Patents

Literature

49results about How to "Quick roll change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

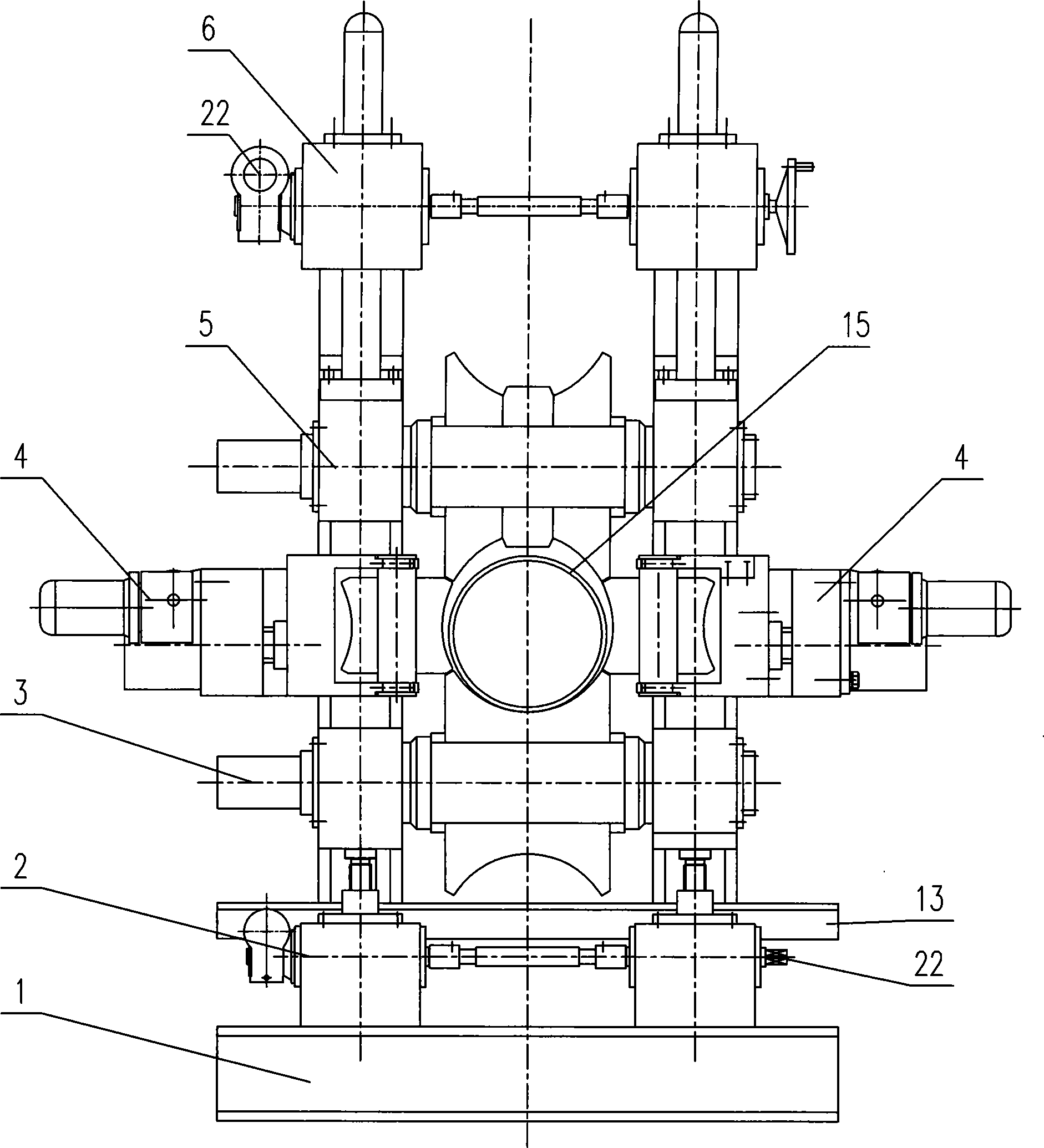

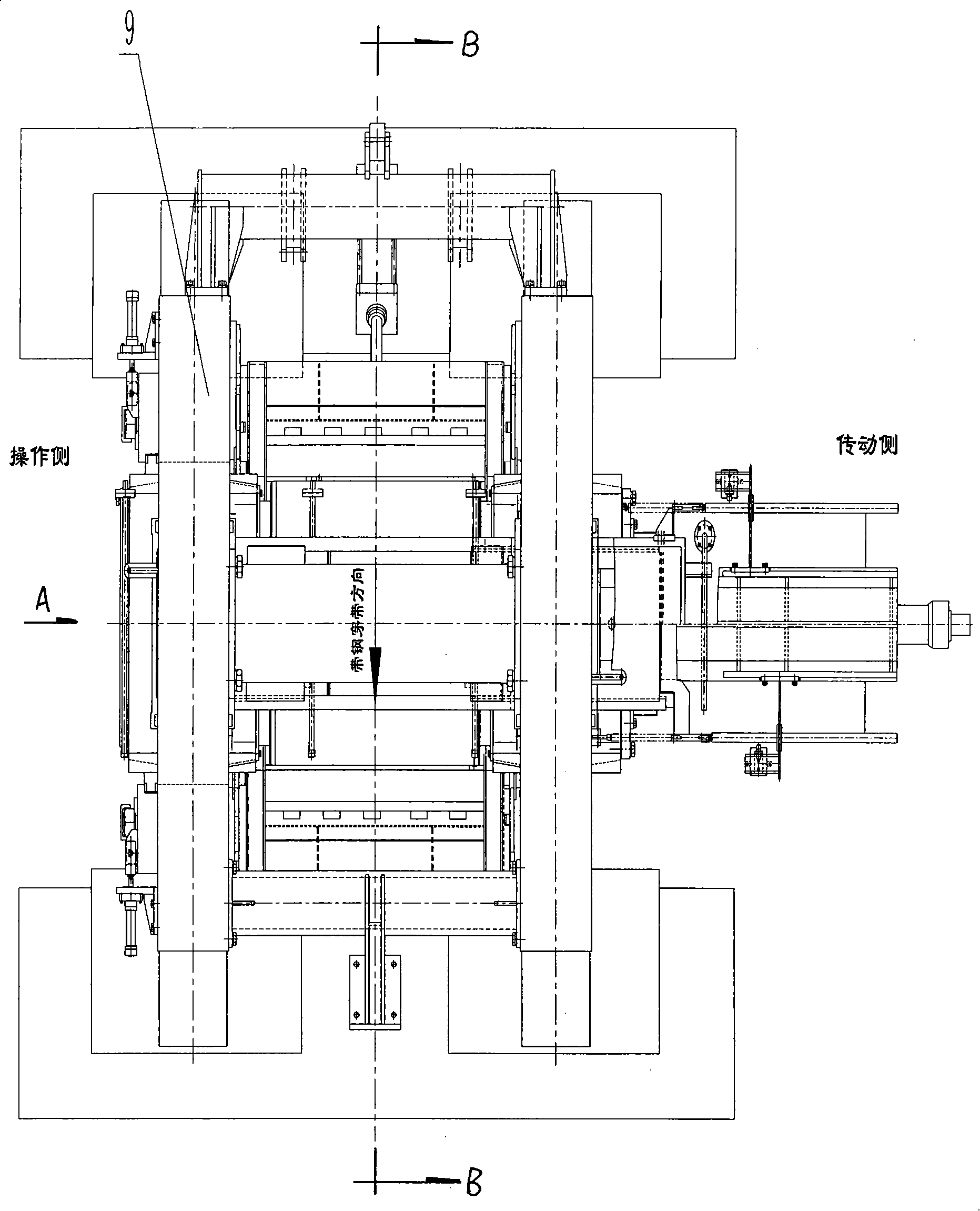

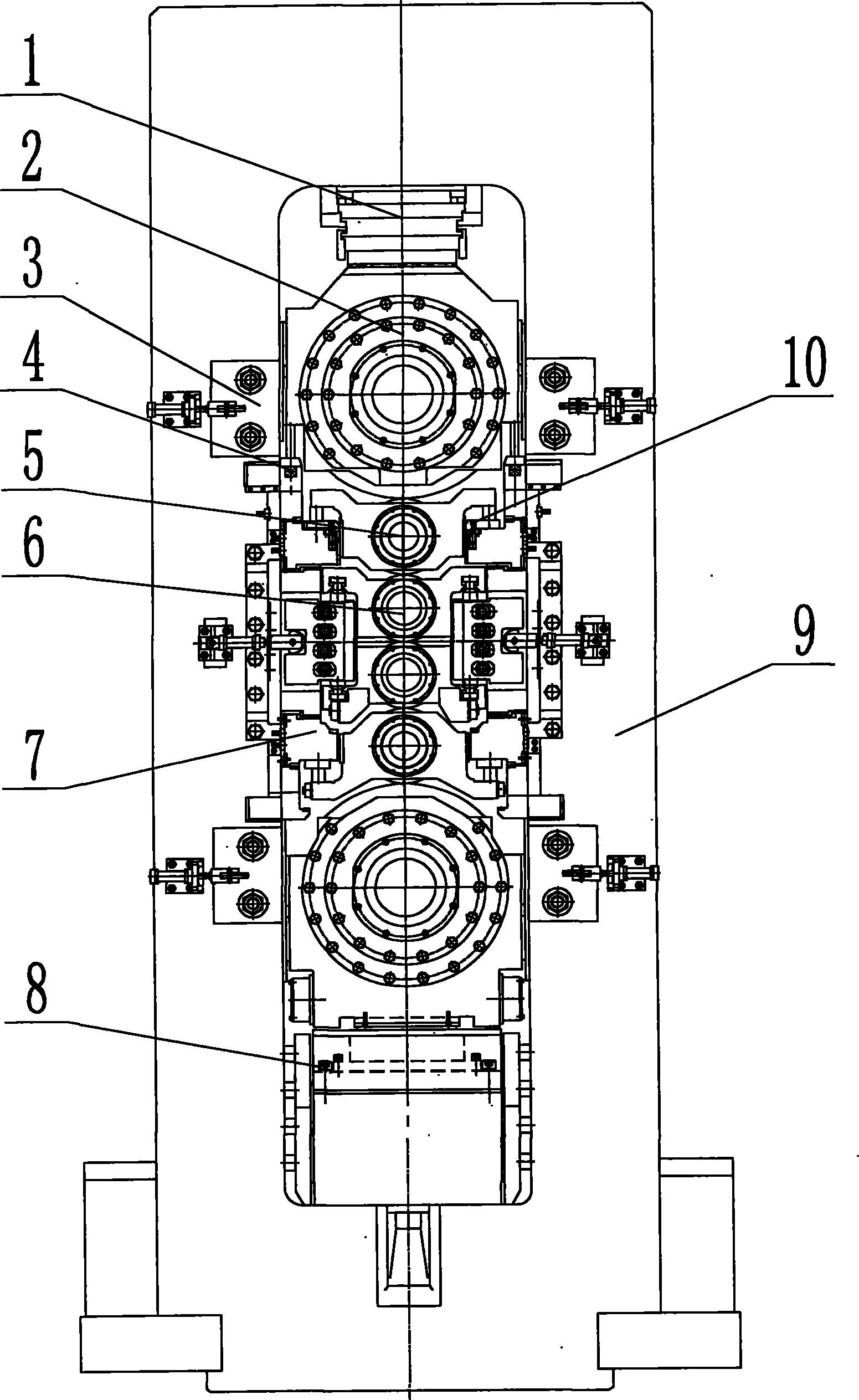

Rough rolling vertical roller mill

InactiveCN101108395AEasy to adjustQuick roll changeMetal rolling stand detailsRolling mill drivesMotor driveGear wheel

The invention relates to a rough rolling vertical milling caster is provided, wherein, the main transmission combination speed reducer is a whole structure, the output axle is two output gear axles arranged vertically, a main transmission motor is connected with the main transmission combine speed reducer by a shaft joint, the two output gear axles extending vertically under the main transmission combination speed reducer are connected with a cross universal spiale, a sleeve at the low end of the cross universal spiale is arranged on the roller platycephaly of a roller structure on a lead rail equipment, the two sides of the roller structure is connected with a side pressure screwdown equipment of a transmission bolt structure with direct current motor driving gear, a hydraulic pressure roll changing lifting device is arranged on a frame under the main transmission combination speed reducer, a side of the lead rail base equipment is arranged with a roll changing structure. The advantage of the invention is that: the invention improves the transmission rigidity and service life, which can meet the requirements of large torsion distance; the invention can realize quick roll changing, which shortens the online roll changing time greatly and improves work efficiency; the invention cooperates with a plain-barrel rolling machine, which can produce blank with different standard and lowers the process cost.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

