Pull force self-coordination type multi-line suspension plate node structure

A self-coordinated, node-structured technology, applied in the direction of cable suspension devices, can solve the problems of increasing the safety of support points, increasing costs, etc., and achieves the effects of simple structure, convenient installation, and reduced distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

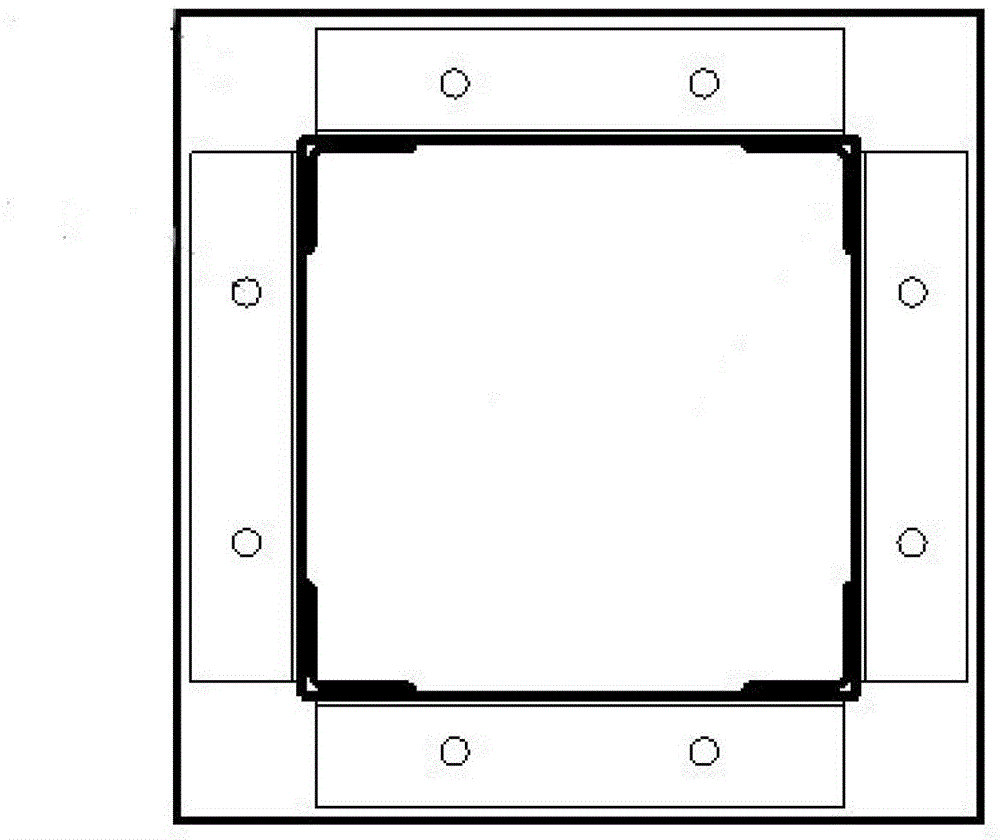

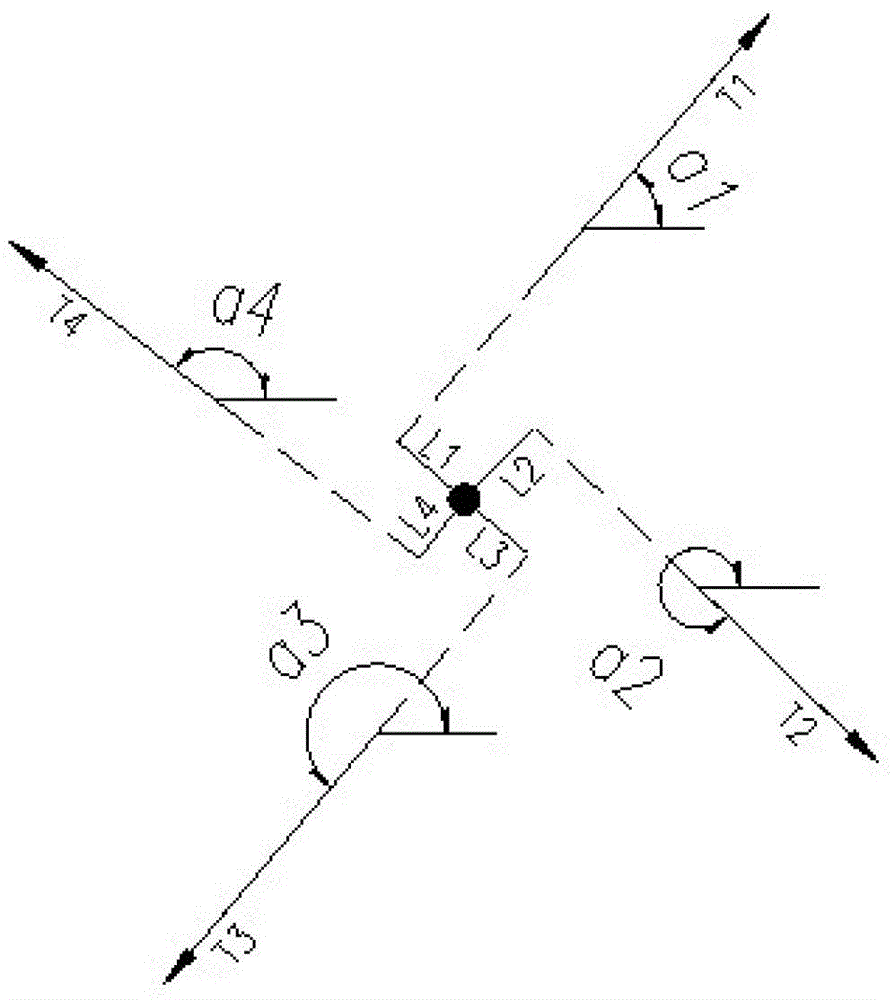

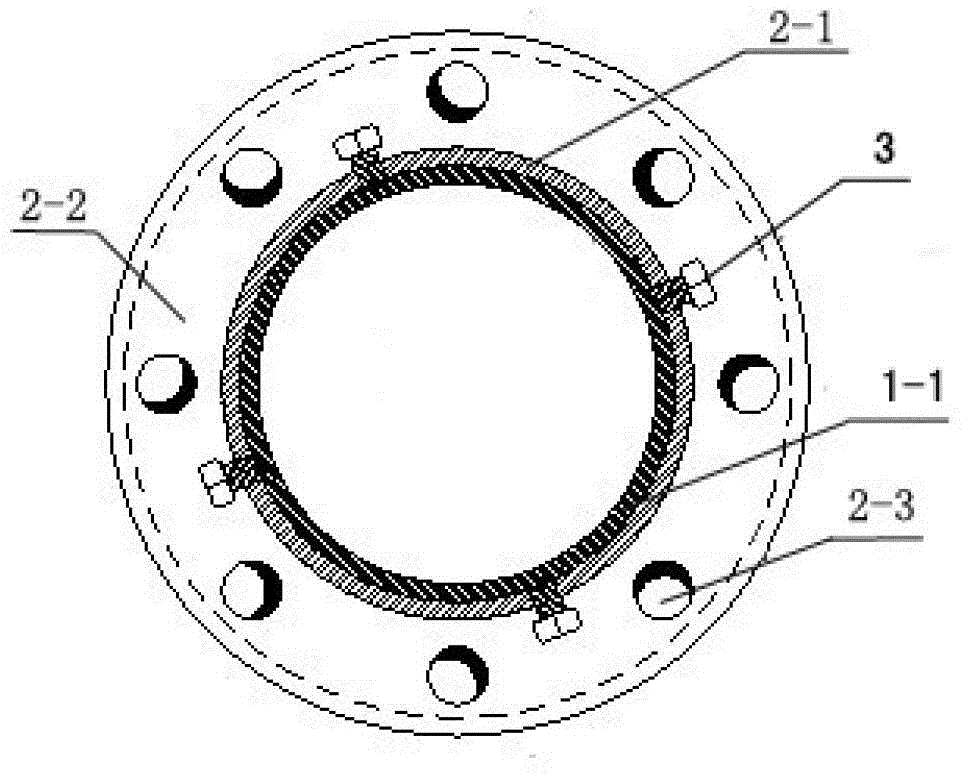

[0025] Such as Figure 3 to Figure 8 As shown, this embodiment includes a fixed part 1 and a movable part 2, the fixed part is fixed by pre-embedding, bolts or welding, and the fixed part has a protruding part 1-1, which is cylindrical or cylindrical, formed Hanging wire support structure; the movable part 2 is sleeved on the protruding part 1-1 of the fixed part to form a relative rotating connection structure, and several hanging wire units are extended from the outer wall of the movable part 2, and the several hanging wire units are scattered The outer wall of the movable part 2 is provided with a plurality of radial screw through holes, and the locking bolt 3 will connect the movable part 2 with the fixed part 1 through the screw through holes.

[0026] In this example:

[0027] The movable part 2 is composed of a concentric cylinder 2-1 and a ring 2-2. The cylinder 2-1 is sleeved on the protruding part 1-1 of the fixed part, and its size and shape coincide with the protr...

specific Embodiment 2

[0034] The characteristics of other embodiments of the present invention are: the same fixed part 1 can be socketed with 1~3 movable parts 2, so as to meet more wires and more height requirements.

specific Embodiment 3

[0035] The characteristics of other embodiments of the present invention are: the plurality of hanging wire holes 2-3 can be one, two, three, four, five, six, seven, eight, nine or more than ten , all the other structures and working principles are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com