Patents

Literature

40results about How to "Reduced risk of warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

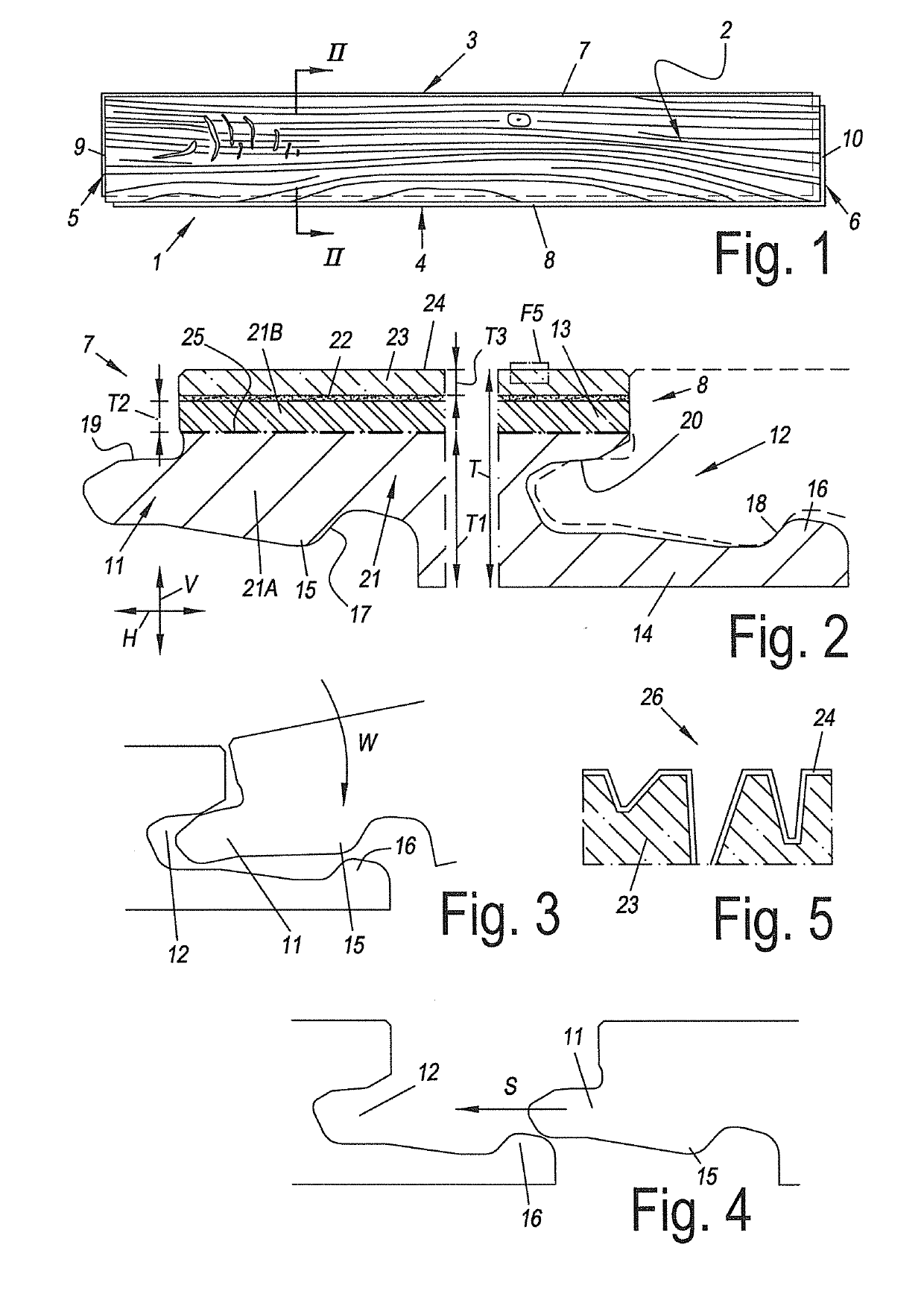

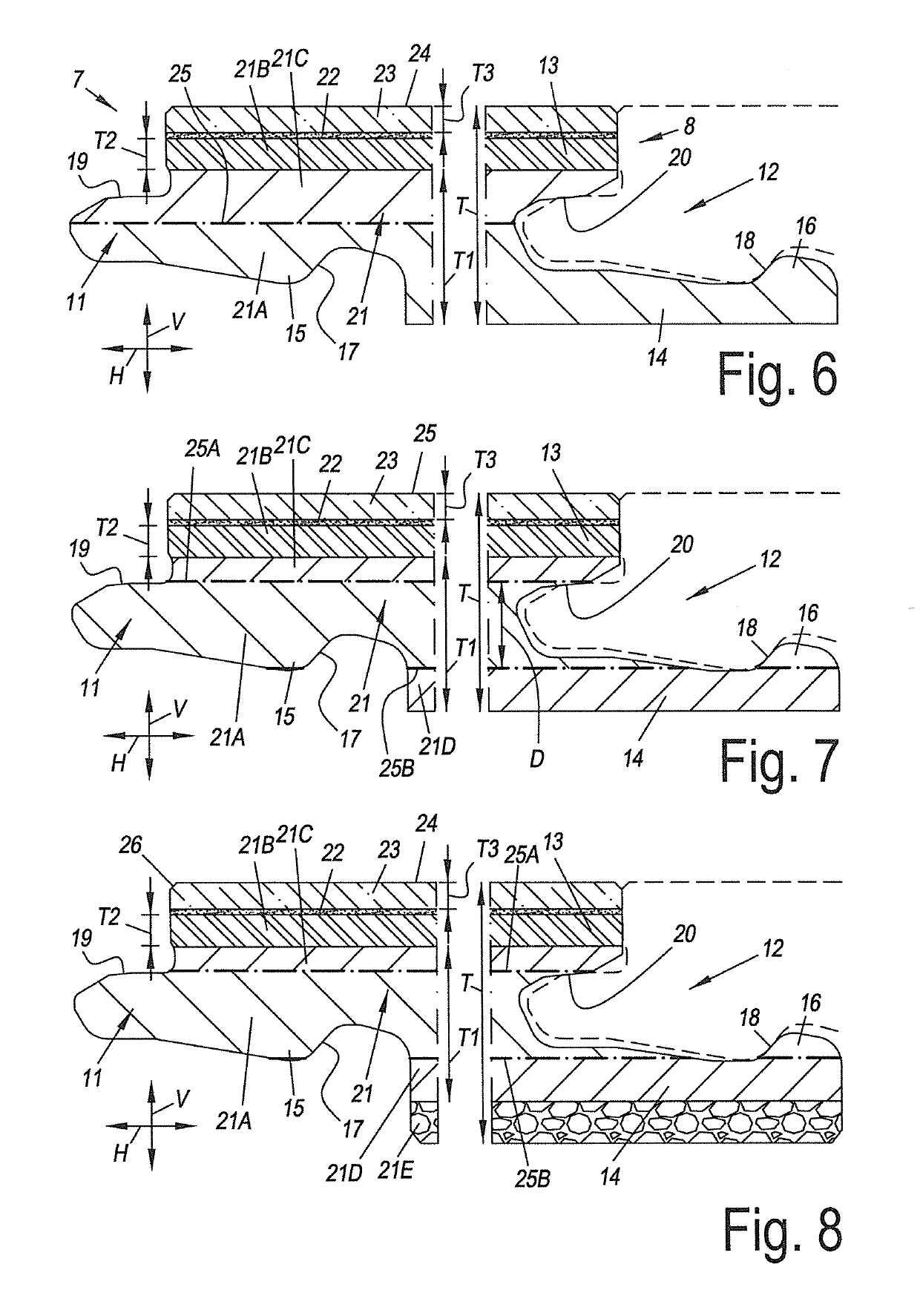

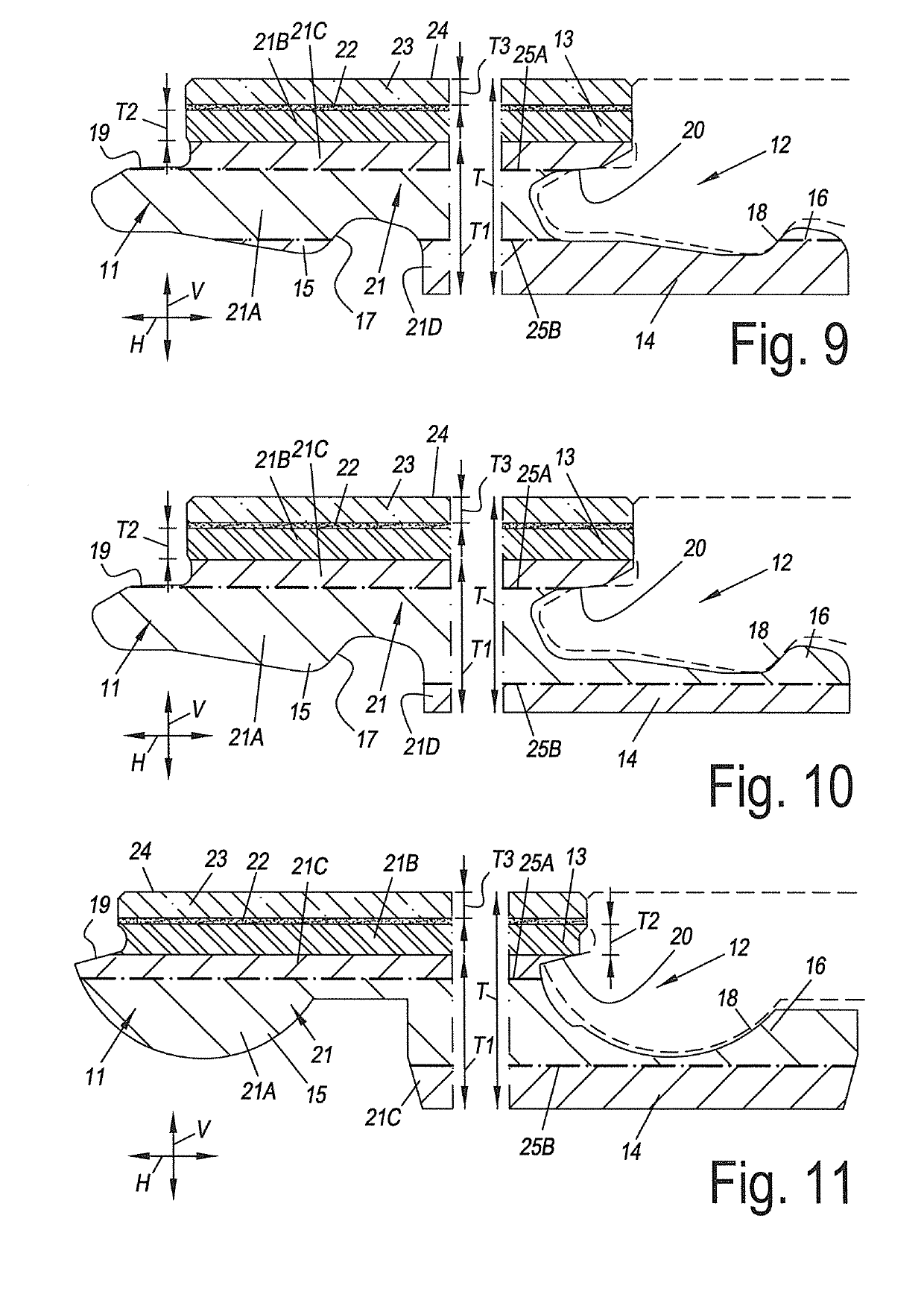

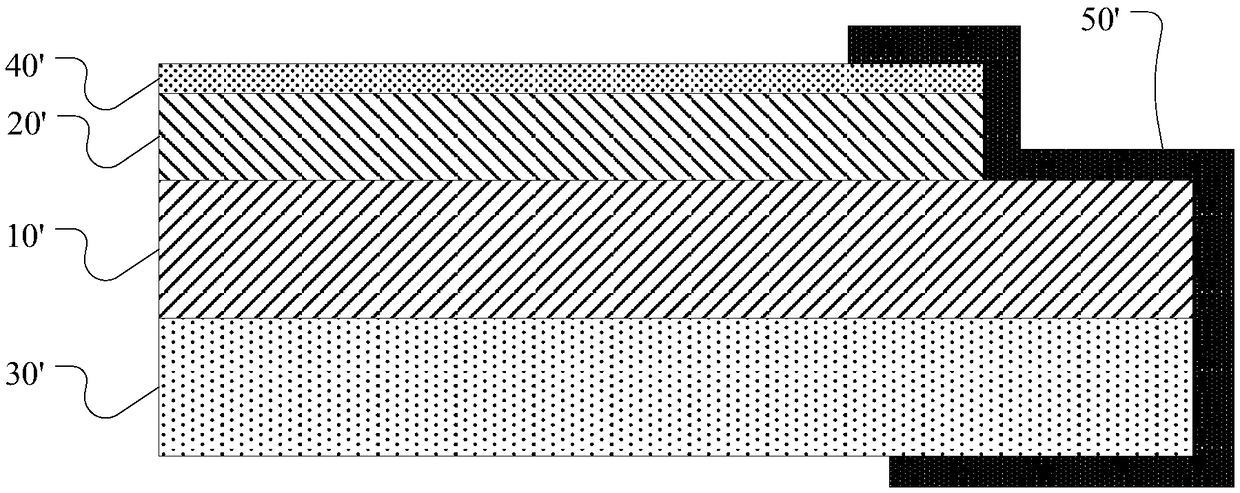

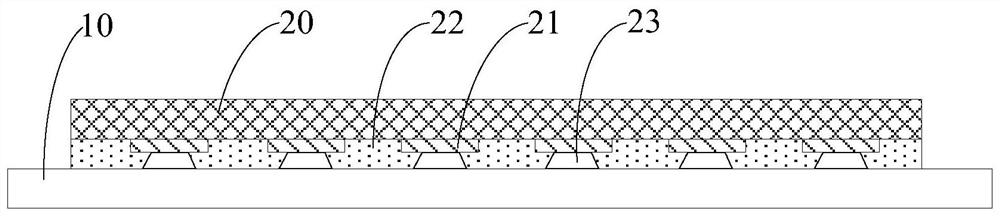

Floor panel and method for manufacturing a floor panel

ActiveUS20190292793A1Good dimensional stabilityReduced risk of warpingCovering/liningsSynthetic resin layered productsGlass fiberEngineering

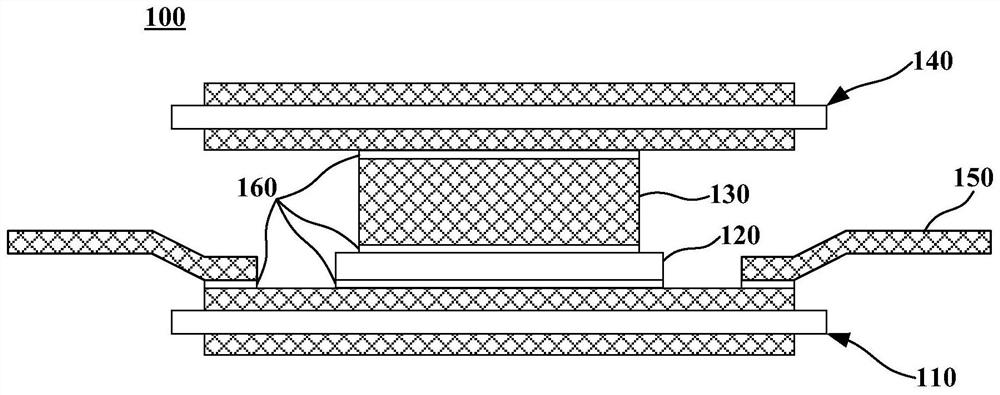

Floor panel with a substrate, including thermoplastic material, a decor provided thereon, and, on at least one pair of opposite edges, coupling parts realized at least partially from the substrate. The coupling parts allow to effect a mechanical locking between two of floor panels, where the substrate includes a rigid substrate layer of thermoplastic material, and a glass fiber layer is present in the floor panel.

Owner:FLOORING IND LTD

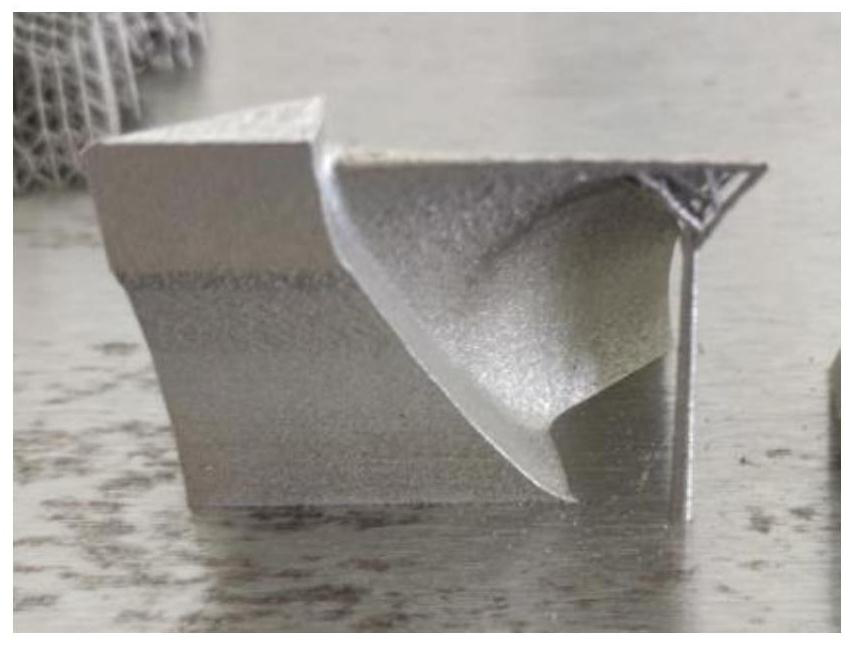

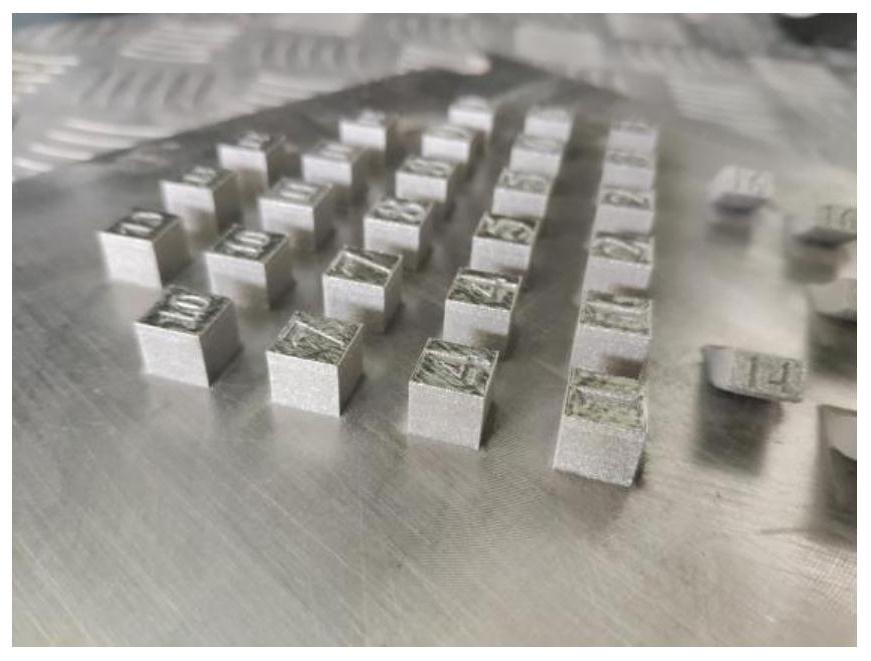

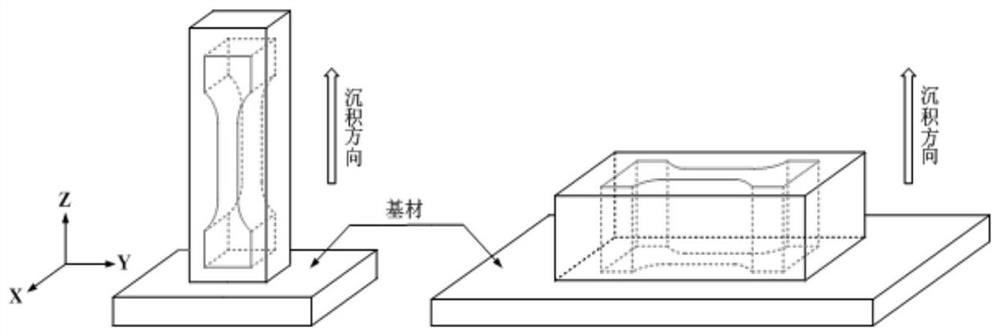

Method for preparing K418 nickel-based high temperature alloy charging turbine based on selective laser melting forming technology

PendingCN112371996AQuick verificationReduced risk of warpingTurbinesAdditive manufacturing apparatusSelective laser meltingArgon atmosphere

The invention discloses a method for preparing a K418 nickel-based high temperature alloy charging turbine based on a selective laser melting forming technology, and belongs to the technical field ofnickel-based high temperature alloy laser additive manufacturing. The method for preparing the K418 nickel-based high temperature alloy charging turbine based on the selective laser melting forming technology solves the problems of many defects, high cost, long period and the like of a traditional casting process in the development stage of the charging turbine. According to the method, firstly, ato-be-formed material is pretreated, then proper forming powder is selected, a model of the K418 charging turbine is constructed, a program file before forming and machining process parameter settingare prepared and imported into SML equipment, under the argon atmosphere, the SML equipment conducts selective melting on the forming powder material on a workbench according to a scanning path and process parameters in a program, and then according to the set layer thickness, the workbench is lowered by one layer thickness, then the powder is laid, the forming powder continues to be subjected toselective melting, the action is repeated, and the charging turbine is formed through step-by-step stacking. By means of the method, the buckling deformation risk of a charging turbine blade is reduced, and part defects caused by stress shrinkage are avoided.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

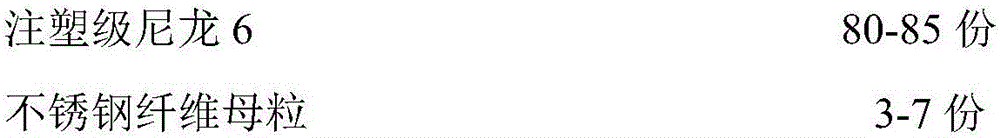

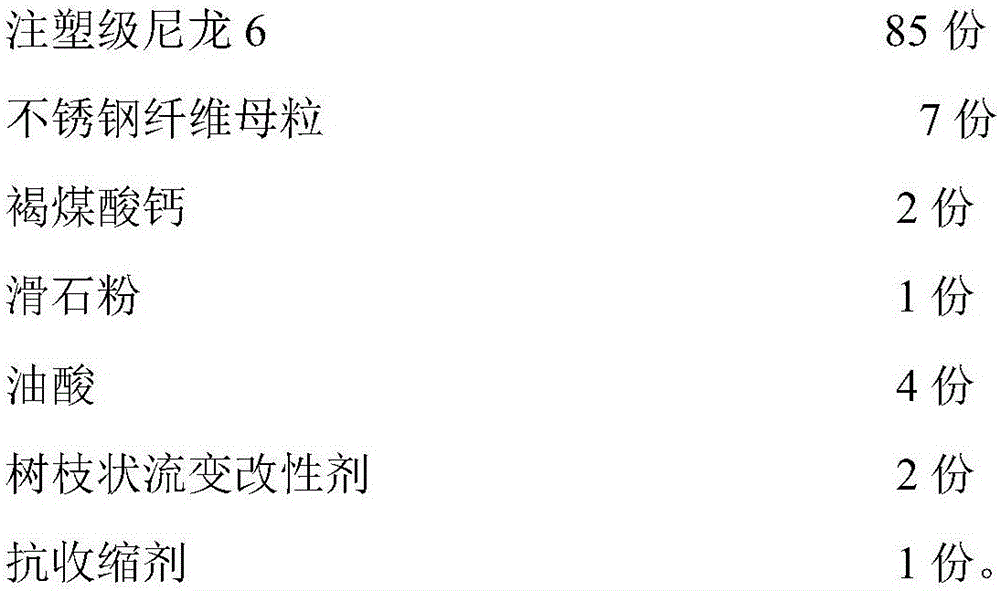

Composite polyamide material for large-thickness-tolerance precision injection molded part and injection molding method

InactiveCN105733249ASolve the shortcomings of poor thermal conductivityUniform temperatureCoatingsMolten statePolyamide

The invention discloses a composite polyamide material for a large-thickness-tolerance precision injection molded part. The composite polyamide material is prepared from, by weight, 80-85 parts of nylon 6, 3-7 parts of stainless steel fiber masterbatch, 0.5-2 parts of montanic calcium, 0.2-1 part of talcum powder, 2-4 parts of oleic acid, 1-2 part of a dendritic rheological modifier and 0.5-1 part of an anti-shrinking agent. The composite polyamide material uses stainless steel fiber masterbatch as the modifier, utilizes high heat conductivity of stainless steel fiber to makes temperature at all portions of the injection molded part in the molding and cooling process more uniform, and accordingly the warping risk is effectively reduced. The anti-shrinking agent, the montanic calcium and the talcum powder are adopted as compound nucleating agents, the crystallization rate of polyamide resin is improved, the grain size is decreased, and accordingly shrinkage of the fabricated part is effectively decreased. The oleic acid and the dendritic rheological modifier are adopted as composite rheological modifiers, so that the composite polyamide material has better liquidity in a molten state, and accordingly liquidity degradation caused by the added stainless steel fiber is effectively relieved.