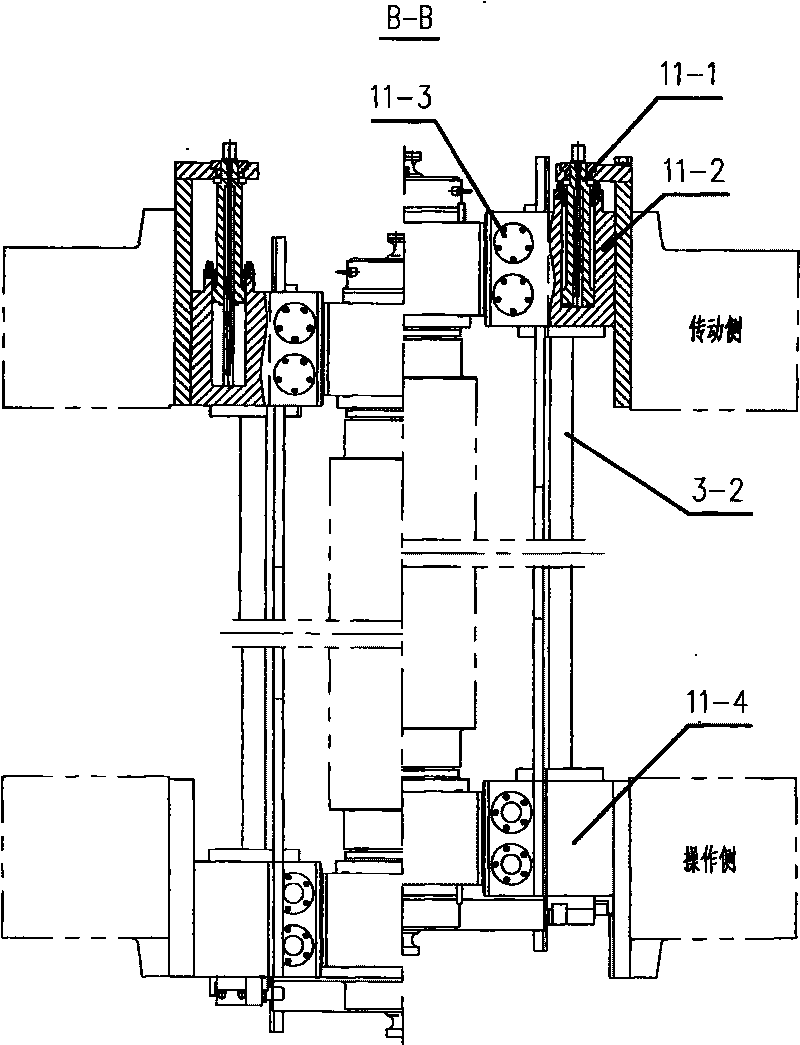

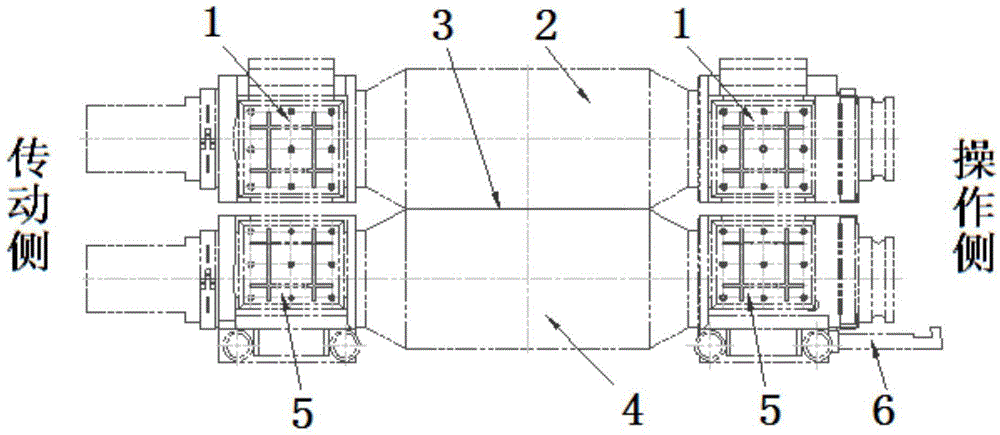

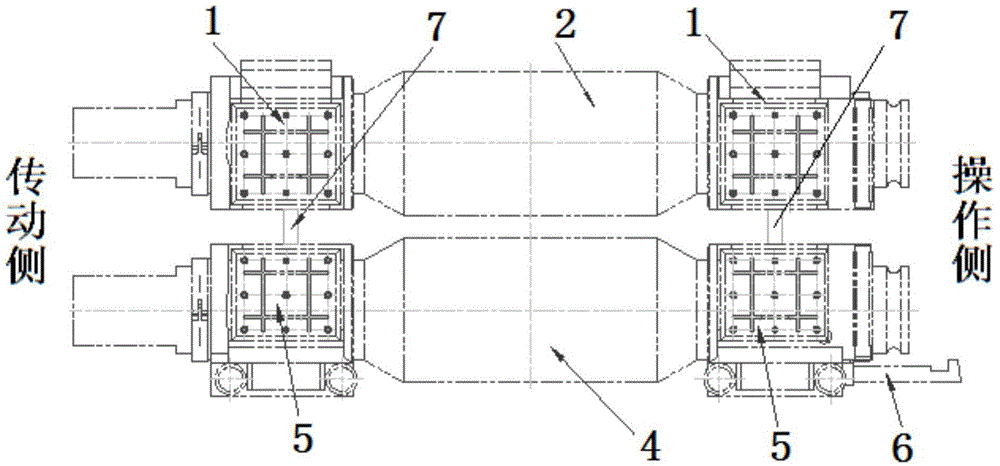

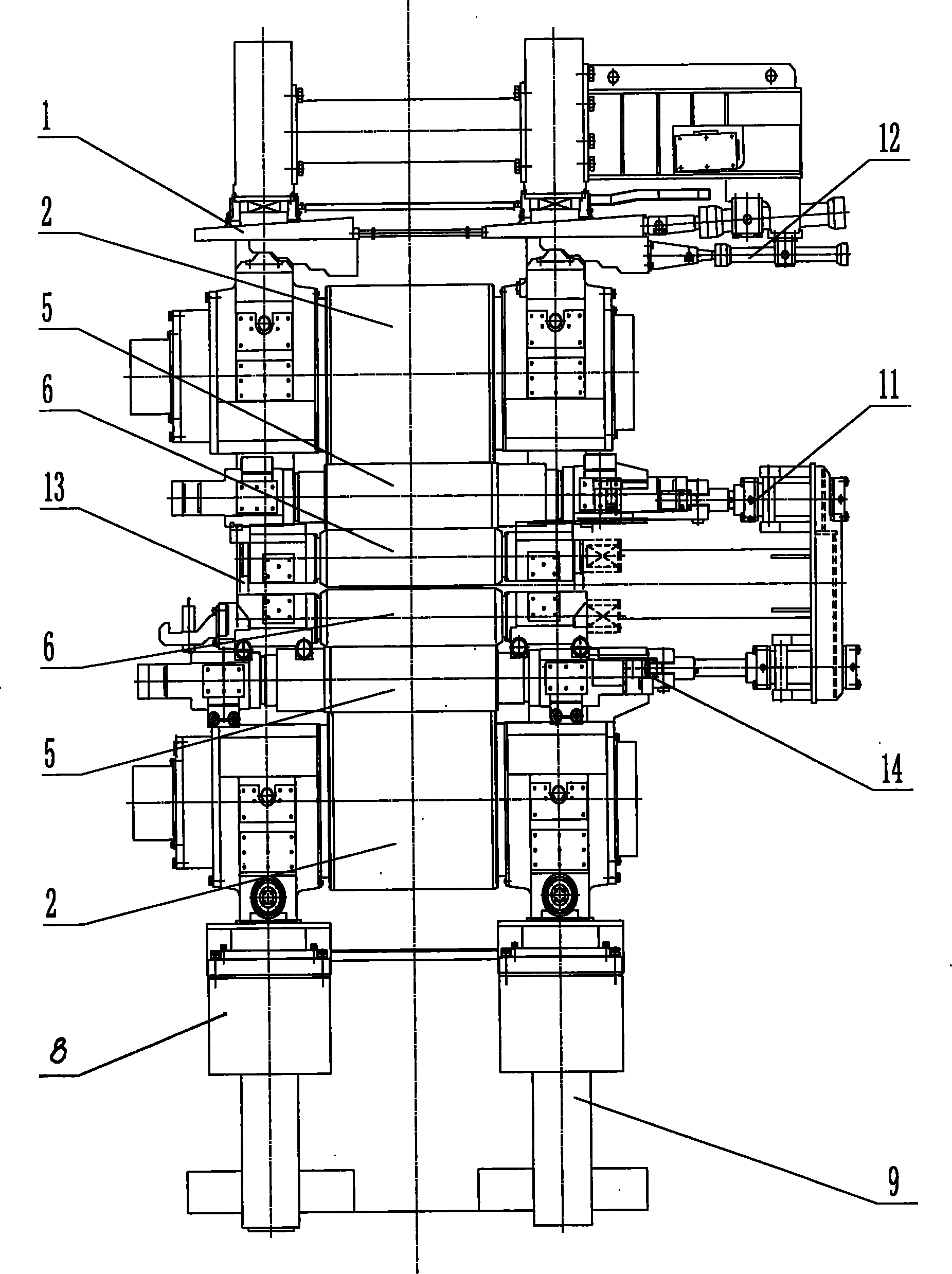

Temper mill with roll bending and shifting functions

ActiveCN101733285AImprove effective utilizationCompact structureMetal rolling stand detailsRolling equipment maintainenceStanding frameWork roll

The invention belongs to the technical field of forming and discloses a temper mill with the roll bending and shifting functions. The temper mill mainly comprises a stand frame, a working roll changing device, a back-up roll changing device, a main transmission gear, upper and lower working roll fittings, a thickness control device, upper and lower back-up roll fittings and a rolling line elevation adjusting device. A working roll shifting and bending device is inlaid in a housing window of the temper mill. Positive and negative roll bending cylinder bodies at the transmission side and a roll shifting cylinder body are integrated on a bending and shifting integrated block. A piston rod of the roll shifting cylinder is fixedly mounted on a housing by an E-shaped block. Positive and negative roll bending cylinders at the operating side are integrated on a roll bending integrated block, without roll shifting cylinders. The integrated blocks at the transmission side and the operating side are connected together by a roll changing rail in the housing of the temper mill to form the working roll shifting and bending device. The invention ensures the means of adjusting the roll gaps to be more flexible, can prolong the service life of the working roll, realize rapid roll changing, shorten roll changing time and reduce the production cost. The invention can be widely applied to strip temper mills.

Owner:CISDI ENG CO LTD

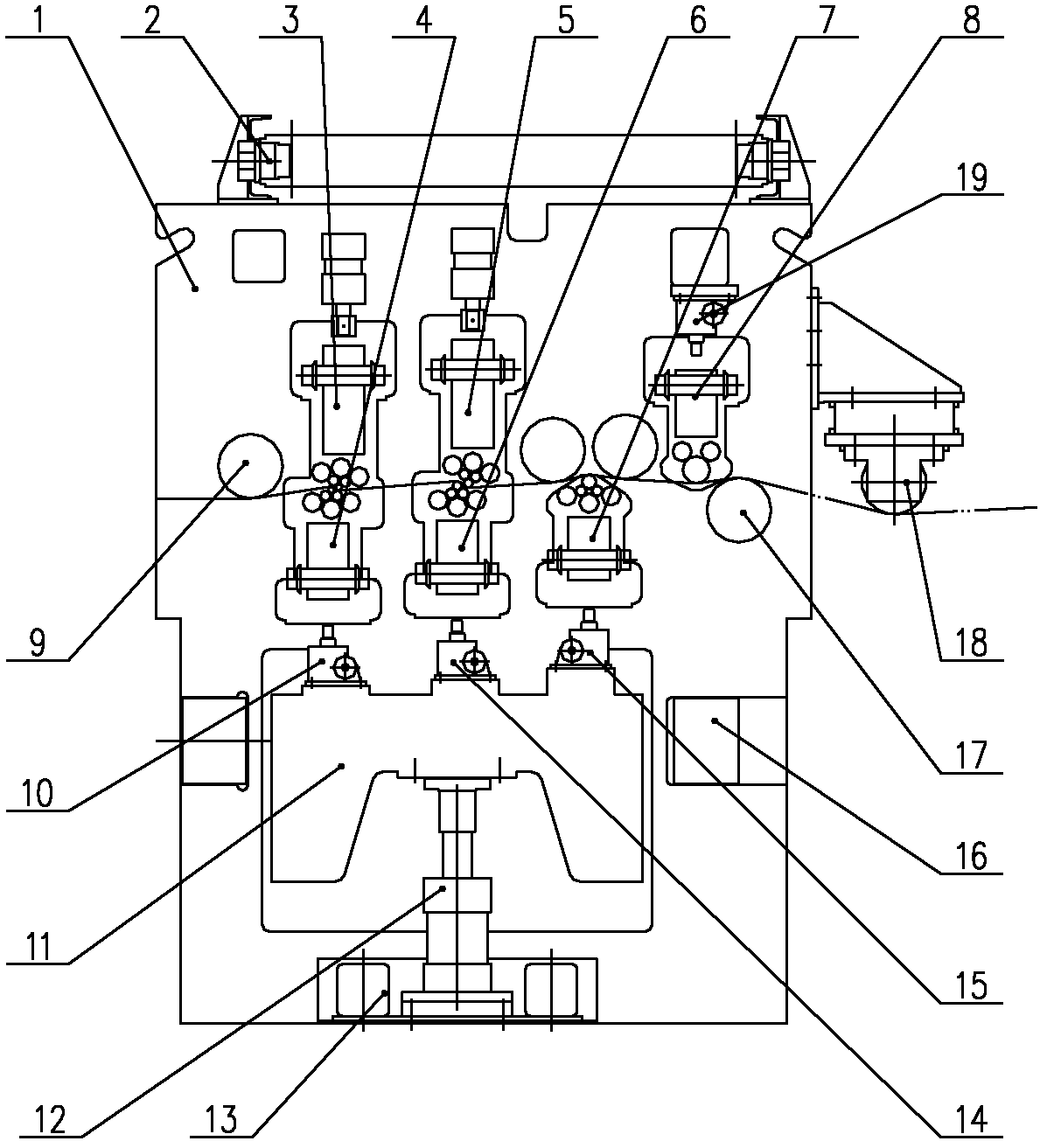

Strip stretch bending leveller

The invention discloses a strip stretch bending leveller. The leveller comprises a stand housing, two bending roll systems, two levelling roll systems, four roll system gap adjusting mechanisms, roll change devices, quick opening devices, guide rolls and a tension measuring roll, wherein six windows are arranged in the stand housing and are respectively correspondingly provided with a 1# upper bending roll set, a 1# lower bending roll set, a 2# upper bending roll set, a 2# lower bending roll set, a 1# levelling roll set and a 2# levelling roll set up and down from left to right; the machine is provided with standby roll sets with diameters different from the diameters of the two bending rolls; the roll change devices are arranged on the top of the stand housing; and connecting rods are arranged between the ends of the roll change devices and the ends of the two bending roll systems. The leveller has the following effects: the working rolls in the bending roll sets have different diameters and can be freely combined; the thickness range of the levelled strip is wider and the levelling effect is better; the roll sets have longer lives; only the working rolls in the bending roll sets have different diameters and the intermediate rolls, supporting rolls and shaft end supports are shared; and the leveller is equipped with the roll change trolleys, thus realizing quick roll change.

