Method for improving magnetic property of high-entropy alloy by heat treatment through constant magnetic field

A technology for high-entropy alloys and magnetic properties, applied in the field of heat treatment of high-entropy alloys to improve the magnetic properties of high-entropy alloys by using constant magnetic field heat treatment, can solve the problem of limited improvement in the magnetic properties of high-entropy alloy materials and unfavorable promotion of high-entropy alloy materials Application, high heat treatment temperature, etc., to achieve the effect of significantly improving the magnetic properties, improving the magnetic properties of the alloy, and reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

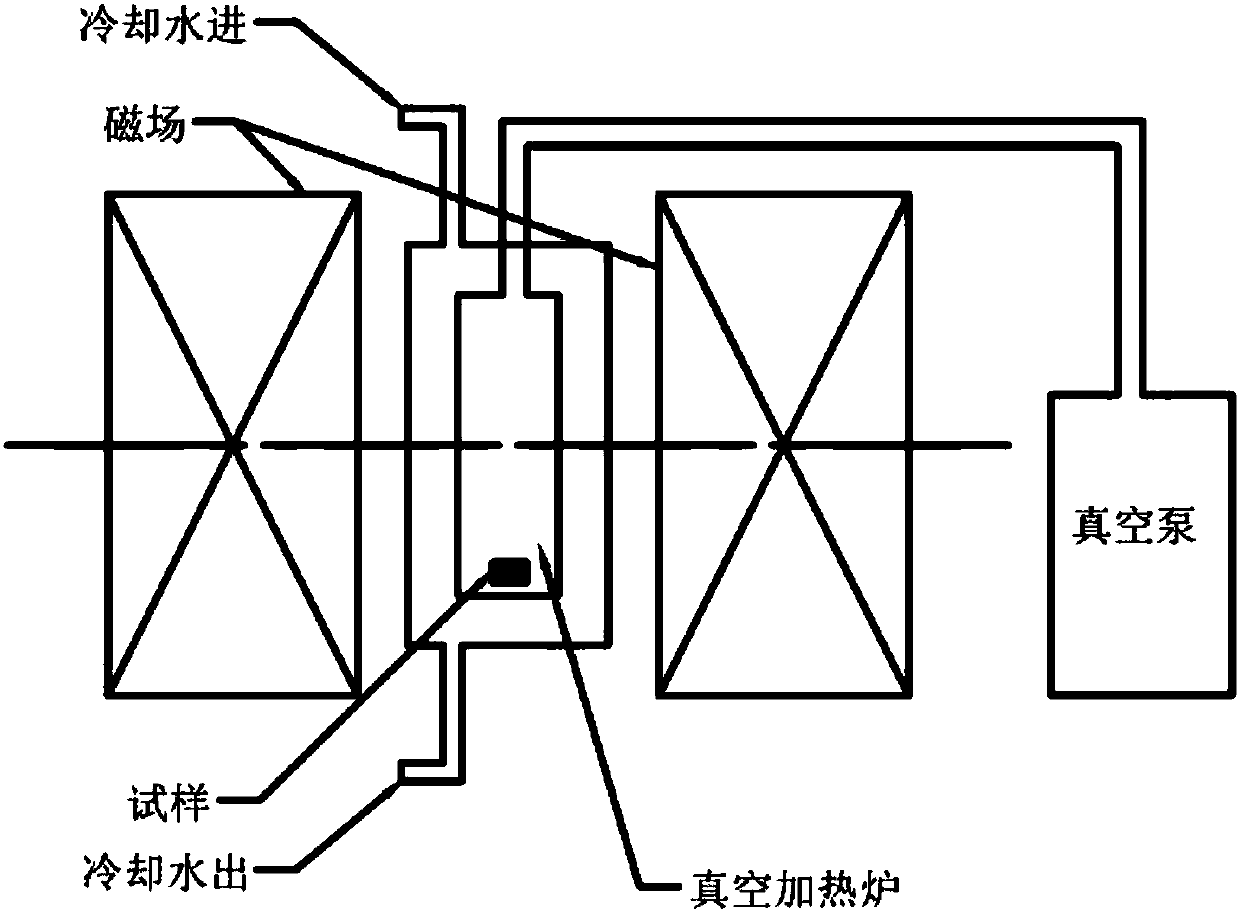

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, a kind of heat treatment using constant magnetic field to improve FeCoNi(CuAl) 0.8 A method for the magnetic properties of high-entropy alloys, comprising the steps of:

[0021] a. Alloy preparation: According to the atomic ratio of Fe, Co, Ni, Cu, and Al in the alloy is 1:1:1:0.8:0.8, use elemental Fe, Co, Ni, Cu, Al metal raw materials with a purity of 99.999% , using a vacuum arc melting method to melt Fe, Co, Ni, Cu, and Al pure metals to obtain a Fe-Co-Ni-Cu-Al master alloy melt;