Owner:ZHEJIANG SENCHUAN FURNITURE

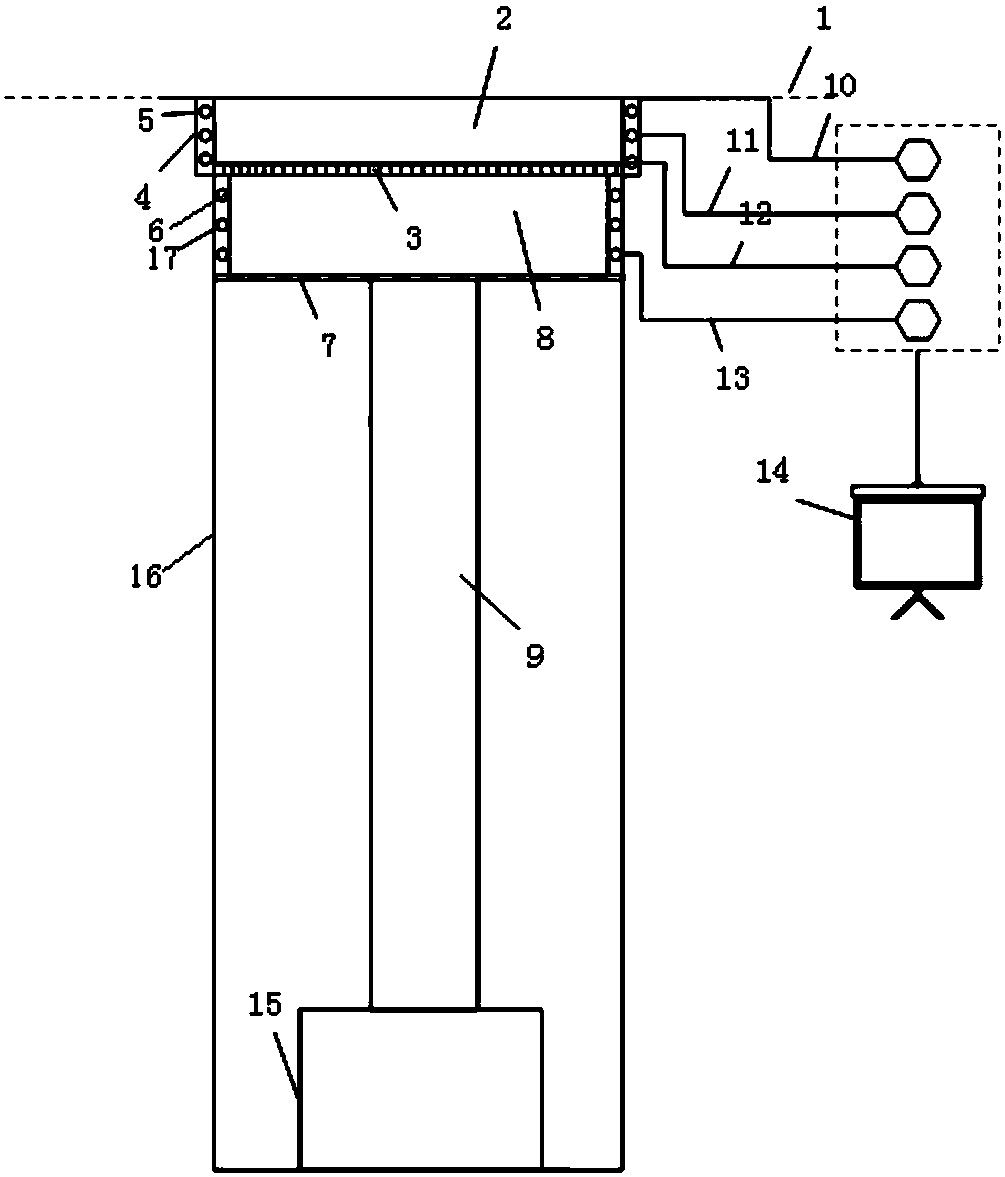

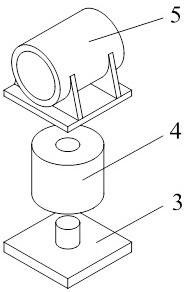

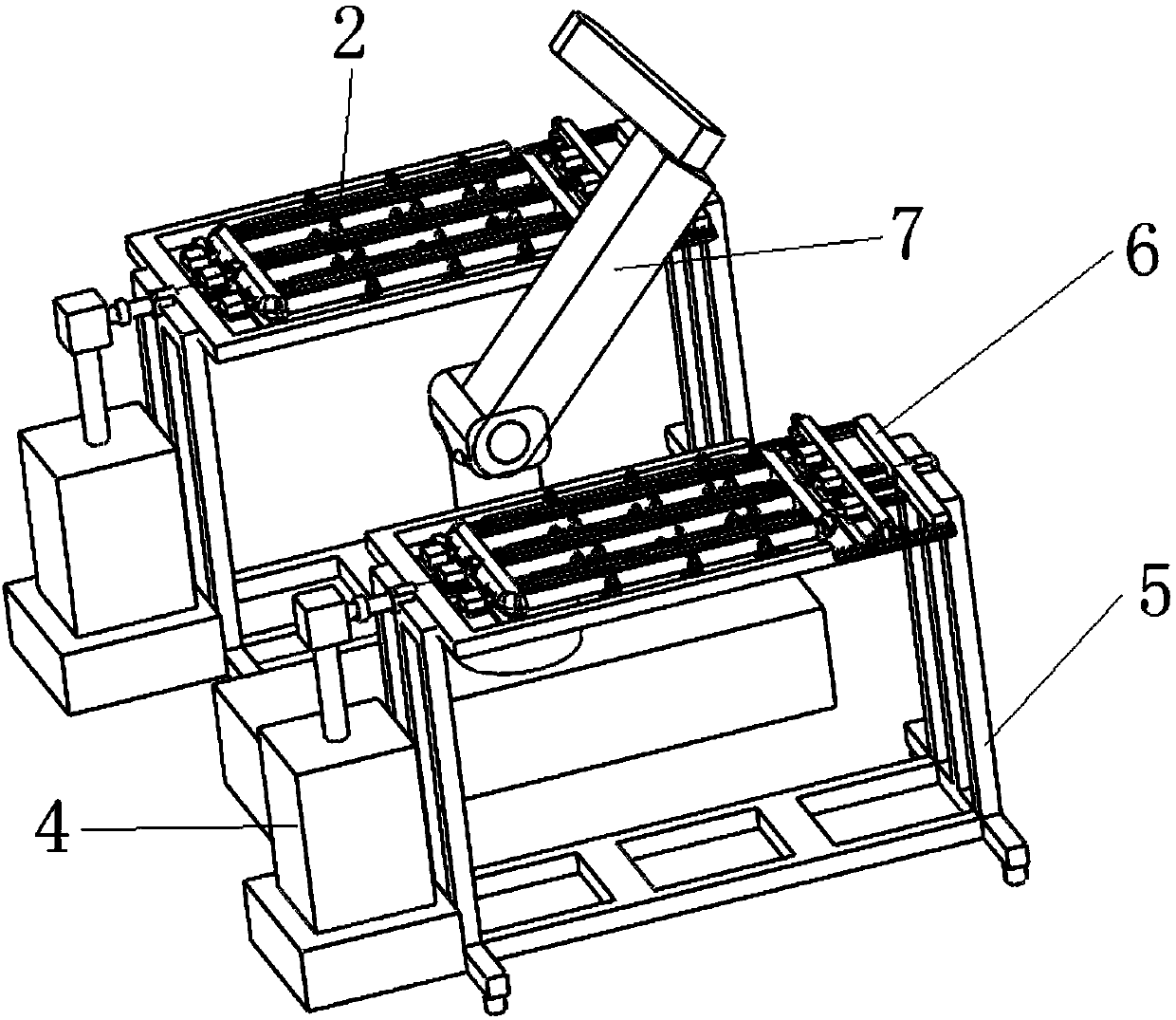

Device and method for alleviating part stress by means of electromagnetic induction in additive manufacturing of powder bed

PendingCN107803500AReduce magnetic field strengthMinor changesAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankElectromagnetic generator

The invention discloses a device for alleviating part stress by means of electromagnetic induction in additive manufacturing of a powder bed. The device is characterized by comprising a forming cylinder, wherein a driving motor is arranged in the forming cylinder; an output shaft of the driving motor is connected to a ball lead screw mechanism; the other end of the ball lead screw mechanism is connected to a heating substrate; electromagnetic generators are integrated around the heating substrate; electromagnetic inducers are arranged around the upper end of the outer wall of the forming cylinder; the electromagnetic inducers are connected to a first electromagnetic generating power supply; the electromagnetic generators are connected to a second electromagnetic generating power supply; and the first electromagnetic generating power supply and the second electromagnetic generating power supply are connected to a master control system of equipment. By adopting a direct flow magnetic field to apply disturbance to leading edge momentum of a liquid-solid interface and solute transmission in a solidification process of a laser molten pool, the solidified crystal state of the liquid-solid interface is changed, so that a purpose of controlling the phase change stress in the solidification process of the laser molten pool is achieved. The invention also discloses a method for alleviating part stress by adopting the device.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

