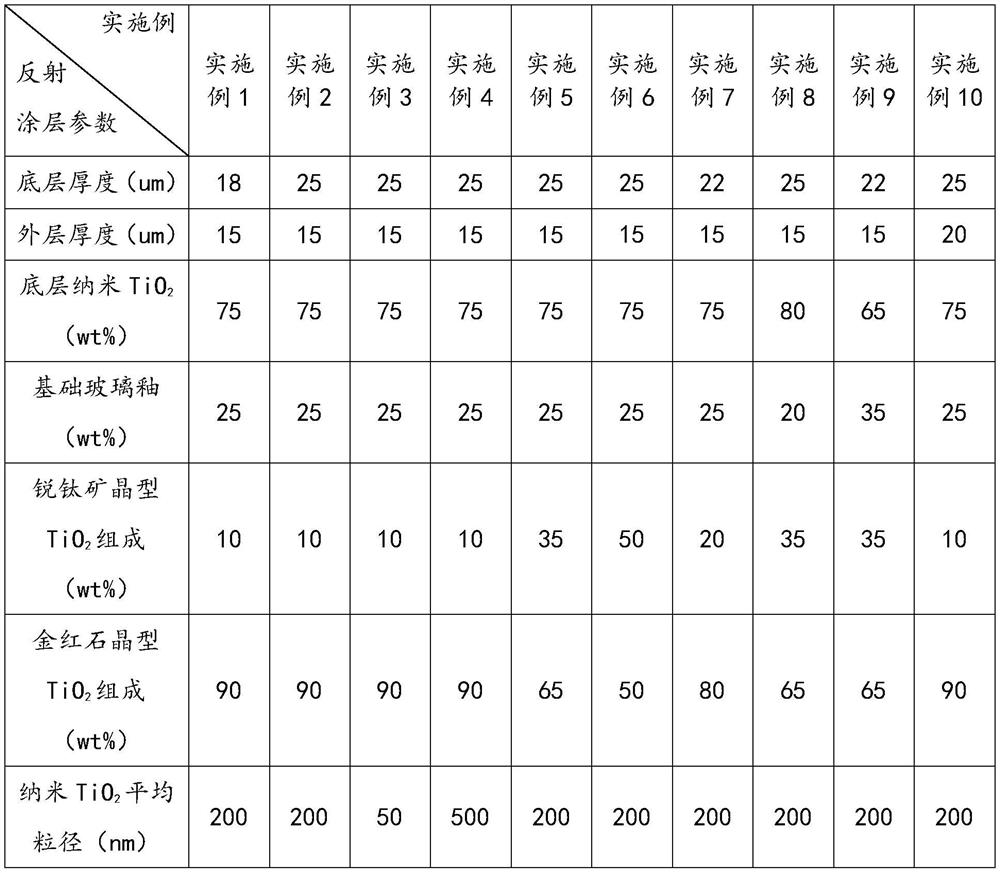

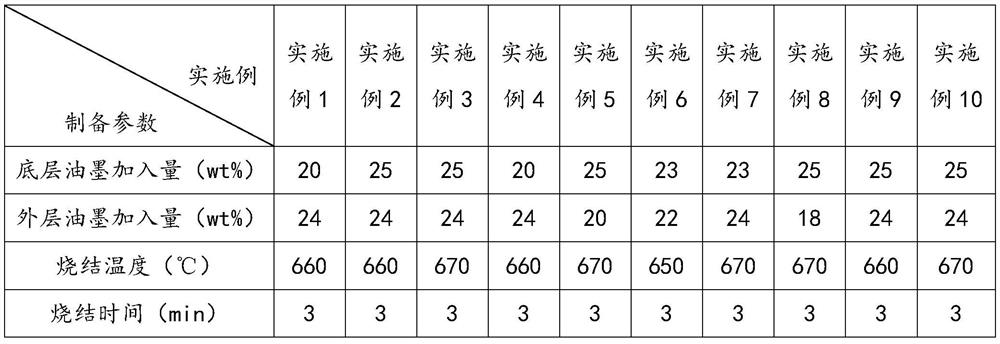

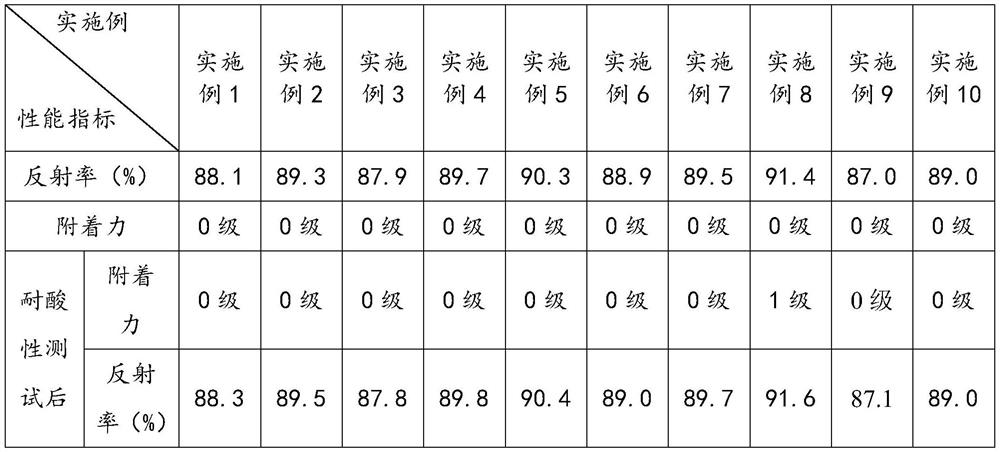

Reflecting coating of double-glass assembly and preparation method of reflecting coating

ActiveCN113998901AStrong adhesionNot easy to scratchCoatingsPhotovoltaic energy generationSlurryChemical stability

The invention provides a reflecting coating of a double-glass assembly. The reflecting coating comprises a high-content titanium dioxide layer on a bottom layer and a transparent glass glaze layer on an outer layer. The invention also provides a preparation method of the reflecting coating for the double-glass assembly. The preparation method comprises the following preparation steps: S1, preparing a basic glass glaze and a transparent glass glaze; S2, preparing bottom-layer slurry; S3, preparing outer-layer slurry; S4, conducting coating of a composite reflective coating; and S5, performing sintering. According to the composite reflecting coating, the outer layer completely wraps the bottom layer, the coating is firmly combined with embossed backboard glass, the compounded coating is high in adhesive force, higher in corrosion resistance compared with a common single reflecting coating, good in chemical stability, high in visible light average reflectivity, low in lipophilicity and small in ink consumption, and production cost is reduced.