Owner:WISDRI ENG & RES INC LTD

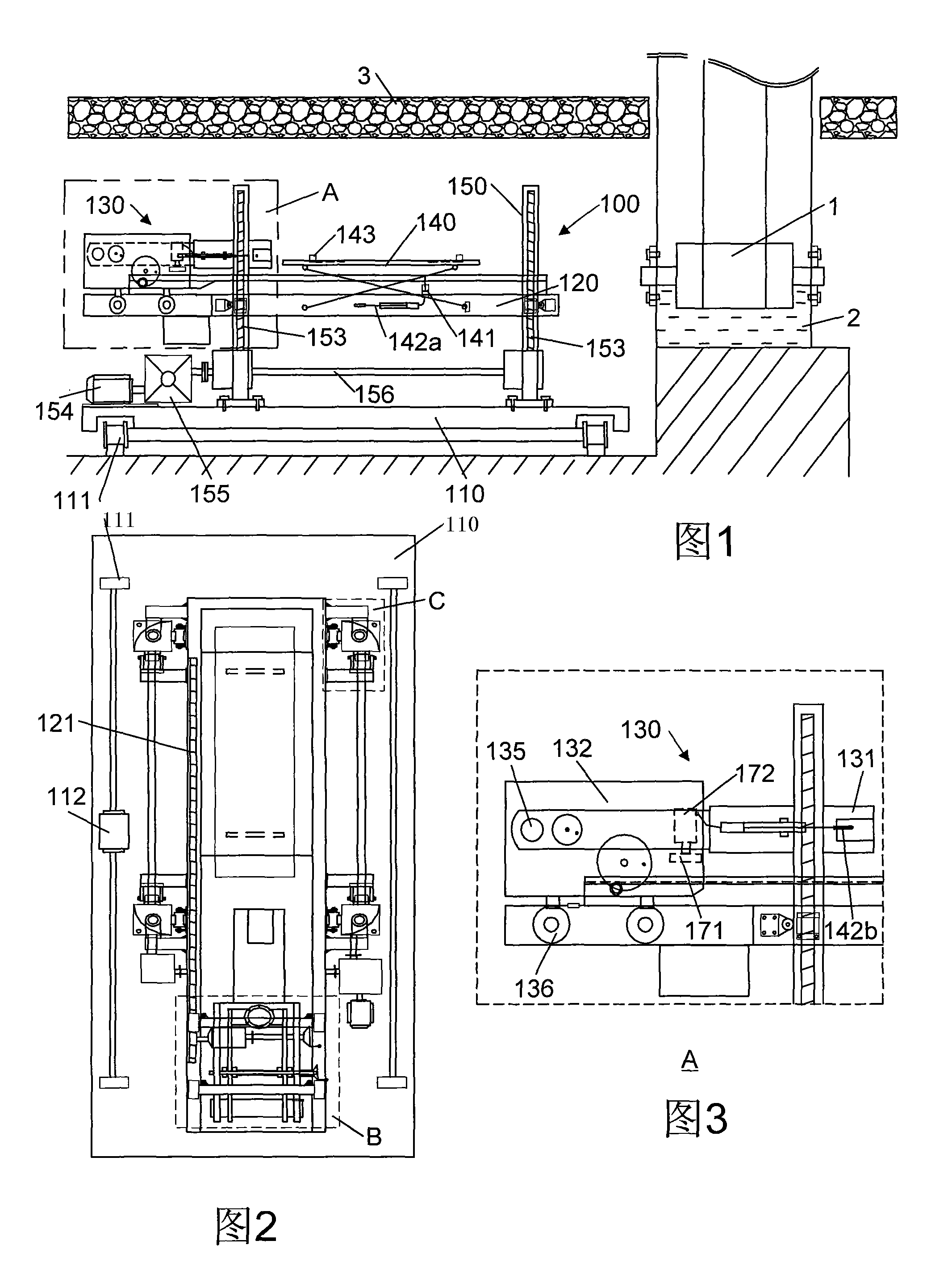

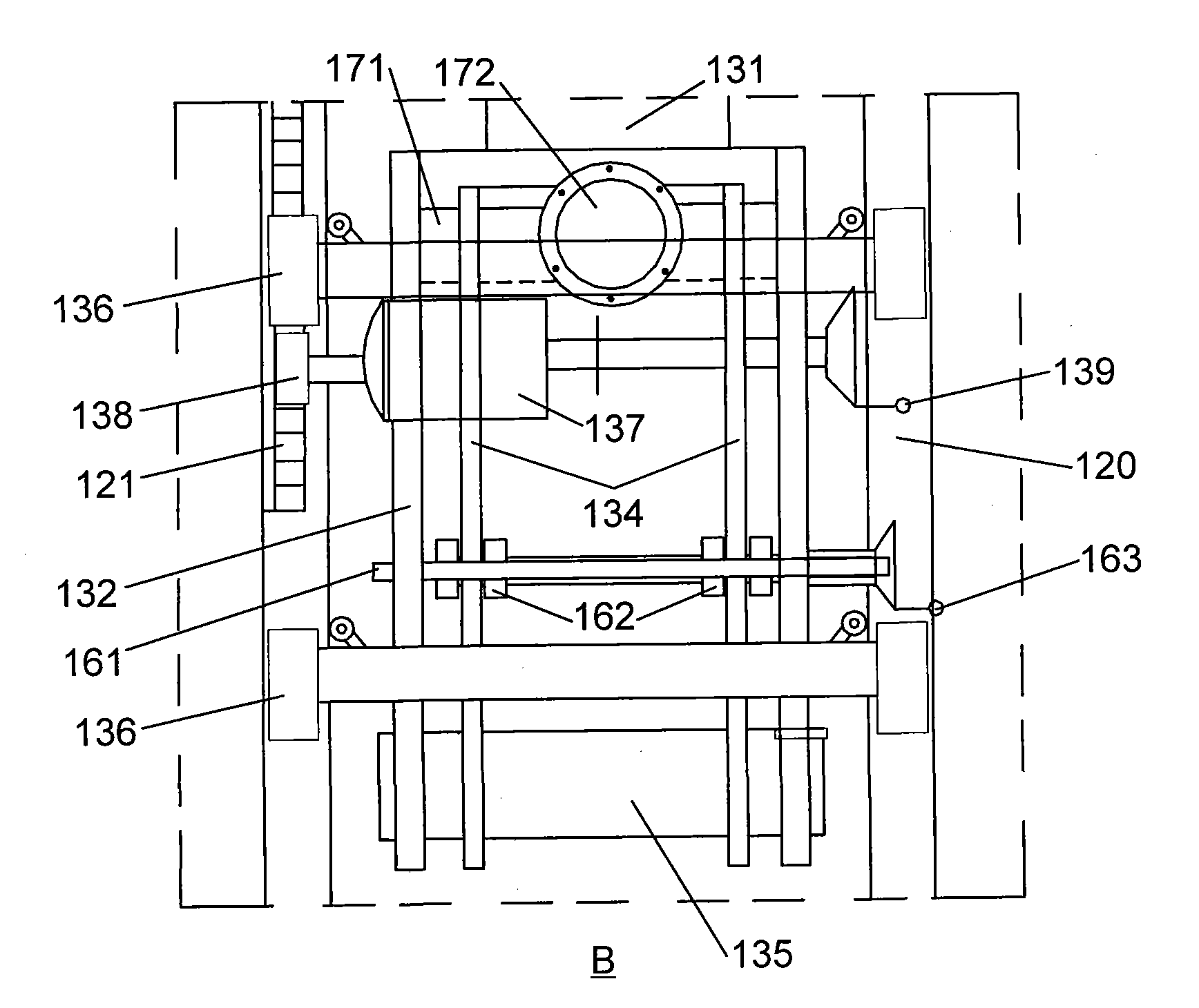

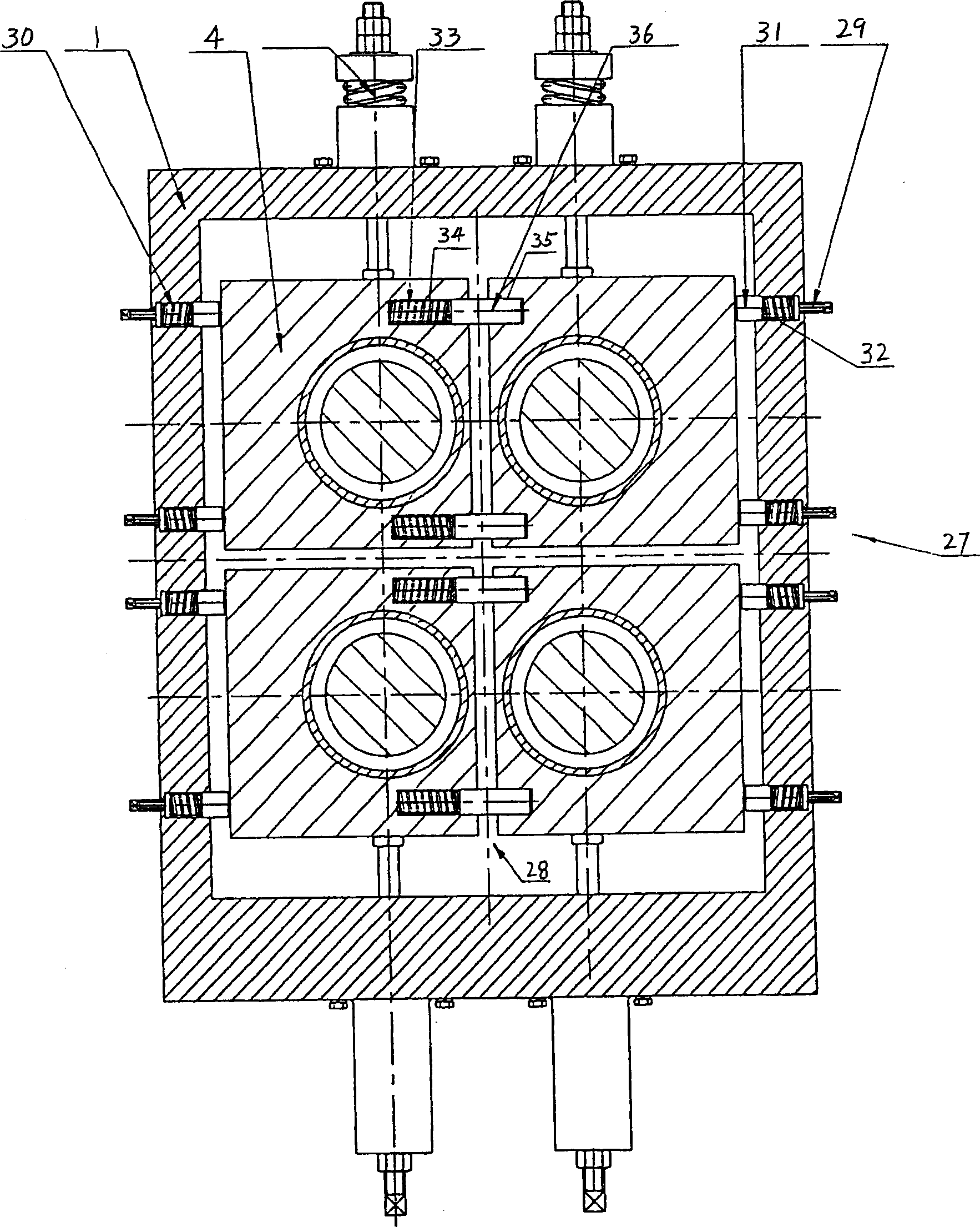

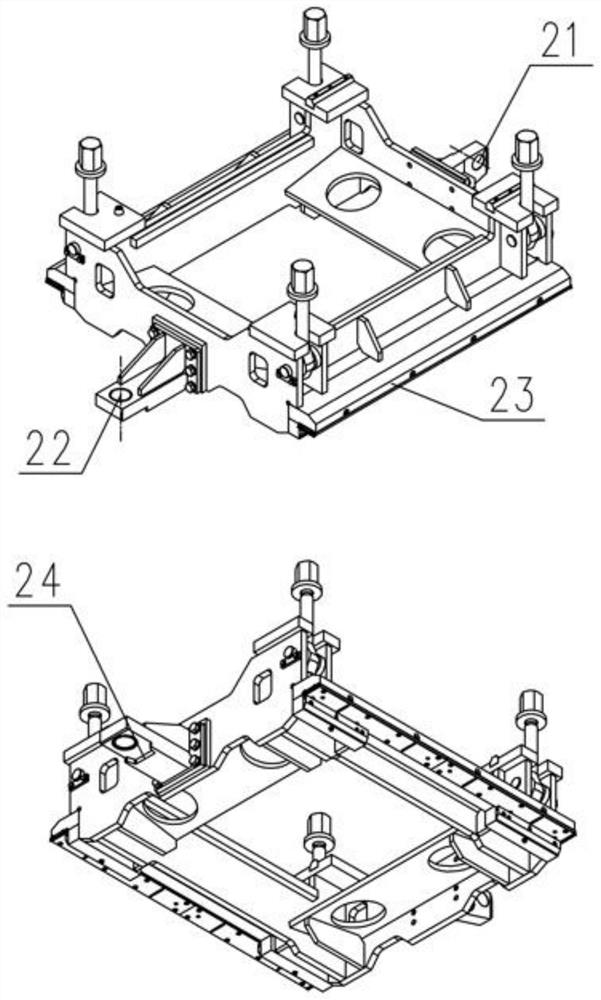

Roll changing device of multi-roll mill

InactiveCN103962382AIncrease production capacityQuick roll changeMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The invention discloses a roll changing device of a multi-roll mill. The roll changing device comprises a travelling trolley, a fixture trolley and a roll frame which are both arranged on the travelling trolley, a lifting frame arranged on the fixture trolley, and a roller clamp arranged at one end of the lifting frame, wherein the travelling trolley is provided with a horizontal crosswise track allowing the fixture trolley to walk, the roll frame is fixedly arranged at one end part of the travelling trolley, the fixture trolley is provided with a horizontal lengthwise track allowing the lifting frame to move laterally, the roller clamp comprises a clamp seat arranged on the lifting frame, an upper clamp, a lower clamp and a clamp oil cylinder, the upper clamp, the lower clamp and the clamp oil cylinder are arranged on the clamp base, and the clamp oil cylinder is connected with the upper clamp through a swing arm. According to the roll changing device of the multi-roll mill, a roll is changed rapidly, accurately, safely and efficiently, the problems of high roll changing frequency and low effective operability troubling the multi-roll mill at present are solved, and the productivity of the mill is increased greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

Roll changing device for cleaning section of hot dip galvanizing unit

ActiveCN101665896AWith lifting functionWith walking functionHot-dipping/immersion processesEngineeringMechanical engineering

The invention discloses a roll changing device for a cleaning section of a hot dip galvanizing unit. The device comprises a base with walking function, a lifting framework with lifting function, a sliding clamp part for changing a roll and a bracket for supporting the roll, wherein the sliding clamp part is arranged at one end of the upper surface of the lifting framework, and is in sliding connection with the lifting framework. The roll changing device clamps a shaft head of a sink roll through a concave hole of a clinch ear, detaches the roll to the bracket through a sliding trolley, and supports the roll through the bracket. Therefore, the device can realize convenient and quick roll changing, greatly reduce labor intensity and improve operation efficiency, is independent of the influence of a cement platform above, and avoids potential safety hazard.

Owner:BAOSHAN IRON & STEEL CO LTD

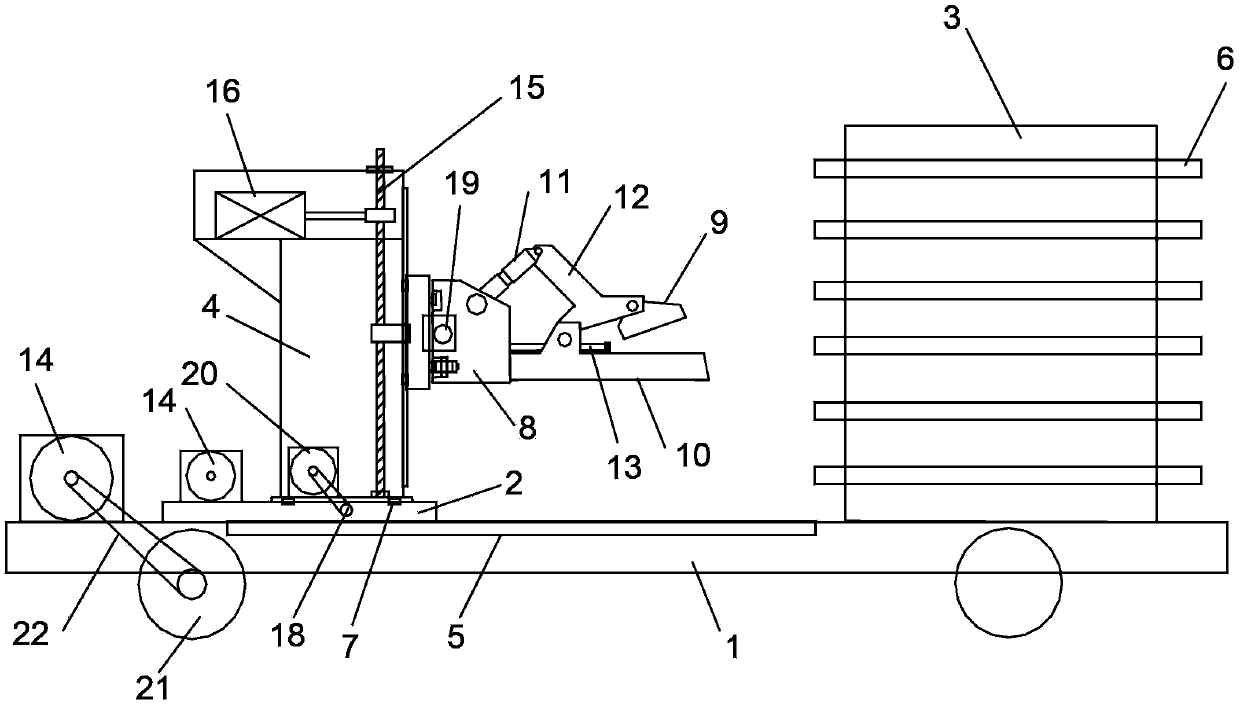

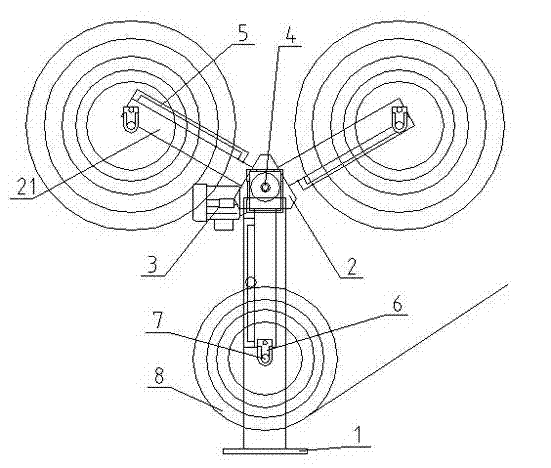

Unreeling device for compound machine

InactiveCN102807114AHigh degree of automationContinuous production constant pressure unwindingWebs handlingDrive motorEngineering

The invention discloses an unreeling device for a compound machine, which is simple in structure and can change reels quickly. The unreeling device includes a rack and a Y-shaped bracket and a rotating drive motor which are mounted at the upper end of the rack. The middle of the Y-shaped bracket is mounted at the upper end of the rack by a rotating shaft, the rotating drive motor is connected to the rotating shaft, a pressure roller is arranged on the side edges of three branch brackets of the Y-shaped bracket, respectively, a rotating mandrel base is arranged at the ends of the three branch brackets of the Y-shaped bracket, respectively and a material mandrel is arranged on the rotating mandrel base. The unreeling device for a compound machine has the advantages of high automation, capability of quick reel change, continuous production, constant-pressure unreeling, simple structure, easy operation and low use cost.

Owner:JIANGSU HONGYE MACHINERY

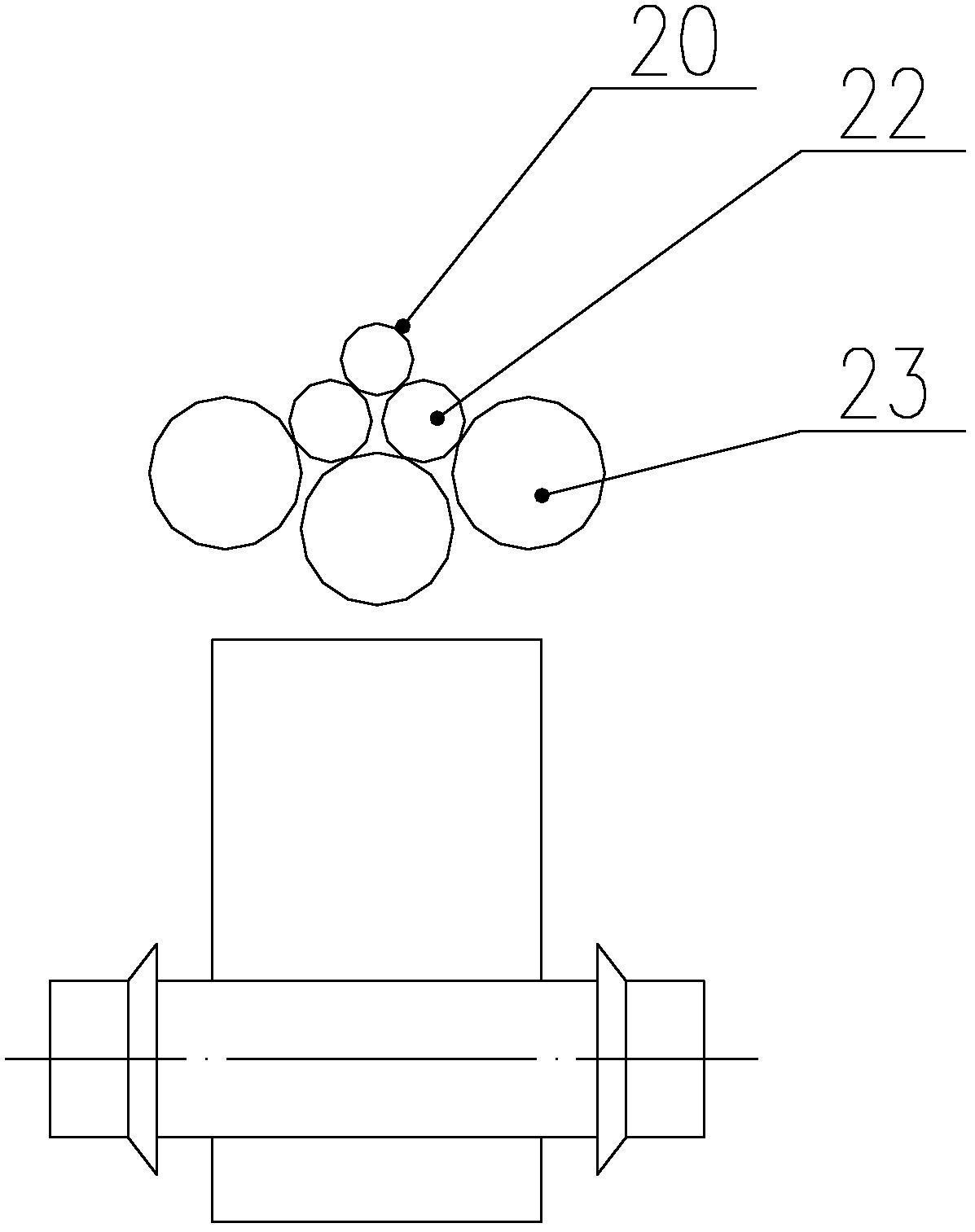

Roller changer for multiple roller rolling mill

InactiveCN1647866AQuick roll changeProvide work efficiencyMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The roller changer for multiple roller rolling mill includes frame, two-layer connecting shaft seats, rotary connecting shafts supported with the connecting shaft seat, and sleeves in one end of the connecting shafts. Under the support of the frame, the connecting shaft seats and thus the connecting shafts may be shifted vertically and / or horizontally, while the sleeves are relatively fixed. The present invention is favorable to the centering of driving rollers and the automatic centering of the sleeves to realize fast roller change in high efficiency.

Owner:郑红专 +1

Quick decomposing roll changing rolling mill

InactiveCN101249513AReasonable designCompact structureMetal rolling stand detailsMetal rolling arrangementsAutomatic controlEngineering

The invention relates to a rolling mill capable of rapidly split-type changing rollers, which is characterized in that independent upper and lower crossbeams and two pillar parts are arranged on a pedestal and are embedded-type matched and connected with each other to form a split-type combined frame; a supporting roller bearing device is arranged on the top of the pillars; an upper and a lower roller lifting adjusting devices are arranged in the upper and the lower crossbeams; the upper crossbeam is connected with an upper slider through a connector; a power-driven pillar upward opening device is arranged on the top of the pillars; a power-driven pillar downward opening device is arranged on the pedestal; chutes are formed on the opposite side surfaces of the two pillars and are formed on the side surfaces of the upper and the lower sliders corresponding thereto; a door frame capable of sliding along the chutes is arranged in the chutes; and a door frame travel mechanism is arranged on the bottom of the door frame corresponding to the bottom surface of the lower slider in a lower shaft system. The rolling mill has the advantages of reasonable design, compact structure, lowered labor intensity, shortened frame disassembly time such as roller changing time, automatic control, rapid and simple roller changing operation, safe and reliable operation, convenient maintenance, etc.

Owner:高国武

Roll changing mechanism for working roll of rolling mill

InactiveCN104858238AQuick roll changeEasy and safe roll changeMetal rolling stand detailsMetal rolling arrangementsWork rollStrip mill

The invention discloses a roll changing mechanism for a working roll of a rolling mill. An upper bearing seat and a lower bearing seat are arranged on an installing seat of a work side and an installing seat of an operating side respectively. The shaft axis of the upper bearing seat and the shaft axis of the lower bearing seat are arranged in parallel. An upper working roll and a lower working roll penetrate through the upper bearing seat and the lower bearing seat respectively. An equal-height hinge pin is fixedly arranged on the upper surface of the lower bearing seat at the working side. A depth hole and a shallow hole are formed in the bottom face of the upper bearing seat at the working side. Another equal-height hinge pin is fixedly arranged on the upper surface of the lower bearing seat at the operating side. A depth hole and a shallow hole are formed in the bottom face of the upper bearing seat at the operating side. According to the structure of the roll changing mechanism for the working roll of the rolling mill, the equal-height hinge pin is included on the upper surface of the lower bearing seat, and two holes with different depths are formed in the bottom of the upper bearing seat correspondingly, the function of adding a height-equal block manually is realized, and fast, convenient and safe roll changing is realized.