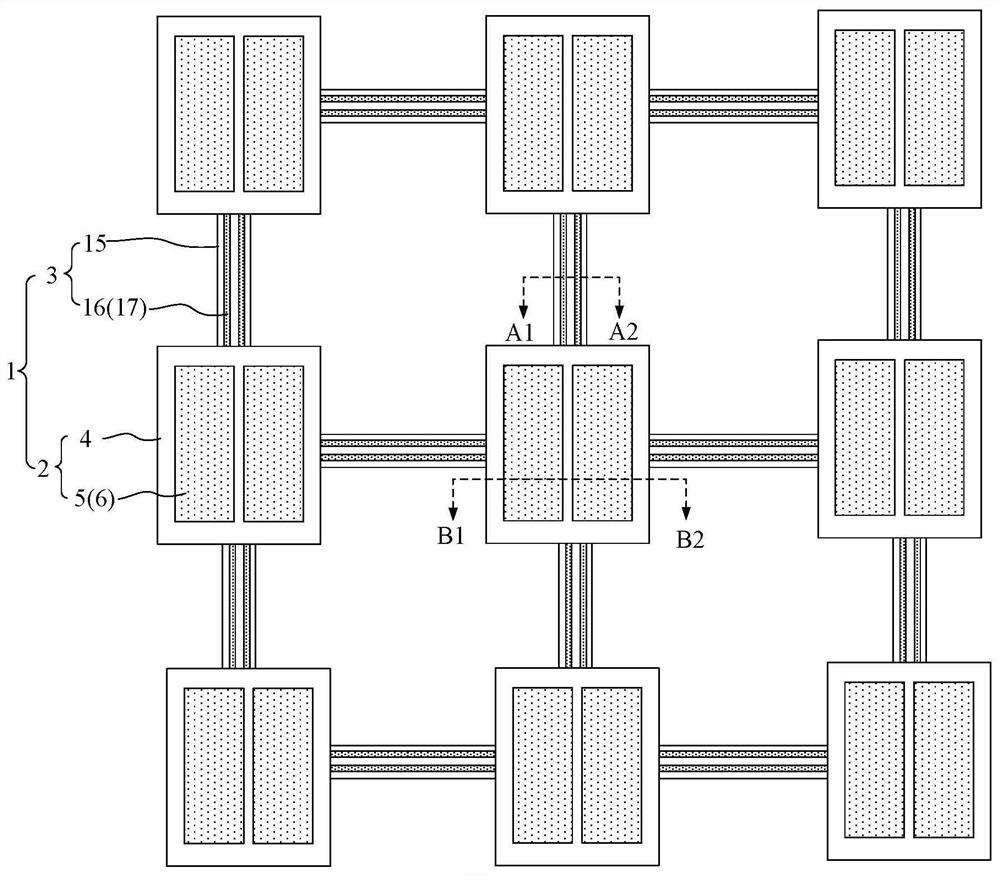

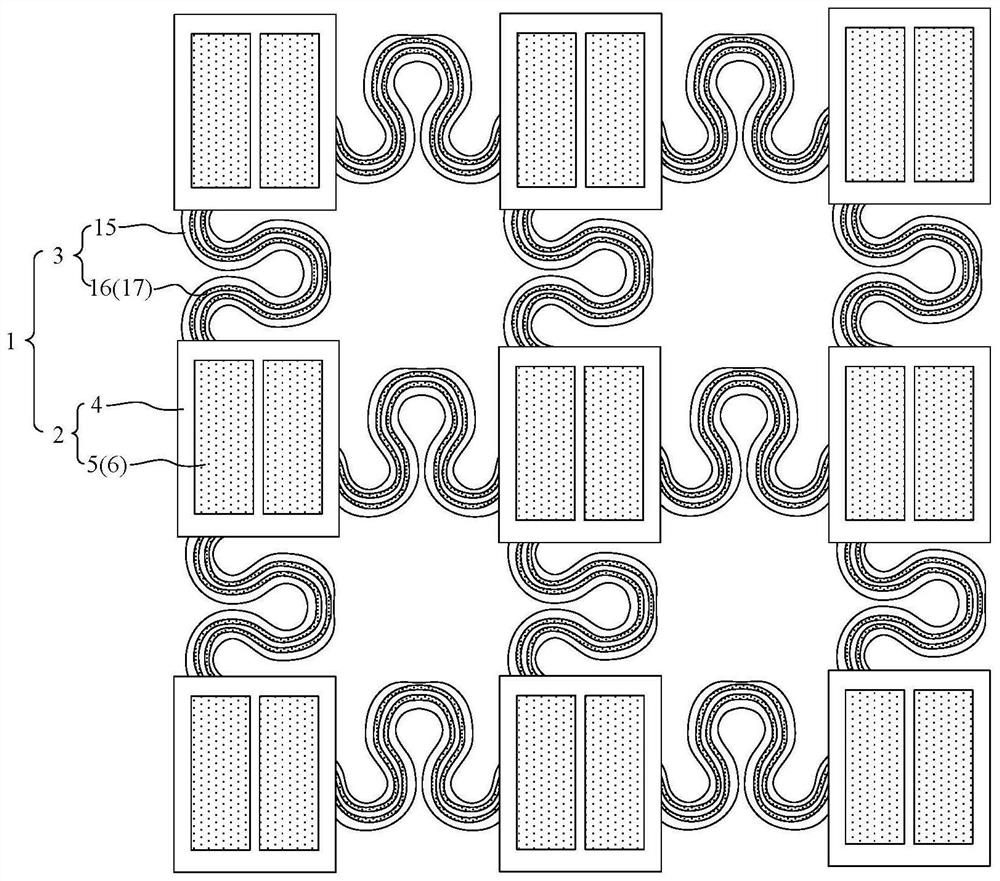

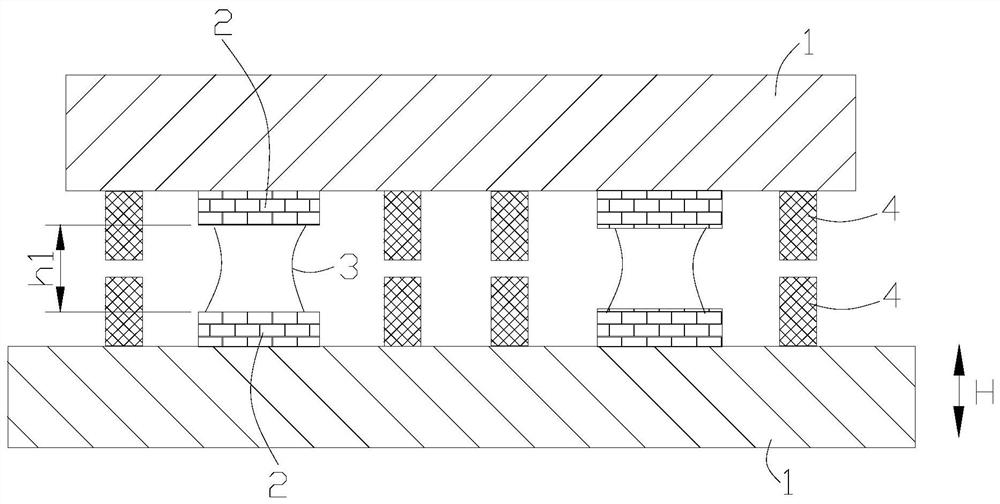

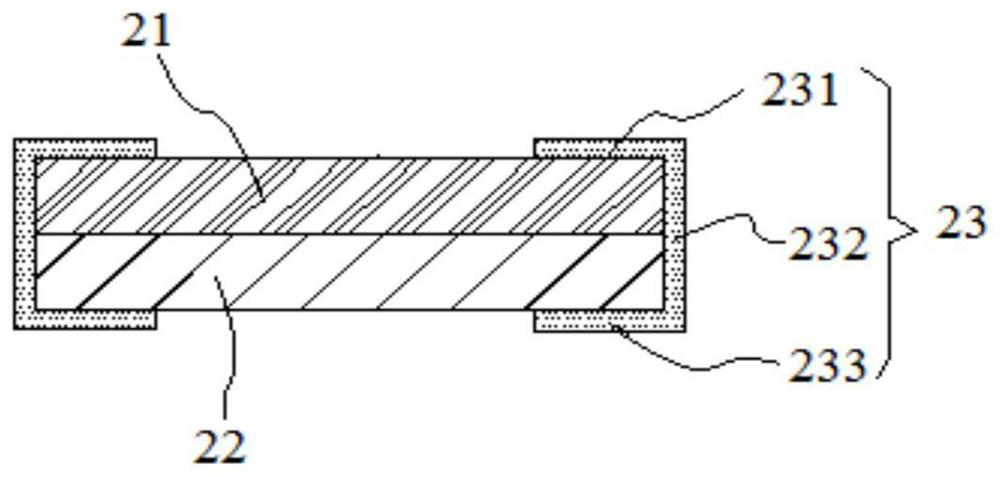

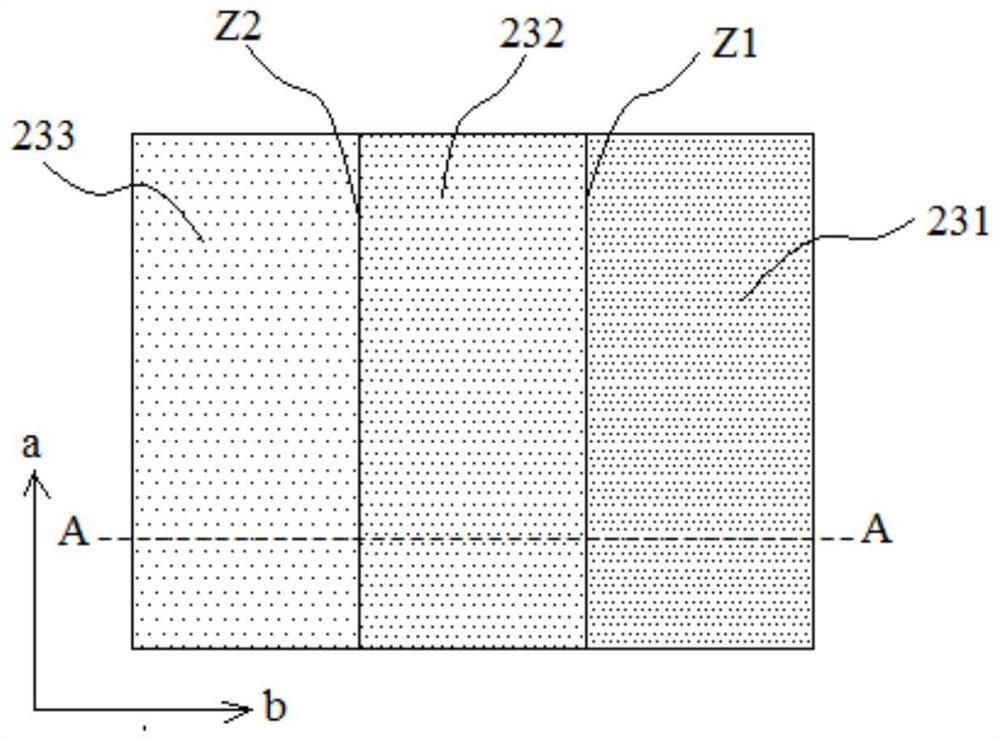

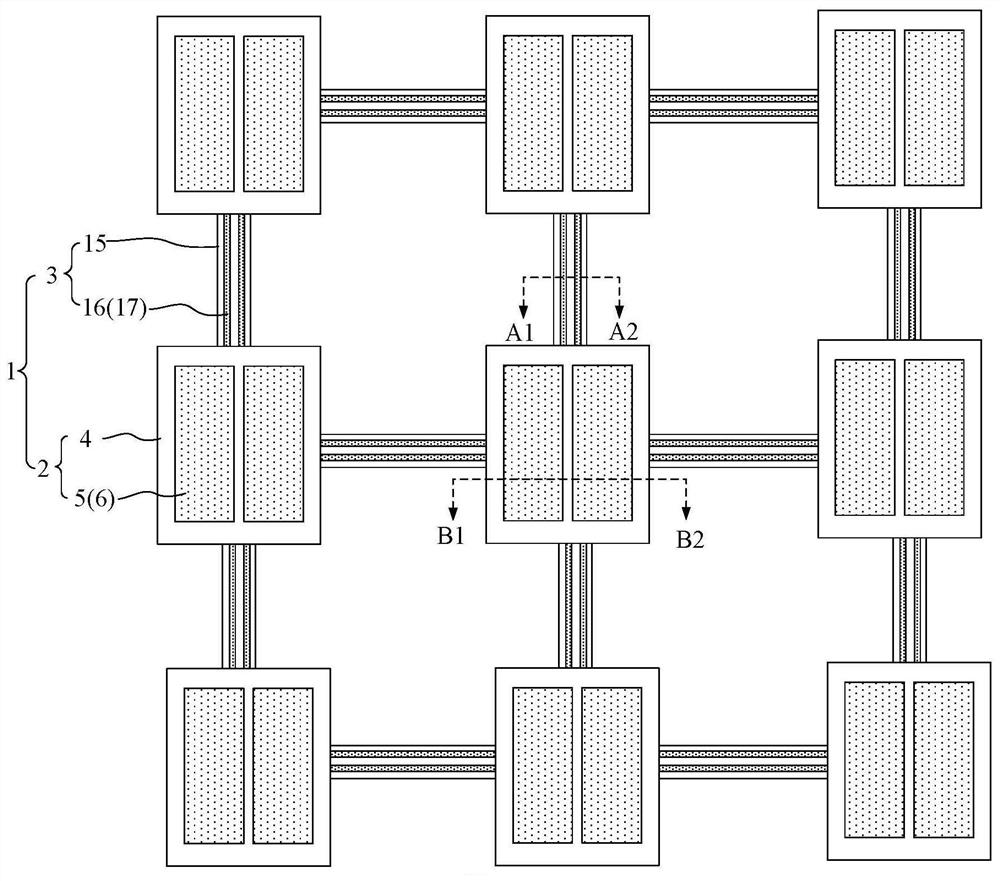

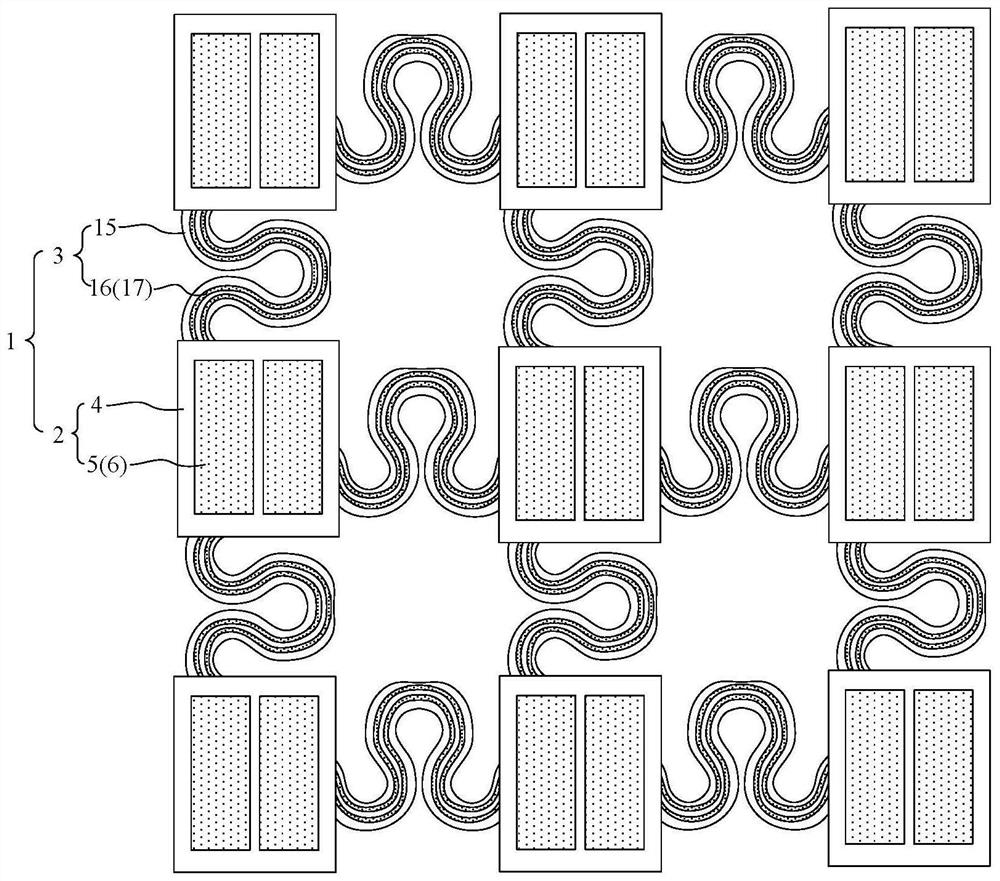

Stretchable display panel and stretchable display device

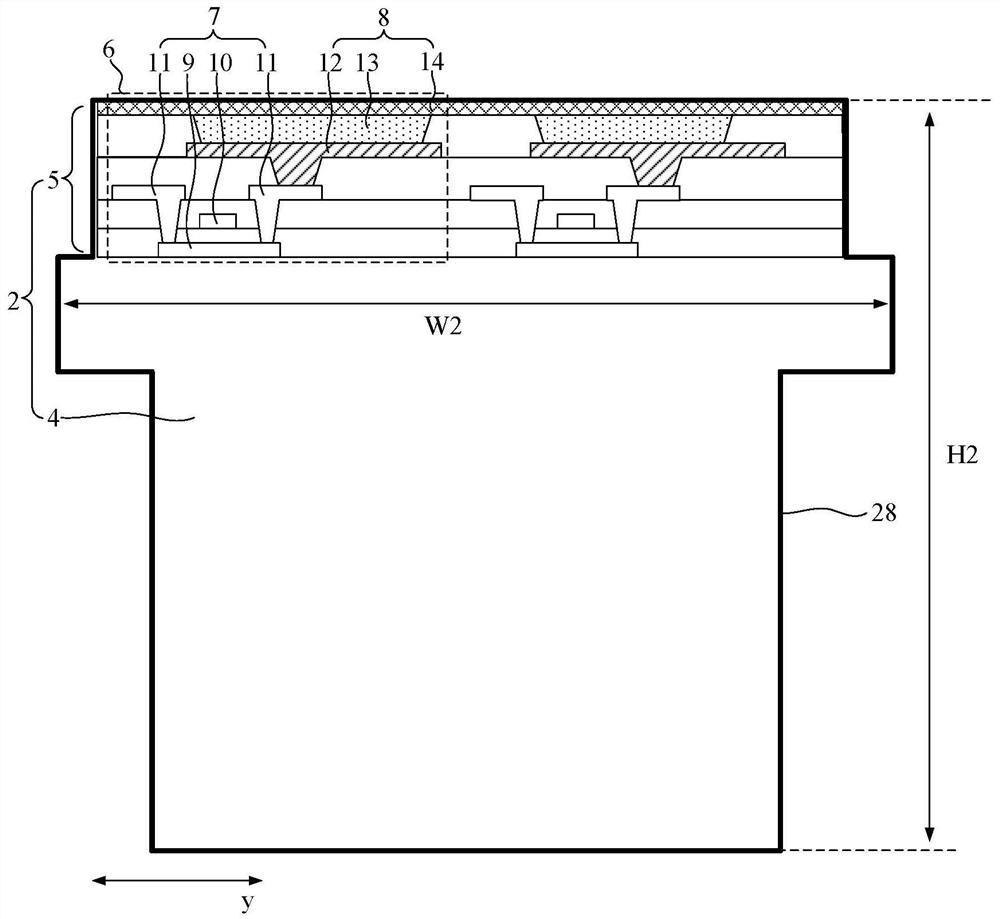

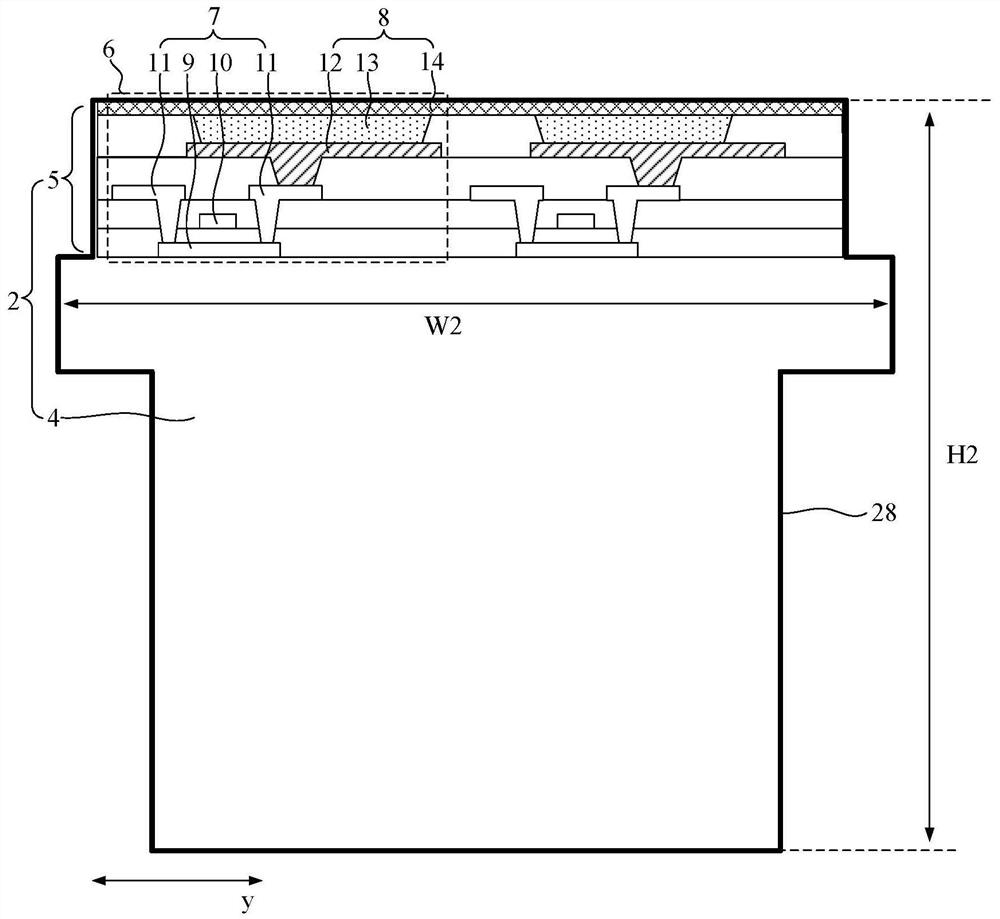

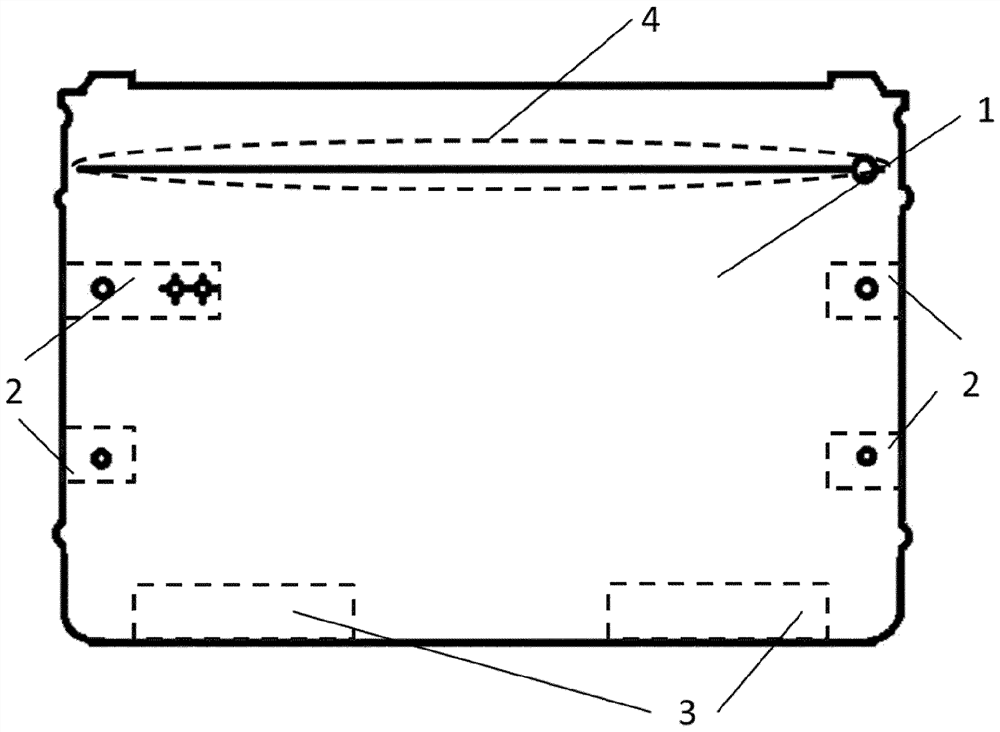

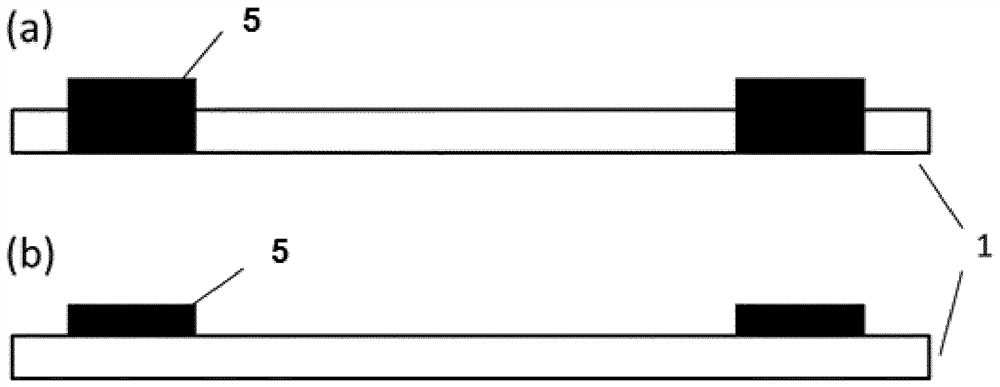

ActiveCN111833753AIncreasing the thicknessMaximum thickness is H1 maximum thicknessStatic indicating devicesLayered productsDisplay devicePhysics

The embodiment of the invention provides a stretchable display panel and a stretchable display device, relates to the technical field of display, and improves the warping phenomenon of the stretchabledisplay panel. The stretchable display panel comprises a stretchable substrate, the stretchable substrate is composed of island-shaped structures and bridge-shaped structures, and every two adjacentisland-shaped structures are connected through the corresponding bridge-shaped structure; each island-shaped structure comprises a first bearing substrate and a first display film layer, each first display film layer comprises pixel units, each bridge-shaped structure comprises a second bearing substrate and a second display film layer, and each second display film layer comprises signal lines; each bridge-shaped structure has a first section perpendicular to the plane of the corresponding second bearing substrate, each first section is perpendicular to the extending direction of the corresponding bridge-shaped structure, the maximum width of each first section in the first direction is W1, the maximum thickness of each bridge-shaped structure in the direction perpendicular to the plane where the second bearing substrate is located is H1, H1 is larger than or equal to W1, and the first direction is parallel to the planes where the second bearing substrates are located and perpendicularto the extending direction of the bridge-shaped structures.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

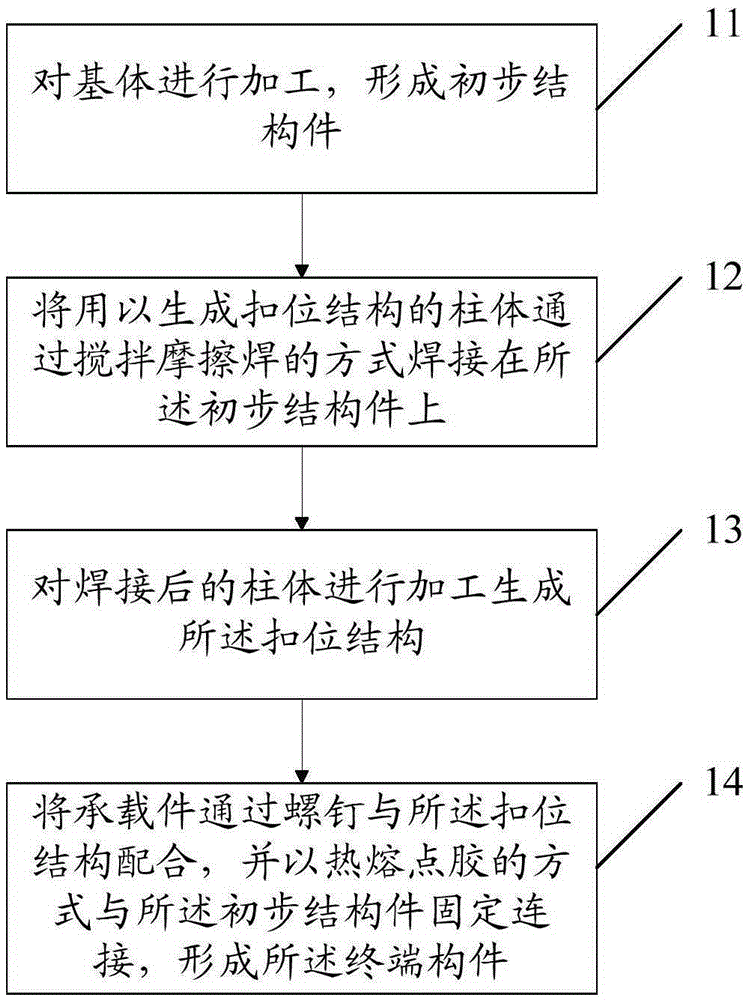

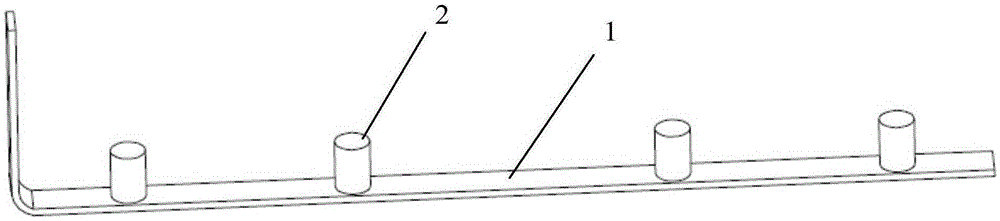

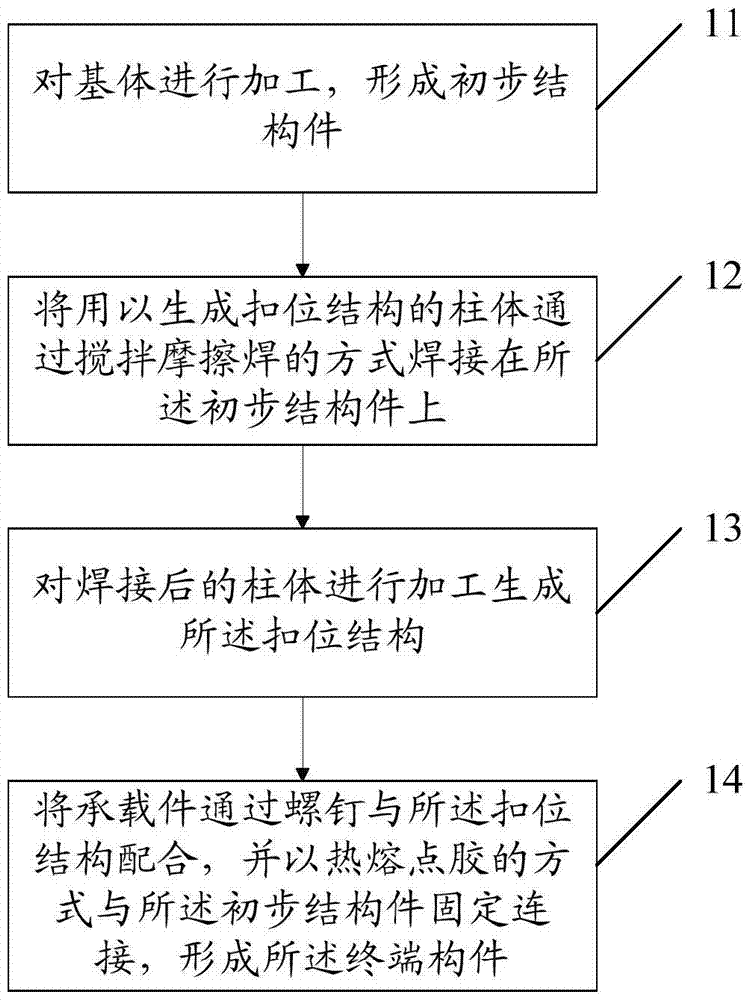

Method for manufacturing terminal member and terminal member

ActiveCN105328327ASimple processIncrease productivityLiquid surface applicatorsCoatingsDistortionEngineering

The invention provides a method for manufacturing a terminal member and the terminal member. The method for manufacturing the terminal member includes the steps that a substrate is processed to form a preliminary structural member; a cylinder for generating a buckling structure is welded to the preliminary structural member in a friction stir welding mode; the welded cylinder is processed to generate the buckling structure; and a bearing part is matched with the buckling structure through screws and fixedly connected with the preliminary structural member in a hot melting adhesive dispensing mode to form the terminal member. According to the scheme, the processed substrate (the preliminary structural member) and the buckling structure (formed by processing the cylinder) are connected together in the friction stir welding mode, and then the bearing part is matched with the buckling structure through the screws and fixedly connected with the preliminary structural member in the hot melting adhesive dispensing mode to finally form the terminal member. The process is greatly simplified, the production efficiency, the material utilization rate and whole terminal strength are improved, and production cost and warping risks of the terminal member due to terminal dropping or distortion are reduced.

Owner:VIVO MOBILE COMM CO LTD

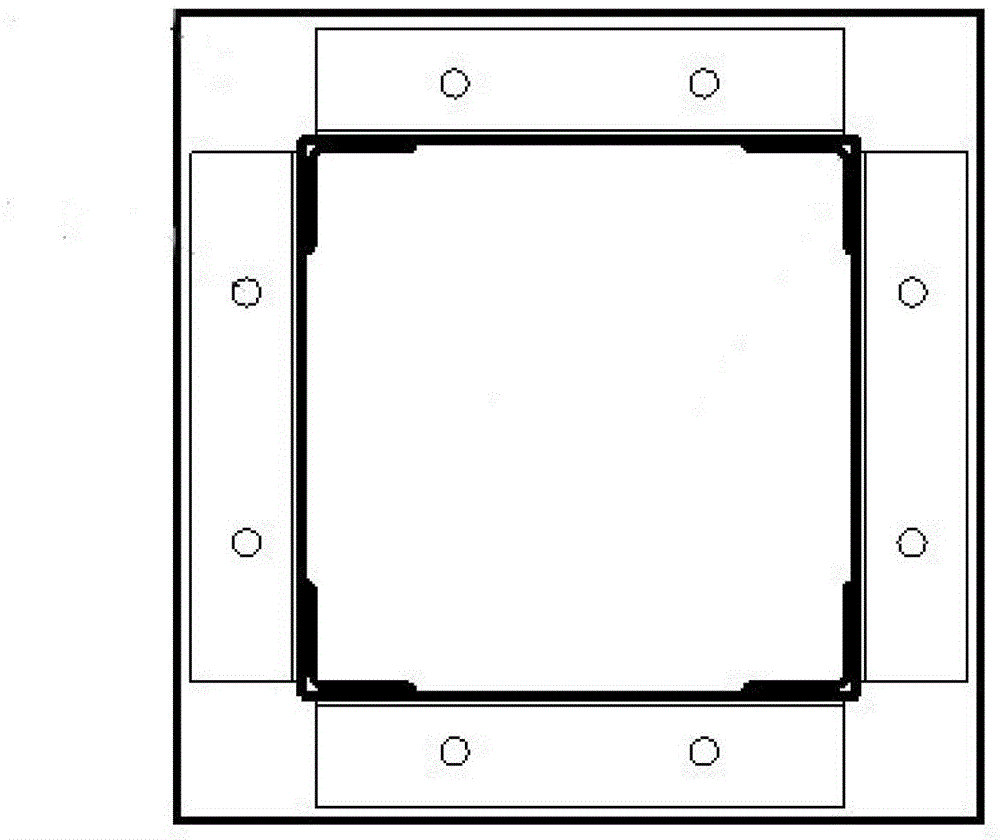

Jig

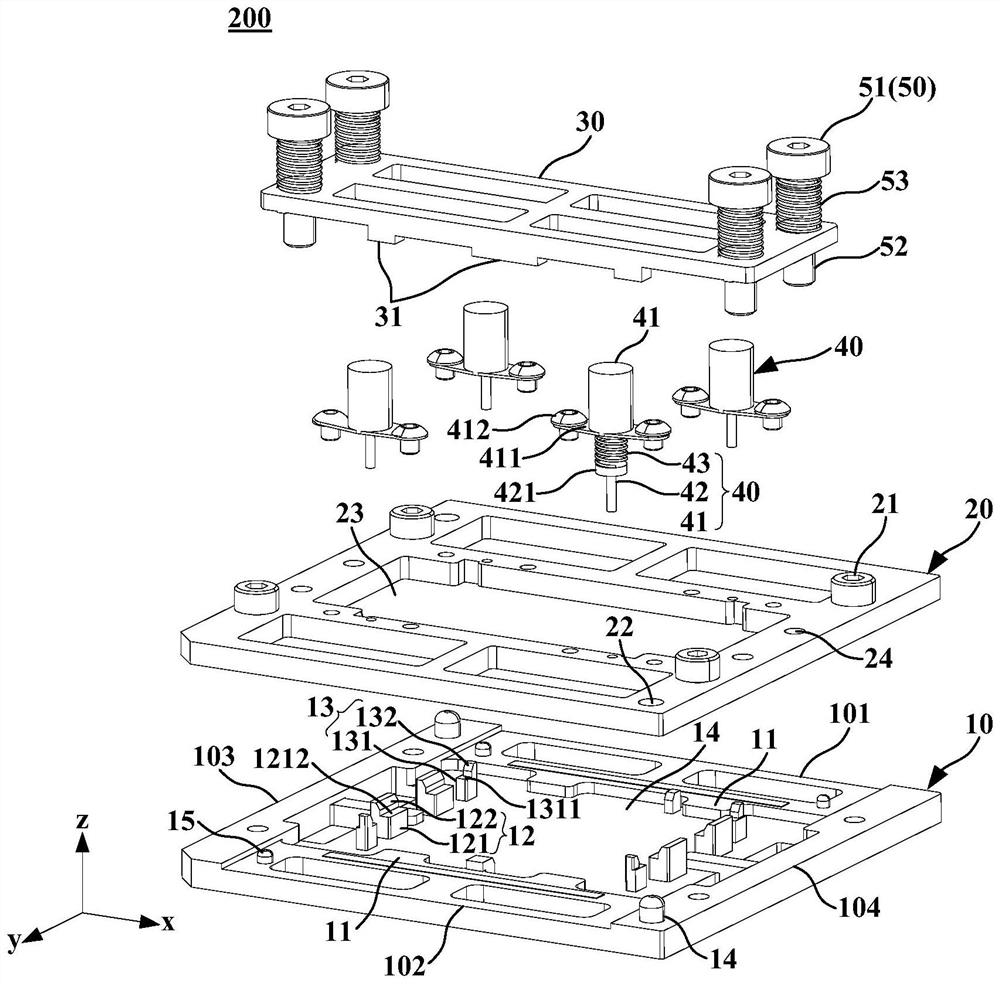

ActiveCN113113378AReduced risk of warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The present invention provides a jig. The height of the heat dissipation substrate of the packaging structure can be limited, the risk of solder overflow in the reflow soldering process is reduced, and the yield of the packaging structure is improved. The jig comprises a base, a cover plate and a pressing plate. First limiting structures are arranged on the two sides, close to the first side edge and the second side edge, of the first face of the base correspondingly. Second limiting structures are arranged on the two sides, close to the third side edge and the fourth side edge, of the first face of the base correspondingly. Third limiting structures are arranged on the two sides, close to the third side edge and the fourth side edge, of the first face of the base respectively, each third limiting structure is provided with a step structure, and the step faces of the third limiting structures are used for supporting the second heat dissipation substrate. The cover plate covers the first surface of the base, and the cover plate is provided with a notch for exposing the second heat dissipation substrate; and the pressing plate is arranged on the face, away from the base, of the cover plate, a plurality of protruding blocks are arranged on the face, facing the base, of the pressing plate, and the protruding blocks can stretch into the notches and abut against the second heat dissipation substrate.