Owner:DONGHUA UNIV +1

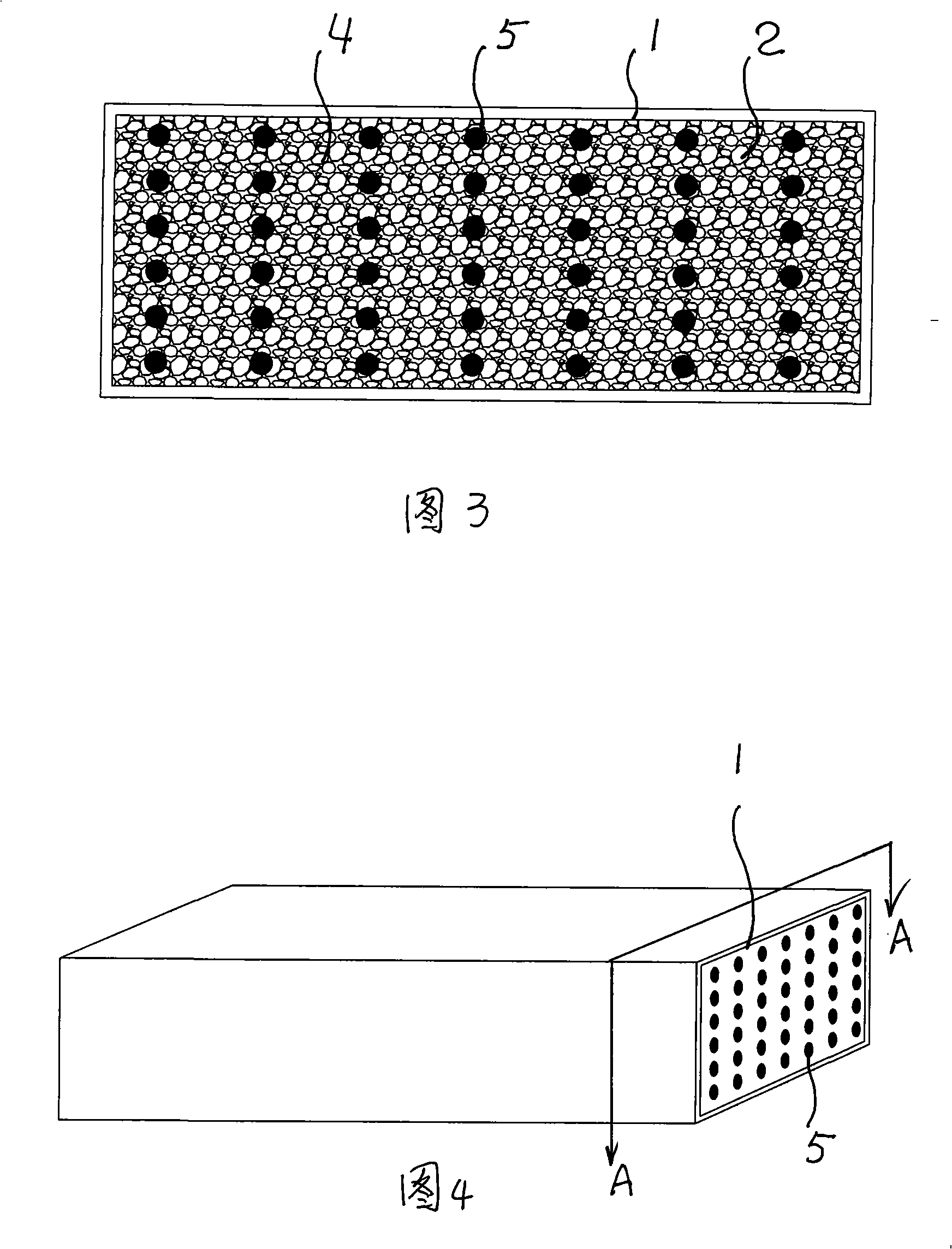

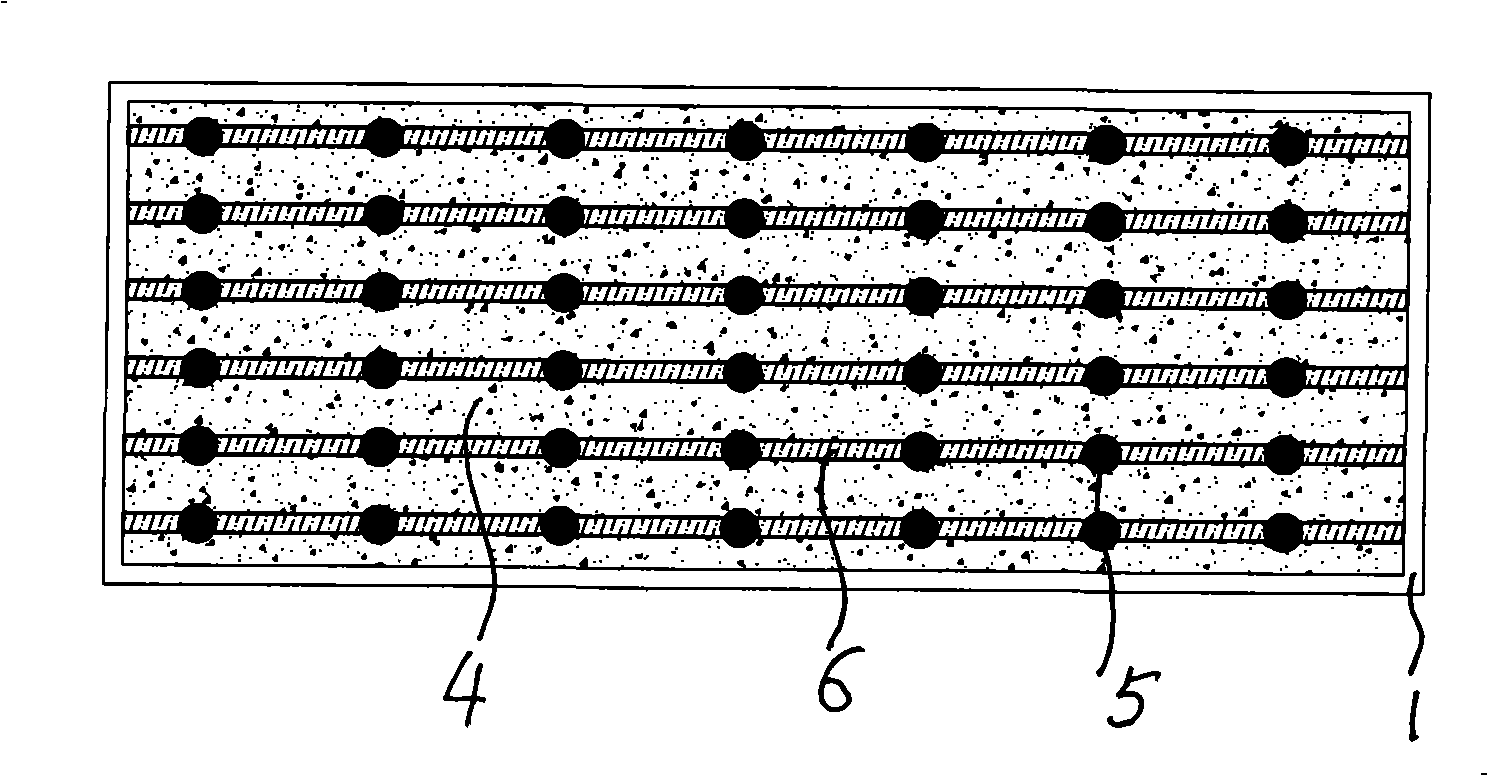

High thermal conductivity metal base circuit board and preparing method thereof

InactiveCN105120591AImprove thermal conductivityGood resistance to cold and heat cyclesPrinted circuit aspectsPrinted circuit manufactureInsulation layerPolyethylene glycol

The invention provides a high thermal conductivity metal base circuit board and a preparing method thereof. The circuit board comprises a metal base plate, a thermal conducting insulation layer arranged on the surface of the metal base plate, and a circuit formed on the thermal conducting insulation layer. The material of the thermal conducting insulation layer includes paint with following components by mass percentage: 40-60% by mass of a mixture of polyethylene glycol terephthalate and polybutylene terephthalate; 30-40% by mass of a mixture of aluminum oxide, aluminium nitride and boron nitride powder; 5-10% by mass of cosolvent; 3-10% by mass of diluent; and 0.5-1% by mass of curing agent. The above mentioned components account for 100% of the total mass percentage content. The heat conduction coefficient of the metal base circuit board ranges from 5W / k.M to 15W / k.M, enabling the metal base circuit board to achieve effective heat conduction, and therefore, the