Owner:MCC SFRE HEAVY IND EQUIP

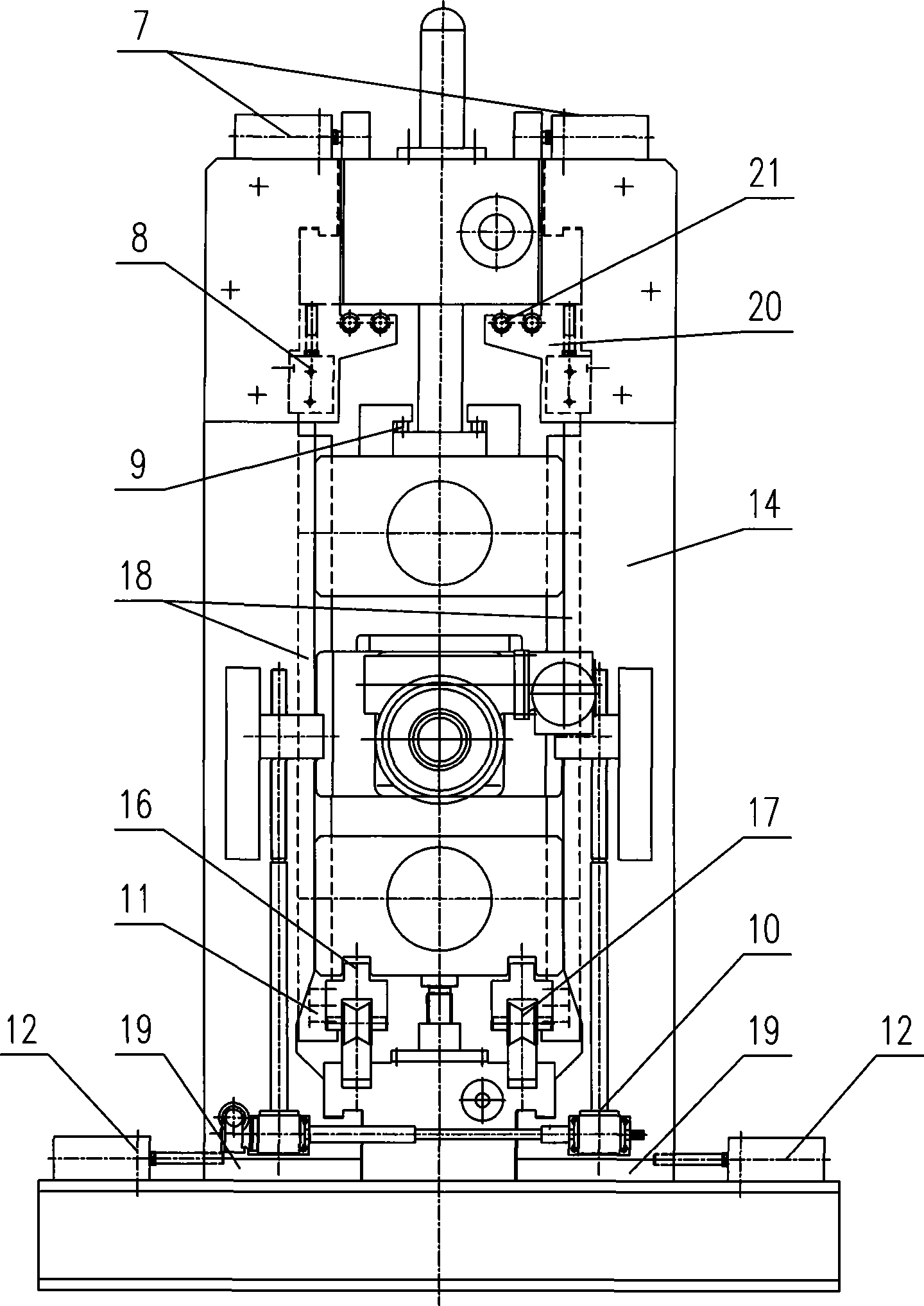

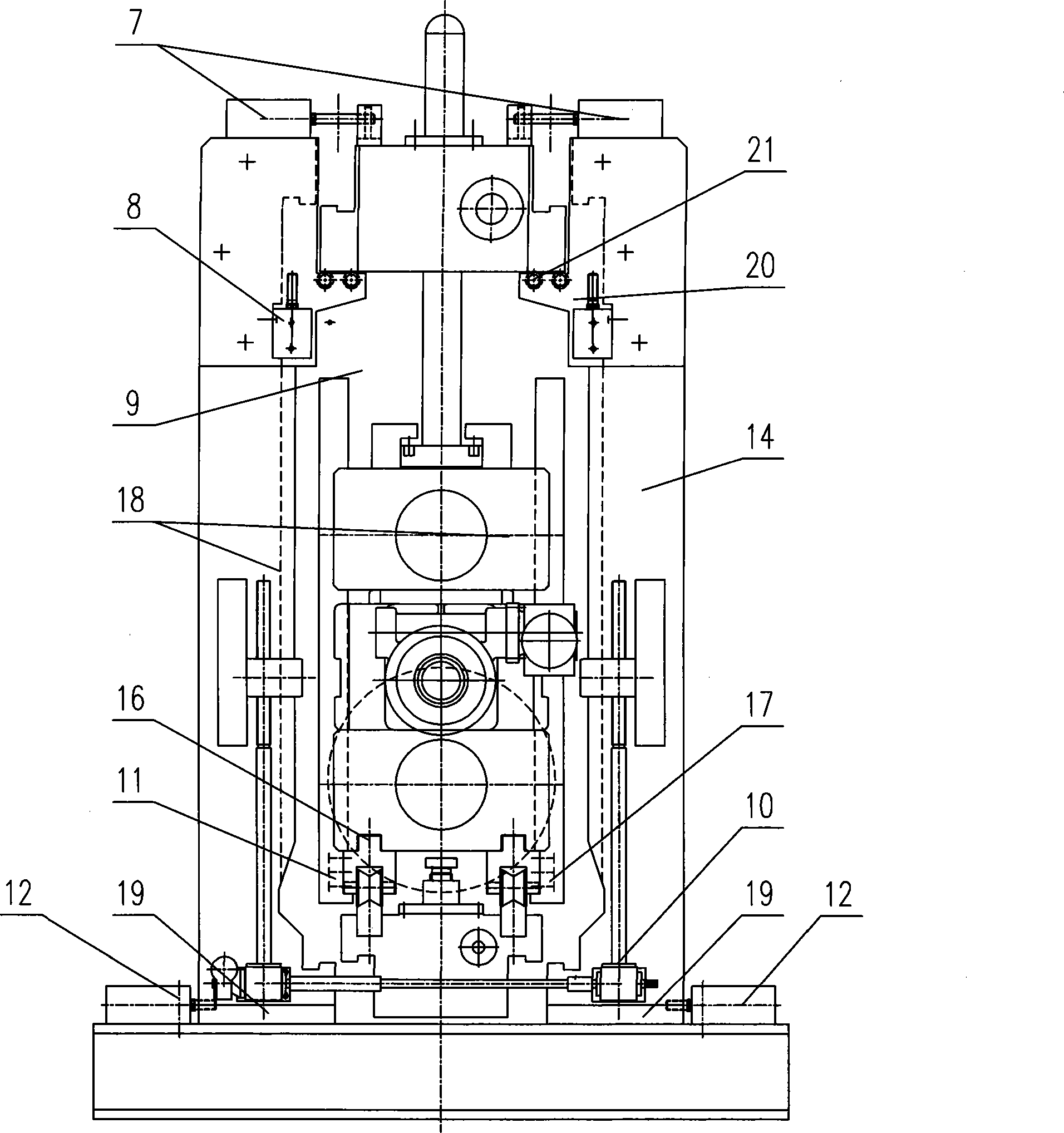

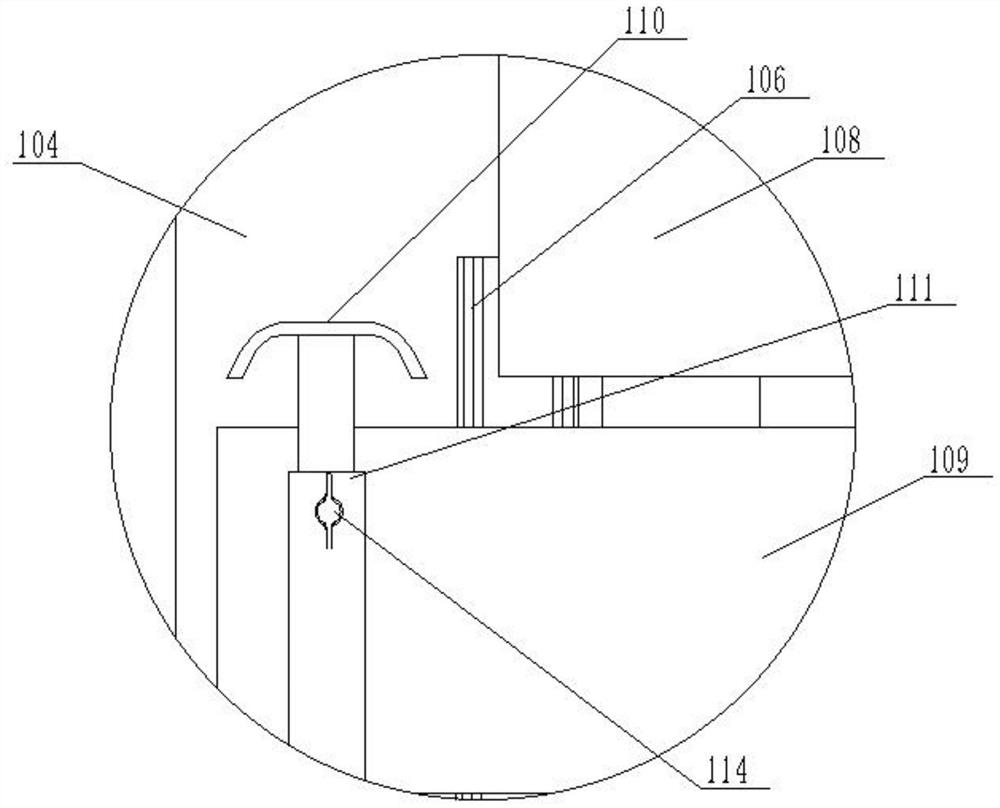

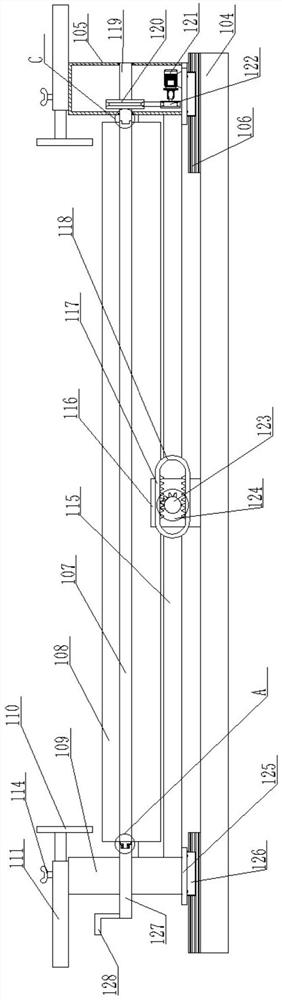

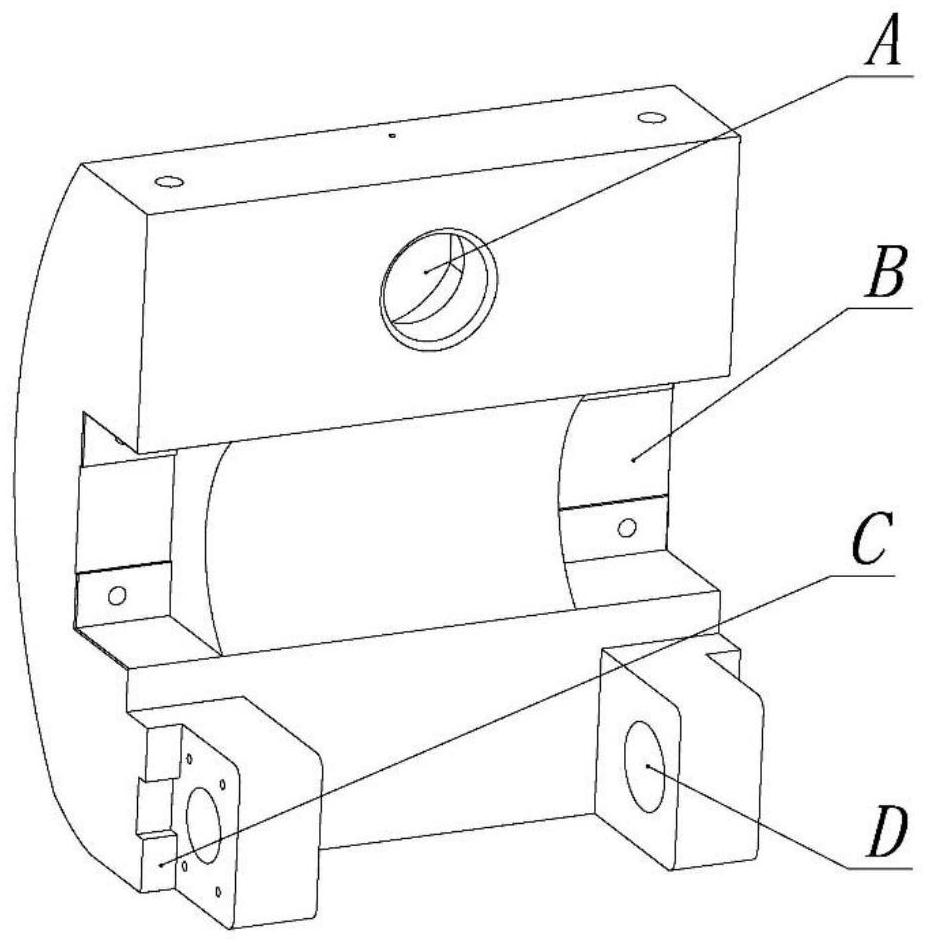

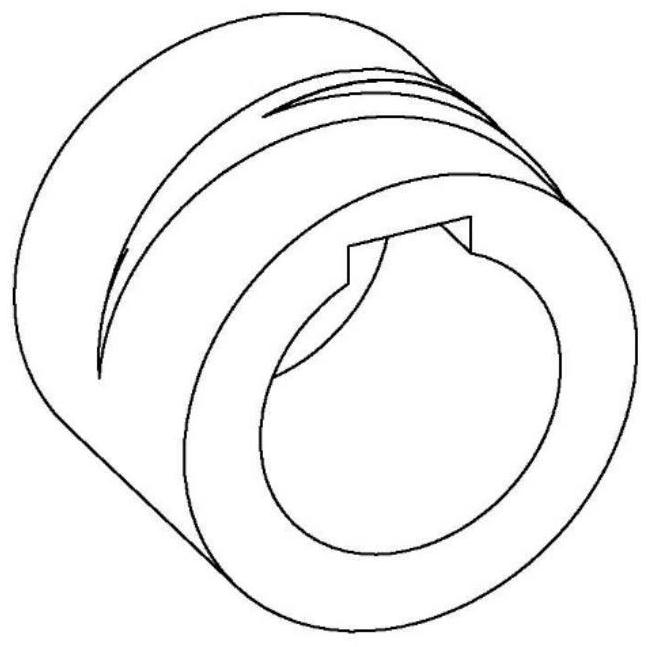

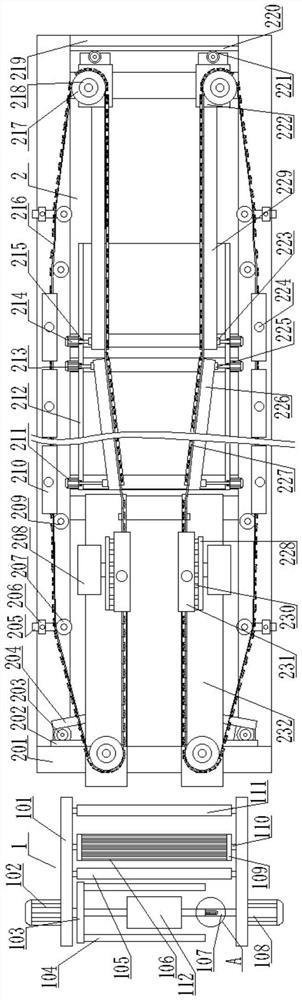

Fast roll changing device of vertical rolling mill

ActiveCN101954379AImprove installation accuracyCompact designMetal rolling stand detailsMetal rolling arrangementsUltimate tensile strengthScrew thread

The invention relates to a fast roll changing device of a vertical rolling mill, belonging roll-type forming mill trains. The fast roll changing device of the vertical rolling mill is characterized in that a slide block which corresponds to each roll in position is provided with two sliding roll-box removing mechanisms; each sliding roll-box removing mechanism comprises a roll-box rack, a press plate, a pull rod and a screw; the slide block is movably provided with the roll-box rack which consists of a base plate, a side vertical plate and the press plate and slides along the slide block; the bottom end of a roll shaft is connected into the base plate, and the top end of the roll shaft is connected into the press plate; a locking groove is arranged in the center of the press plate positioned at one side of the side vertical plate; the screw is articulated with the outer side of the lower part of the roll-box rack which corresponds to the locking groove in position; the center of the screw is in female connection with the bottom end of the pull rod; and the pull rod is clamped and locked in the locking groove of the roll-box rack by twisting a step positioned on the top segment of the pull rod. The invention not only has compact, simple and practical design structure and can fast change the rolls and greatly reduce the labor intensity, but also has the advantages of high production efficiency, convenient operation, very convenient use, and the like.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