Owner:HUAWEI TECH CO LTD

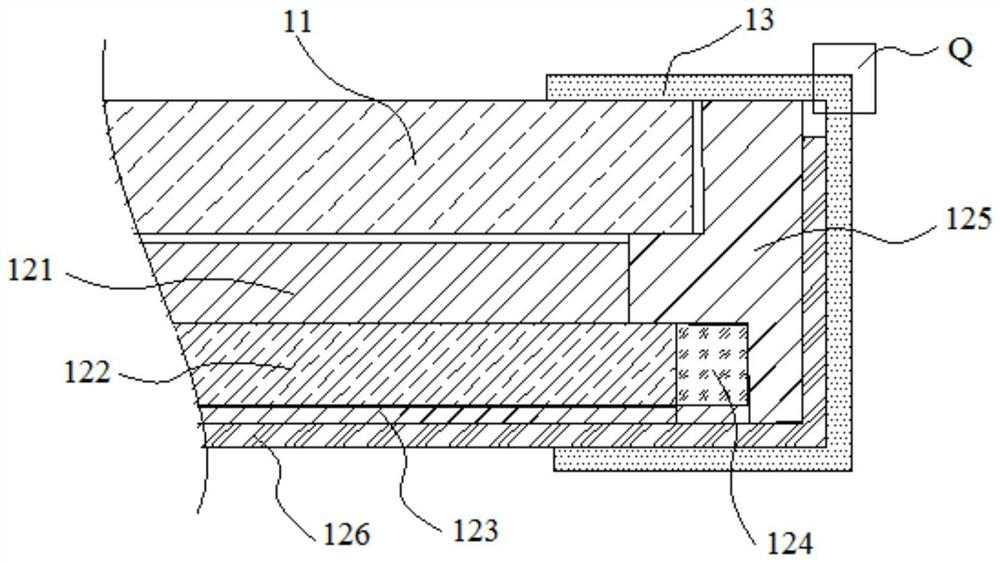

Display module and manufacturing method thereof, polaroid module and manufacturing method thereof

InactiveCN109143678AIncrease bonding areaReduced risk of warpingNon-linear opticsOptical elementsTectorial membraneEngineering

The invention discloses a display module and a manufacturing method thereof, a polaroid module and a manufacturing method thereof. The display module comprises a display panel; a first polaroid; a backlight module; a protective film covered on one side surface, far away from the display panel, of the first polaroid, wherein the distance between a first edge of the protective film and the first edge of a panel is greater than the distance between the first edge of the polaroid and the first edge of the panel; a first anti-upwarp adhesive tape, wherein the first anti-upwarp adhesive tape comprises a first adhesive tape part, a second adhesive tape part and a third adhesive tape part which are mutually and orderly arranged, the first adhesive tape part is located at one side, far away from the display panel, of the backlight module, the third adhesive type is covered at one side surface, far away from the display panel, of the first polaroid, and is located at a region between the first edge of a protective film and the first edge of the polaroid. Through the display module disclosed by the invention, the risk that the display panel upwarps from the backlight module in the display module can be reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

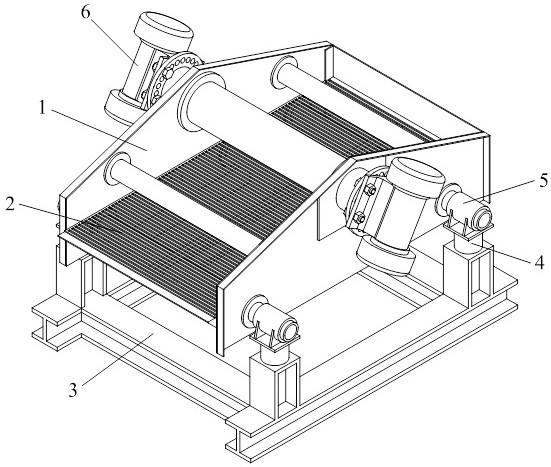

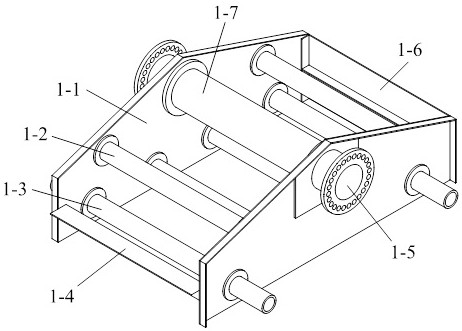

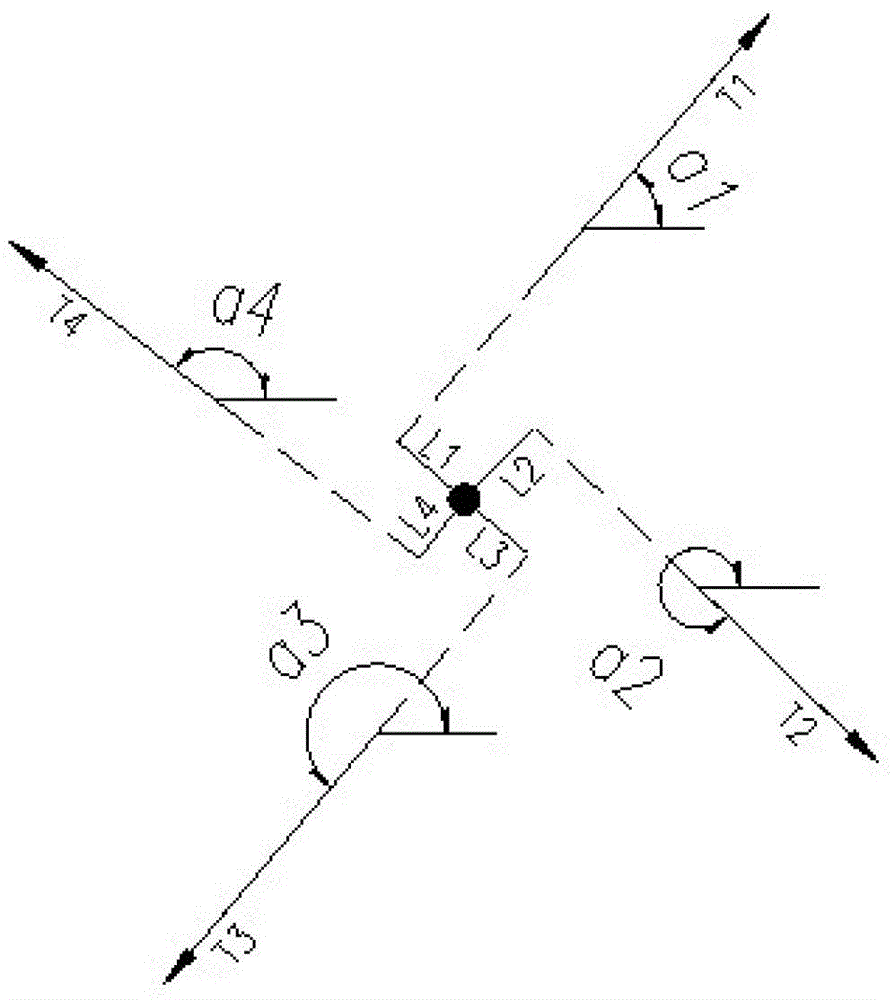

Linear vibrating screen with adjustable amplitude and vibration direction angle

The invention discloses a linear vibrating screen with the adjustable amplitude and vibration direction angle. The linear vibrating screen comprises a main screen body, a screen face, a machine frame,a rubber spring, a spring support and vibration motors, wherein the main screen body is composed of side plates, a reinforcing pipe beam, a supporting cross beam, a discharging port, motor supports,a rear baffle and a main beam. The main beam, the reinforcing pipe beam, the supporting cross beam, the discharging port, the rear baffle, the motor support and the spring support are fixed to the side plates through bolts, the two vibration motors are installed on the motor supports on the two sides respectively, the main screen body is connected with the machine frame through the rubber spring,and the machine frame is fixed to the ground through foundation bolts. The amplitude of the main screen body can be changed by changing the sizes of the rubber spring, the included angle between the vibration direction and the screen face can be changed by changing the fixing positions of the bolts on the vibration motors and the motor supports, adjustment of the amplitude and the vibration direction angle is achieved, the vibration screen can adapt to different working conditions, the good screening effect is guaranteed, operation is easy, and efficient reliability is achieved.

Owner:LINYI UNIVERSITY

High-flowability easy-demolding nylon 6 composite material and preparation method thereof

The invention belongs to the field of high-polymer composite materials, and relates to a high-flowability easy-demolding nylon 6 composite material and a preparation method thereof. The preparation method comprises the following steps: A. preparing the following components in parts by mass: 75-86 parts of injection-molding-grade nylon 6, 5-15 parts of EXPANCEL microsphere powder, 0.5-2 parts of calcium montanate, 0.3-1.4 parts of talcum powder and 1-2 parts of oleic acid; B. mixing: thoroughly mixing the components in the step A to obtain a blend; and C. preparation: extruding the blend in the step B through the head of an extruder, and granulating to obtain the high-flowability easy-demolding nylon 6 composite material. The composite material has the advantages of high flowability and easy demolding, and can be used for designing thinner parts, thereby saving the material.

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

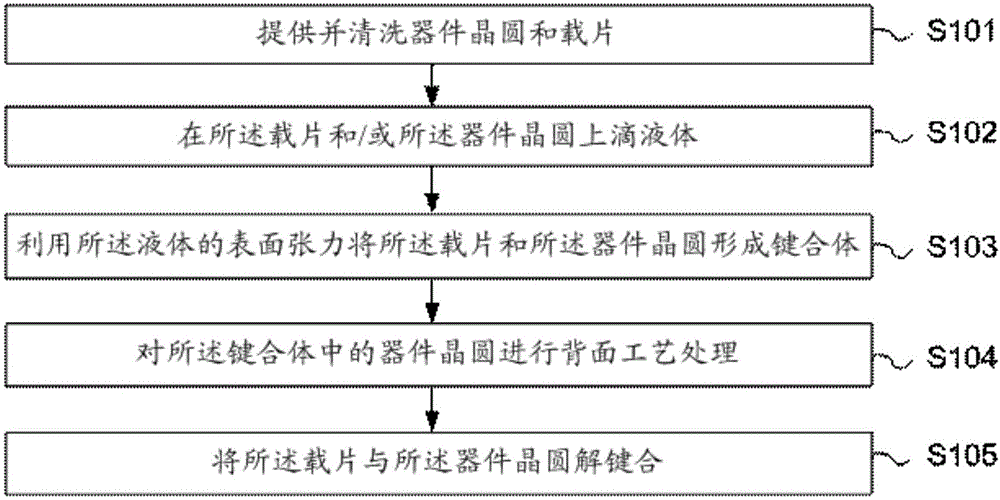

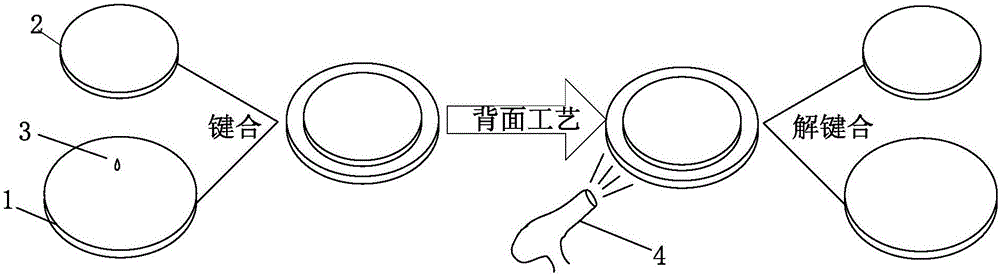

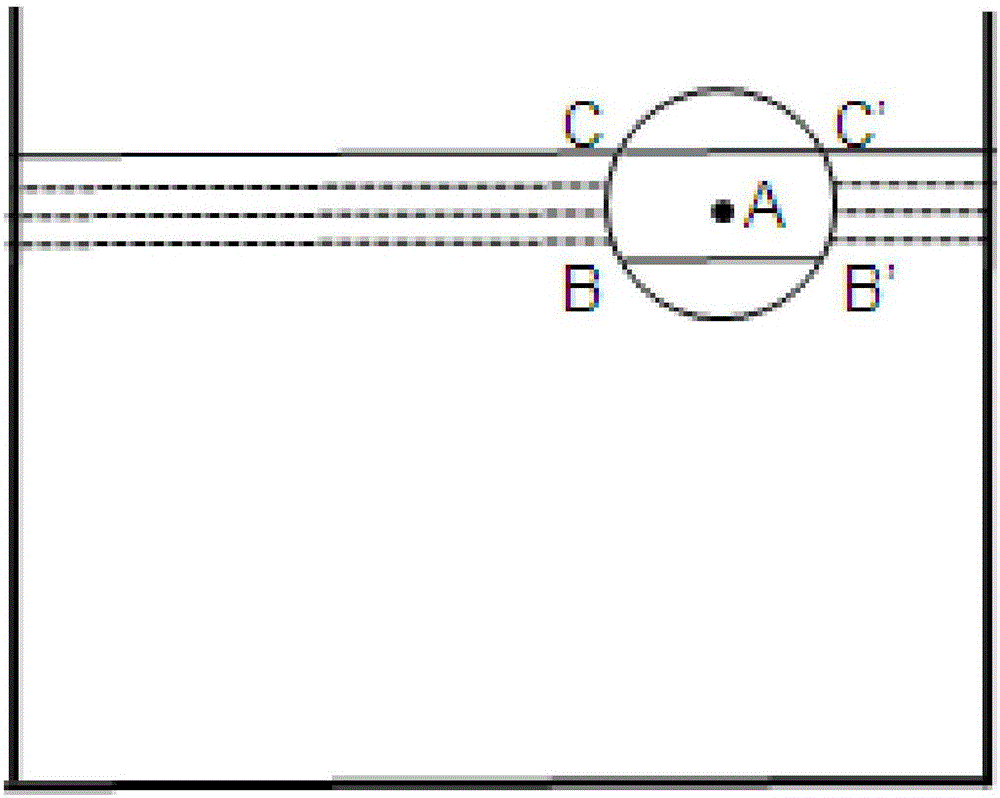

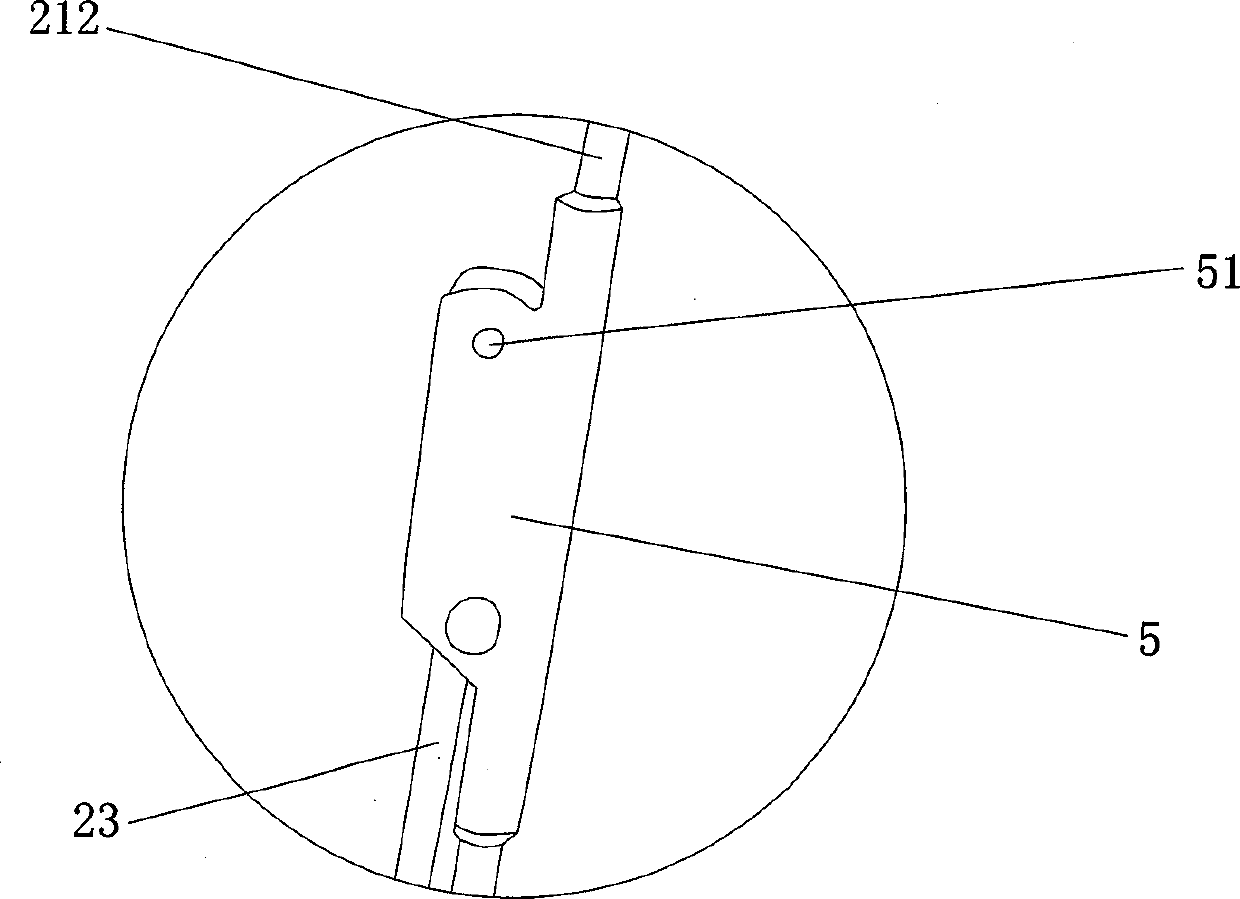

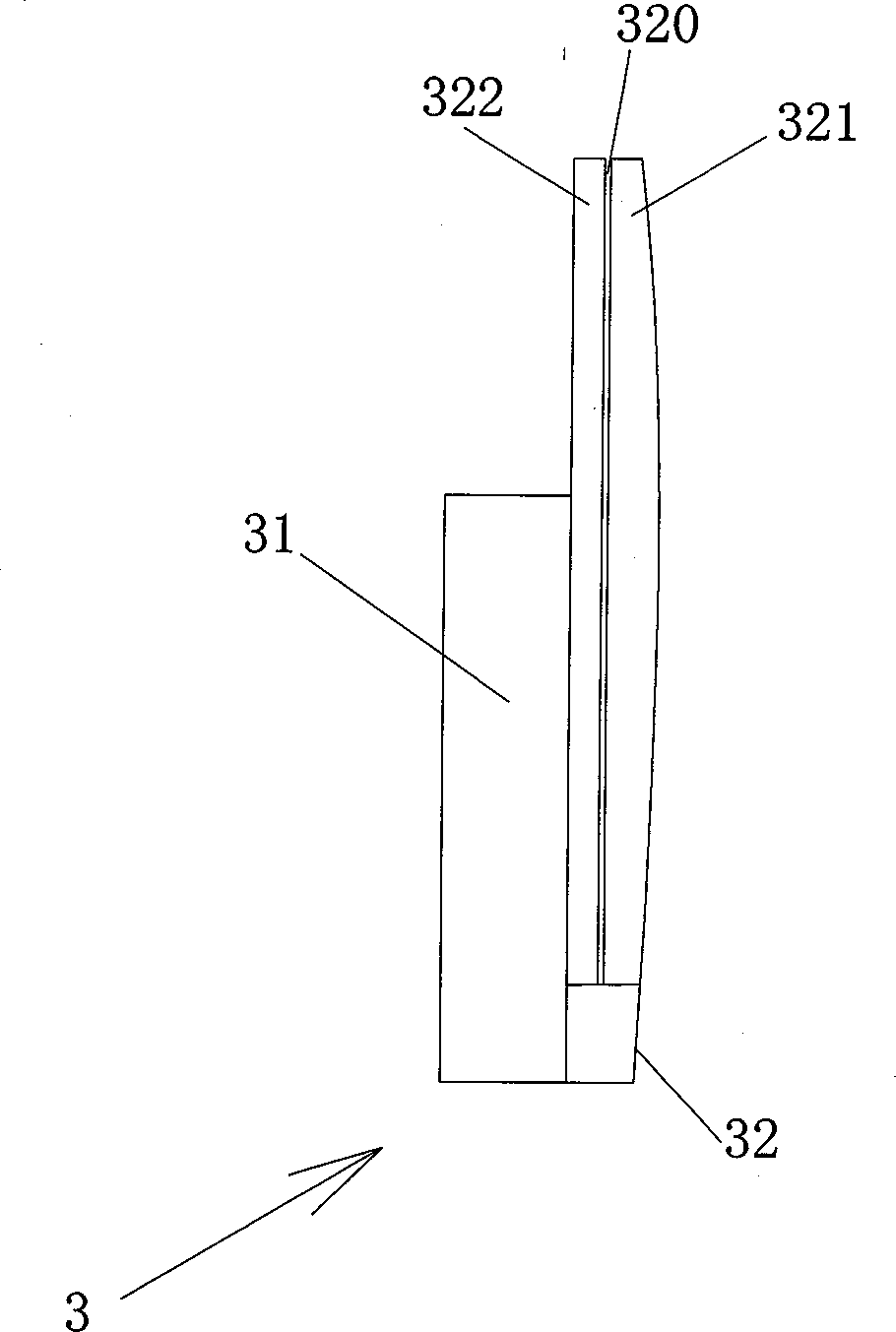

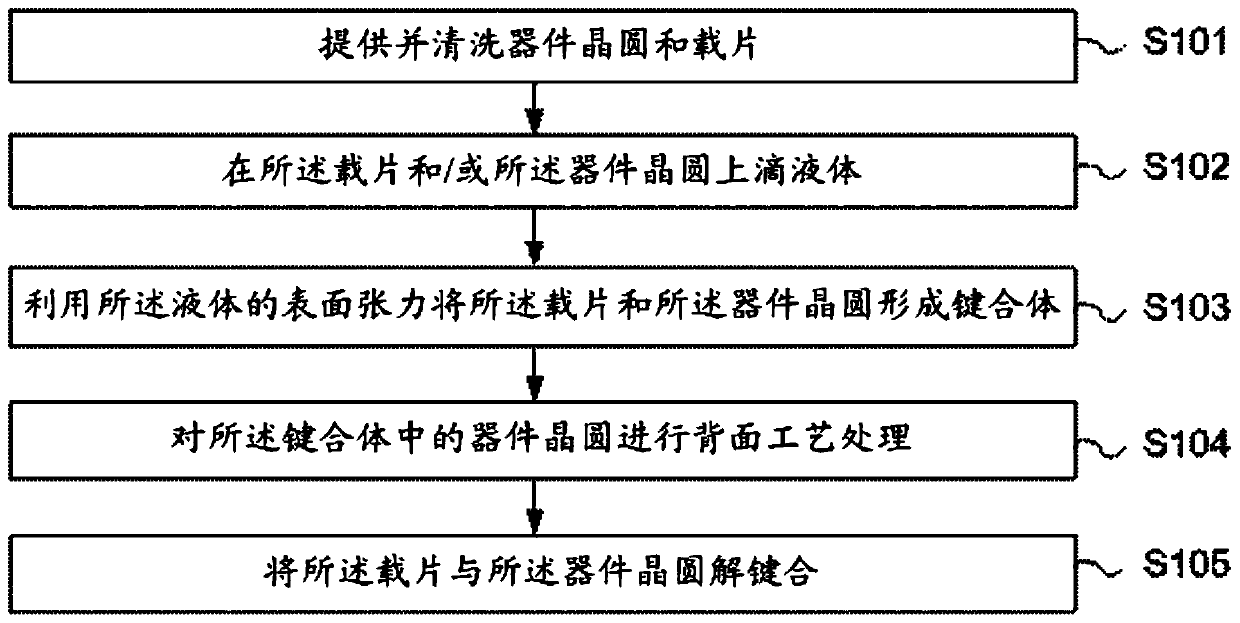

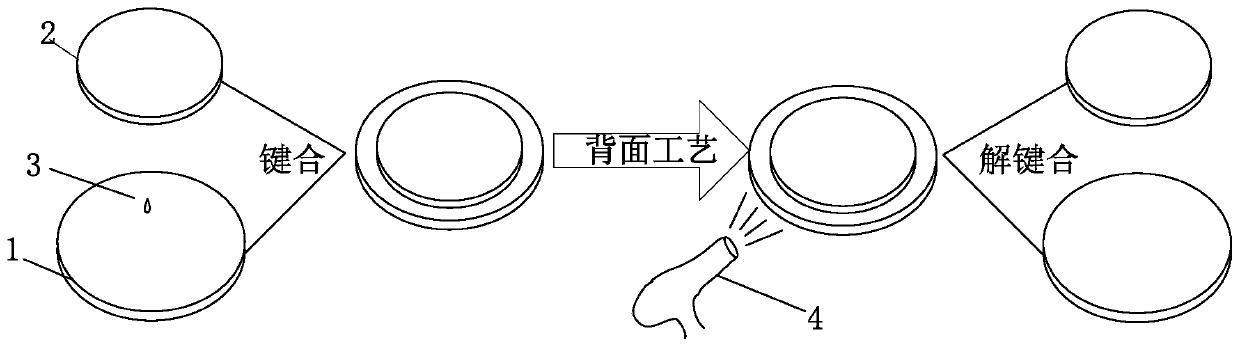

Wafer temporary bonding method

ActiveCN106816405AReduce process stepsAvoid warpingSolid-state devicesSemiconductor/solid-state device manufacturingGlass slideHigh heat

