Production process of high-hardness ceramic tile

A production process and high hardness technology, applied in the field of ceramic tile production, can solve the problems of inability to effectively reduce the deformation of ceramic tiles and poor quality of ceramic tiles, and achieve the goal of improving high temperature deformation resistance and drying strength, ensuring glaze quality and increasing content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

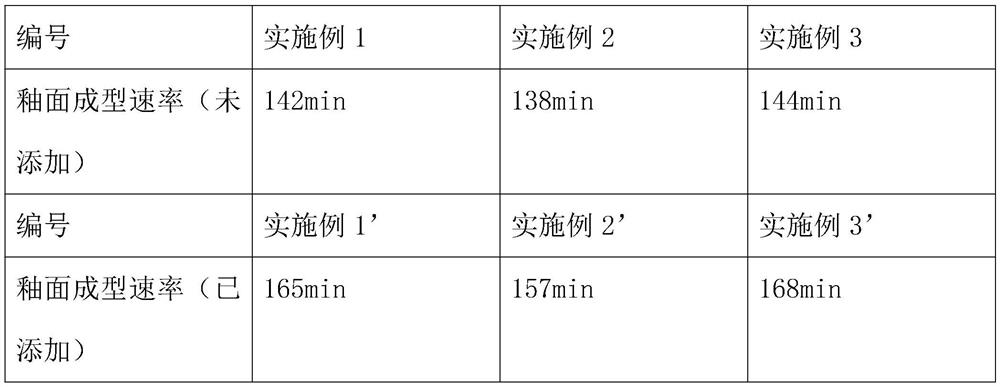

Embodiment 1

[0043] The invention provides a technical solution: a production process of high-hardness tiles, comprising the following steps:

[0044] S1, carry out material retrieving, select enough mud material, sand material, embryo body and embryo body reinforcing agent, wherein, mud material has two kinds respectively to be black mud and white mud, and black mud is used for improving the plasticity of material, and white mud Used to improve the whiteness of the material, the sand material is SiO 2 , the embryo body is Al 2 o 3 , CaO, MgO and KNaO, the embryo body reinforcing agent is sodium carboxymethyl cellulose, and the parts by weight of added mud, sand material, embryo body and embryo body reinforcing agent are 50 parts, 80 parts, 40 parts respectively copies and 15 copies;

[0045] S2. Take the sand material and the part of the embryo body and place them in a ball mill for ball milling. During the ball milling process, add the embryo body and sand material in batches. The abo...

Embodiment 2

[0057] The invention provides a technical solution: a production process of high-hardness tiles, comprising the following steps:

[0058] S1, carry out material retrieving, select enough mud material, sand material, embryo body and embryo body reinforcing agent, wherein, mud material has two kinds respectively to be black mud and white mud, and black mud is used for improving the plasticity of material, and white mud Used to improve the whiteness of the material, the sand material is SiO 2 , the embryo body is Al 2 o 3 , CaO, MgO and KNaO, the embryo body reinforcing agent is sodium carboxymethyl cellulose, and the parts by weight of added mud, sand material, embryo body and embryo body reinforcing agent are 60 parts, 85 parts, 45 parts respectively copies and 13 copies;

[0059] S2. Take the sand material and the part of the embryo body and place them in a ball mill for ball milling. During the ball milling process, add the embryo body and sand material in batches. The abo...

Embodiment 3

[0071] The invention provides a technical solution: a production process of high-hardness tiles, comprising the following steps:

[0072] S1, carry out material retrieving, select enough mud material, sand material, embryo body and embryo body reinforcing agent, wherein, mud material has two kinds respectively to be black mud and white mud, and black mud is used for improving the plasticity of material, and white mud Used to improve the whiteness of the material, the sand material is SiO 2 , the embryo body is Al 2 o 3 , CaO, MgO and KNaO, the embryo body reinforcing agent is sodium carboxymethyl cellulose, and the parts by weight of added mud, sand material, embryo body and embryo body reinforcing agent are 70 parts, 90 parts, 50 parts respectively copies and 10 copies;

[0073] S2. Take the sand material and the part of the embryo body and place them in a ball mill for ball milling. During the ball milling process, add the embryo body and sand material in batches. The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com