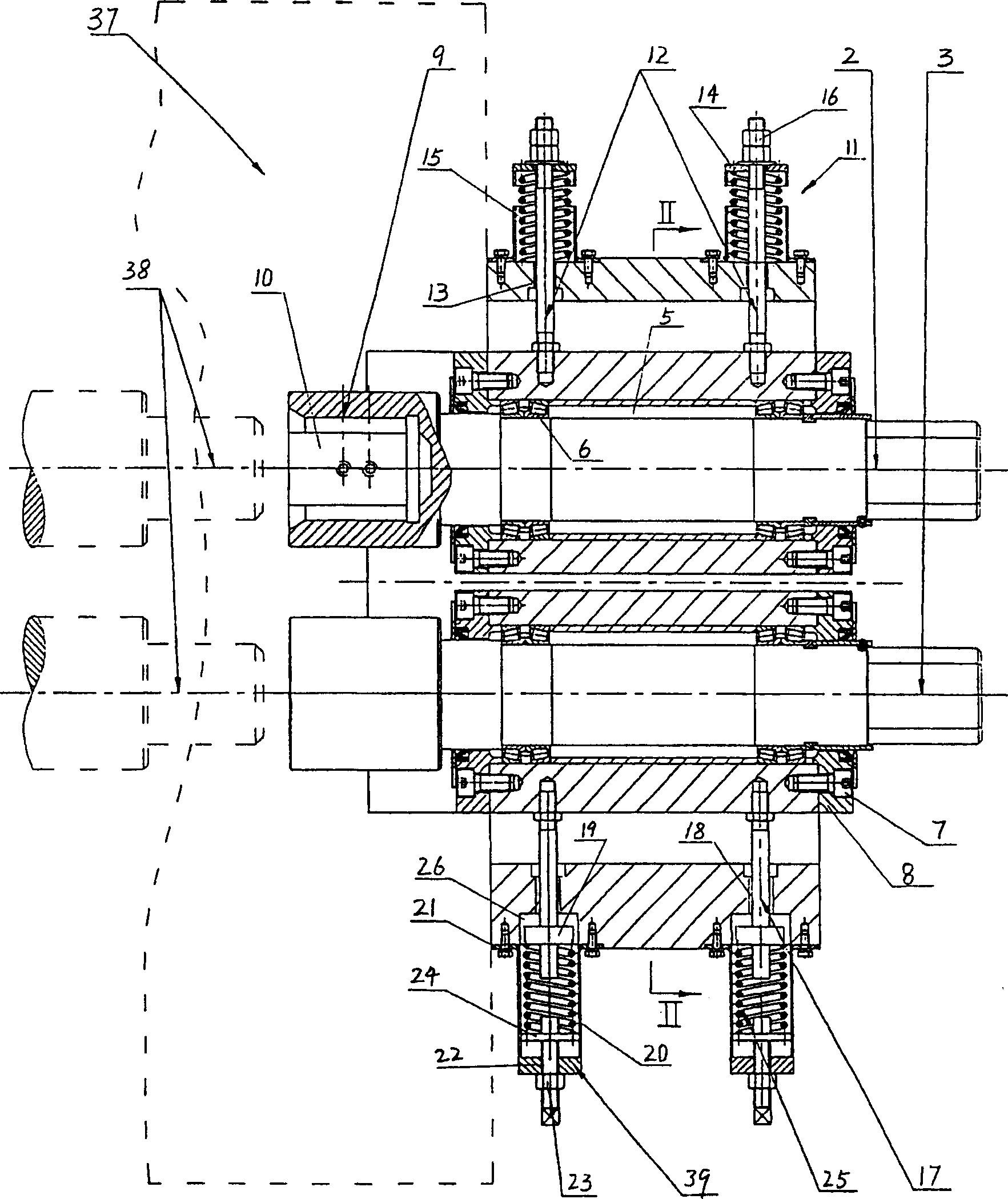

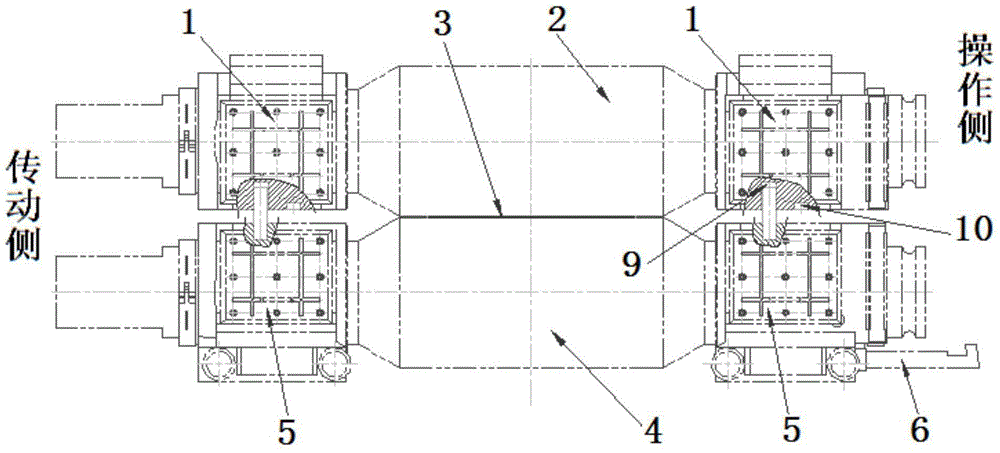

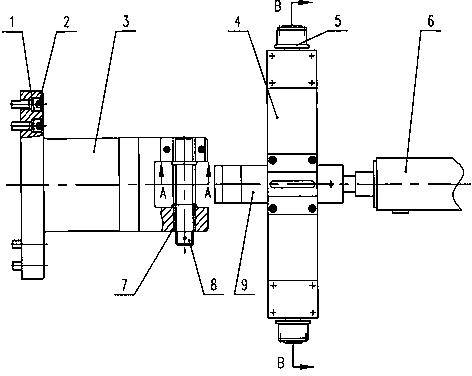

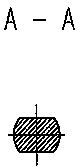

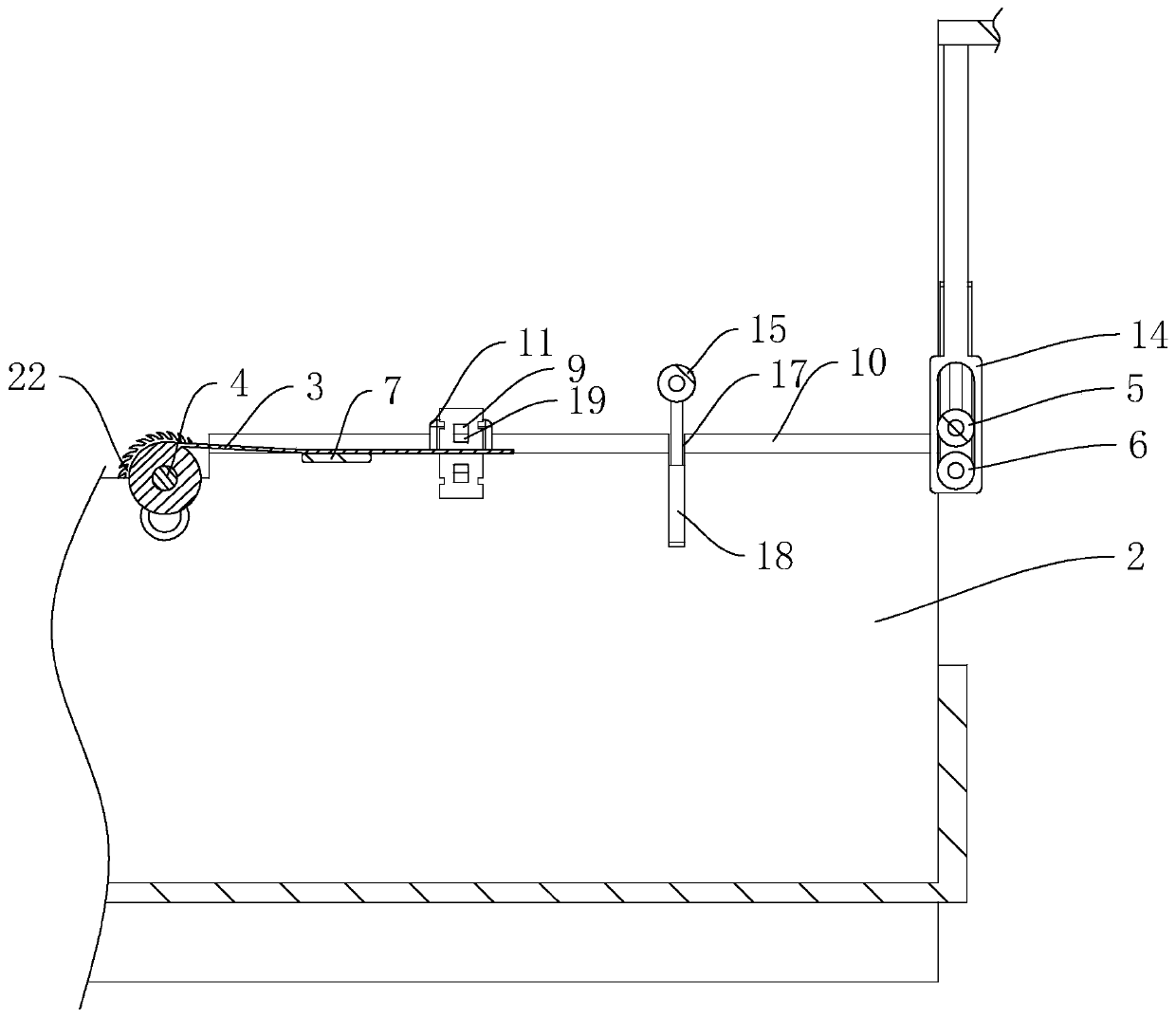

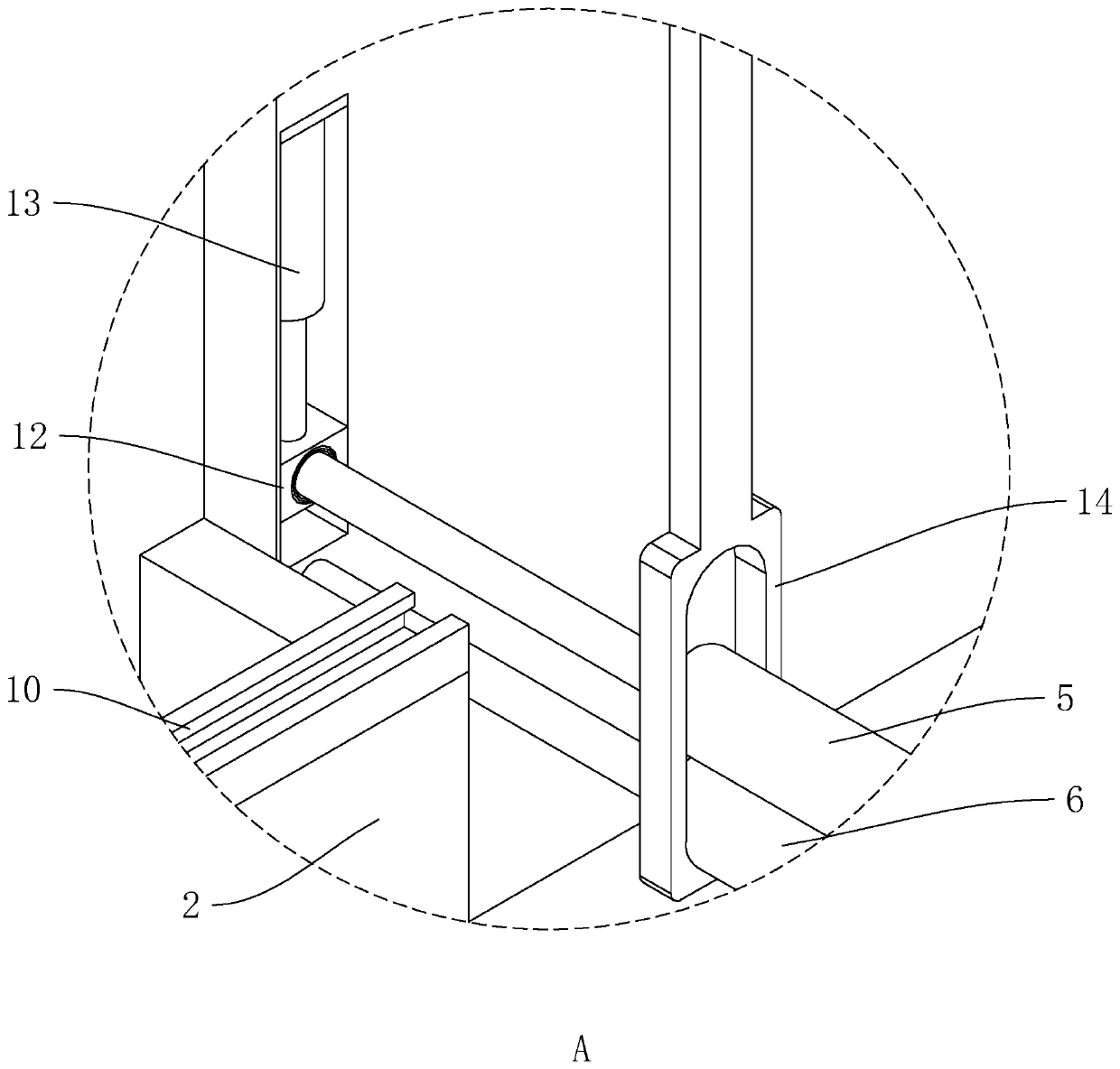

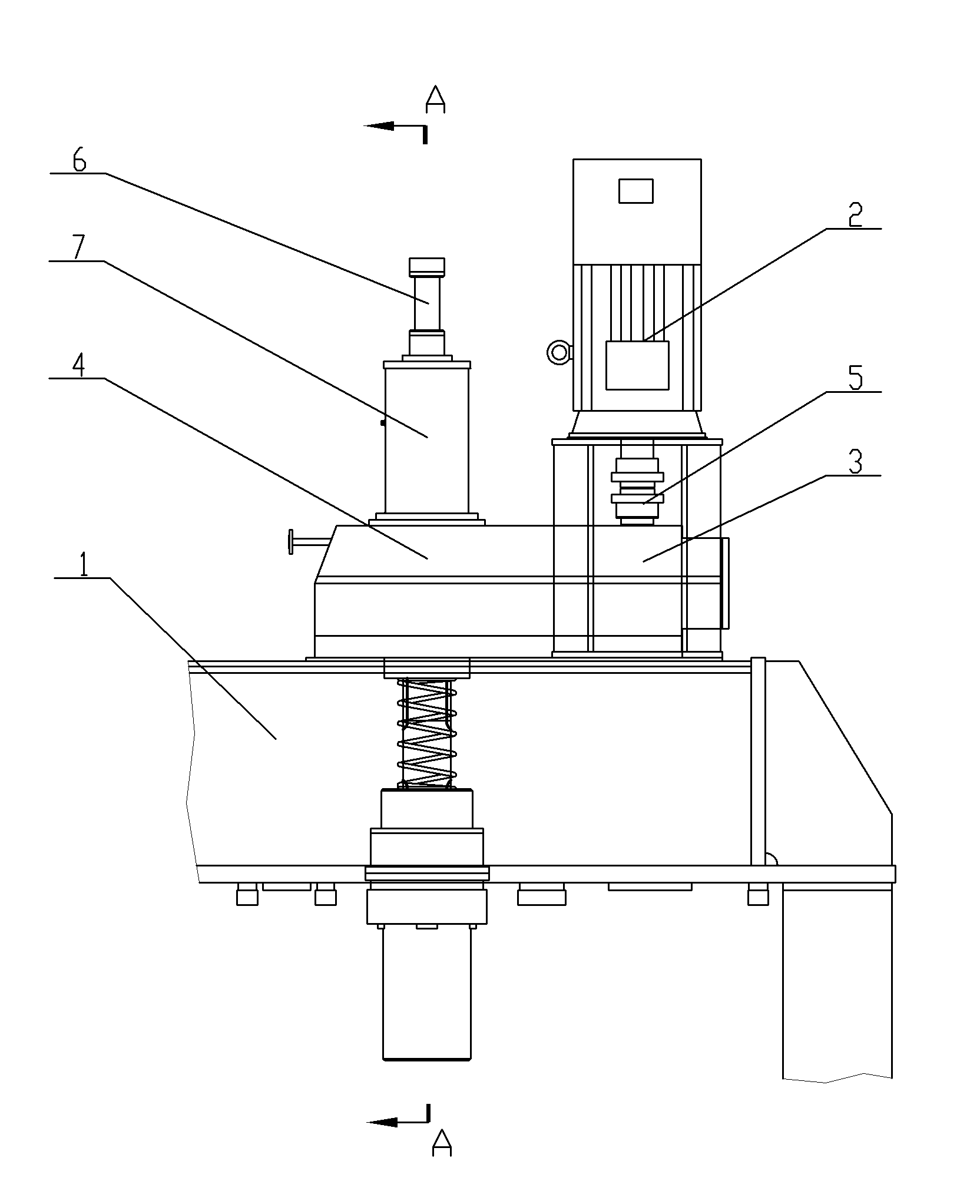

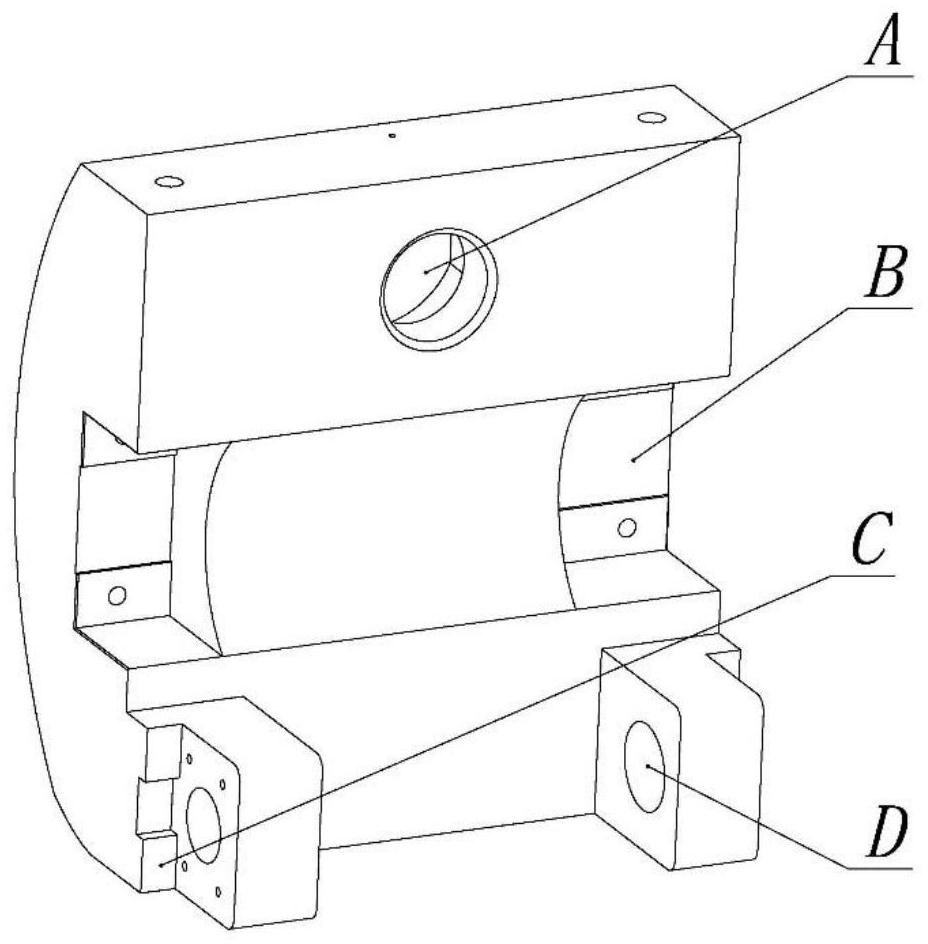

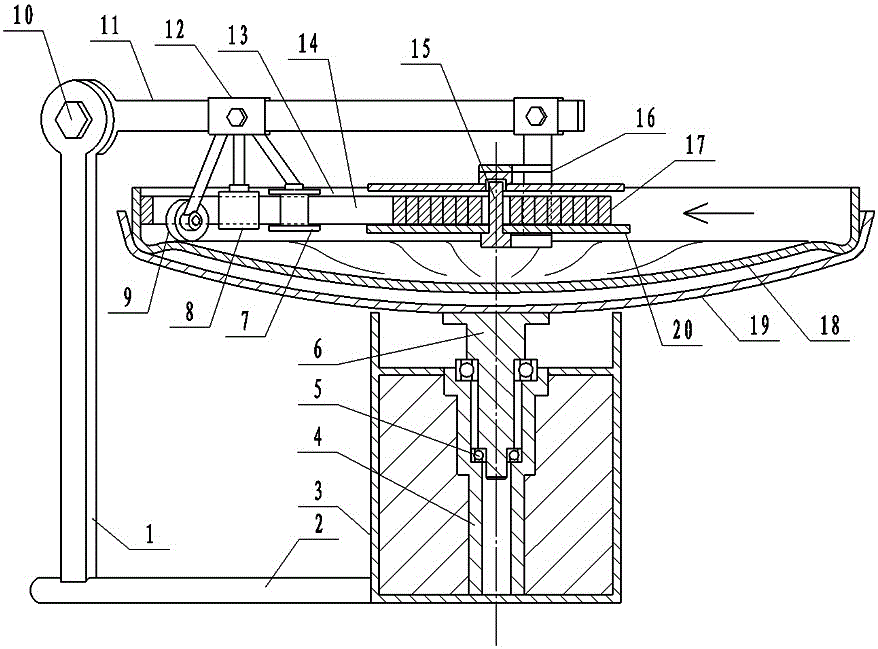

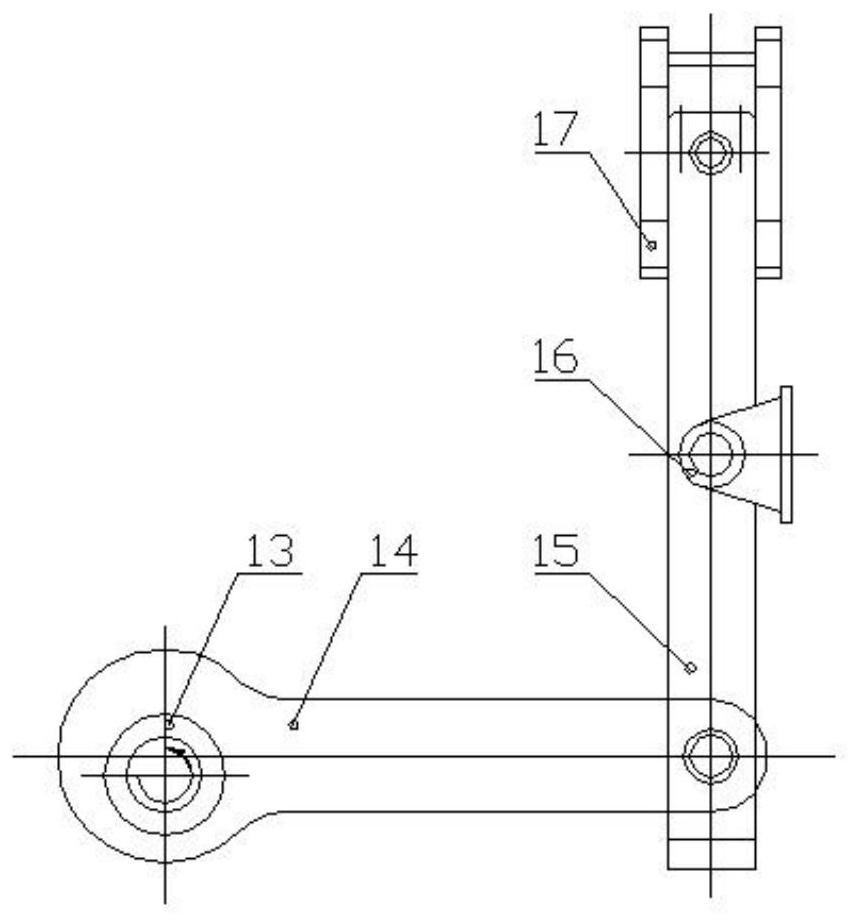

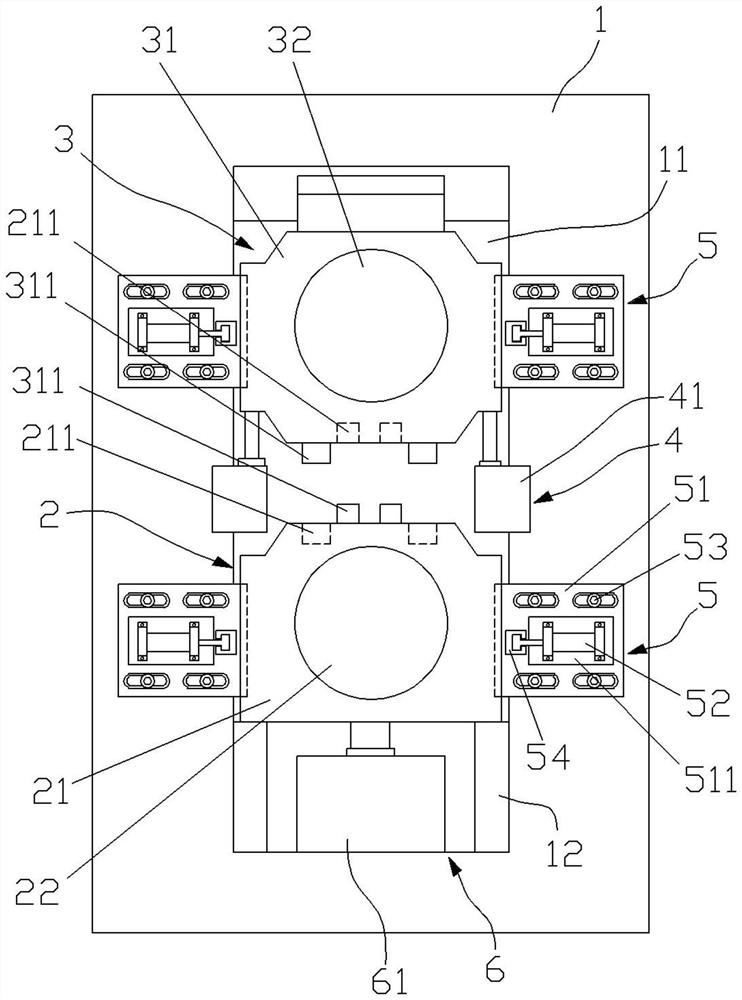

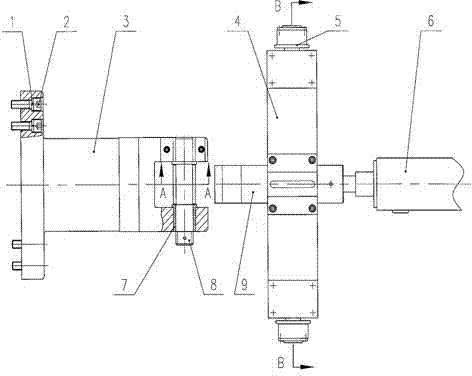

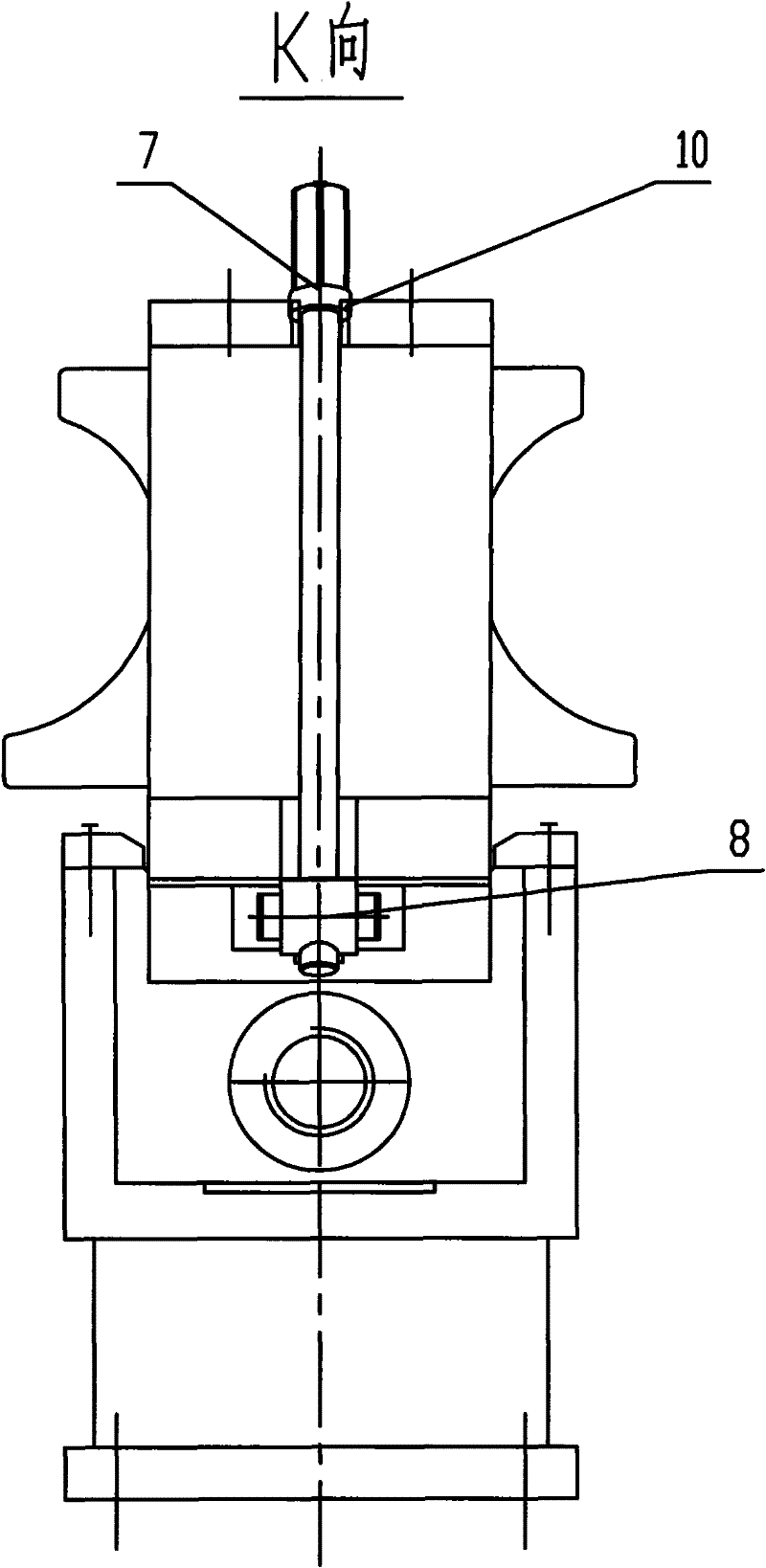

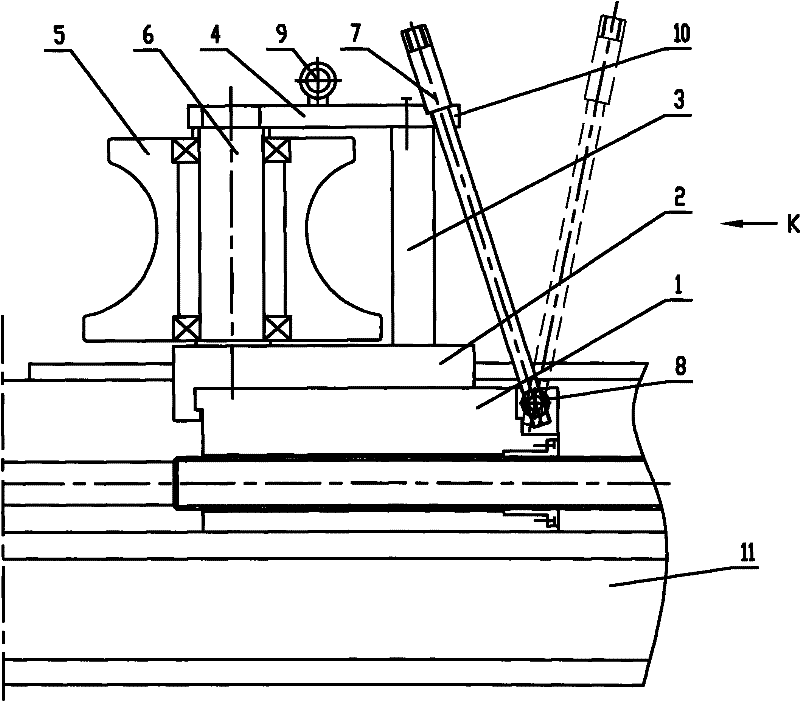

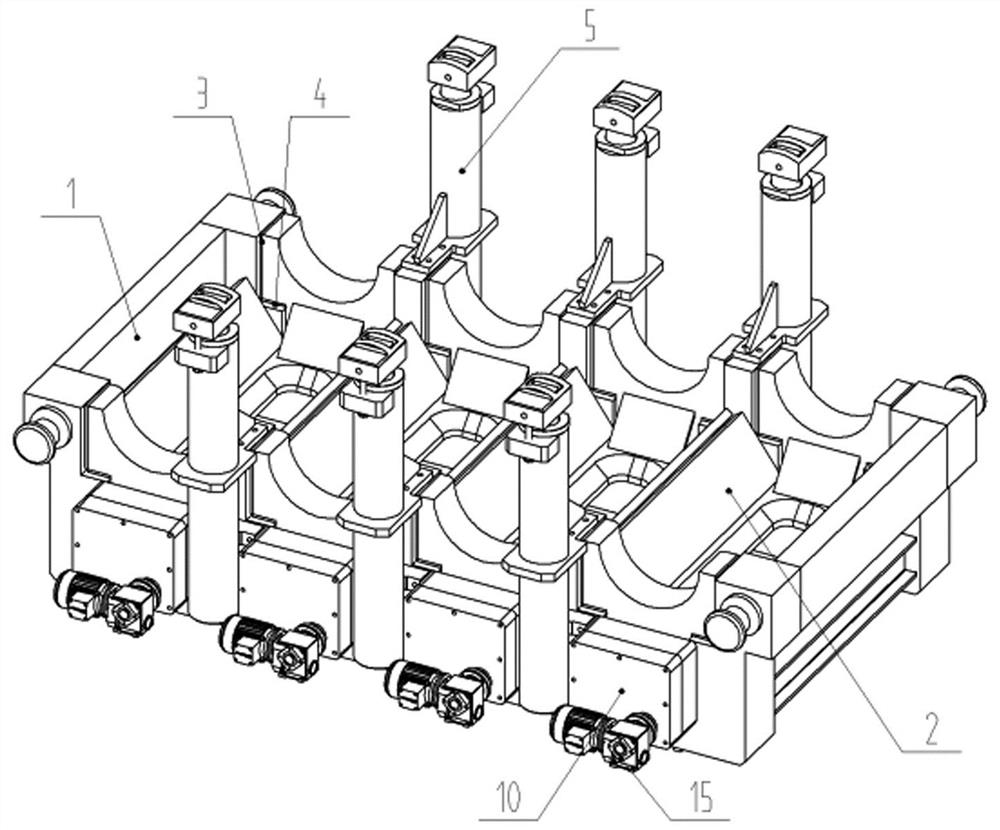

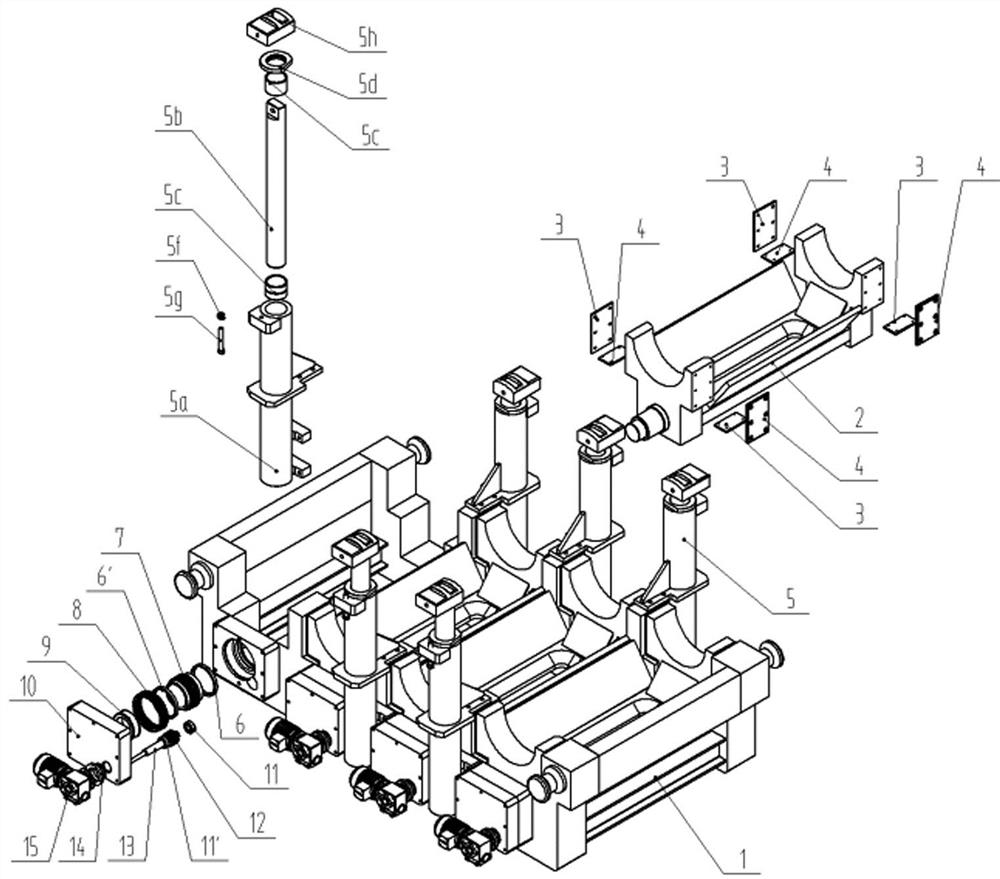

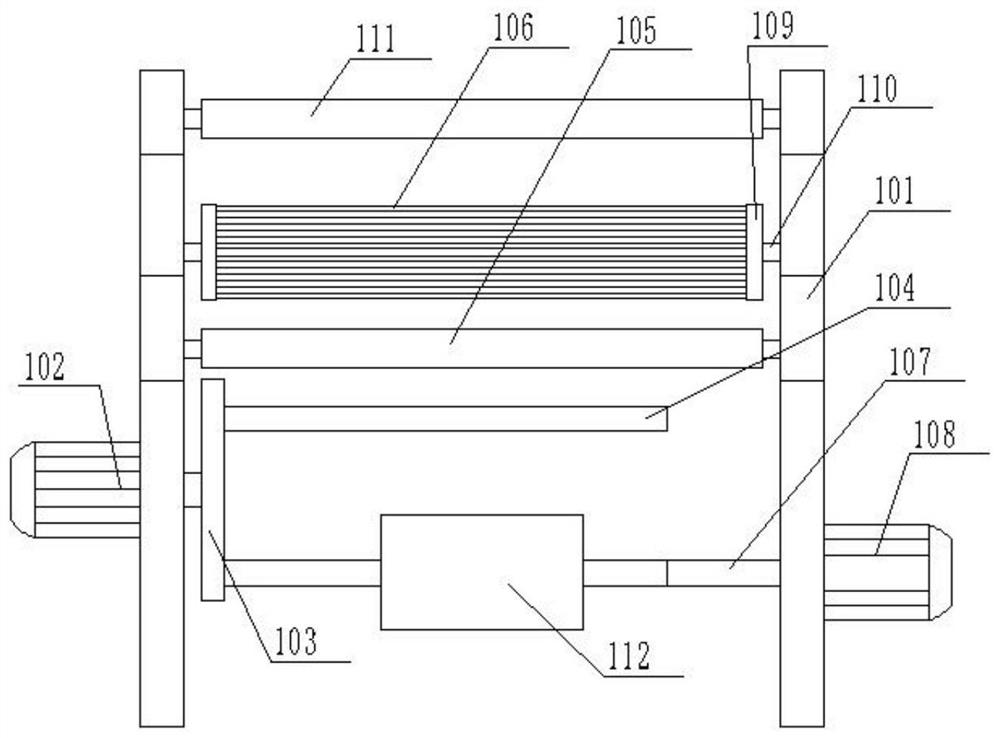

Rapid supporting roller changing mechanism for plate strip rolling mill

ActiveCN103406358AEasy maintenance and operationReduced roll change timeMetal rolling stand detailsMetal rolling arrangementsPiston rodRolling mill

The invention relates to a rapid supporting roller changing mechanism for a plate strip rolling mill. The rapid supporting roller changing mechanism comprises a supporting roller hook (3) and a connecting shaft (8) and is driven by an oil cylinder (6). The rapid supporting roller changing mechanism is characterized in that the connecting shaft (8) is fixed on the supporting roller hook (3) through a bearing and a bearing gland (14), the cross section of the middle of the connecting shaft (8) is in a flat shape with two symmetrically-scraped sides, a shaft hole (18) and an opening both corresponding to the connecting shaft (8) are formed at one end of an oil cylinder connector (9), the diameter of the shaft hole (18) is not less than the section diameter of the connecting shaft (8), a gap at the opening of the end portion of the shaft hole (18) is larger than the distance between two symmetric planes of the connecting shaft (8) and smaller than the section diameter of connecting shaft (8), the piston rod (19) of the oil