Device and method for alleviating part stress by means of electromagnetic induction in additive manufacturing of powder bed

A technology of additive manufacturing and electromagnetic induction, which is applied in the field of reducing the stress of parts, powder bed additive manufacturing electromagnetic induction to reduce the stress of parts, and achieves the effects of easy maintenance, operation and control, small magnetic field strength, and reduced risk of warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

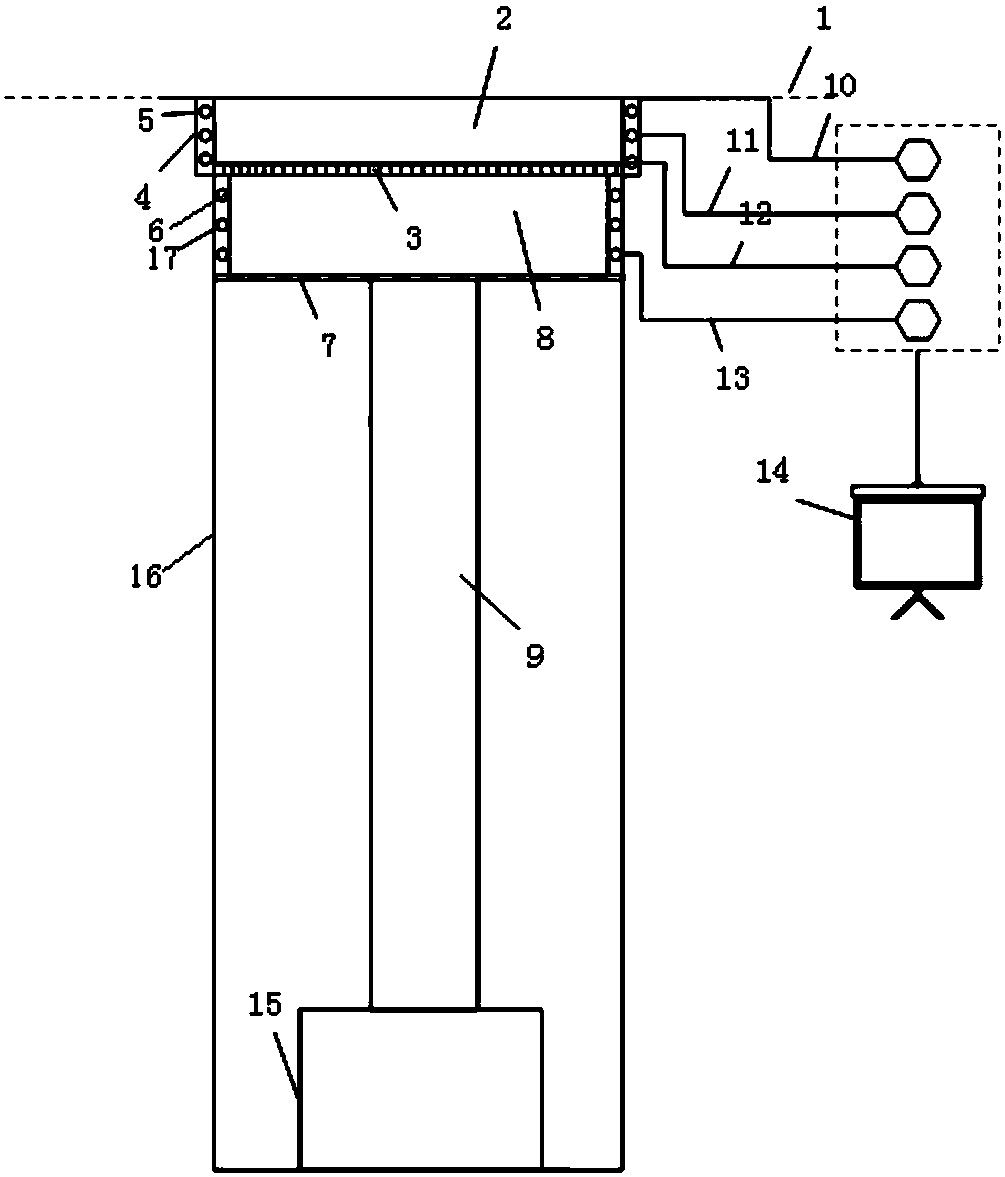

[0031] A device for reducing the stress of parts by electromagnetic induction in powder bed additive manufacturing of the present invention, the structure is as follows figure 1 As shown, the forming cylinder 16 is included, the forming cylinder 16 is provided with a drive motor 15, the output shaft of the drive motor 15 is connected with a ball screw mechanism 9, the other end of the ball screw mechanism 9 is connected with a heating substrate 8, and the heating substrate 8 is The inner wall of the forming cylinder 16 is set, the heating base plate 8 is surrounded by an electromagnetic generator 17, an electromagnetic inductor 4 is arranged around the outer wall of the forming cylinder 16, the electromagnetic inductor 4 is arranged on the upper end of the forming cylinder 16, and the electromagnetic inductor 4 is connected to a first electrom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com