stability and service lifetime of an electronic component can be improved. It is also possible to make a circuit, including an abnormal-shaped circuit on a metal carrier, providing a new method to attain circuit boards of different purposes. The invention also provides a preparing method for such high thermal conductivity metal base circuit board.

Owner:SHENZHEN LAITENING NEW MATERIAL TECH

Heat sink material for power device and preparation method thereof

The invention discloses a heat sink material for power devices and a preparation method thereof, and belongs to the technology field of members of power devices. The heat sink material for power devices is prepared from (by weight parts) copper 5-20 and tungsten 80-95 by compounding, pressure moulding, sintering and post treatment. The inventive heat sink material for power devices has expansion coefficient matched with semiconductor materials and high thermometric conductivity, and can satisfy the requirements of high-power devices. The inventive heat sink material also has directional heat-conducting property.

Owner:宋希振

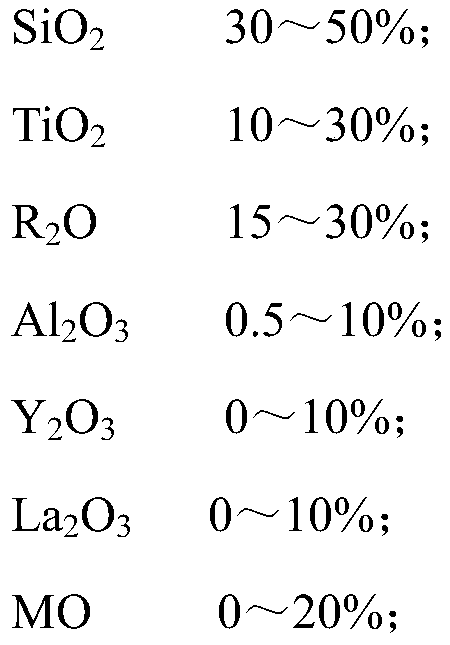

Substrate glass for optical communication, glass preform, optical element, and optical instrument

InactiveCN111003934AQuality improvementHigh modulus of elasticityOptical elementsPhysical chemistryThin membrane