cylinder (6) is detachably connected at one end of the oil cylinder connector (9), and the oil cylinder connector (9) is fixed on a frame (4) with wheels (5). The rapid supporting roller changing mechanism has the advantages that convenience in operation and maintenance is realized, roller changing time is saved, and auxiliary rolling time is reduced.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

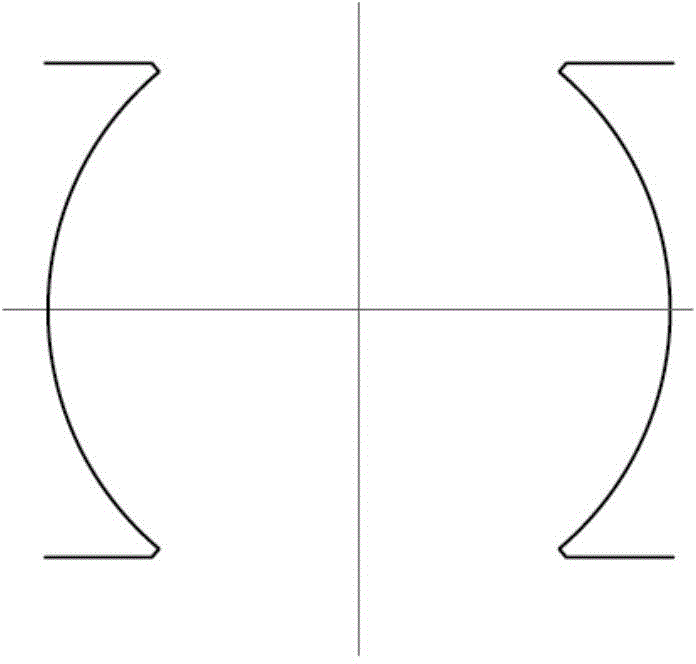

Large thick-wall special-shaped pipe cold roll forming method

InactiveCN105583230AQuality improvementWide forming rangeMetal rolling stand detailsMetal rolling arrangementsThick wallEngineering

The invention belongs to the technical field of machine manufacturing, and particularly relates to a large thick-wall special-shaped pipe cold roll forming method. The method comprises the following steps that firstly, at the round pipe selecting stage, a round pipe with the corresponding diameter is selected according to the specification of a needed square pipe or rectangular pipe; secondly, at the rough forming stage, five universal rolling mills are totally arranged, transformation rollers of flat rollers and vertical rollers are adopted for enabling the round pipe to be formed into the needed square pipe or rectangular pipe, wherein the flat rollers and the vertical rollers are symmetric, and the flat rollers are perpendicular to the vertical rollers; thirdly, at the finish forming stage, the square pipe or rectangular pipe formed through rough rolling is subjected to finishing through a sixth flat roller rolling mill, and the square pipe or rectangular pipe can meet various precision requirements; and fourthly, the torsion resistance is adjusted, the square steel pipe or rectangular steel pipe subjected to finishing enters a straightener, the torsion resistance of the square pipe or rectangular pipe is adjusted, the square pipe or rectangular pipe of the needed specification is formed, and accordingly the product quality can be guaranteed.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