The invention discloses a wafer temporary bonding method which comprises the steps of supplying and cleaning a device wafer and a glass slide; dripping liquid on the glass slide and / or the device wafer; forming a bonded member through the glass slide and the device wafer by means of surface tension of the liquid; performing back surface processing on the device wafer in the bonded member; and debonding the glass slide and the device wafer. According to the wafer temporary bonding method provided by the invention, the device wafer is temporarily bonded with the glass slide by means of a surface tension effect of the liquid, and processes such as high-temperature processing or drying are not required, thereby reducing processes in wafer temporary bonding, preventing wafer warpage caused by high-temperature processing or a drying process, and reducing a wafer warpage risk.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

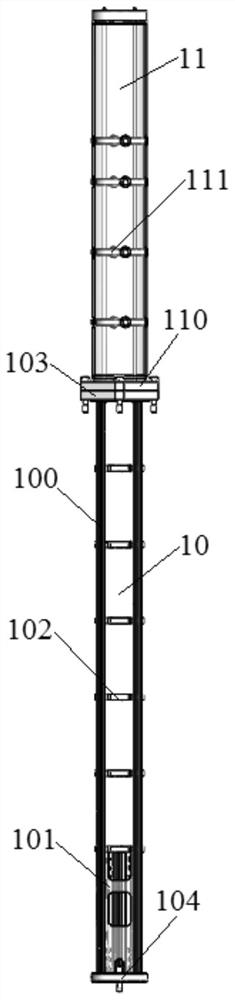

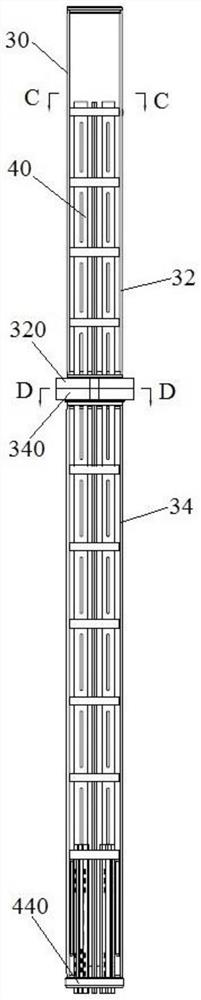

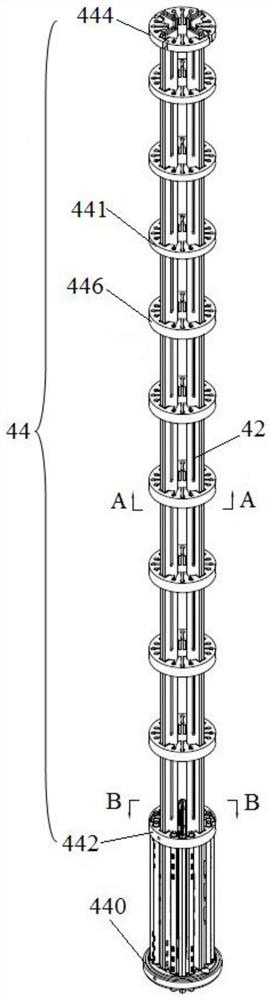

Nuclear power station control rod guide cylinder

PendingCN114464331AOptimize travel protection functionReduced risk of bar bending deformationNuclear energy generationReactor fuel elementsEngineeringNuclear power plant

The invention discloses a nuclear power station control rod guide cylinder. The nuclear power station control rod guide cylinder comprises a protective cover and a whole-course guide assembly installed in the protective cover. The whole-course guide assembly comprises at least one whole-course continuous guide element, a whole-course continuous guide channel is arranged in the whole-course continuous guide element, and the whole-course continuous guide channel conducts whole-course continuous guide on at least one control rod in the single control rod assembly within the stroke range of the guide cylinder. Compared with the prior art, the nuclear power station control rod guide cylinder has the advantages that discontinuous guide section structures of the guide gratings arranged at intervals are changed into whole-course continuous guide sections formed by long duplex pipe structures, so that the control rod stroke protection function is optimized, and the risk that the control rod is bent and deformed due to transverse impact of fluid in an upper cavity is reduced; the integrity of the control rod structure is ensured; meanwhile, the wear resistance of the specific position of the control rod guide cylinder is improved, so that the service life of the control rod guide cylinder is greatly prolonged, and the later operation cost is reduced.

Owner:中广核工程有限公司 +3

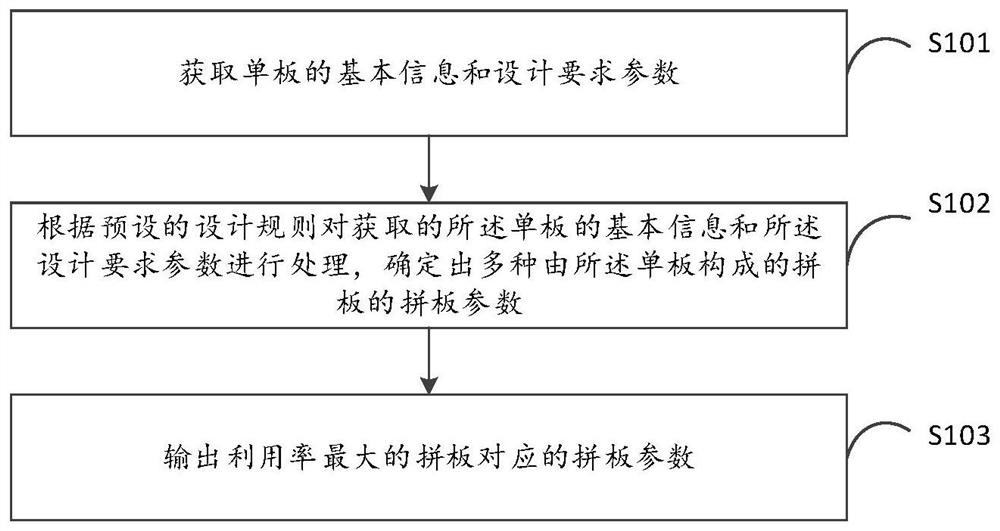

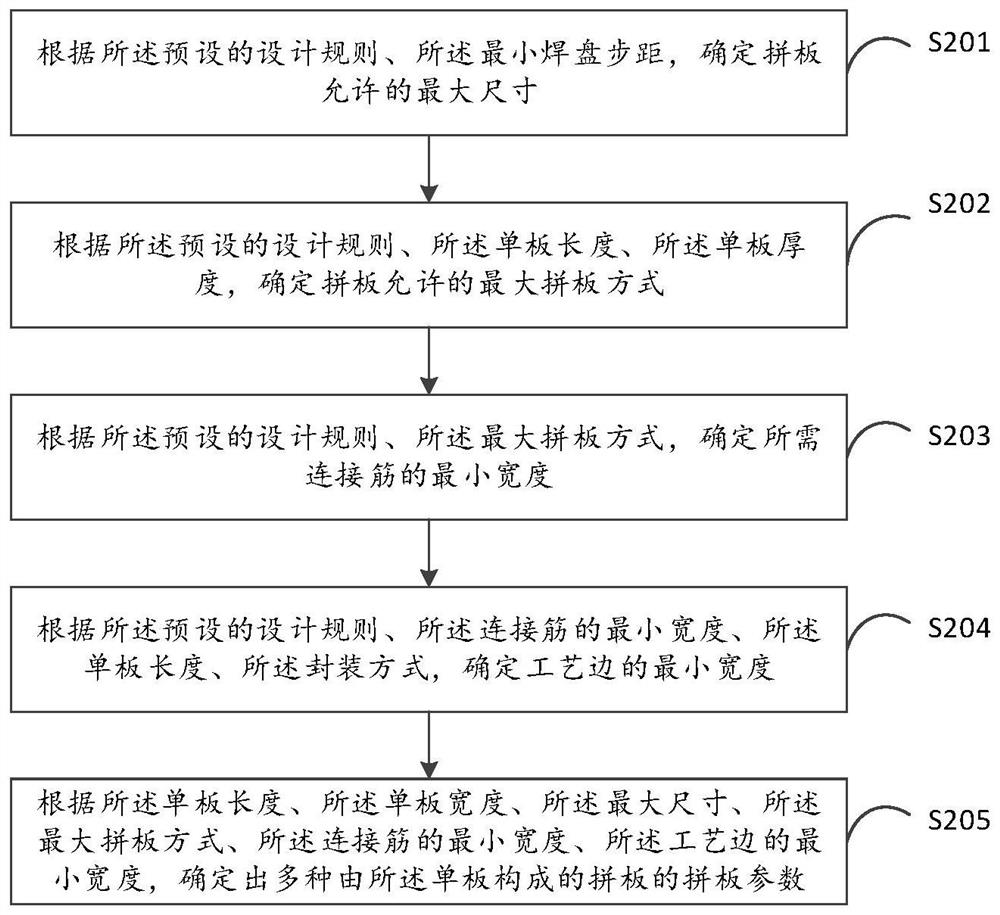

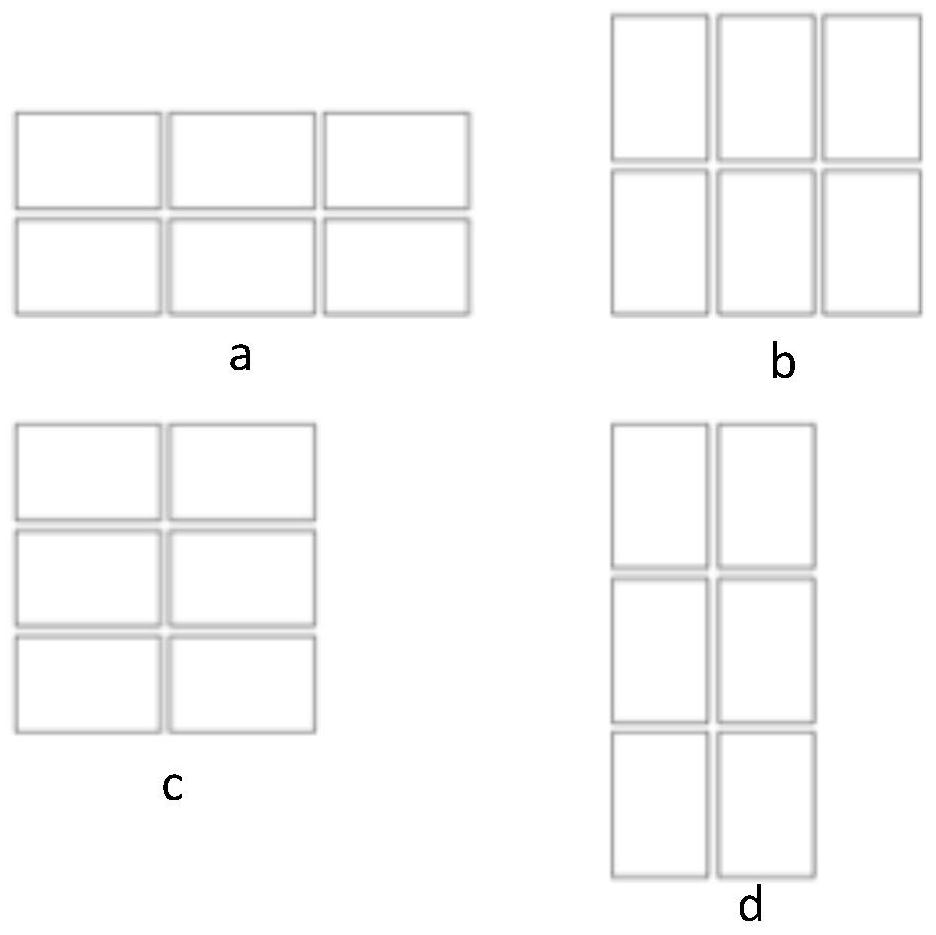

PCB jointed board determination method and device, electronic equipment and storage medium

PendingCN113204933ADetermine the minimum widthFast operationCAD circuit designSpecial data processing applicationsProcess engineeringMonoboard

The invention relates to a PCB jointed board determination method and device, electronic equipment and a storage medium, and belongs to the technical field of electronics. The method is applied to the electronic equipment and comprises the following steps: acquiring basic information and design requirement parameters of a single board; according to a preset design rule, processing the obtained basic information of the single boards and the design requirement parameters, and determining multiple jointed board parameters of jointed boards formed by the single boards, wherein the preset design rule is obtained by processing the jointed board parameters of multiple PCB jointed boards meeting the industrial standard; and outputting the jointed board parameter corresponding to the jointed board with the maximum utilization rate. According to the method, the design rule considering the quality and the utilization rate of the jointed board is obtained by processing the jointed board parameters of the plurality of PCB jointed boards meeting the industrial standard, so the optimal jointed board scheme can be quickly obtained only by inputting the basic information and the design requirement parameters of the single board during the subsequent jointed board design.

Owner:QUECTEL WIRELESS SOLUTIONS

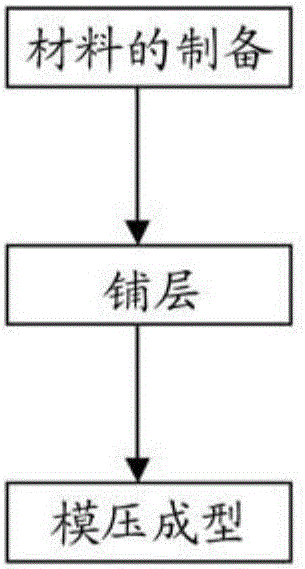

Electronic product shell and manufacture method thereof

InactiveCN106827711AQuality improvementImprove liquiditySynthetic resin layered productsLaminationCompression moldingEngineering

The invention relates to an electronic product shell. The shell is manufactured by combining and curing a continuous prepreg sheet material and a short-cut prepreg sheet material by adopting a compression molding method. The invention further relates to a method for manufacturing the electronic product shell.

Owner:LENOVO (BEIJING) CO LTD

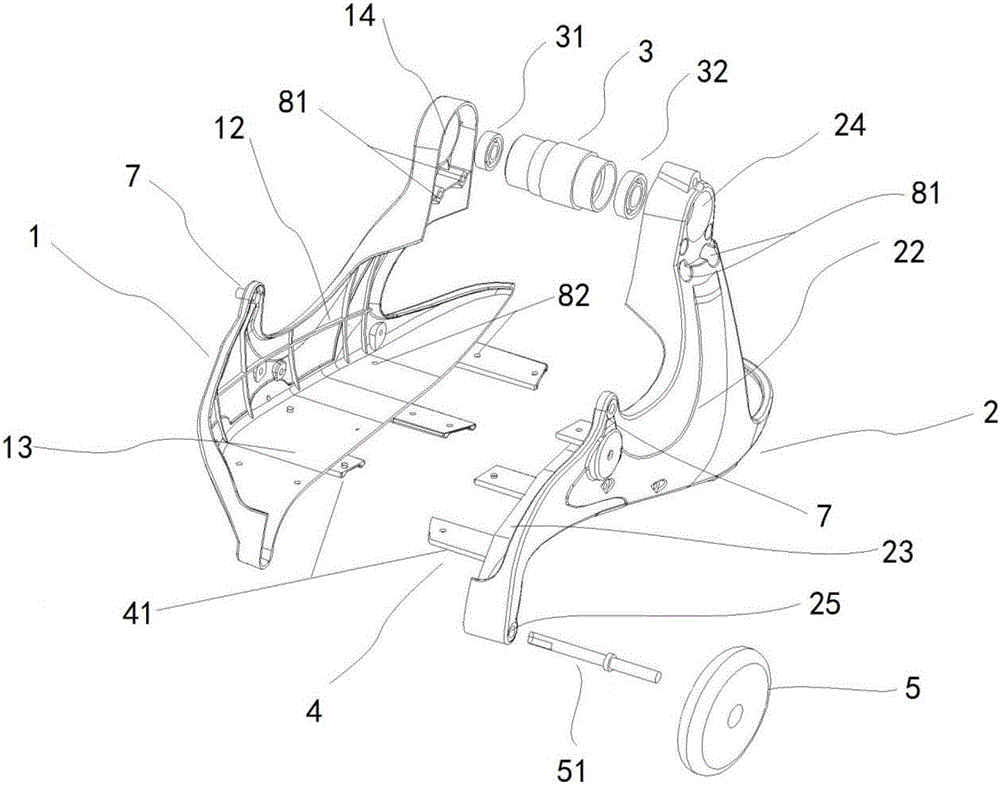

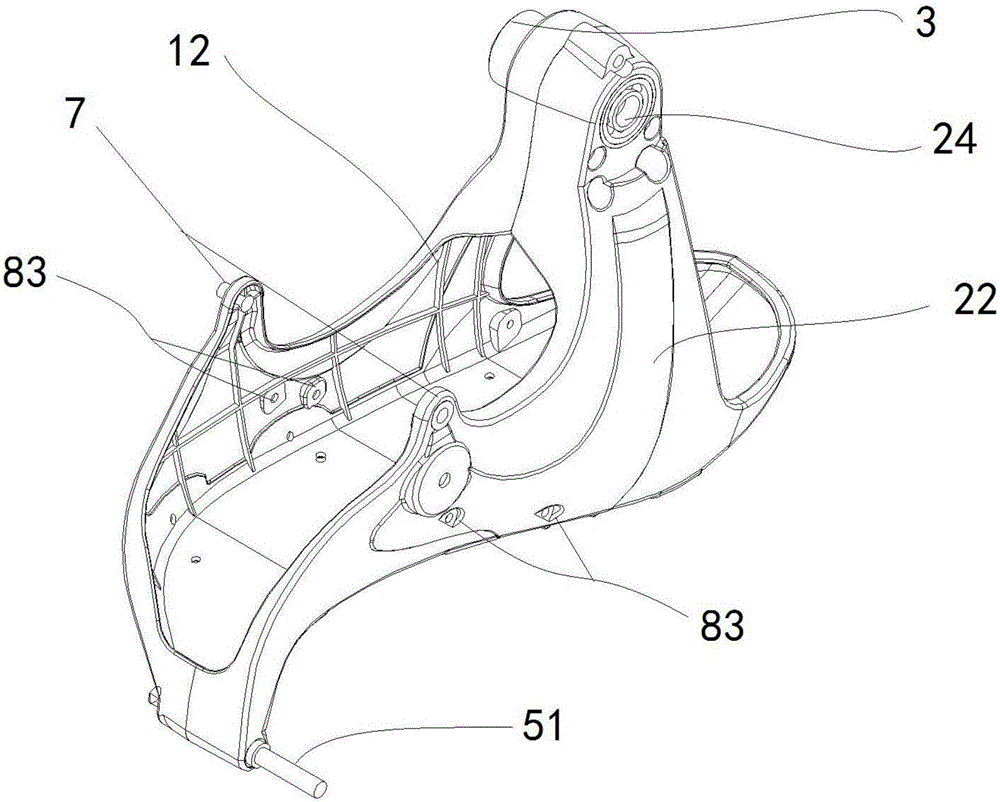

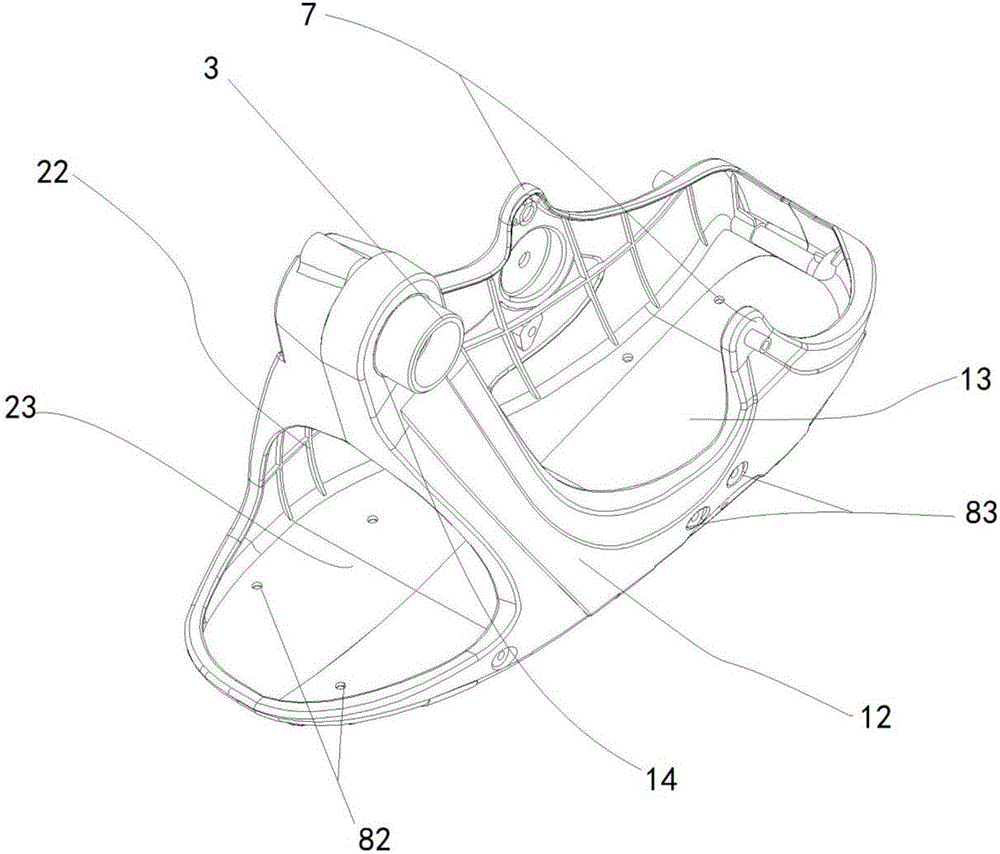

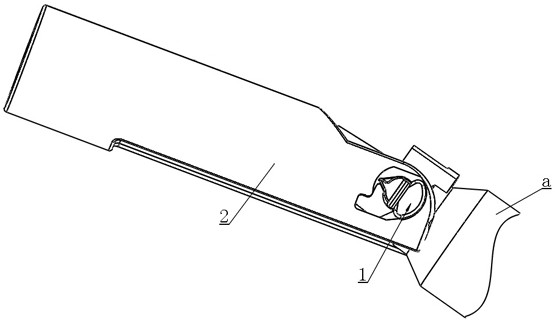

Pedal device for roller skating

PendingCN106110632AThe process steps are simpleReduced risk of warpingSkate-boardsRoller skatesRoller skatingStructural engineering

The invention discloses a pedal device for roller skating, wherein the pedal device is of a separated combined structure; the pedal device comprises a first pedal part and a second pedal part which is fixedly connected to the first pedal part; a first shaft hole is formed in the first pedal part; a second shaft hole is formed in the second pedal part; and the first shaft hole and the second shaft hole correspond in position. The pedal device for the roller skating provided by the invention, when manufactured, is easy for production and assembling, so that production cost is reduced, and meanwhile, a production cycle is shortened; as for the structure, the product (the pedal device), due to the separated combined structure, is prevented from becoming bent or deformed easily in a using process, so that the service life of the pedal device is prolonged.

