A method of manufacturing shaped articles and shaped articles manufactured thereby

A product and thermoforming technology, which is applied in the field of manufacturing shaped products, can solve problems affecting yield and warpage, achieve high joint strength and reduce the risk of warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Step i)

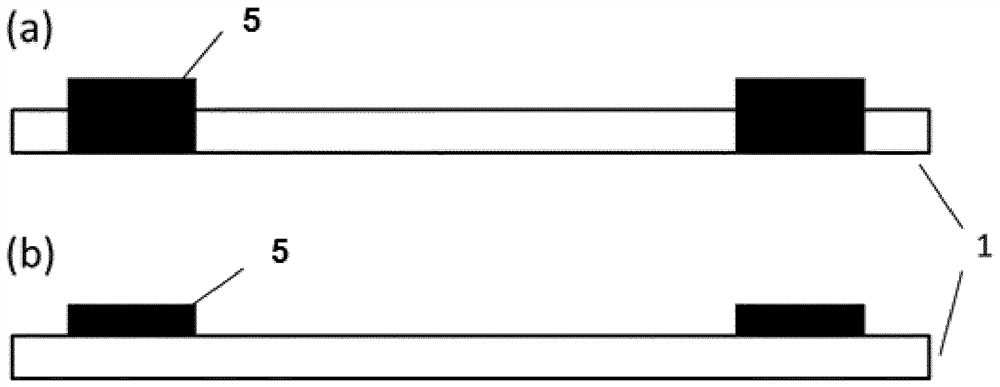

[0024] A composite sheet in the sense of the present invention is a sheet comprising thermoplastic material a and continuous fibers, preferably the composite sheet comprises at least three layers of fiber composite. The composite sheet is preferably a flat composite element for forming a composite part, more preferably a pre-cut flat composite sheet.

[0025] The fibrous composite layers of the composite sheet comprise continuous fibers, preferably unidirectionally aligned within the respective layer and preferably embedded in a polycarbonate-based plastic.

[0026] In the context of the present invention, "unidirectional" is understood to mean that the continuous fibers are arranged substantially unidirectionally, ie the longitudinal directions point in the same direction and thus have the same running direction. In this context, "essentially unidirectional" is understood to mean that a deflection of up to 5% is possible in the direction in which the fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com