Ceramic binding agent for ceramic grinding block and preparation method thereof

A ceramic bonding agent and bonding agent technology, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve problems such as immaturity, and achieve the effect of improving service life, good holding force, and good infiltration of abrasives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

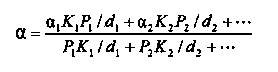

Method used

Image

Examples

Embodiment 1

[0048] A preparation method for a vitrified bond for a ceramic grinding block, comprising the steps of:

[0049] a. Compounding raw materials: weigh each raw material according to the following weight unit (in kilograms), SiO 2 45Kg, Al 2 o 3 17 Kg, ZnO 1 Kg, TiO 2 1 Kg, ZrO 2 Kg, Na 2 CO 3 12 Kg, Li 2 CO 3 9 Kg, H 3 BO 3 13 Kg, dropped into the mixer and mixed for 2 hours;

[0050] b. Powder smelting: Pour the uniformly mixed raw materials into a glass melting furnace for melting, the melting temperature is 1350°C, and the melting time is 1.5 hours, and the uniformly mixed raw materials are smelted into molten glass;

[0051] c. Solution quenching: the smelted glass liquid is quickly poured into cold water for rapid cooling to form a coarse material, wherein the temperature of the cold water is 20°C, and the cooling time is 30s;

[0052] d. Coarse material crushing: Pour the coarse material obtained in step c into a crusher for crushing, and pass through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com