Owner:吴洪良

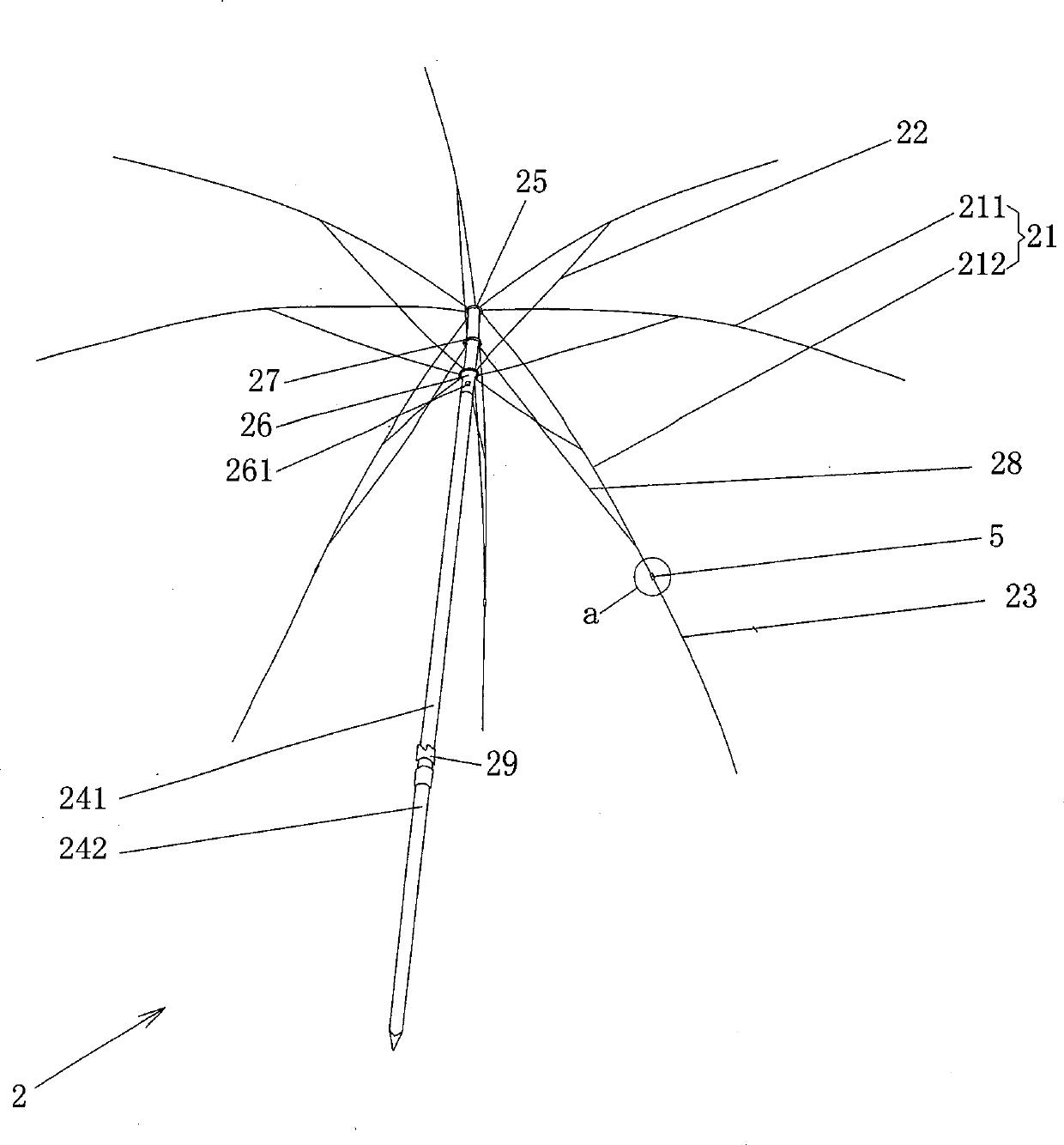

Novel outdoor umbrella

The invention discloses a novel outdoor umbrella. Back umbrella ribs of the outdoor umbrella are lengthened, and side curtains are added at two sides of an umbrella surface, so the umbrella is integrally in a semi-surrounded tent shape, and the protection area is increased. The novel outdoor umbrella comprises the umbrella surface, an umbrella frame and a plurality of umbrella rib caps, wherein the umbrella frame is covered by the umbrella surface, the umbrella frame comprises a plurality of main umbrella ribs and a plurality of support ribs, the tail ends of the support ribs are hinged with the upper parts of the main umbrella ribs, the main umbrella ribs comprise a plurality of ordinary umbrella ribs and at least two lengthened umbrella ribs with extending ribs, the tail ends of the lengthened umbrella ribs are provided with hook parts used for fixing the extending ribs, the top ends of the extending ribs are hinged with the lower parts of the lengthened umbrella ribs, the tail ends of the extending ribs and the tail ends of the ordinary umbrella ribs are respectively connected with the edge of the umbrella surface through the umbrella rib caps, the left side of the umbrella surface is provided with a left side curtain, the right side of the umbrella surface is provided with a right side curtain, and the left side curtain, the right side curtain and the umbrella surface are surrounded to form a semi-surrounded space.

Owner:陈天益

A kind of wafer temporary bonding method

ActiveCN106816405BReduce process stepsAvoid warpingSolid-state devicesSemiconductor/solid-state device manufacturingWaferStructural engineering

The invention discloses a wafer temporary bonding method which comprises the steps of supplying and cleaning a device wafer and a glass slide; dripping liquid on the glass slide and / or the device wafer; forming a bonded member through the glass slide and the device wafer by means of surface tension of the liquid; performing back surface processing on the device wafer in the bonded member; and debonding the glass slide and the device wafer. According to the wafer temporary bonding method provided by the invention, the device wafer is temporarily bonded with the glass slide by means of a surface tension effect of the liquid, and processes such as high-temperature processing or drying are not required, thereby reducing processes in wafer temporary bonding, preventing wafer warpage caused by high-temperature processing or a drying process, and reducing a wafer warpage risk.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for preparing tungsten on semiconductor wafer

PendingCN114420533AReduced risk of warpingRelieve built-up stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingWaferingChemical vapor deposition

The invention relates to a method for producing tungsten on a semiconductor wafer. According to the method, tungsten is deposited on a first surface of a semiconductor wafer through chemical vapor deposition, a second surface, opposite to the first surface, of the semiconductor wafer, namely the back face is attached to a base, and at least one time of thermal annealing operation is inserted in the body growth stage. By means of the thermal annealing operation, the stress accumulated by tungsten deposited on the semiconductor wafer can be relieved, the warping risk of the semiconductor wafer is reduced, damage of process gas of chemical vapor deposition to the back face of the semiconductor wafer is reduced, and the purpose of protecting the back face of the wafer is achieved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

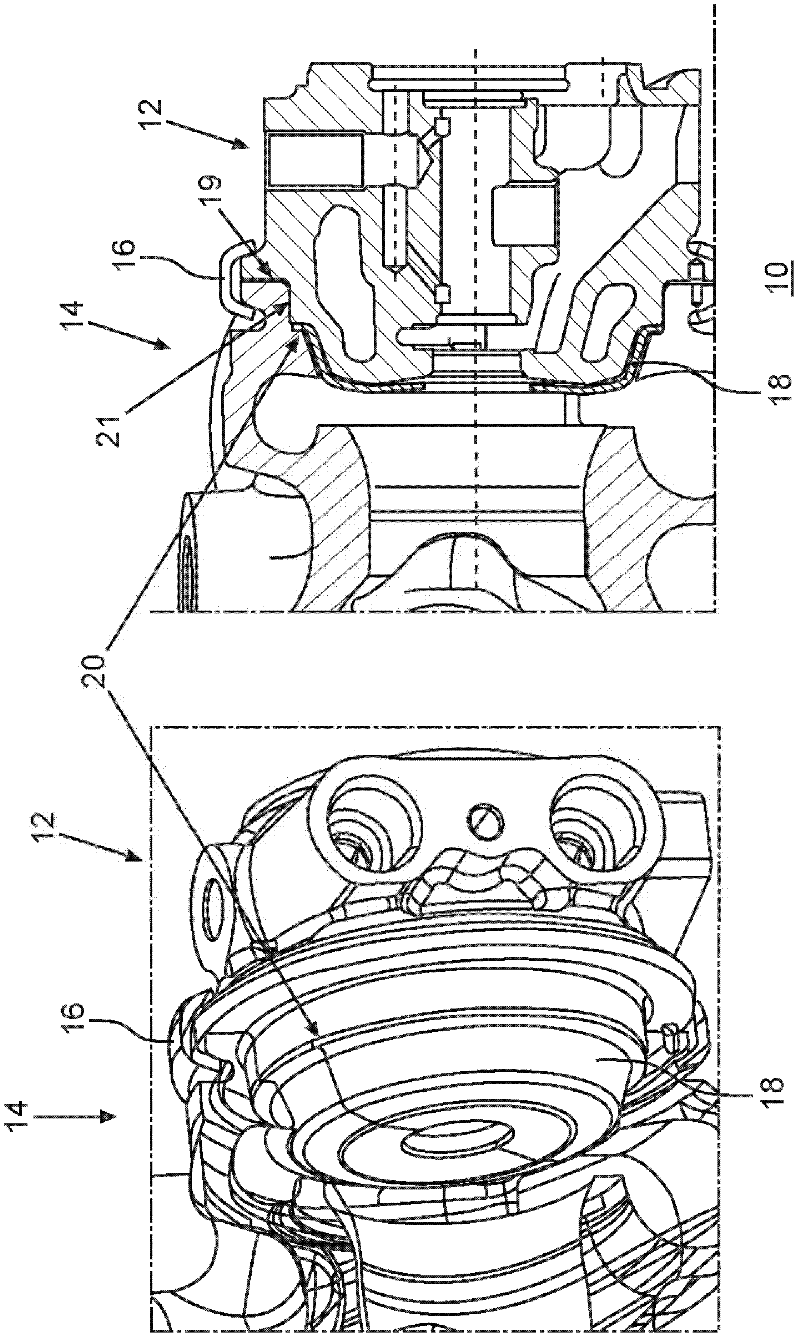

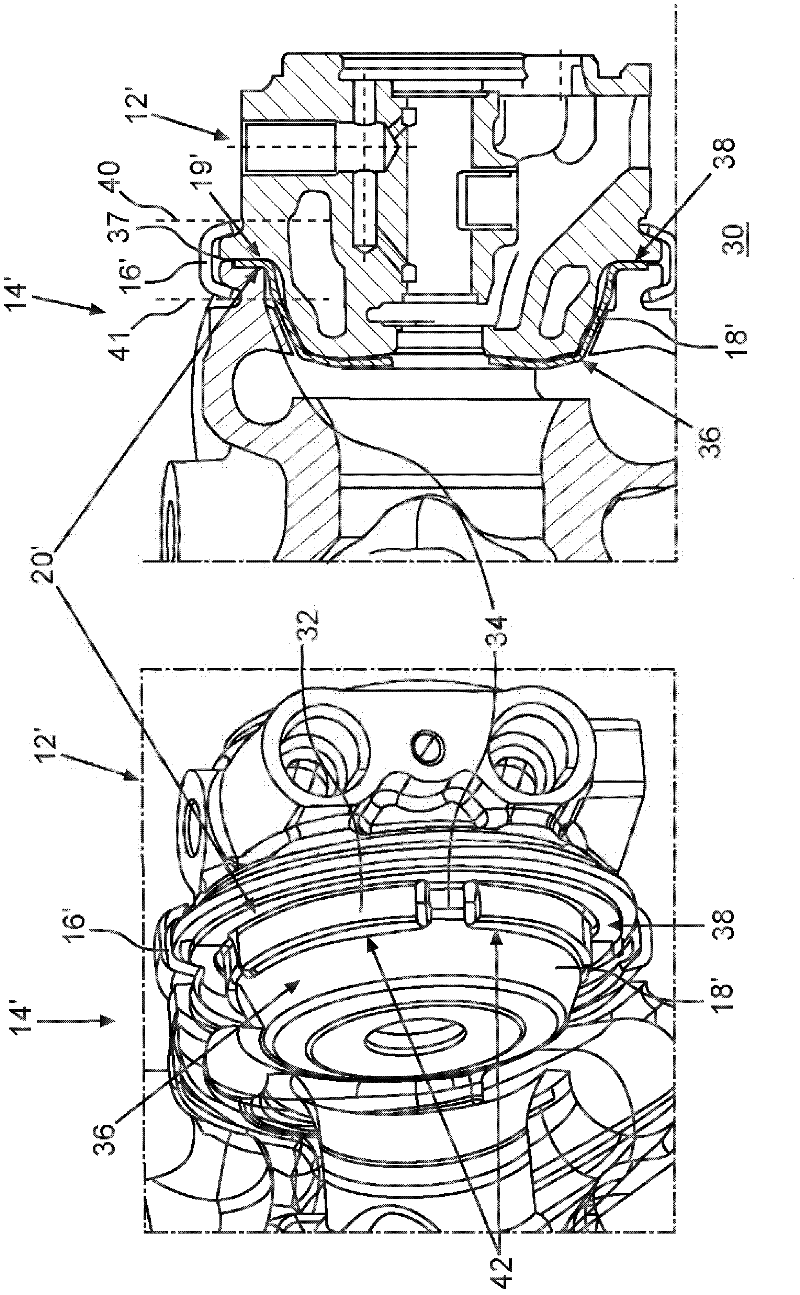

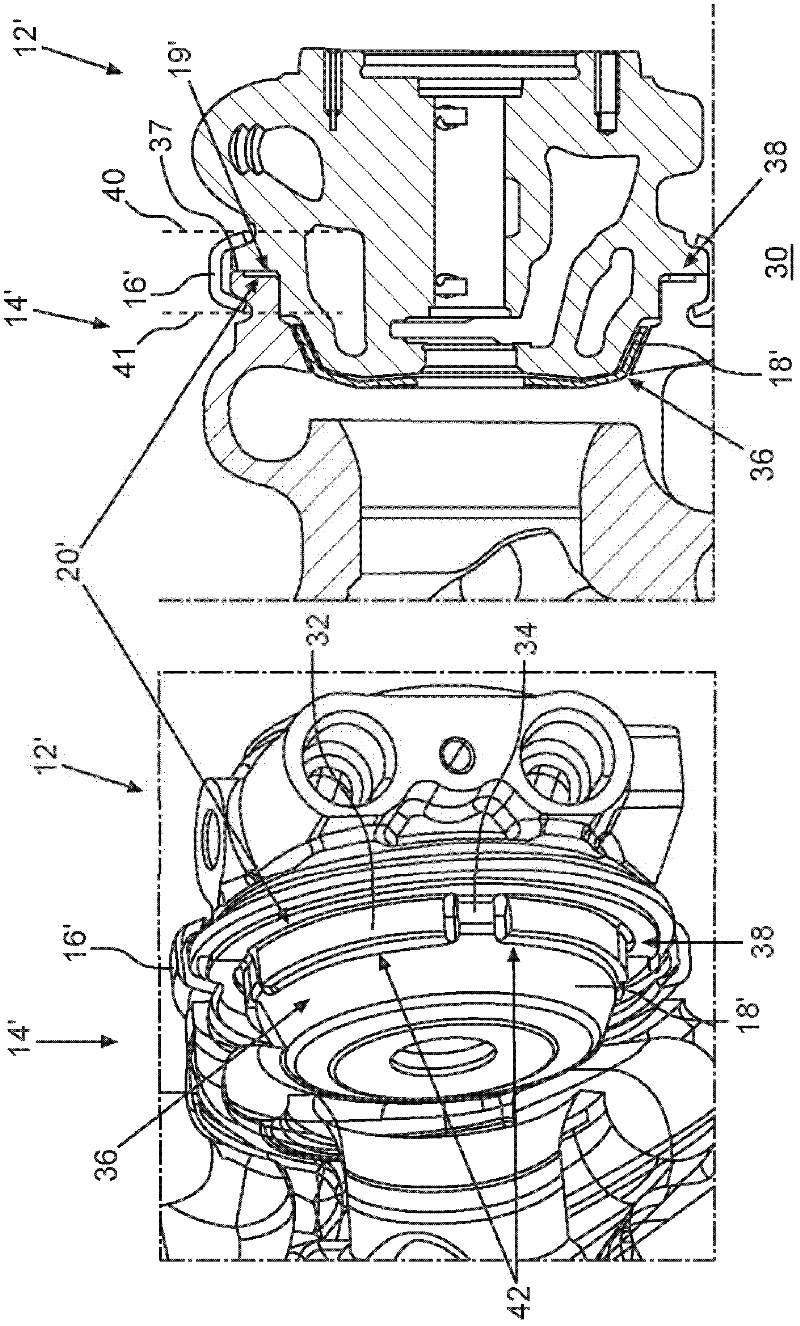

Connection assembly for connecting turbine housing to support housing and exhaust gas turbocharger

InactiveCN102282349APrecise positioningPrevent leakageEngine manufactureGas turbine plantsTurbochargerHeat shield

Owner:IHI CHARGING SYST INT

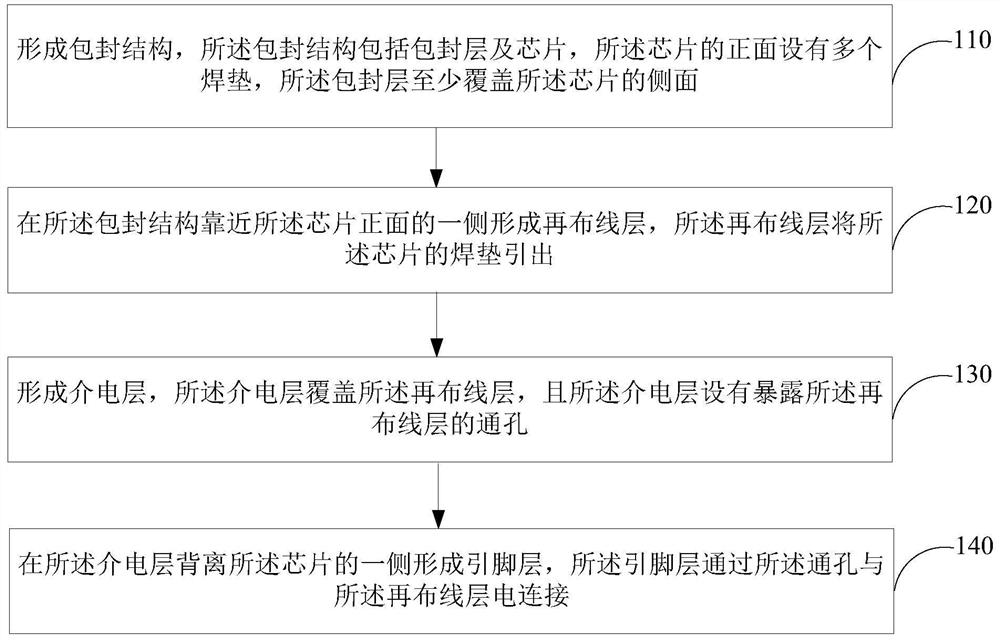

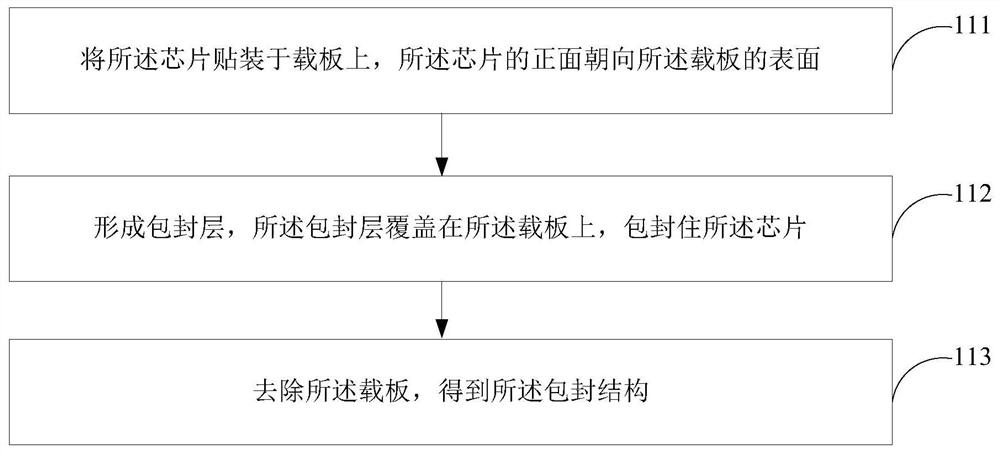

Semiconductor packaging method and semiconductor packaging structure

PendingCN113990759AReduce contact areaIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectrical connection

The invention provides a semiconductor packaging method and a semiconductor packaging structure. The semiconductor packaging method comprises the following steps: forming an encapsulation structure, wherein the encapsulation structure comprises an encapsulation layer and a chip, a plurality of welding pads are arranged on the front surface of the chip, and the encapsulation layer at least covers the side surface of the chip; forming a rewiring layer on one side, close to the front surface of the chip, of the packaging structure, wherein the rewiring layer leads out the welding pads of the chip; forming a dielectric layer, wherein the dielectric layer covers the rewiring layer, and a through hole for exposing the rewiring layer is formed in the dielectric layer; and forming a pin layer on one side, deviating from the chip, of the dielectric layer, wherein the pin layer is electrically connected with the rewiring layer through the through hole.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