Automatic high-speed vacuum blister forming machine

InactiveCN110696335AQuick roll changeImprove roll changing efficiencyMolding machineElectric machinery

The invention discloses an automatic high-speed vacuum blister forming machine, and relates to the field of blister forming equipment. According to the technical key points, the automatic high-speed vacuum blister forming machine comprises a blister forming machine body and a feeding device, wherein the feeding device comprises a placing frame, and a material roller with a plastic sheet wound around is rotationally connected on the placing frame; one end, close to the blister forming machine body, of the placing frame is rotationally connected with an upper pressing roller and a lower pressingroller, wherein a placing plate is horizontally arranged on the side, facing the lower pressing roller, of the material roller, the placing plate is arranged in the axial direction of the material roller, the upper surface of the placing plate is coplanar with the highest point of the surface of the lower pressing roller, and one end of the lower pressing roller is provided with a motor for driving the lower pressing roller to rotate; and the two ends, located on the placing plate, of the placing frame are correspondingly provided with finger air cylinders for clamping the plastic sheet, sliding rails are arranged on the placing frame in the moving direction of the plastic sheet, sliding blocks are slidably connected in the sliding rails, the sliding blocks are fixedly connected with cylinder bodies of the finger cylinders, and a driving device for driving the sliding blocks to move along the sliding rails are arranged on the placing frame. The automatic high-speed vacuum blister forming machine has the advantages of being high in roll changing efficiency and capable of reducing potential safety hazards.

