Co-firing sealing high-efficiency ceramic lamp and preparation method thereof

A co-firing and ceramic technology is applied in the field of co-firing and sealing high-efficiency ceramic lamps and their preparation, which can solve the problems of solder corrosion and sealing damage, and achieve the effects of avoiding corrosion, improving air tightness and good air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

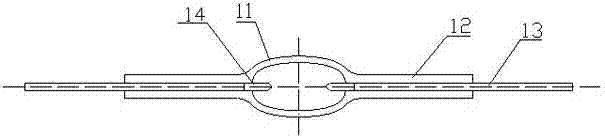

[0028] like figure 2 As shown, the present invention discloses a co-fired and sealed high-efficiency ceramic lamp, which includes a discharge chamber 11 and an electrode tube 12 arranged at the end of the discharge chamber 11. The electrode tube 12 is inserted with a ceramic metal electrode 13, and the ceramic metal electrode 13 is connected to a tungsten electrode 14 near the end of the discharge chamber 11, wherein the ceramic metal electrode 13 and the electrode tube 12 are sealed by co-firing.

[0029] In this embodiment, the end of the ceramic metal electrode 13 and the corresponding part of the electrode tube 12 are co-fired and sealed. Of course, the ceramic metal electrode 13 can also be co-fired and sealed with the entire electrode tube 12 .

[0030] The outer diameter of the ceramic metal electrode 13 matches the inner diameter of the electrode tube 12. Compared with the sealing method using solder, the contact area between the co-fired arc tube and the ceramic met...

Embodiment 2

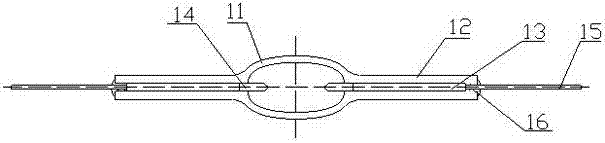

[0037] The structure of this embodiment is similar to that of Embodiment 1, the difference is that the metal lead is a separate component, such as image 3 As shown, the end of the cermet electrode 13 is also connected with an anti-oxidation metal lead 15, and a welding groove 16 is also provided between the end of the electrode tube 12 and the end of the cermet electrode 13, and the metal lead 15 extends through the welding groove 16. Out of the electrode tube 12, the welding groove 16 is used for filling glass solder. Wherein, the diameter of the metal lead wire 15 is smaller than that of the cermet electrode 13 .

[0038] In the above scheme, in order to prevent the oxidation of the cermet electrode 13, an anti-oxidation metal lead wire 15 is connected to the end of the cermet electrode 13, and the end of the cermet electrode 13 is shorter than the end of the electrode tube 12, and then the end is melted with glass solder to cover the cermet electrode 13 to prevent oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com