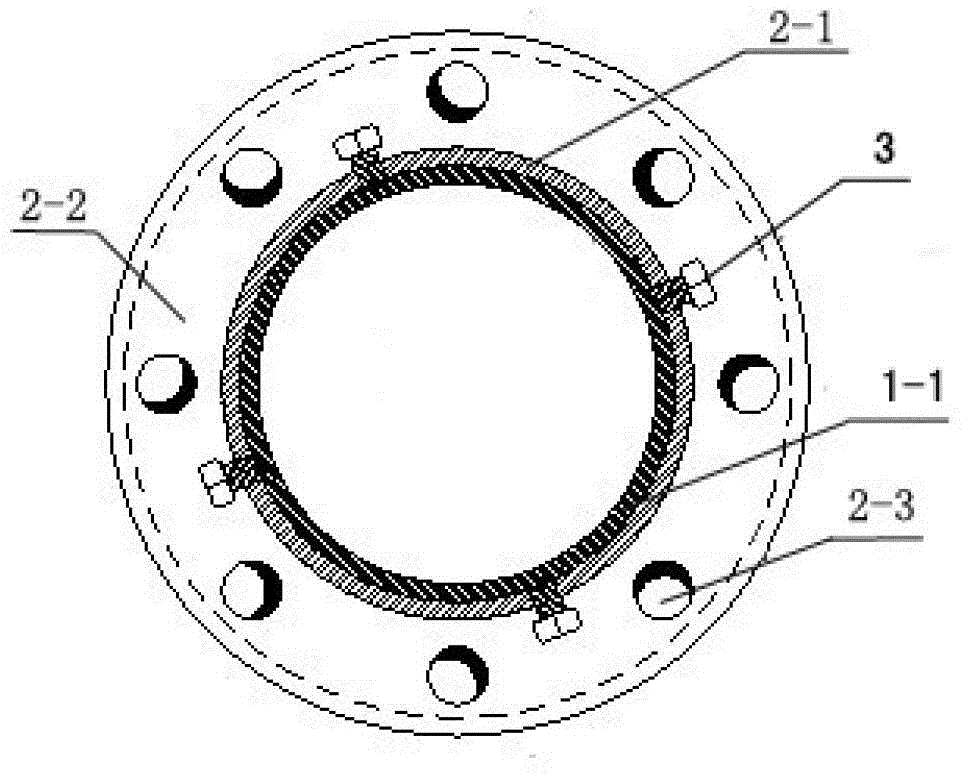

Pull force self-coordination type multi-line suspension plate node structure

InactiveCN102751686AEliminate torqueForce is smallSuspension arrangements for electric cablesCoordination typeBarrel Shaped

The invention discloses a pull force self-coordination type multi-line suspension plate node structure. The pull force self-coordination type multi-line suspension plate node structure comprises a fixed part and a movable part and is characterized in that the fixed part is fixed to a lower part structure through embedding, bolts or welding and is provided with a projection part; the projection part is in a cylinder shape or in a barrel shape and forms a suspension line supporting structure; the movable part is sleeved onto the projection part of the fixed part and forms a relatively rotatable connection structure; a plurality of suspension line units extend from the outer side wall of the movable part and are radially arranged and located on the same plane; a plurality of radial screwing through holes are formed on the outer side wall of the movable part; and the movable part is connected with the fixed part by a locking bolt through the screwing through holes after suspension lines are mounted. The pull force self-coordination type multi-line suspension plate node structure is simple in structure; and with the adoption of the pull force self-coordination type multi-line suspension plate node structure, the resultant force of a plurality of pull lines finally acting on the fixed part is minimal, the torque effect cannot be generated, and a supporting frame is more stable.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

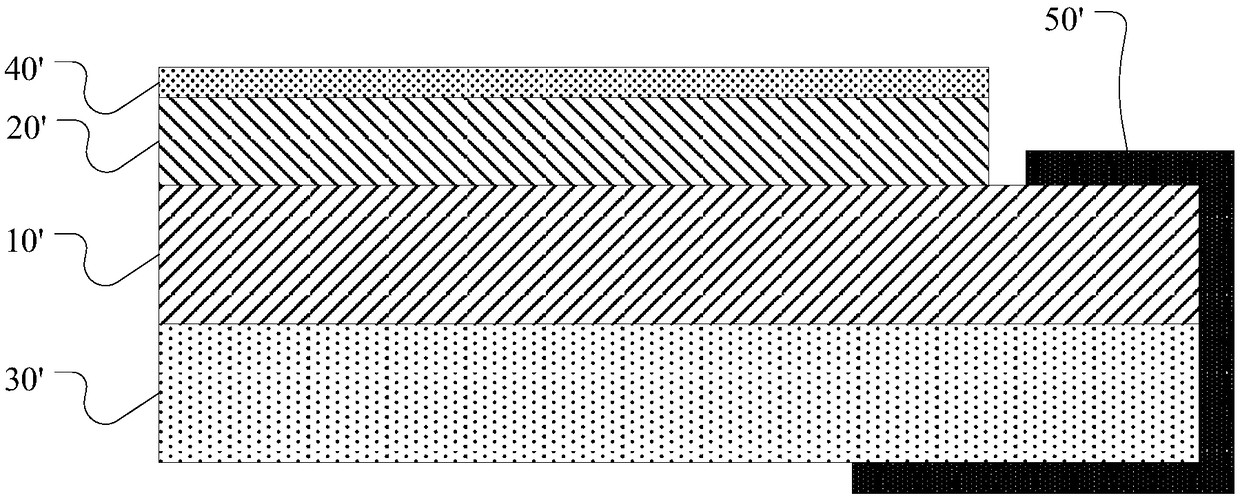

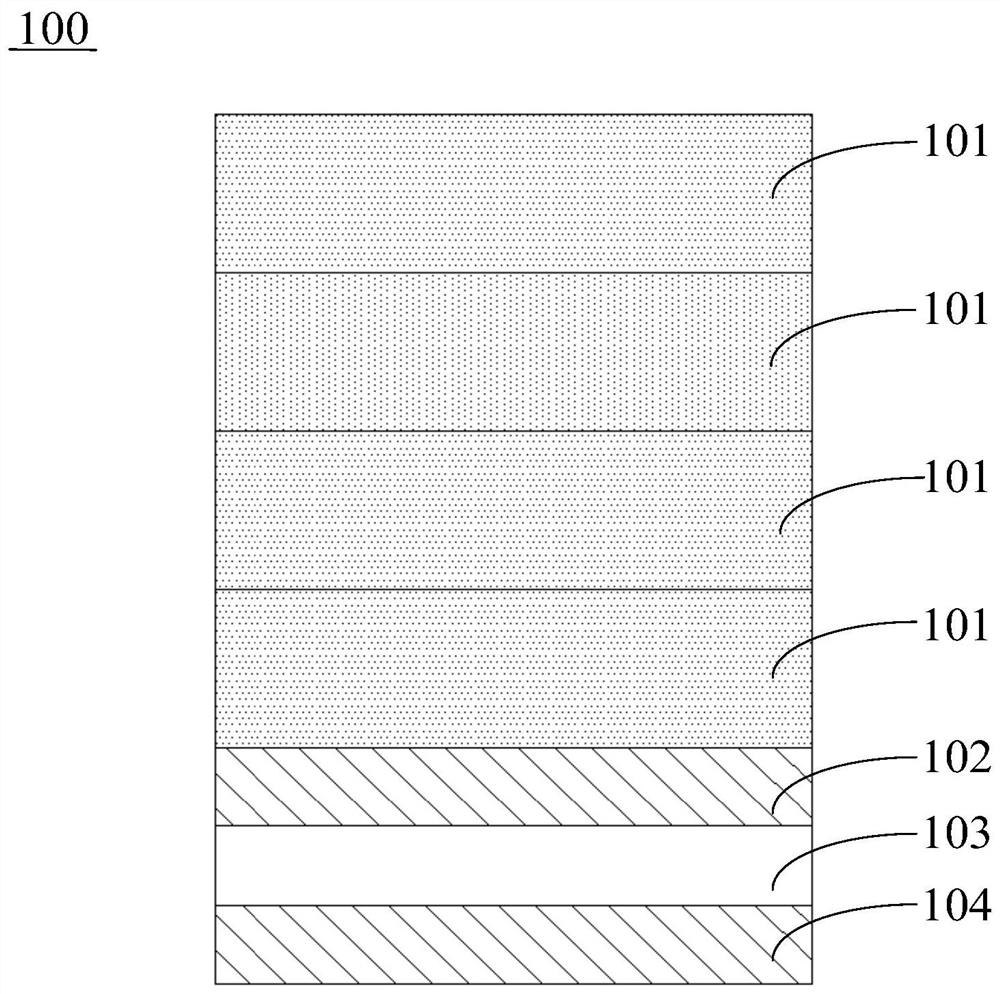

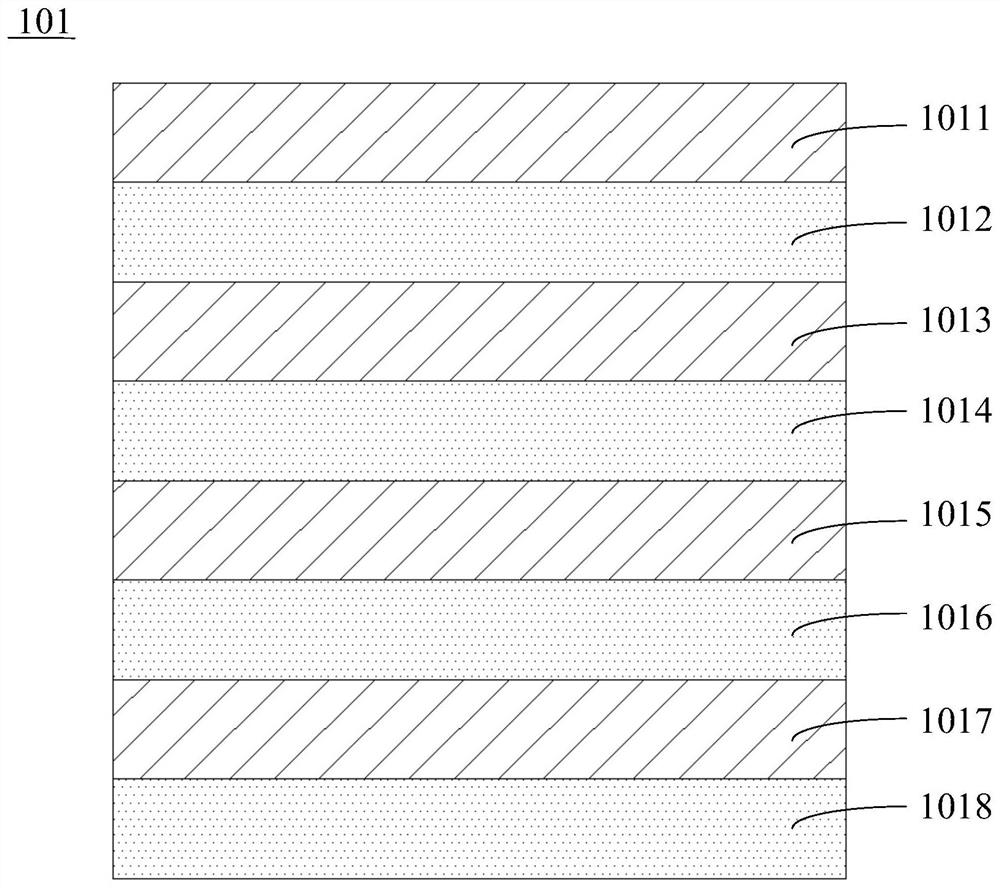

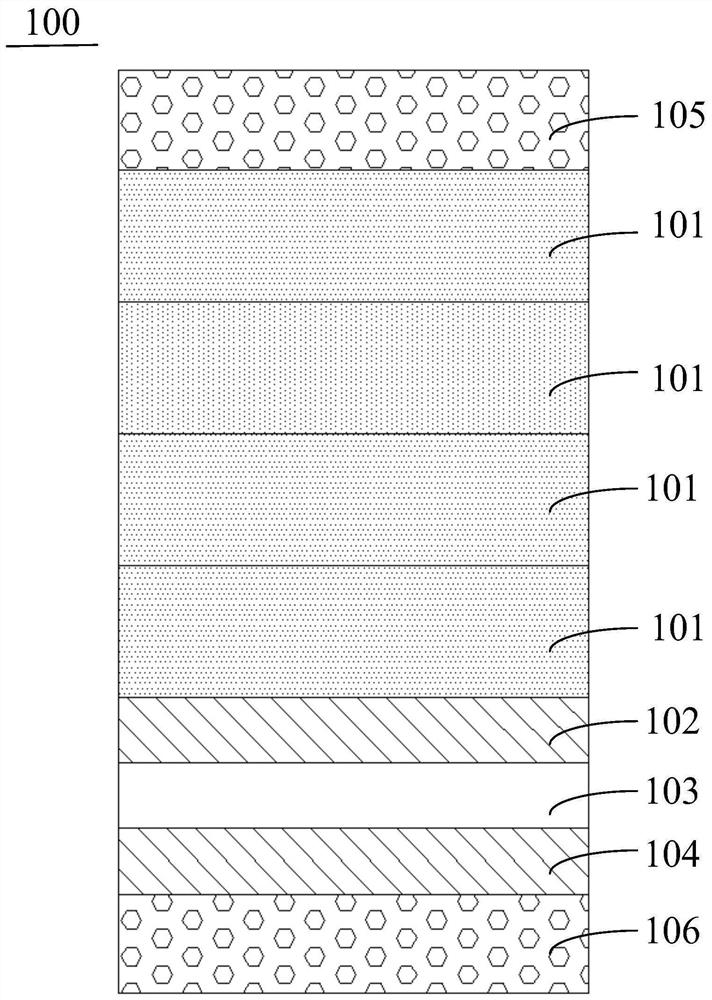

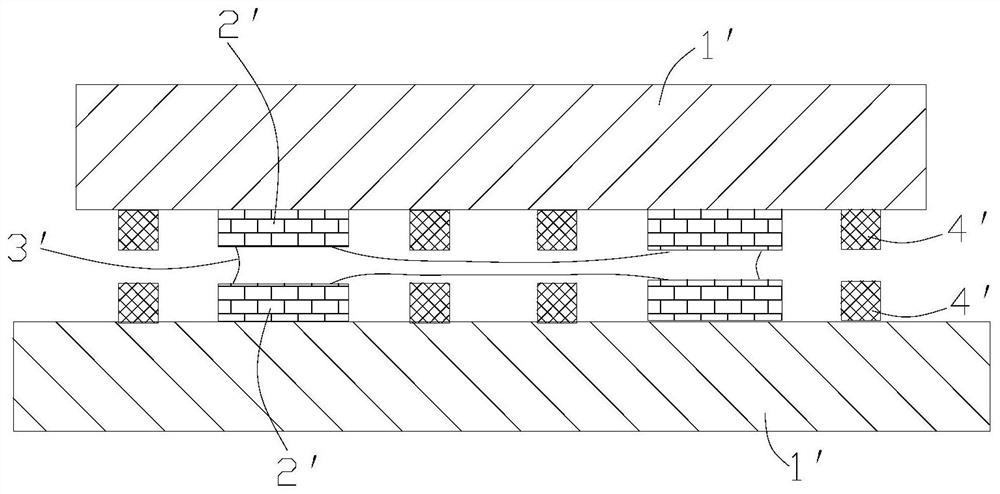

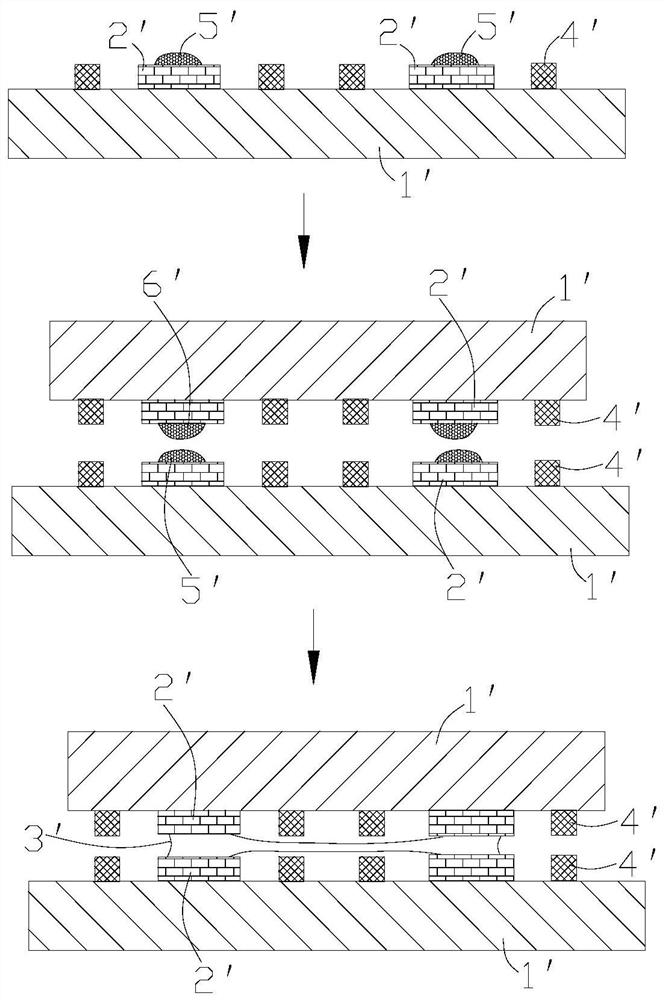

Pressing structure of PCB and processing method of PCB

ActiveCN113423199AReduced risk of warpingMaintain pressing efficiencyMultilayer circuit manufacturePrinted circuit simultaneous processingIsolation layerEngineering

The invention relates to a pressing structure of a PCB and a processing method of the PCB. In the pressing structure, through the arrangement of a first isolation layer, a second isolation layer, a third isolation layer, a fourth isolation layer, a first buffer layer and a second buffer layer, the influence of instantaneous high temperature and high pressure on a first copper foil layer, a first semi-cured layer, a core board layer, a second semi-cured layer and a second copper foil layer during pressing can be effectively avoided, and the flatness of the first copper foil layer, the core board layer and the second copper foil layer is kept. Furthermore, the even number of board arrangement layers are sequentially stacked, and the BOT surfaces of the core board layers of the first to nth board arrangement layers are opposite to the BOT surfaces of the core board layers of the (n+1)-2nth board arrangement layers in orientation, so that the internal stress of the pressing structure in the pressing process can be effectively balanced, and the flatness of the first copper foil layer, the core board layers and the second copper foil layer can be better maintained; and the PCB is further prevented from warping after being laminated.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

A kind of preparation method of terminal member and terminal member

ActiveCN105328327BHigh strengthReduced risk of warpingLiquid surface applicatorsCoatingsHot meltEngineering

The invention provides a method for manufacturing a terminal member and the terminal member. The method for manufacturing the terminal member includes the steps that a substrate is processed to form a preliminary structural member; a cylinder for generating a buckling structure is welded to the preliminary structural member in a friction stir welding mode; the welded cylinder is processed to generate the buckling structure; and a bearing part is matched with the buckling structure through screws and fixedly connected with the preliminary structural member in a hot melting adhesive dispensing mode to form the terminal member. According to the scheme, the processed substrate (the preliminary structural member) and the buckling structure (formed by processing the cylinder) are connected together in the friction stir welding mode, and then the bearing part is matched with the buckling structure through the screws and fixedly connected with the preliminary structural member in the hot melting adhesive dispensing mode to finally form the terminal member. The process is greatly simplified, the production efficiency, the material utilization rate and whole terminal strength are improved, and production cost and warping risks of the terminal member due to terminal dropping or distortion are reduced.

Owner:VIVO MOBILE COMM CO LTD

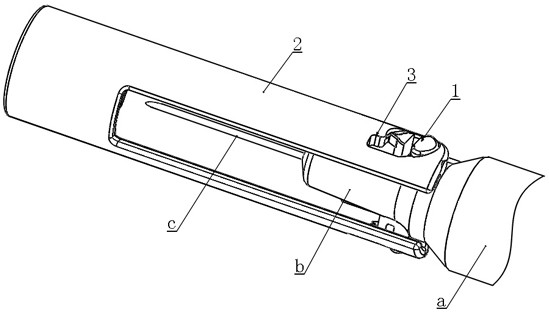

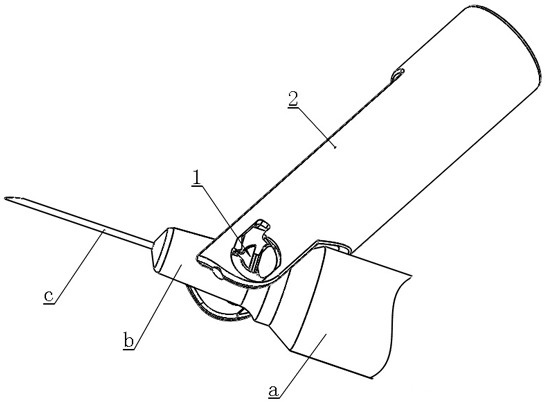

Protective needle cylinder with precise positioning function

PendingCN114146262AReduced risk of warpingSimple and stable snap-in operationInfusion syringesInfusion needlesPhysicsMedicine

The invention belongs to the technical field of medical instruments, and particularly relates to a protective needle cylinder with an accurate positioning function. By arranging the fixed shaft body unit, the opening rotating pipe unit, the mounting hole unit and the protruding block unit on the connecting pipe of the needle cylinder, the whole injection operation process of the needle cylinder is safer, more accurate and more reliable. The invention has the following advantages: firstly, the open rotating tube unit can perform structural protection on the needle head, so that the risk that the needle head is bent and deformed is reduced; secondly, the opening rotating tube unit has a clamping and positioning effect during injection and scrapping, so that a needle head is not easy to expose accidentally, and puncture accidents are not easy to cause; thirdly, the whole rotating and clamping operation of the opening rotating pipe unit is simple, stable, reliable and accurate; and fourthly, the external structure protection function of the whole needle head is simple and efficient, and after the needle head is matched with an internal rubber tube, the comprehensive sealing protection and structure protection effects can be achieved.

Owner:上海倍莱弗科技有限公司

Circuit board assembly and electronic equipment

PendingCN114501792AReduce the risk of tinningImprove welding reliabilityElectrical connection printed elementsPrinted circuits structural associationsStructural engineeringMechanical engineering

The invention relates to a circuit board assembly and electronic equipment, the circuit board assembly comprises a plurality of board bodies arranged along the thickness direction, the board bodies are provided with a plurality of bonding pads, and the bonding pads of the adjacent board bodies are welded; insulating parts are arranged between the adjacent bonding pads of the board body, the bonding pads are provided with first edges in the thickness direction of the circuit board assembly, the insulating parts are provided with second edges, and the second edges of at least part of the insulating parts exceed the first edges. When the second edge of the insulating part exceeds the first edge of the bonding pad, the space between the bonding pads of the adjacent board bodies which are mutually welded is increased, so that more filling tin can be accommodated between the bonding pads of the adjacent board bodies, and the risk of tin connection between the adjacent bonding pads caused by excessive tin flowing outwards when the amount of the filling tin is large is reduced; and the risk of tin connection caused by excessive tin between the bonding pads during welding of the adjacent board bodies due to incomplete tin removal of the repaired board bodies is reduced, the risk of short circuit caused by tin connection of the adjacent bonding pads is reduced, and the safety and reliability of the circuit board assembly are improved.

Owner:HONOR DEVICE CO LTD

Display modules and display devices

ActiveCN107479231BReduce the risk of bad displayImprove performance reliabilityNon-linear opticsComputer hardwareDisplay device

The invention discloses a display module and a display device. The display module includes: a display panel, a backlight module, and an adhesive tape for fixing the display panel and the backlight module; wherein, the adhesive tape has a first bending axis and a second bending axis extending in a first direction and parallel to each other. A bending axis and a second bending axis divide the adhesive tape into the first part, the second part and the third part which are sequentially connected; when the adhesive tape is unfolded into a flat state, the adhesive tape includes multiple auxiliary functions which are superimposed on each other in the third direction Layers, at least one auxiliary function layer includes a plurality of auxiliary units extending along a first direction and arranged sequentially along a second direction, and the third direction is respectively perpendicular to the first direction and the second direction. The display module and the display device provided by the present invention reduce the risk of the adhesive tape lifting from the surface of the display panel, thereby reducing the risk of poor display of the display module, and improving the performance reliability of the display module and the display device.