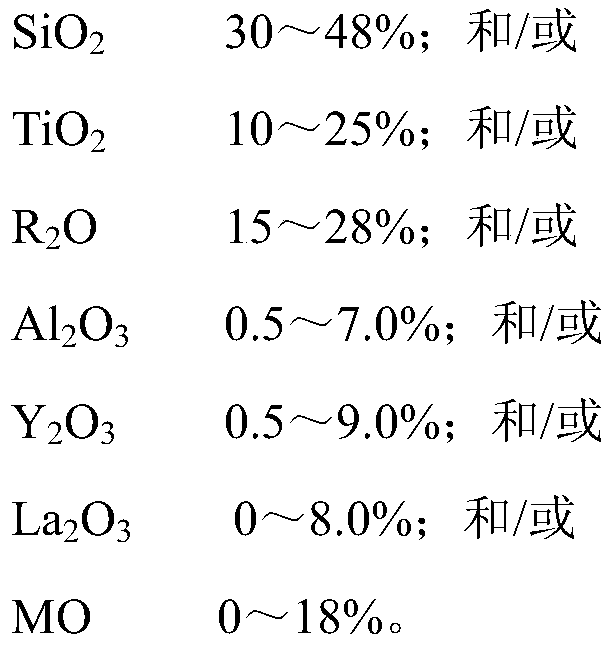

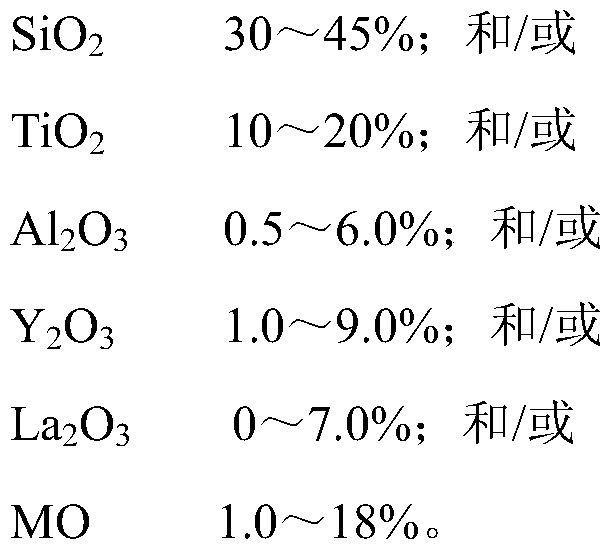

The invention discloses substrate glass for optical communication, a glass preform, an optical element and an optical instrument. The substrate glass comprises the following components in percentage by weight: 30-50% of SiO2; 10 to 30 percent of TiO2; 15 to 30 percent of R2O; 0.5 to 10 percent of Al2O3; 0 to 10 percent of Y2O3; 0 to 10 percent of La2O3; 0-20% of MO; wherein R2O is at least one ofLi2O, Na2O and K2O; and M is at least one of Mg, Ca, Sr, Zn and Ba. According to the invention, the effects of SiO2, TiO2, R2O, Al2O3, MO, La2O3 and Y2O3 in the formula are comprehensively considered;all the components have a mutual synergistic effect; the dosage of each component is reasonably set; the cooperative mechanism is balanced, finally, the prepared substrate glass for optical communication has relatively high transmittance in a wave band of 960 to 1600nm; and the optical communication substrate prepared by the method does not change color under irradiation of space rays, has high elasticity modulus, has an expansion coefficient matched with that of a plated film, has better heat resistance compared with an optical communication substrate prepared from plastic, and has a lower cost compared with an optical communication substrate prepared from microcrystalline glass.

Owner:CDGM GLASS LLC

High-temperature environment-friendly colored glaze

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a high-temperature environment-friendly colored glaze. The high-temperature environment-friendly colored glaze is prepared from the following raw materials: silicon dioxide, magnesium oxide, iron nitride, niobium pentoxide, vanadium boride, silicon nitride, aluminum nitride, zirconium oxide, cerium dioxide, hornblende, hard clay, table salt and pigments. A glaze surface becomes flat and smooth through short-time high-temperature burning and expansion coefficient matching, energy is saved, and no lead is dissolved out; the high-temperature environment-friendly colored glaze is safe, nontoxic and environment-friendly, and the production cost is lower by about 12.6 percent; the raw materials are mixed after being subjected to one-time ball milling, and are then subjected to repeated melting, quenching and ball milling, so that the colored glaze is fine and smooth in texture; the table salt is added after primary quenching, so that the high-temperature environment-friendly colored glaze is convenient to be added with water and mixed uniformly in use, and has the advantages of fineness, high fluidity, uniform glazing and smooth texture; the pigments are added after second melting, and high-temperature calcination is performed, so that the stability of the colored glaze and the pigments are enhanced, and the colored glaze is gorgeous, uniform in brightness and colorfast.

Owner:界首市伟盛古窑彩陶制作发展有限公司

A method of reducing pinholes and air bubbles in glaze

The invention mainly relates to the technical field of ceramic glaze processing and discloses a method for decreasing glaze pinholes and bubbles; the method comprises: mixing materials, melting for the first time, quenching for the first time, melting for the second time, quenching for the second time, ball-milling and pulverizing, and glazing and firing; the method is simple and convenient to perform, and can decrease glaze pinholes and bubbles by 90.9% and save product cost by 21.2%; the raw materials are crushed, water is added for melting, mixing well the materials is facilitated, sodium nitrate solution is added for quenching, double melting and quenching are performed, emission of the gas from the materials is quickened, the stability, mobility and compactness of the glaze are improved, glaze can be applied evenly, the cost can be saved as low-temperature slow firing is performed, the glaze has bright color and zero pinholes and bubbles, has matching expansion coefficient, and has smooth surface, good corrosion resistance and service life extended by 16.4%.

Owner:界首市伟盛古窑彩陶制作发展有限公司

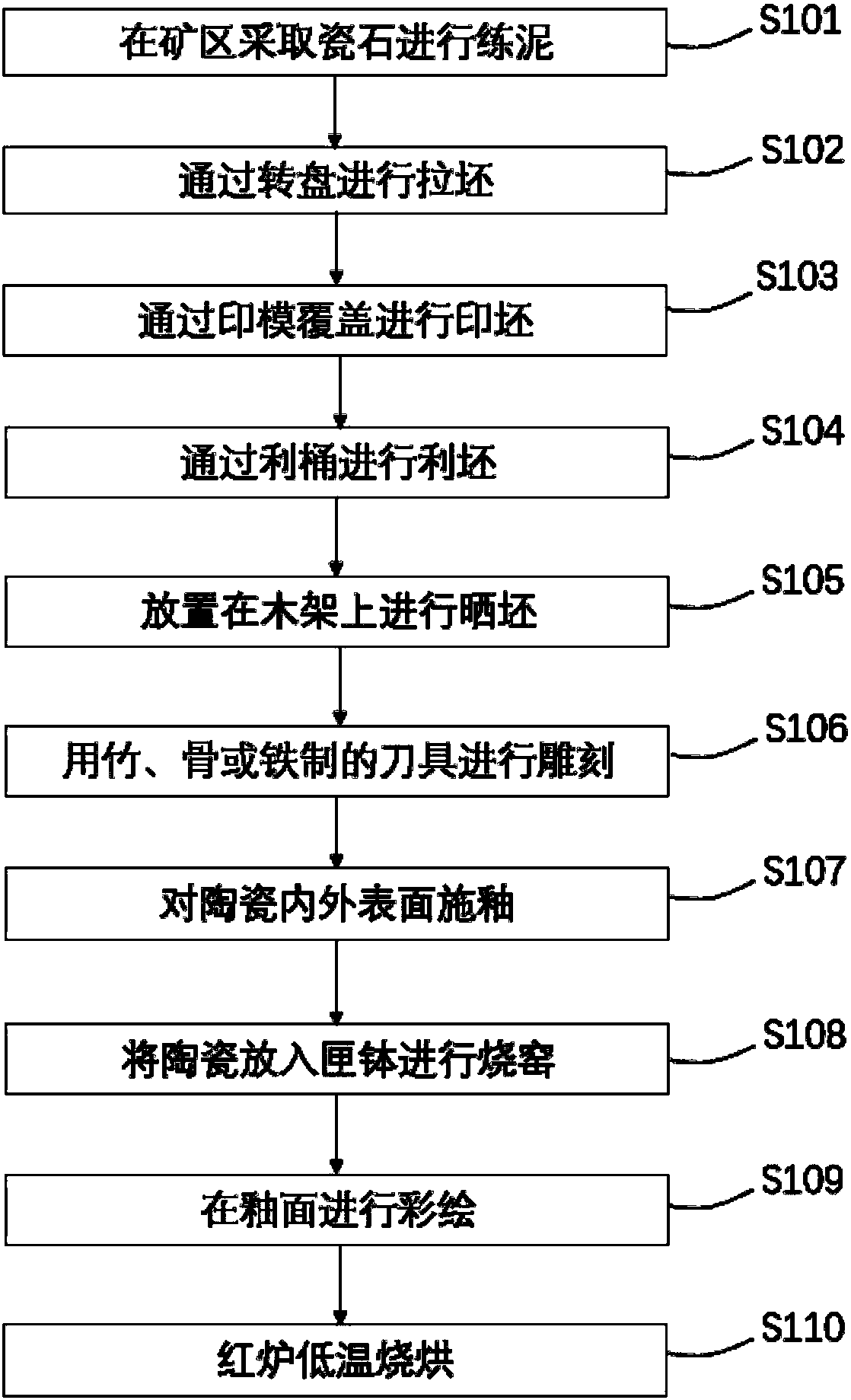

Yangwuling-kiln ceramic product with circularly engraved pattern and preparation method thereof

