Pressing structure of PCB and processing method of PCB

A PCB board and processing method technology, applied in the field of PCB processing, can solve problems affecting the normal use of electronic products, board surface warpage, etc., to achieve the effect of reducing warpage and maintaining pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

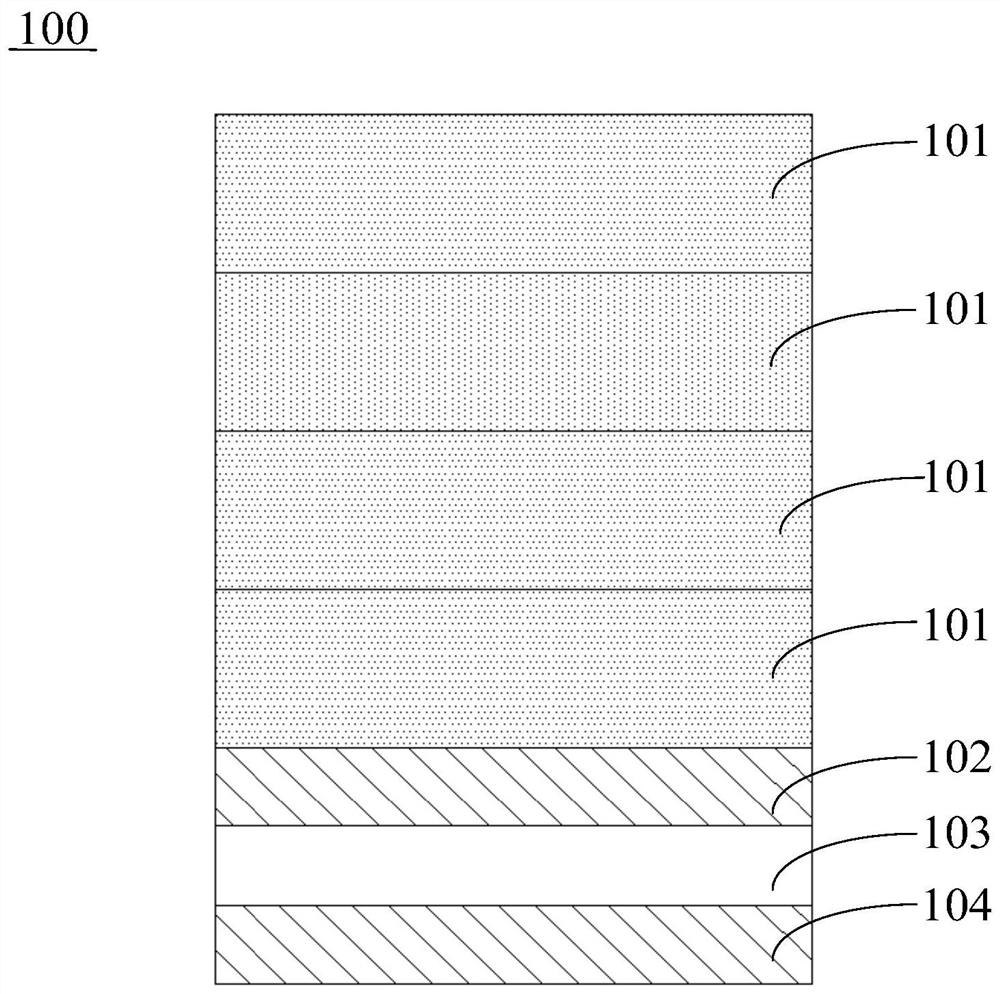

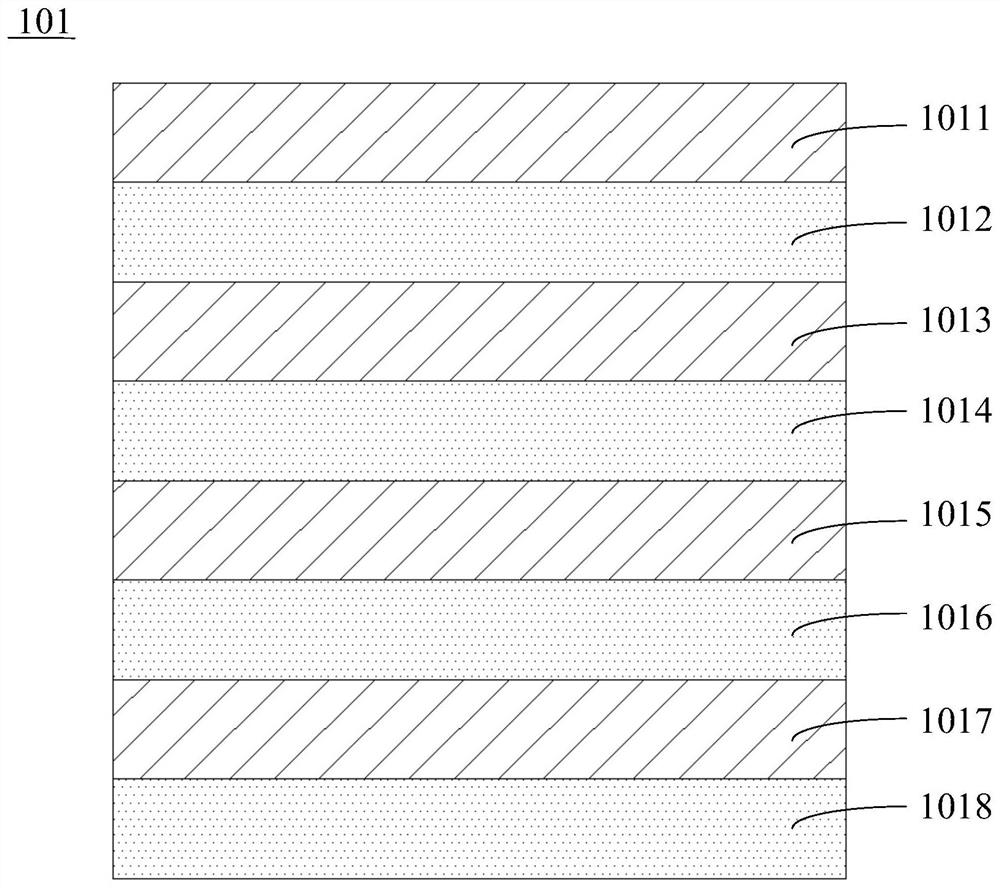

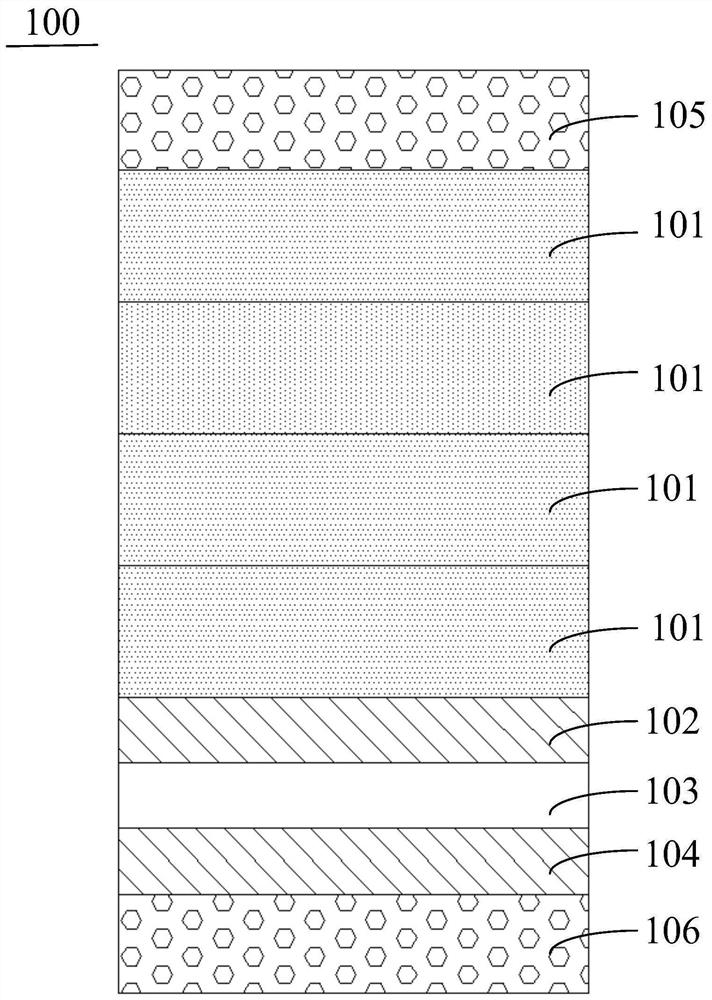

[0069] In this embodiment, the pressing structure is as image 3 As shown, where the row of board layers is as figure 2 As shown, there are 4 board layers. The direction of the BOT surface of the core layer of the 1st to 2nd rowing layers is opposite to the direction of the BOT surface of the core layer of the 3rd to 4th rowing layer. That is to say, the BOT face of the core layer of the 1st to 2nd row of board layers faces down, and the BOT face of the core layer of the 3rd to 4th row of board layers faces up.

[0070] The first buffer layer, the second buffer layer, the first prepreg layer and the second prepreg layer are all prepreg layers formed of prepreg sheets.

[0071] The first isolation layer, the second isolation layer, the third isolation layer and the fourth isolation layer are copper foil layers with a thickness of 0.5 oz.

[0072] The thickness of the first copper foil layer is 0.5 oz, and the thickness of the second copper foil layer is 0.5 oz. The thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com