A kind of conductive silver paste and its preparation method and 5g ceramic filter

A technology of conductive silver paste and silver paste, which is applied in the field of material chemistry, can solve the problems of medium performance, high density requirements for multiple thermal shocks, high filter performance requirements, and high ceramic density, and achieves good high temperature thermal shock performance. , Excellent dielectric properties and high sintering density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

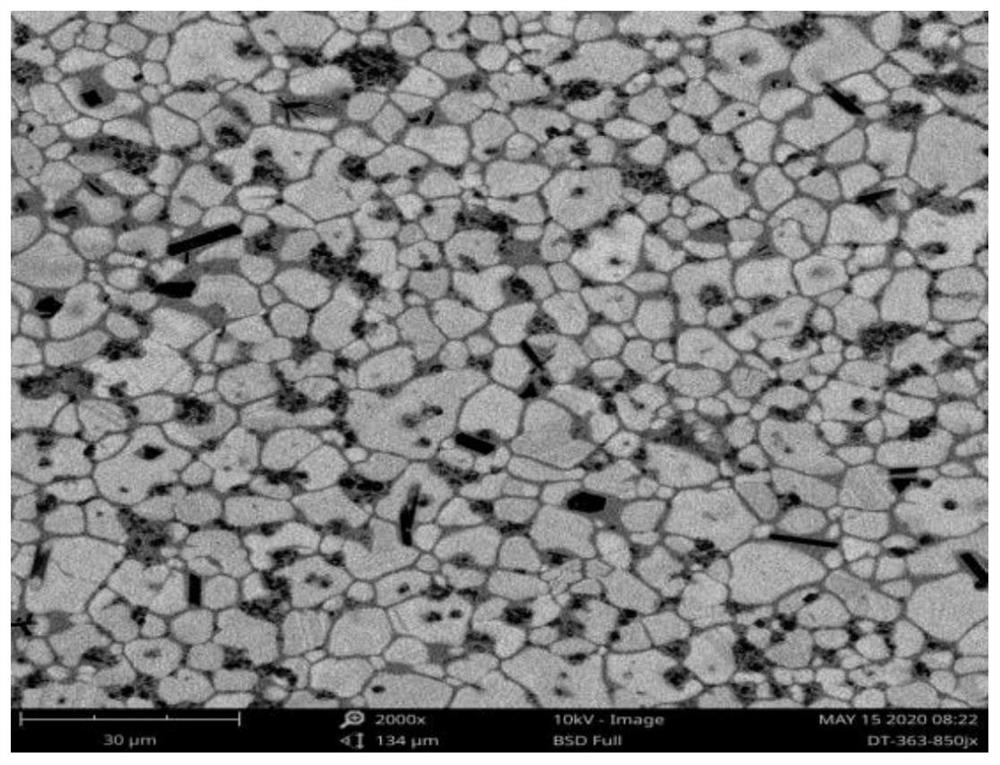

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing conductive silver paste described in the above technical scheme, comprising the following steps:

[0040] Silver powder, glass powder, inorganic additives, silver paste additives and organic vehicle are mixed and ground to obtain conductive silver paste.

[0041] In the preparation method provided by the present invention, firstly, silver powder, glass powder, inorganic additives, silver paste additives and organic vehicle are uniformly mixed in proportion, and then ground and rolled to obtain the conductive silver paste provided by the present invention. Wherein, the fineness of the conductive silver paste is preferably ≤10 μm.

[0042] In the preparation method provided by the present invention, the source of the glass powder is not particularly limited, and it is preferably prepared according to the following steps:

[0043] The raw materials used to prepare glass are mixed and placed in a melting furnace, and...

Embodiment

[0053] Unless otherwise specified in the following component contents, the figures representing the proportions of the components all represent percentages by weight.

[0054] (1) Preparation of glass powder

[0055] After weighing the raw materials for preparing glass according to the proportion, fully mix them with a mixer, put them into a corundum crucible, put them into a high-temperature furnace, and heat up to 1450°C for smelting with the furnace heating up for 220 minutes. Pour the molten glass liquid into deionized water for water quenching, and finally ball mill the quenched glass slag for 460 minutes, dry and sieve to obtain glass powder with an average particle size of 5 μm.

[0056] This example prepared CaO-SrO-BaO-SiO 2 -Al 2 o 3 -B 2 o 3 System glass powder and TeO 2 -V 2 o 5 -SiO 2 -ZnO-Al 2 o 3 -CuO-B 2 o 3 The system glass powder, its raw material component distribution ratio is detailed in the table below:

[0057] Table 1 CaO-SrO-BaO-SiO 2 -A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com