PendingCN108383499ATightly boundIncrease success rateSpecial ornamental structuresCharacter and pattern recognitionBrickChina stone

The invention belongs to the technical field of ceramic preparation, and discloses a Yangwuling-kiln ceramic product with a circularly engraved pattern and a preparation method thereof. The preparation method comprises the following steps of making into a brick-shaped clod by adopting china stone from an ore district, carrying out throwing through the bending and stretching of a turn-table freehand method, covering a printed mold through a printing mold, then cooperating with the rotation of a turning disc through a convenient barrel to carry out fine trimming, and putting a finely trimmed ceramic on a wooden stand to carry out airing; engraving the well aired ceramic by using a bamboo, bone or iron knife tool, afterwards, glazing the internal and external surfaces of the ceramic, then putting the ceramic into a saggar to carry out kilning, taking out after the firing is completed, next, carrying out colored drawing on glazed surfaces, and finally putting into a decorating kiln to carry out low-temperature fire-baking. The method is explicit and clear; the steps from clod making to the fire-burning are all introduced in detail; the preparation success rate and attractiveness of theceramic are greatly improved; the production efficiency and the profit are improved, and the method has prodigious popularization value and significance.

Owner:HUNAN CITY UNIV

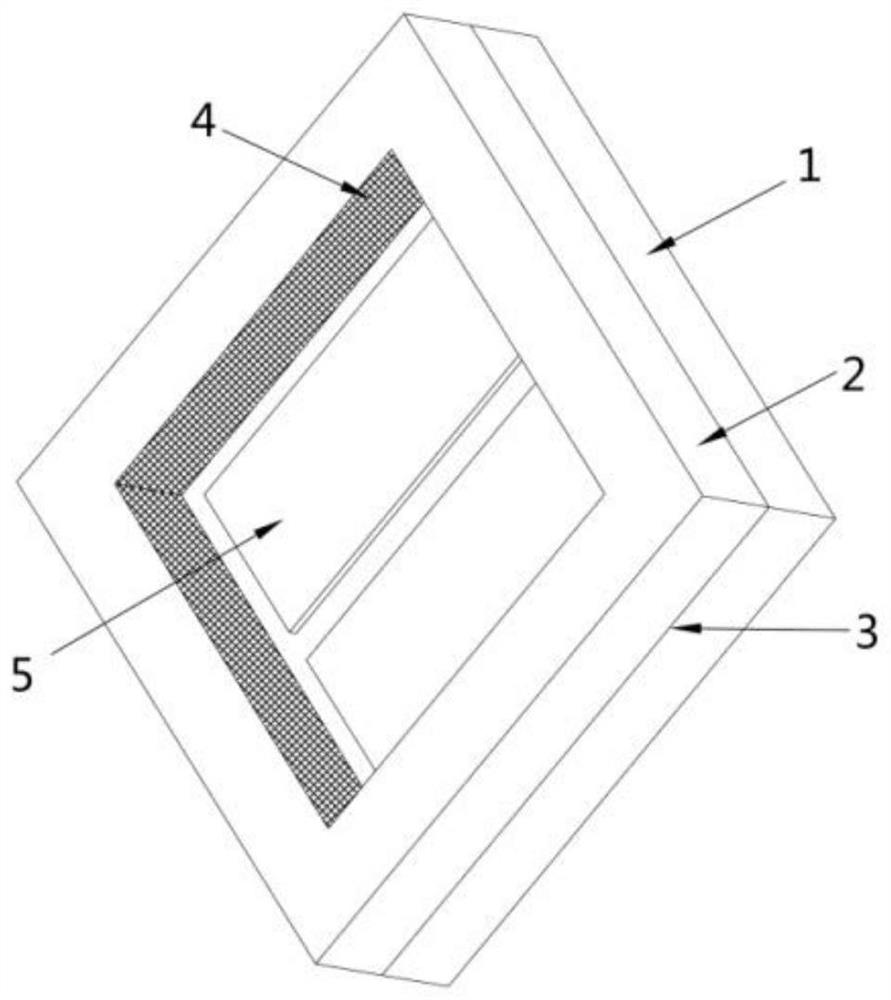

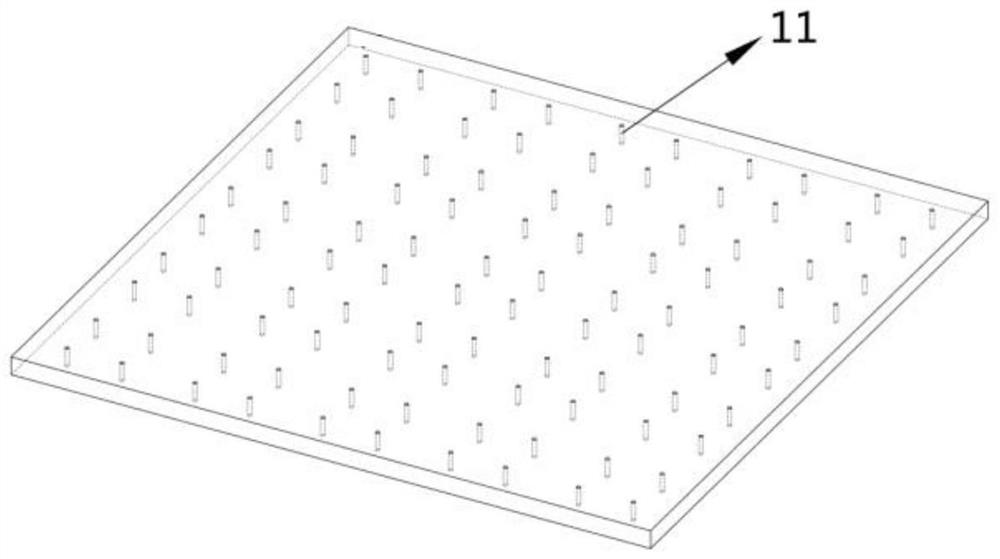

Manufacturing method of box dam ceramic substrate for ultraviolet LED packaging and product thereof

PendingCN112289753AAvoid heat damageImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesUltraviolet lightsSapphire

.The invention discloses a manufacturing method of a box dam ceramic substrate for ultraviolet LED packaging and a product thereof. According to the method, local localized heating instead of overallheating is carried out on the contact surface of the ceramic substrate and the box dam through laser, so that the process is simple and energy-saving, batch production is facilitated, and thermal damage to original circuit metal of the ceramic substrate caused by high temperature is effectively avoided Meanwhile, compared with existing gluing or reflow soldering, laser welding forms reliable welding, welding points can bear higher temperature, and the reliability is higher; compared with an existing metal box dam, the box dam is made of glass or ceramic or glass ceramic or sapphire materials,the expansion coefficient of the box dam is better matched with that of the ceramic substrate, and the product reliability is further improved. Meanwhile, the metal coating is arranged on the inner wall of the box dam, ultraviolet light can be well reflected, the problem of ultraviolet light absorption is avoided, the comprehensive performance is good, and wide application and popularization are facilitated.