[0022] b. Alloy material shaping treatment and compactness treatment: using copper mold suction casting method, the Fe-Co-Ni-Cu-Al alloy melt obtained in the above step a is made into 80mm×10mm×2mm flake FeCoNi (CuAl) 0.8 alloy material; then FeCoNi(CuAl) 0.8 The alloy material is cold rolled, FeCoNi(CuAl) 0.8 The alloy material is cold-rolled and compressed by 10% of its volume to obtain densified FeCoNi(CuAl) 0.8 Alloy; then using wire cutting technology, the o...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, especially in that:

[0026] In this embodiment, a kind of heat treatment using constant magnetic field to improve FeCoNi(CuAl) 0.8 A method for the magnetic properties of high-entropy alloys, comprising the steps of:

[0027] a. alloy preparation: this step is identical with embodiment one;

[0028] b. Alloy material shaping treatment and compactness treatment: this step is the same as that of Embodiment 1;

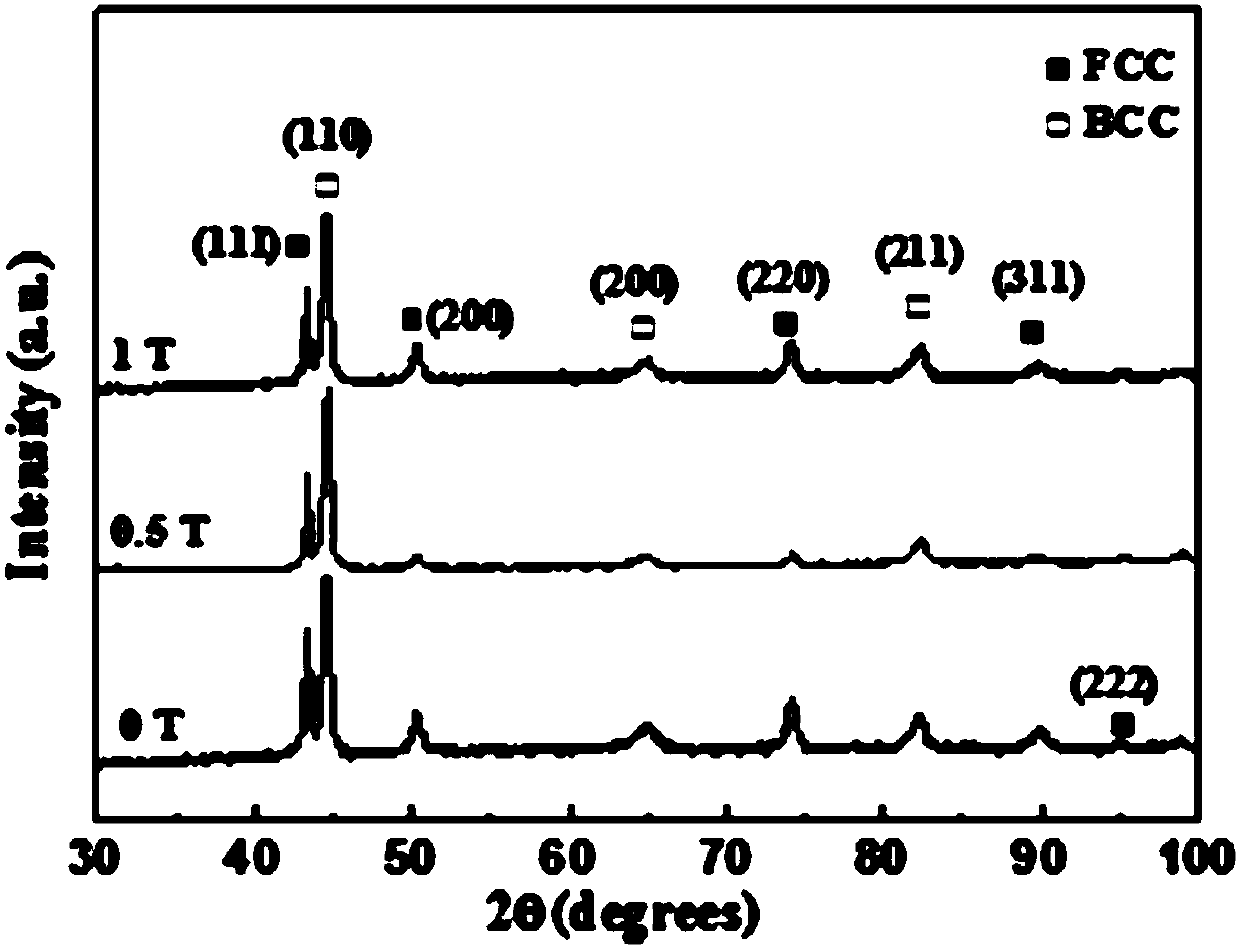

[0029] c. Magnetic field heat treatment: using magnetic field heat treatment equipment, under a uniform magnetic field with a magnetic field strength of 1.0T, heat to the target heat treatment temperature of 400°C at a heating rate of 20°C / min in an annealing furnace, and the heat treatment will be carried out in the step b. Prepared FeCoNi(CuAl) 0.8 The alloy flakes were kept warm for 1 hour, subjected to constant magnetic field heat treatment, and then passed through argon gas to cool to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com