Owner:SHANGHAI AVIC OPTOELECTRONICS

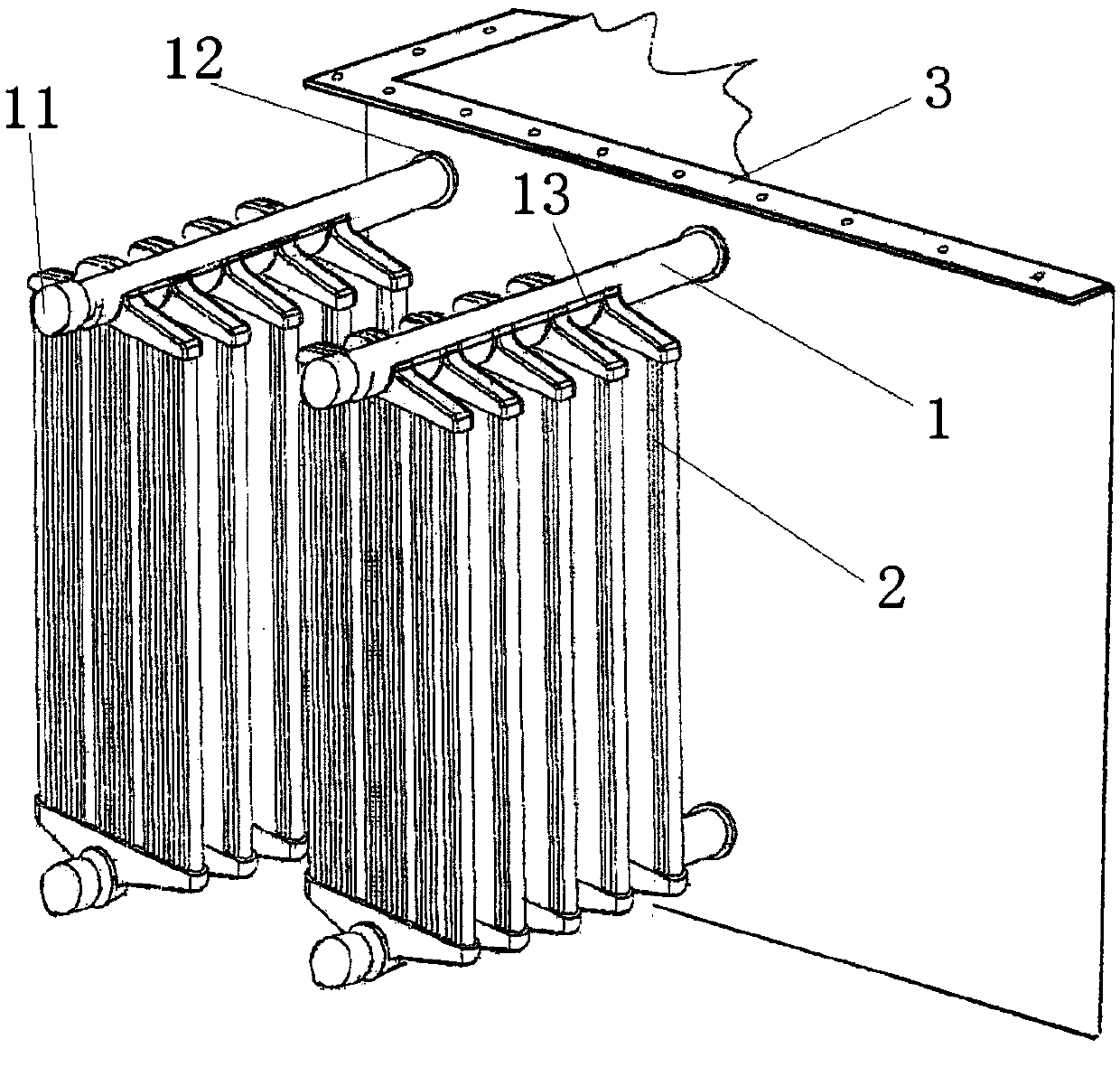

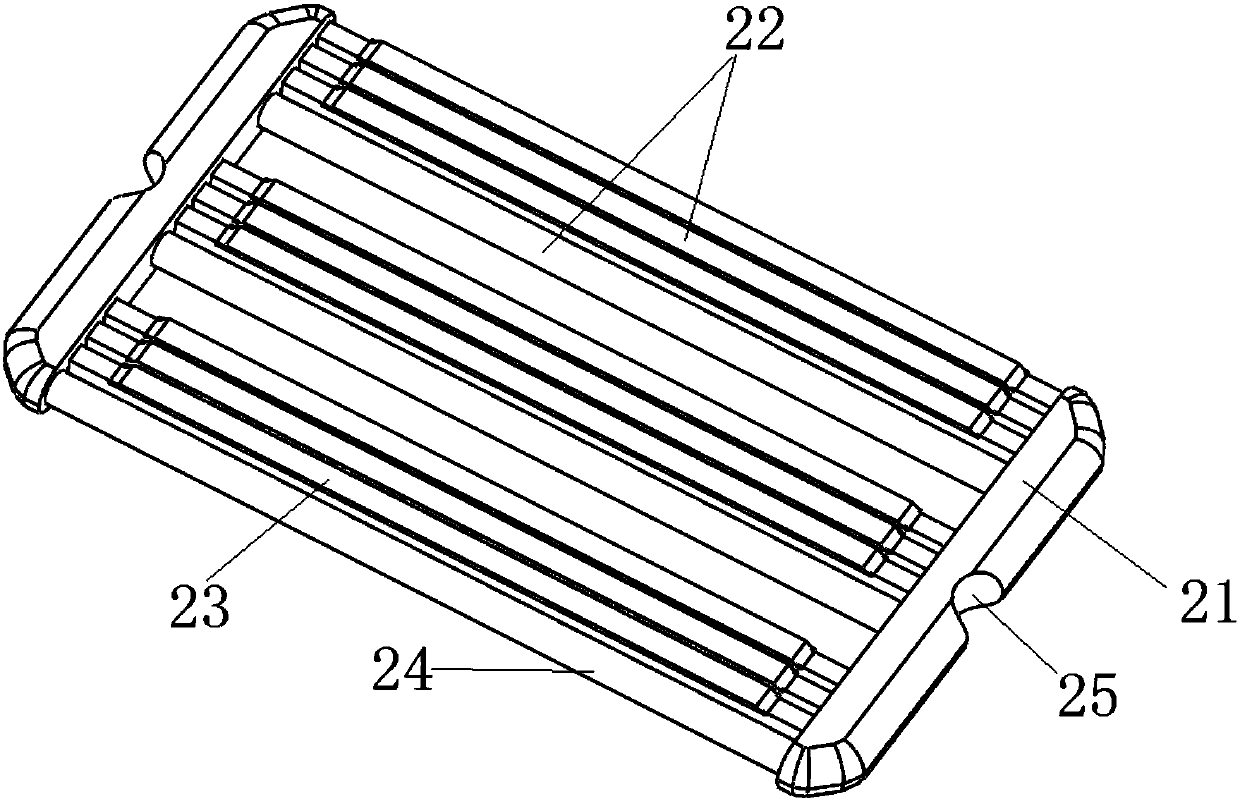

Clamping mechanism and process flow of heat sink of aluminum alloy transformer

InactiveCN105458640BImprove welding qualitySimple and reliable processingWelding/cutting auxillary devicesAuxillary welding devicesTransformerAlloy

The invention discloses a novel aluminum alloy transformer cooling fin clamping mechanism and a technological process. The novel aluminum alloy transformer cooling fin clamping mechanism comprises fixed supports, a rotating support is installed on each fixed support and connected with a turning mechanism, a transformer cooling fin is installed on each rotating mechanism and connected with a main circulation pipeline, the transformer cooling fins are welded through a six-degree-of-freedom welding robot, and the six-degree-of-freedom welding robot conducts welding on the transformer cooling fins simultaneously; oil chambers are directly connected with the main circulation pipeline by omitting a connecting plate, and the risk of welding bending deformation of oil chambers is reduced; by means of design of the transformer cooling fin clamping mechanism, the problem that due to the fact that clamping and positioning are poor, bending deformation of the oil chambers and / or the cooling fins occurs in the welding process of the transformer cooling fins is solved; by means of the six-degree-of-freedom welding robot, the speed and precision of welding are increased; by means of design of the technological process of the transformer cooling fins, machining of the transformer cooling fins is easier and more reliable.

Owner:ZIBO DINGDIAN ELECTRICAL EQUIP CO LTD

Stretchable display panel and stretchable display device

ActiveCN111833753BIncreasing the thicknessMaximum thickness is H1 maximum thicknessStatic indicating devicesLayered productsDisplay deviceMechanical engineering

Embodiments of the present invention provide a stretchable display panel and a stretchable display device, which relate to the field of display technology and improve the warping phenomenon of the stretchable display panel. The stretchable display panel includes: a stretchable substrate, the stretchable substrate is composed of an island structure and a bridge structure, and two adjacent island structures are connected by a bridge structure; the island structure includes a first carrier substrate and a bridge structure. The first display film layer, the first display film layer includes pixel units, the bridge structure includes a second carrier substrate and the second display film layer, the second display film layer includes signal lines; the bridge structure has a first section, the first section Vertical to the plane where the second carrier substrate is located, and the first section is perpendicular to the extension direction of the bridge-like structure, the maximum width of the first section in the first direction is W1, and the maximum thickness of the bridge-shaped structure in the direction perpendicular to the plane where the second carrier substrate is located H1, H1≥W1, the first direction is parallel to the plane where the second carrier substrate is located, and is perpendicular to the extending direction of the bridge-shaped structure.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

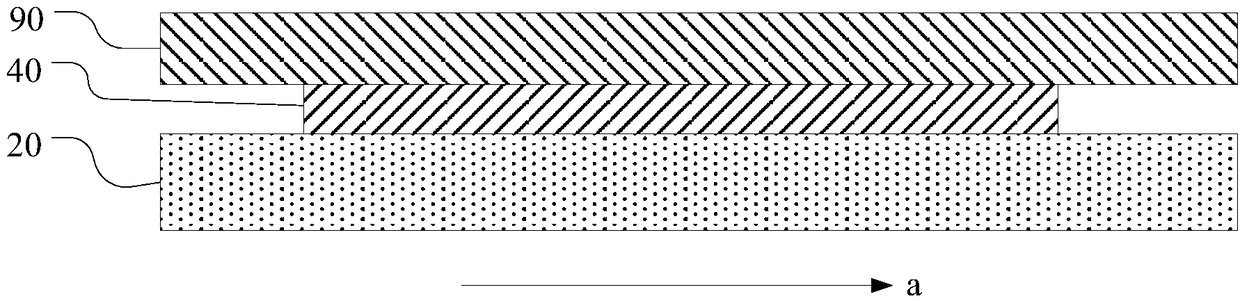

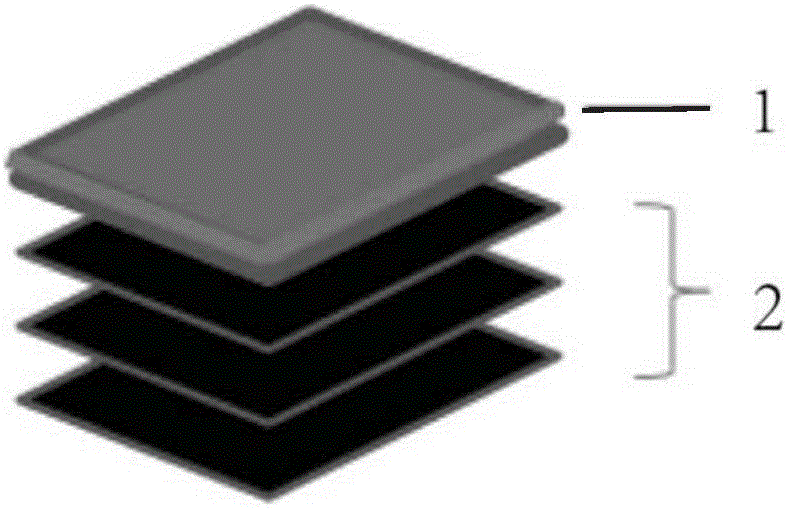

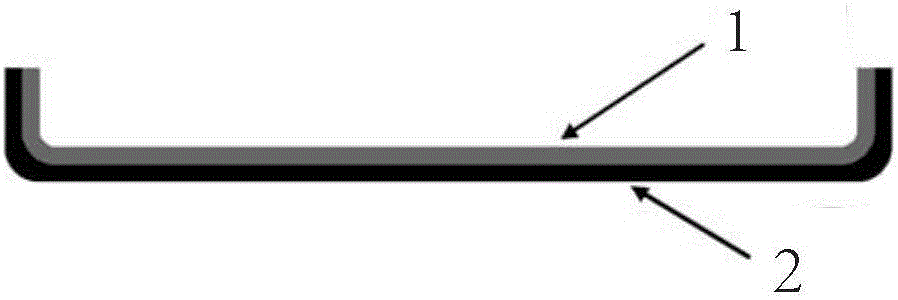

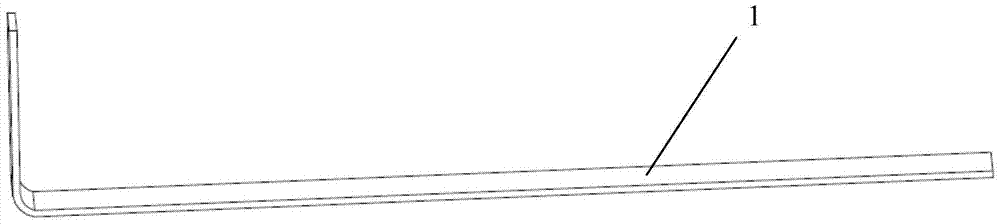

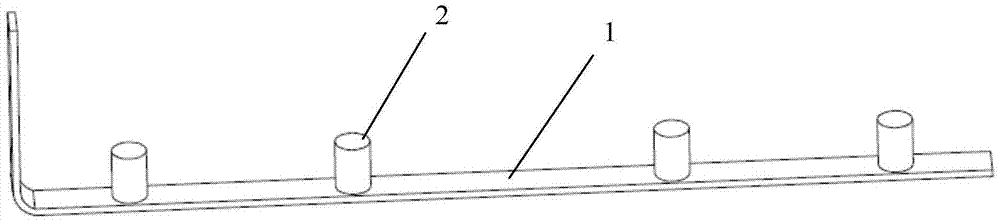

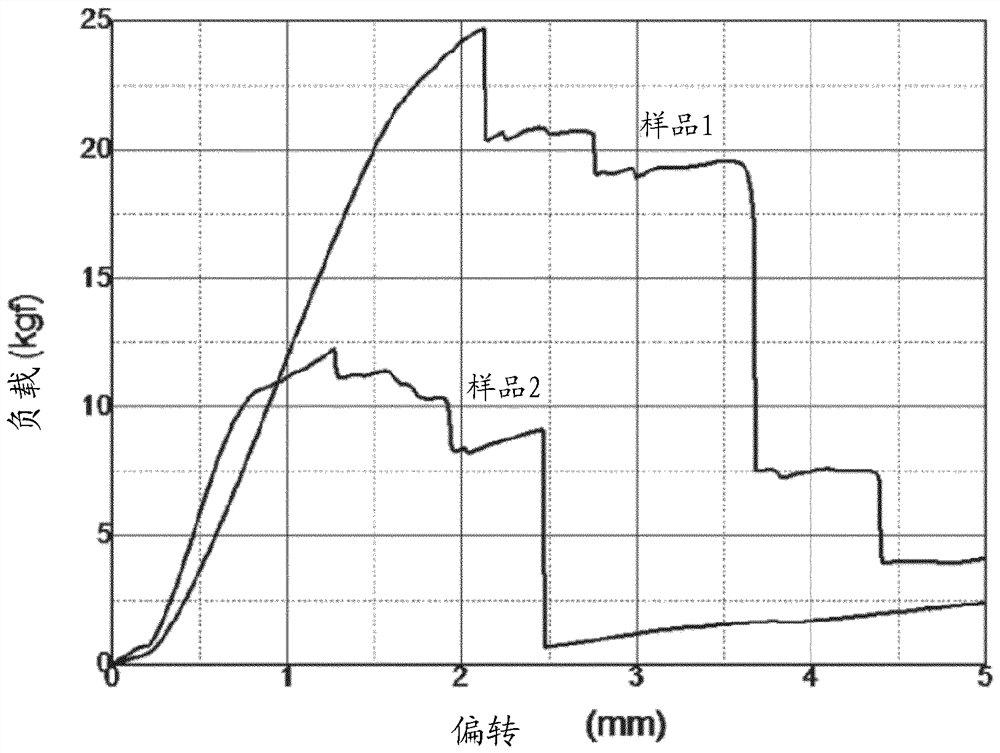

A method of manufacturing shaped articles and shaped articles manufactured thereby

ActiveCN110520282BReduced risk of warpingReduce surface defectsAdditive manufacturing apparatusSynthetic resin layered productsPolymer scienceThermoplastic composites

A method of manufacturing a shaped article comprising a long fiber thermoplastic composite sheet (1) and short fiber filled thermoplastic components (2,3), thermoforming them, wherein the thermoplastic component is preferably injected across the surface of the composite sheet .

Owner:COVESTRO POLYMERS CHINA CO LTD +1

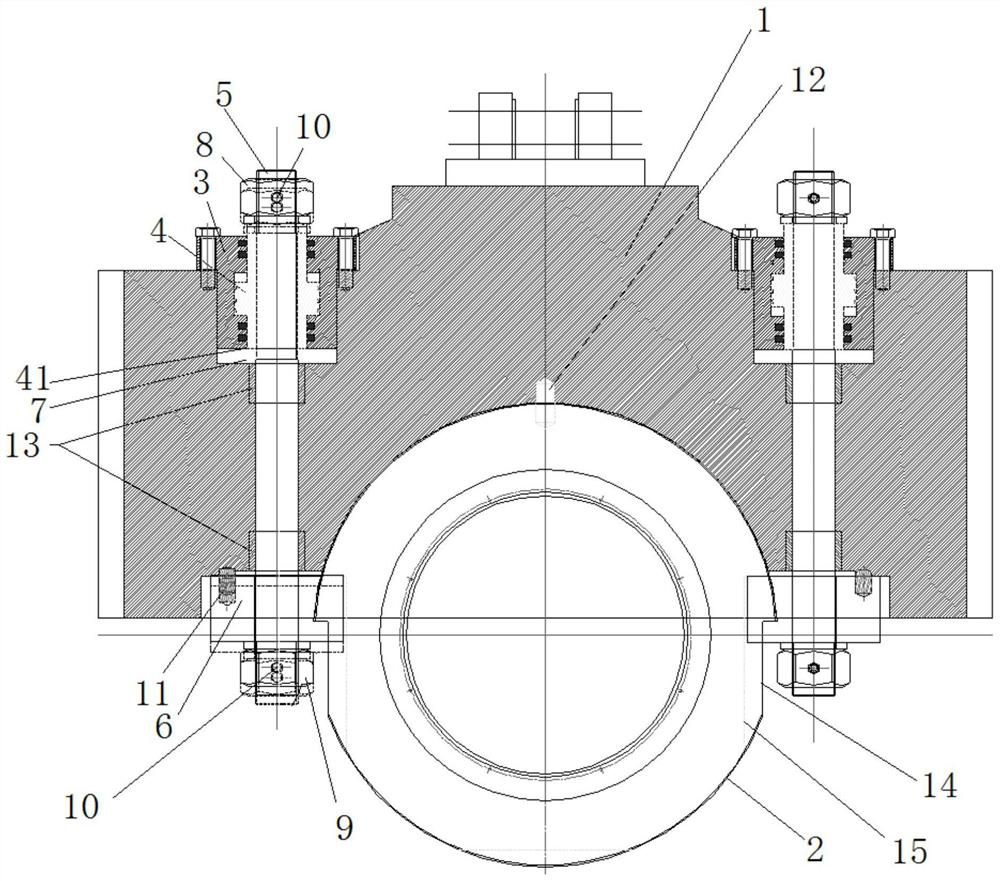

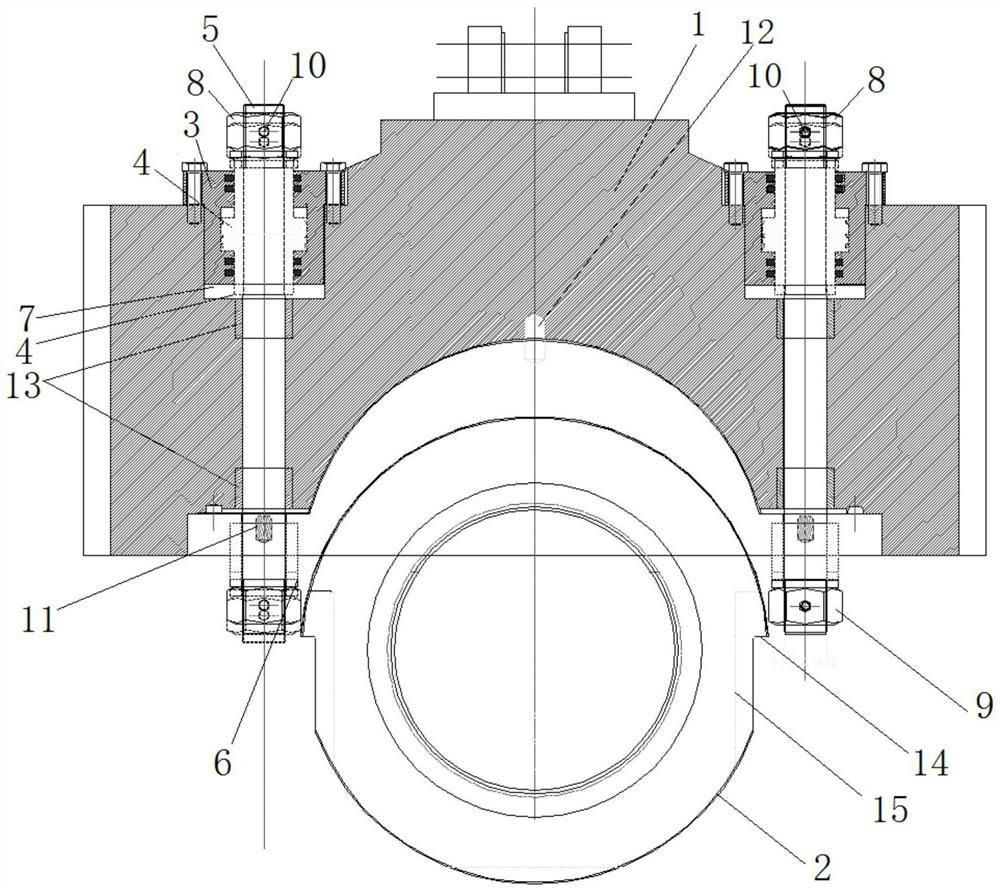

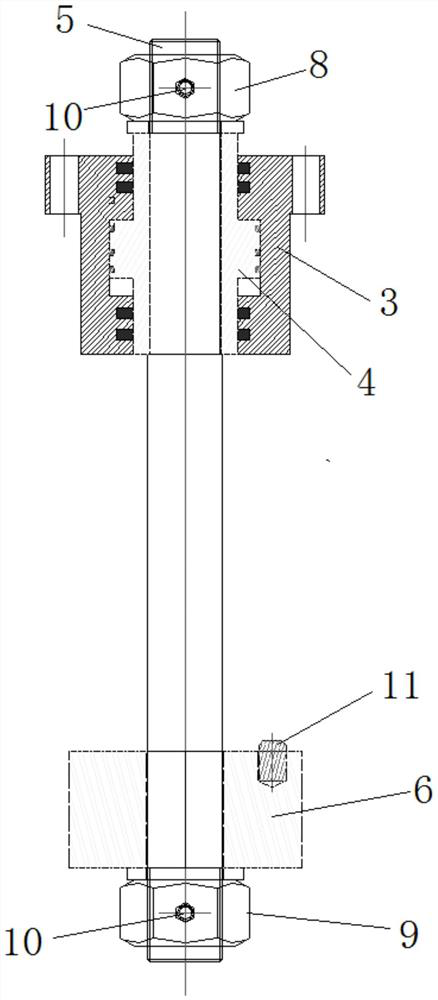

Locking device for roller bearing seat of pipe mill

ActiveCN114406008AEasy to fixQuick roll changeMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderClassical mechanics

The invention relates to the technical field of rolling equipment, in particular to a locking device for a roller bearing seat of a pipe mill. The locking device for the roller bearing seat of the pipe mill is used for locking the roller bearing seat, and comprises a base, a locking device, a locking device and a locking device, and the base is provided with a bearing seat accommodating groove and two through holes; cylinder bodies of the two hydraulic cylinders are fixed to the base and located at the tops of the two through holes respectively, output rods of the hydraulic cylinders penetrate through the through holes and stretch out of the bottom ends of the through holes, and locking blocks are arranged on the stretching-out parts; the roller bearing seat is arranged on the roller bearing in a sleeving mode and embedded into the bearing seat containing groove, two step faces are oppositely arranged on the peripheral face of the roller bearing seat, each step face is formed by a first plane and a second plane, and the first plane is perpendicular to the axis of the through hole; when the output rods of the hydraulic cylinders are located at the upper end of the moving stroke, the locking blocks are driven to be pressed on the corresponding first planes, the two locking blocks are matched, and the roller bearing seat is pressed and fixed in the bearing seat containing groove.

Owner:DAYE SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com