Owner:SONGSHAN LAKE MATERIALS LAB

Glass frit composition, glass frit paste composition, sealing method, and electric device

ActiveCN104045236BExpansion coefficient matchingAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingFritVolumetric Mass Density

The invention discloses a glass frit composition, which comprises a glass frit base material and a filler. The filler includes a quasicrystal material, and the quasicrystal material accounts for 5%-45% of the total mass of the filler. The glass frit composition, the glass frit paste composition and the sealing method and device using the glass frit paste composition provided by the present invention have a negative thermal expansion coefficient, which can well reduce the thermal expansion coefficient of the glass frit, so that the glass frit It is more matched with the expansion coefficient of the substrate, and provides a channel for venting large pores, improves the density and bonding strength of the glass frit composition, thereby improving the packaging yield and improving the stability of OLED packaging.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

A kind of double glass component reflective coating and preparation method thereof

ActiveCN113998901BStrong adhesionNot easy to scratchCoatingsPhotovoltaic energy generationPolymer scienceGlaze

The invention provides a double-glass component reflective coating, which comprises a high-content titanium dioxide layer on the bottom layer and a transparent glass glaze layer on the outer layer. The present invention also provides a method for preparing a reflective coating for a double-glass component, comprising the following preparation steps: S1. preparation of basic glass glaze and transparent glass glaze; S2. preparation of bottom layer slurry; S3. preparation of outer layer slurry; S4. Composite reflective coating coating; S5. Sintering. The composite reflective coating of the invention, the outer layer completely covers the bottom layer, the coating is firmly combined with the embossed back glass, the composite coating has strong adhesion, stronger corrosion resistance than ordinary single-reflective coatings, and good chemical stability , The average visible light reflectivity is high, and the lipophilicity is low, the ink usage is less, and the production cost is reduced.

Owner:DONGHUA UNIV +1

A rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929BImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusThermoelectric materialsCobalt

The invention relates to a fast diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The purpose is to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with electrodes. Method: Take the electrode and clean the surface to be welded, plate an alloy barrier layer on the surface of the electrode to be welded, clean the surface to be welded with skutterudite thermoelectric material, and perform diffusion welding. The present invention prepares the barrier layer by electroplating on the electrode side, and then realizes diffusion welding with the skutterudite thermoelectric material at a relatively low pressure and relatively low temperature, and there is no element diffusion between the weld element and the skutterudite in the process , can prevent the volatilization of Sb element and the occurrence of element diffusion. The invention is suitable for welding skutterudite thermoelectric materials and electrodes.

Owner:HARBIN INST OF TECH

A method of preparation of color glaze and exquisite porcelain

The invention relates to a preparation method of color glaze exquisite porcelain, step 1: selecting high-temperature ceramic body mud to form a body; step 2: performing bisque firing on the body for the first time; step 3: preparing color glaze for ceramic decoration Step 4: Apply transparent glaze inside the body, and apply the prepared color glaze on the outer surface of the body after drying; Step 5: Carry out the second biscuit firing of the prepared glaze body; Decorate patterns, use sandblasting jet technology to spray Linglong holes; Step 7: Prepare Linglong glaze with high temperature and strong permeability to fill Linglong holes; Step 8: Wash the glaze blank that has been sprayed with Linglong holes in Step 6, dry and apply Linglong Glaze, after washing the glaze, it is glazed and fired at a high temperature of 1295 ℃, and it is out of the kiln to obtain a porcelain body decorated with color glaze and exquisite glaze. The present invention combines the color glaze of Jingdezhen with Linglong glaze, and obtains colorful Linglong porcelain by designing a brand-new base glaze formula and process parameters, so it has a broad market space.

Owner:景德镇市望龙陶瓷有限公司

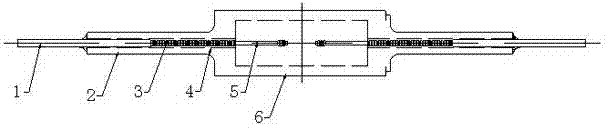

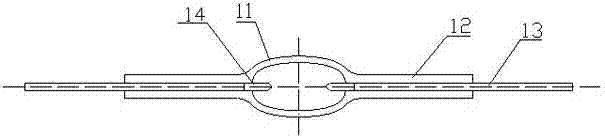

Co-firing sealing high-efficiency ceramic lamp and preparation method thereof

InactiveCN101980353BAvoid corrosionImprove air tightnessGas discharge lamp detailsCold cathode manufactureCeramic metalAir tightness

Owner:杨潮平

A kind of preparation method of aluminum nitride insulating layer cathode heating wire

InactiveCN105931932BLow equipment requirementsExpansion coefficient matchingElectrolytic coatingsThermionic cathode manufactureRheniumInsulation layer

The invention belongs to the field of a microwave device and relates to a preparation method of an aluminum nitride insulation layer cathode hot wire formed, with the aluminium nitride materials being as raw materials and through an electrophoretic deposition method, by preparing a layer of compact aluminium nitride ceramic coating on the surface of the cathode hot wire for a travelling wave tube. Aluminum nitride powders are subjected to ultrasonic dispersion through organic solvents of alcohol and the like to obtain a stable suspension liquid; a layer of aluminium nitride film is deposited on the surface of a cleaned tungsten-rhenium wire through electrophoretic deposition; and the cathode hot wire having the compact aluminium nitride insulation layer is obtained after high-temperature sintering. The method is simple in process and low in device requirement; the coating and the tungsten-rhenium wire have better thermal expansion matching; the coating is not easy to crack or shed, and the coating has the advantages of high thermal conductivity and large resistivity; and the prepared coating hot wire is long in service life and high in reliability.

Owner:UNIV OF SCI & TECH BEIJING

A kind of conductive silver paste and its preparation method and 5g ceramic filter

ActiveCN112037960BImprove performanceExpansion coefficient matchingNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePolymer science

Owner:湖南利德电子浆料股份有限公司

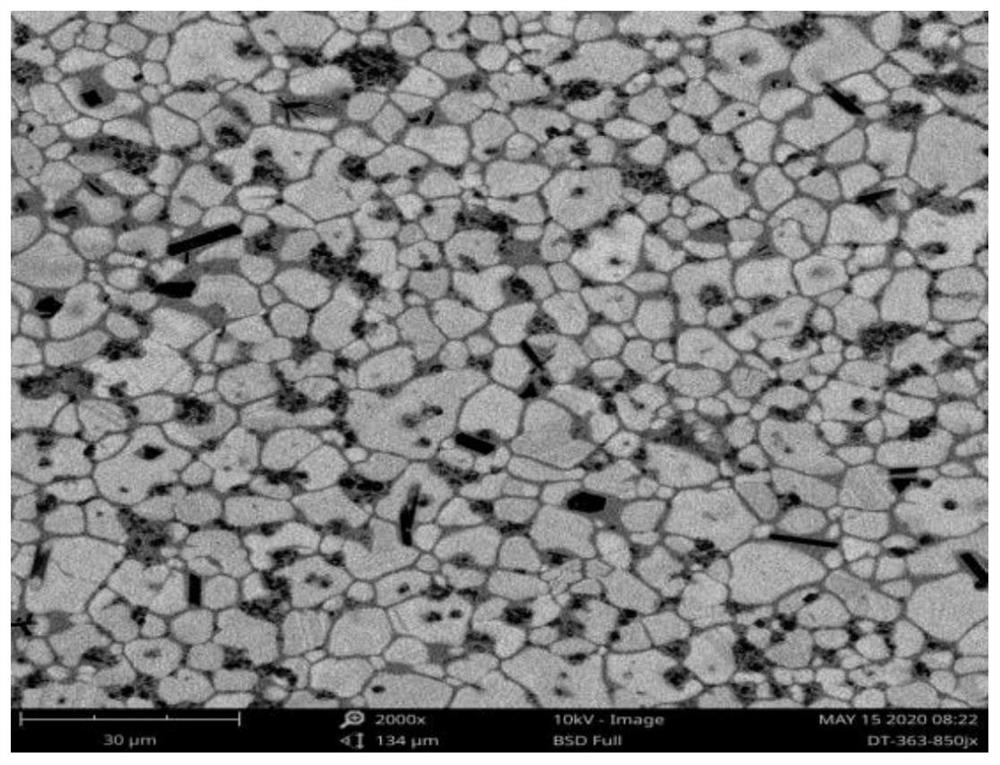

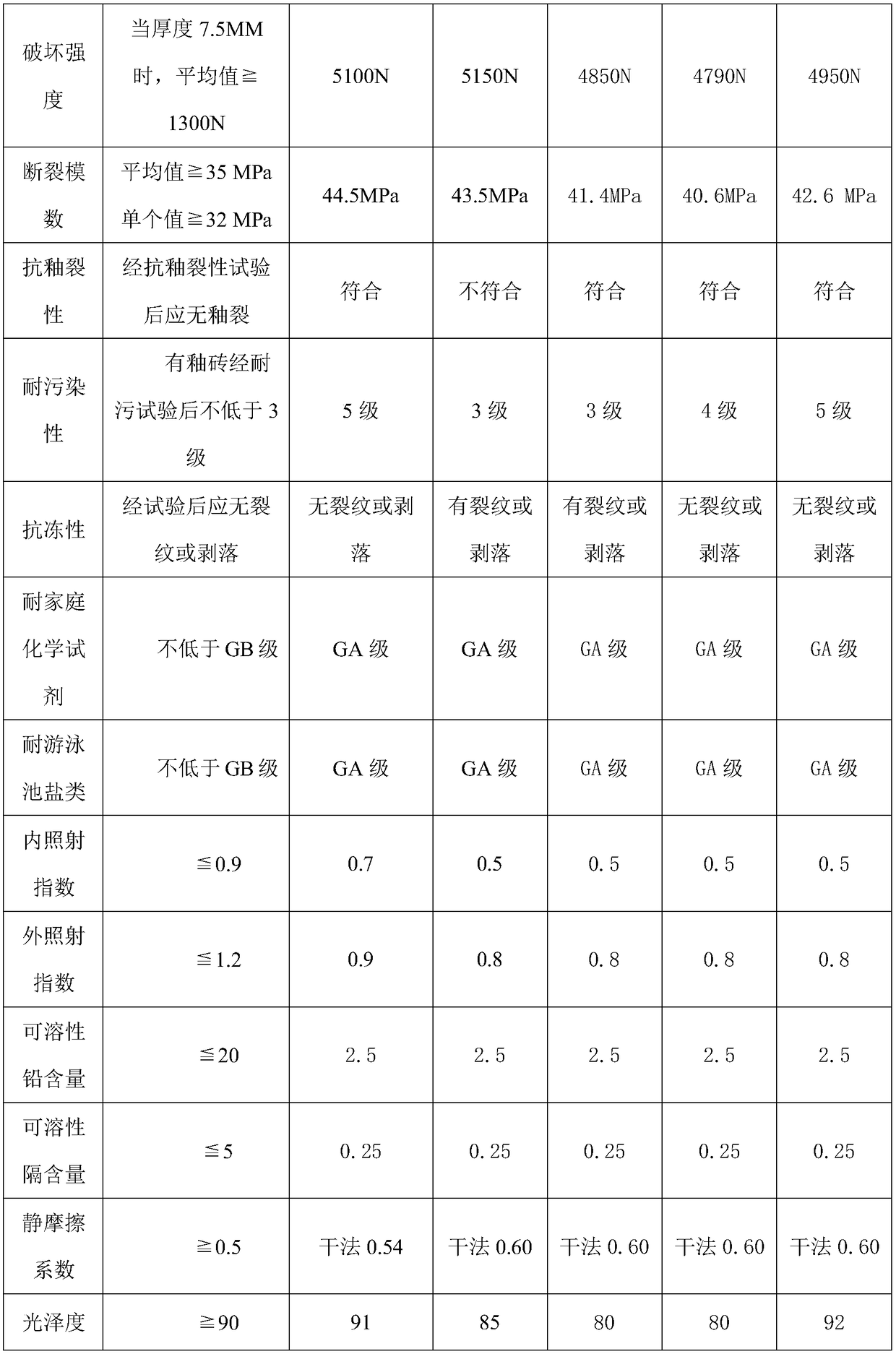

Production process of high-hardness ceramic tile

PendingCN114057476ASmall degree of deformationImprove high temperature deformation resistance and dry strengthCeramic tilesBall mill

The invention discloses a production process of a high-hardness ceramic tile, and belongs to the technical field of ceramic tile production. The production process comprises the following steps: taking materials, selecting sufficient pug, sand, a blank body and a blank body reinforcing agent, taking the sand material and the blank body, putting the sand material and the blank body into a ball mill, and carrying out ball milling. By properly increasing the content of aluminum oxide in the ceramic tile formula and adding a proper amount of blank reinforcing agent, the deformation degree of the prepared ceramic tile can be effectively reduced, the high-temperature non-deformability and drying strength of the material are improved, the thermal expansion coefficient of the blank is reduced, the expansion coefficients of the later material and glaze are better matched, the glaze quality is ensured, and glaze forming rate is improved. Meanwhile, a slurry sieving process and a multi-time iron removal process are set, coarse particles and some impurities which are not finely ground during ball milling can be effectively removed through sieving, the situation that black spots, molten holes, impurities and other defects are formed on the surface of the ceramic tile can be effectively avoided through multi-time iron removal, meanwhile, the whiteness of the ceramic tile is guaranteed, the quality of the ceramic tile is improved, and the application effect of the method is improved.

Owner:佛山市美地陶瓷有限公司

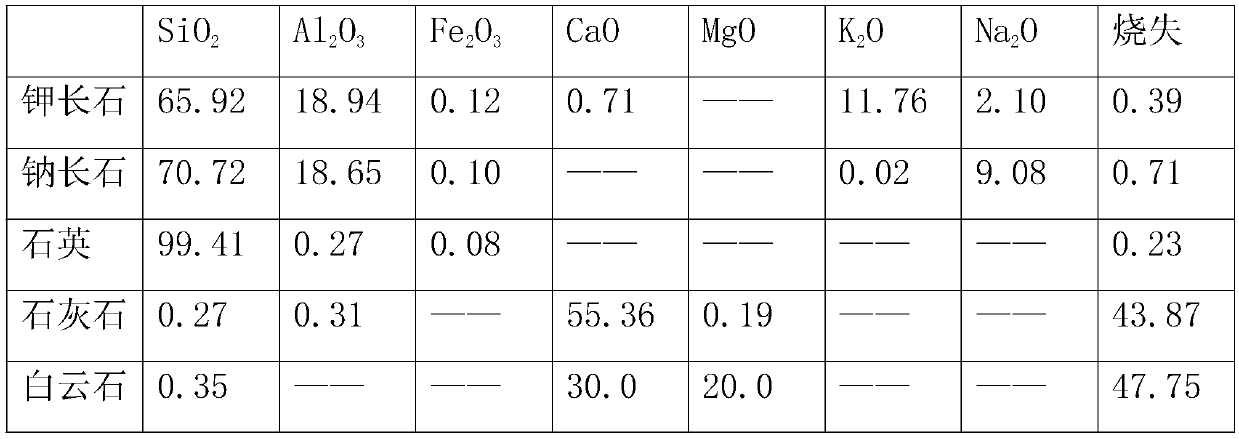

A kind of frit with high transparency and preparation method thereof

The invention discloses high-transparency frit and a preparation method thereof. The high-transparency frit is mainly composed of 10-20 parts of Al2O3, 45-55 parts of SiO2, 0.05-0.10 part of Fe2O3, 10-15 parts of CaO, 4-8 parts of MgO, 1-3 parts of K2O, 1-3 parts of Na2O, 0.01-0.03 part of TiO2, less than 0.01 part of SrO, 0.30-0.60 part of LiO2, less than 0.01 part of PbO, less than 0.01 part of ZnO, 3-6 parts of B2O3, 0.1-0.5 part of P2O5 and 1-4 parts of F chemically, and loss on ignition is 3-5%. Frit particles can be closely combined with a ceramic substrate and are free of breakaway and layering; the frit and a blank are matched in expansion coefficient, so that a fired product has a flat surface; the surface of the fired product is free of air bubbles and pinholes, and the fired product is high in glossiness and transparency; raw materials which are extremely low in lead-cadmium content are adopted for formulation, so that the frit is environment-friendly.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

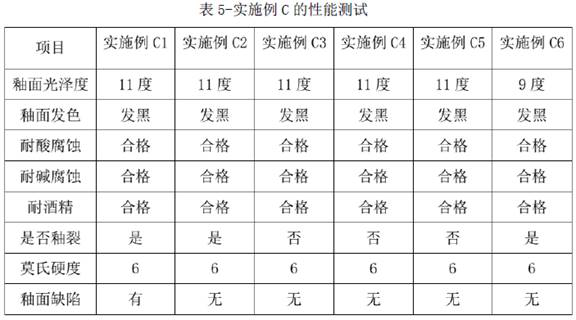

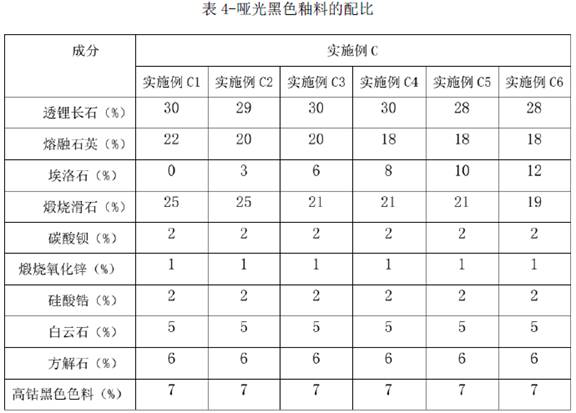

Matt black glaze and sanitary ware and preparation method and application thereof

The invention relates to matte black glaze and sanitary ware and preparation methods and application thereof, belonging to the field of ceramics. The matte black glaze comprises the following raw materials: petalite, fused quartz, halloysite, calcined talc, barium carbonate, calcined zinc oxide, zirconium silicate, dolomite, calcite and high-cobalt black pigment. The preparation method of the matte black glaze is used for preparing the matte black glaze. A matte black glaze layer is arranged on the surface of the matte black sanitary ware. The preparation method of the matte black sanitary ware is used for preparing the matte black sanitary ware. The matte black glaze is used for the sanitary ware; the glaze is well combined with a green body; and after high-temperature sintering, the matte black glaze has acid and alkali resistance, water washing resistance and organic solvent resistance, is free of the quality problem of fading, and overcomes the problem that matte smooth ware is formed by conducting paint spraying and secondary processing on common bright emulsion-white glaze sanitary ware in the prior art.

Owner:佛山市三水大岛制釉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com