Owner:苏州耀鑫新型包装材料有限公司

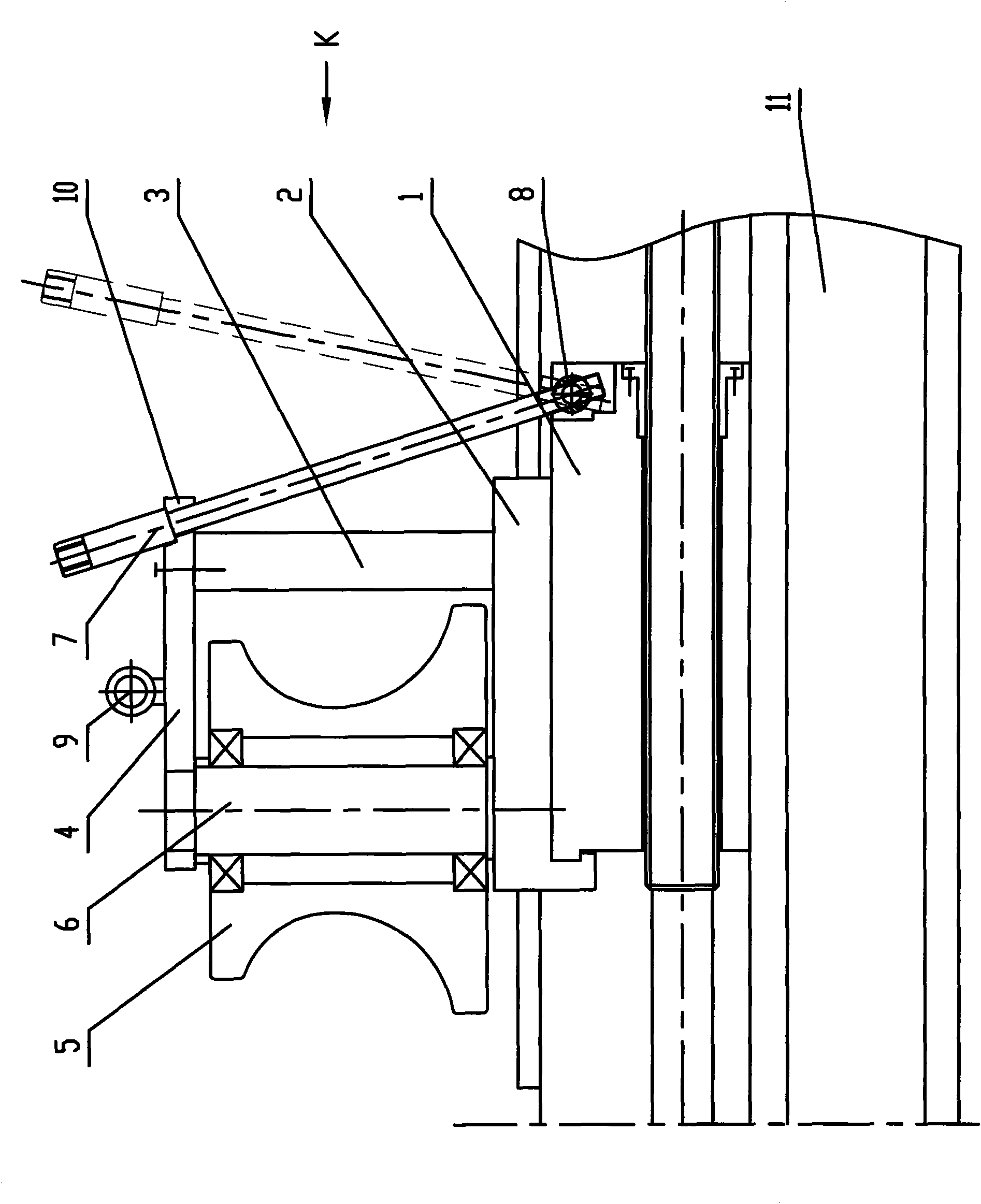

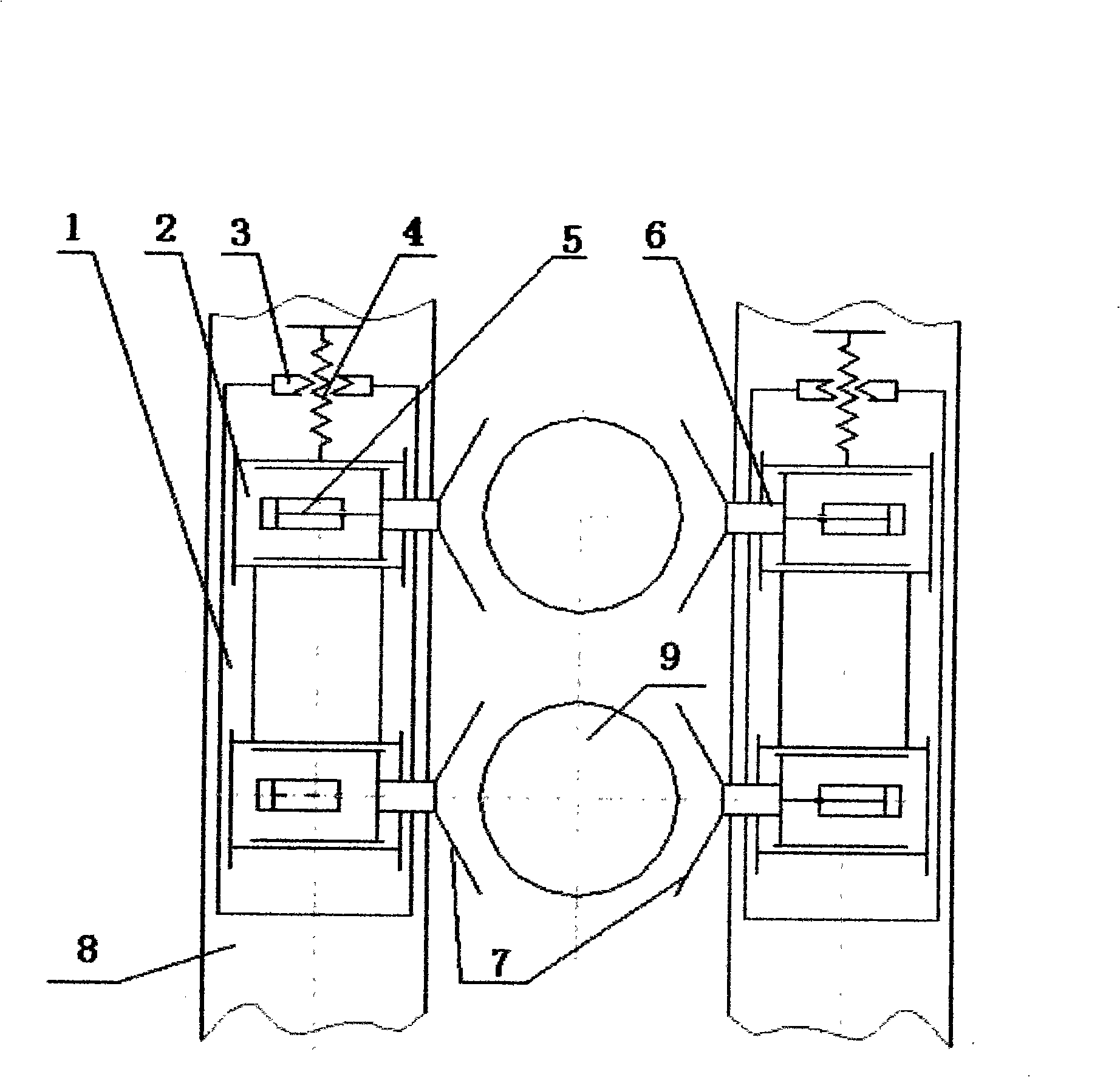

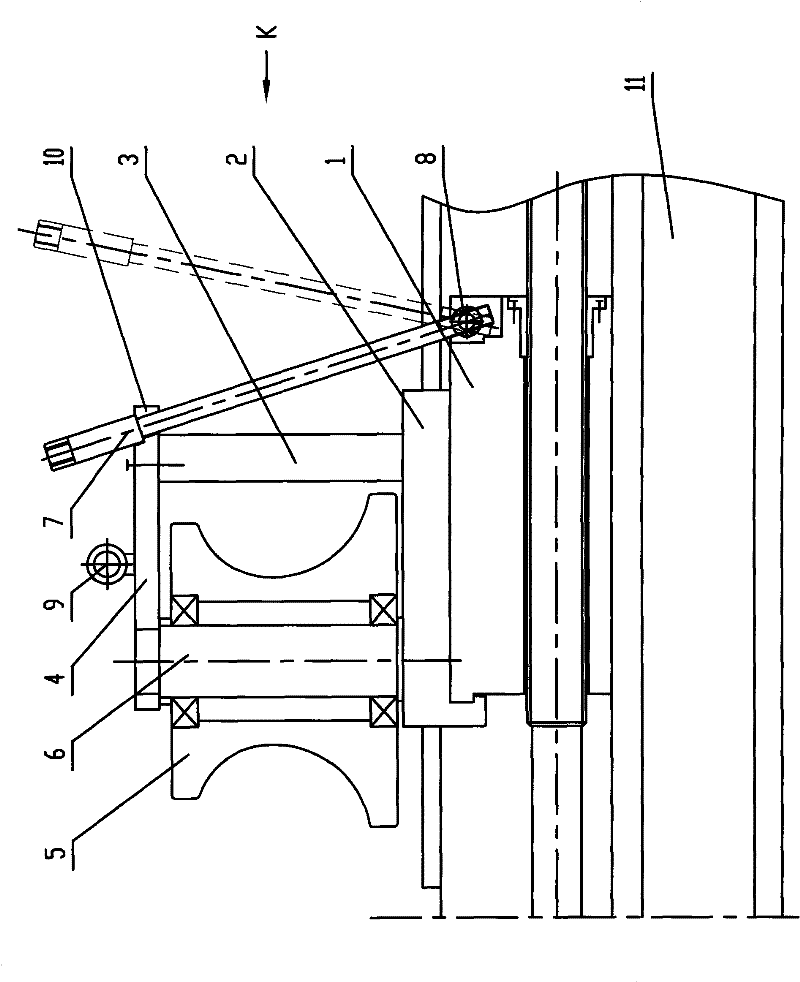

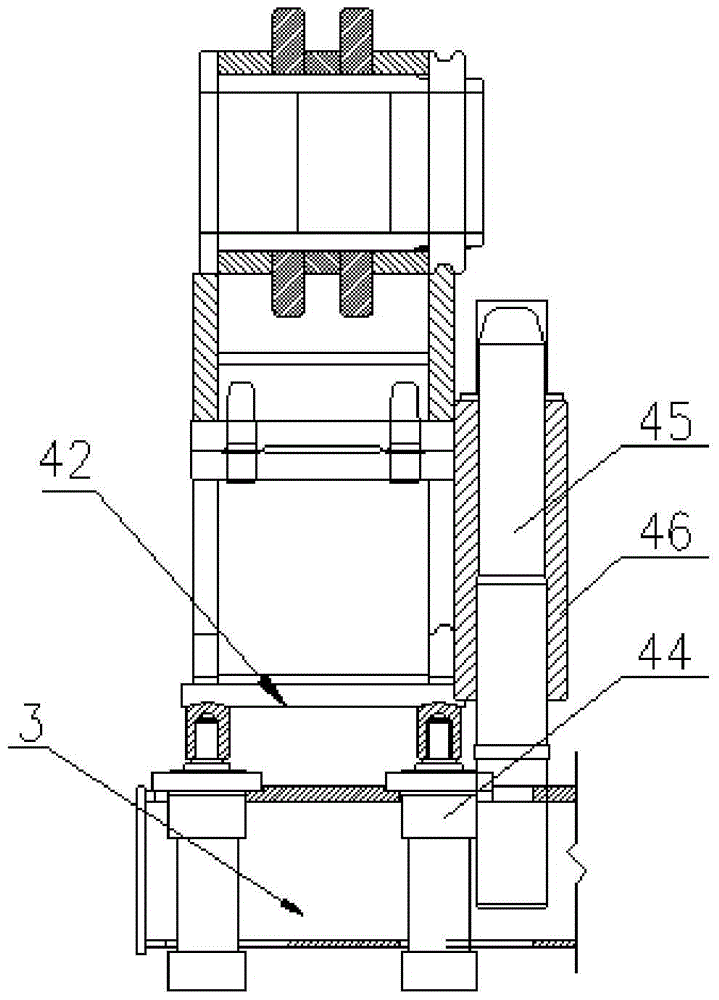

Floating type equipment for enclasping spindle nose

InactiveCN101352730AQuick roll changeSimple structureMetal rolling stand detailsMetal rolling arrangementsNoseEngineering

The invention belongs to the field of metallurgical equipment, and in particular relates to a floating type spindle head clasping device for a hot rolling mill assembly to realize quick roll changing. The device is characterized in that a vertical slide rail (1) is fixed on the two sides of a driving window of a rolling mill housing (8), the two sides of the vertical slide rail (1) are respectively provided with vertical moving slide blocks and a horizontal slide rail (2); a lifting nut (3) is fixed on the upper end of the vertical slide rail (1); the lower end of a lifting screw (4) is fixed on the vertical moving slide blocks and the horizontal slide rail (2); the lifting nut (3) is connected with the lifting screw (4); the lifting screw (4) moves up and down along the lifting nut (3) to drive the two vertical moving slide blocks and the horizontal slide rail (2) to move up and down; the vertical moving slide blocks at the two sides and the horizontal slide rail (2) are respectively connected with a clasping oil cylinder (5), and a piston rod (6) is connected with a clasping V-shaped block (7). The floating type spindle head clasping device has the advantages of simple structure, safe and reliable performance, which can realize quick roll changing.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

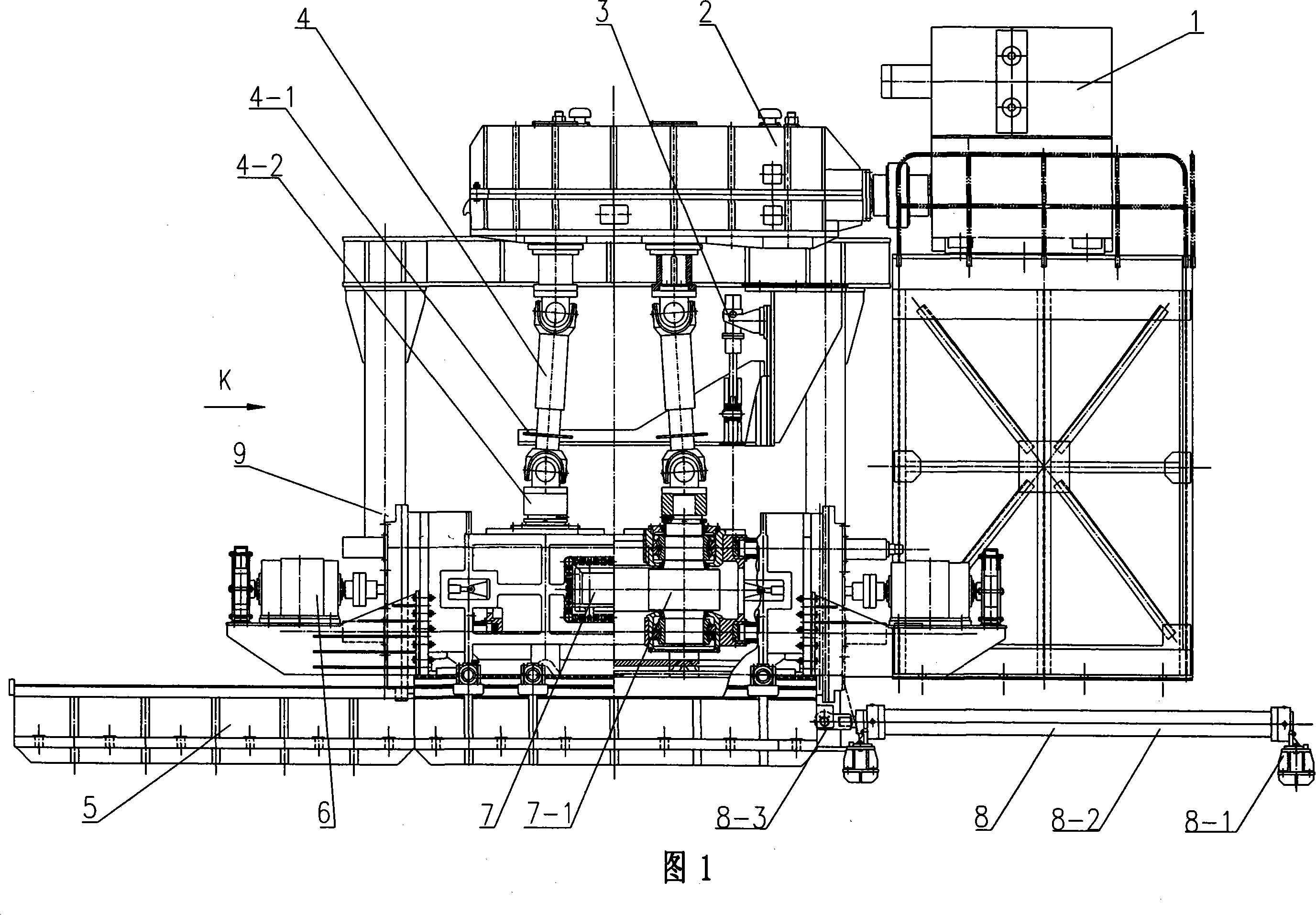

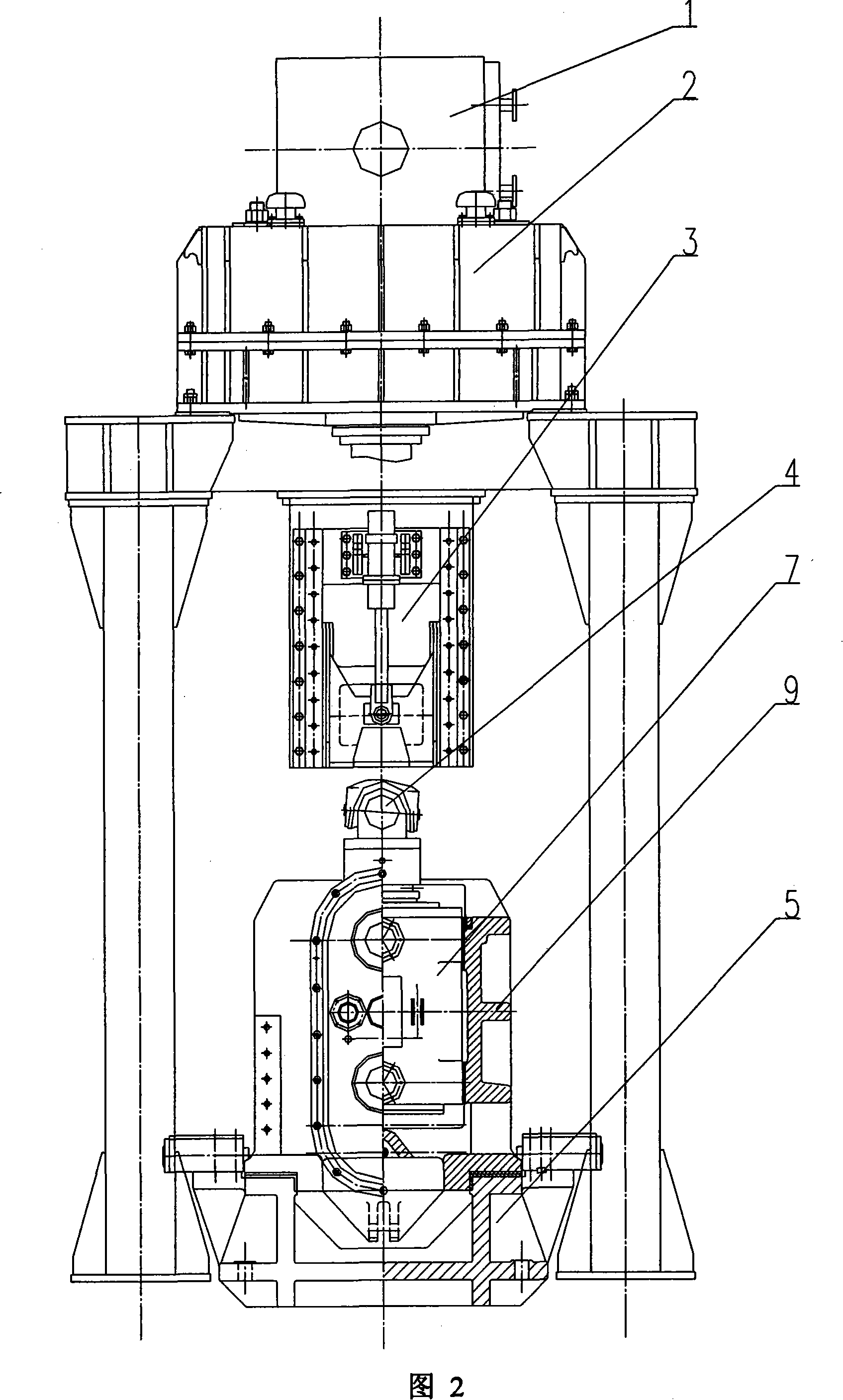

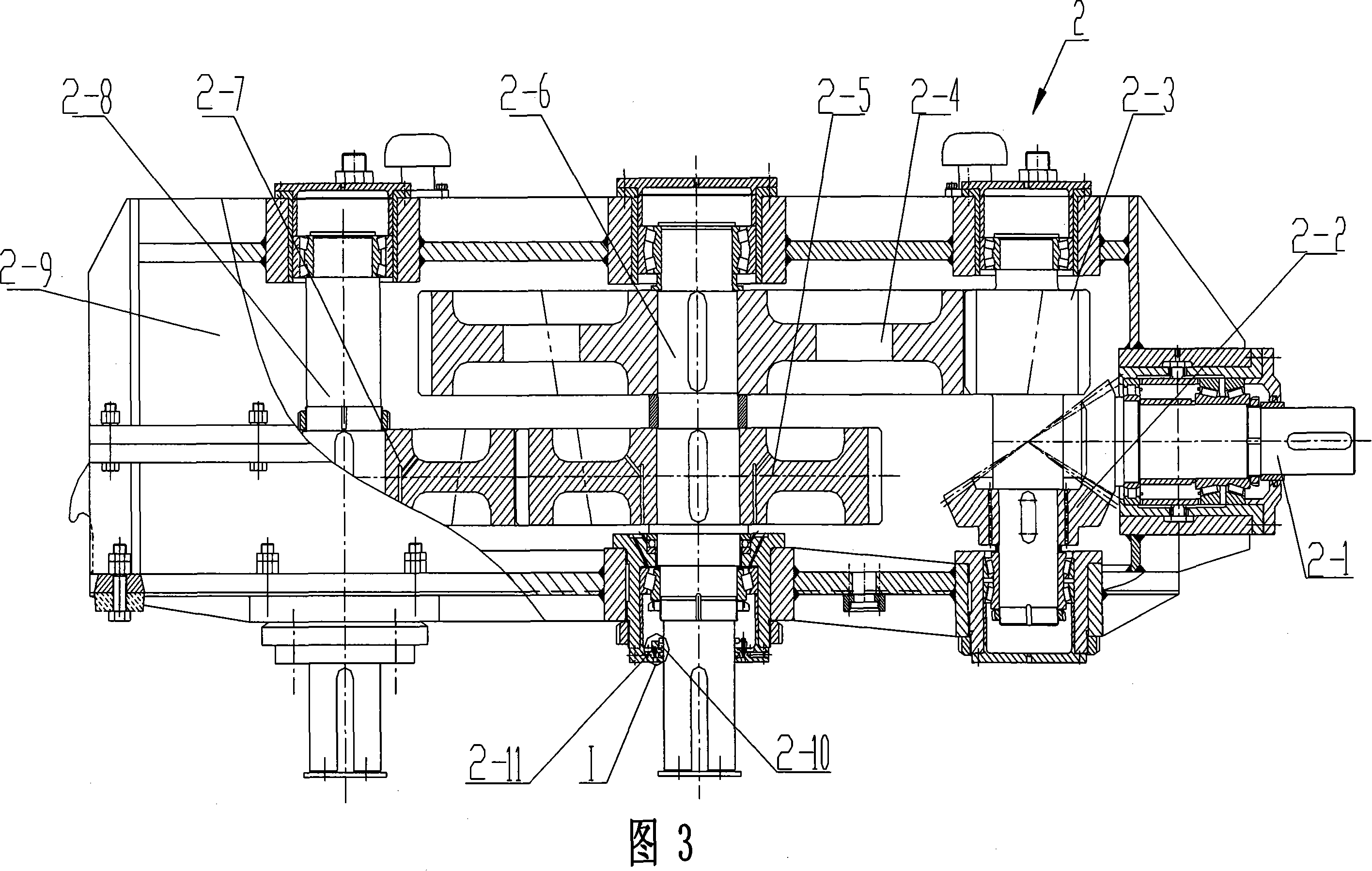

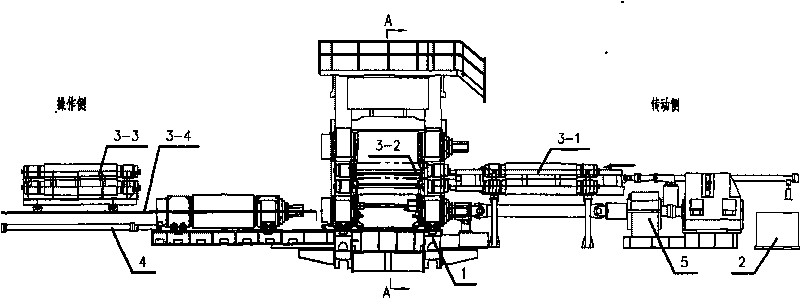

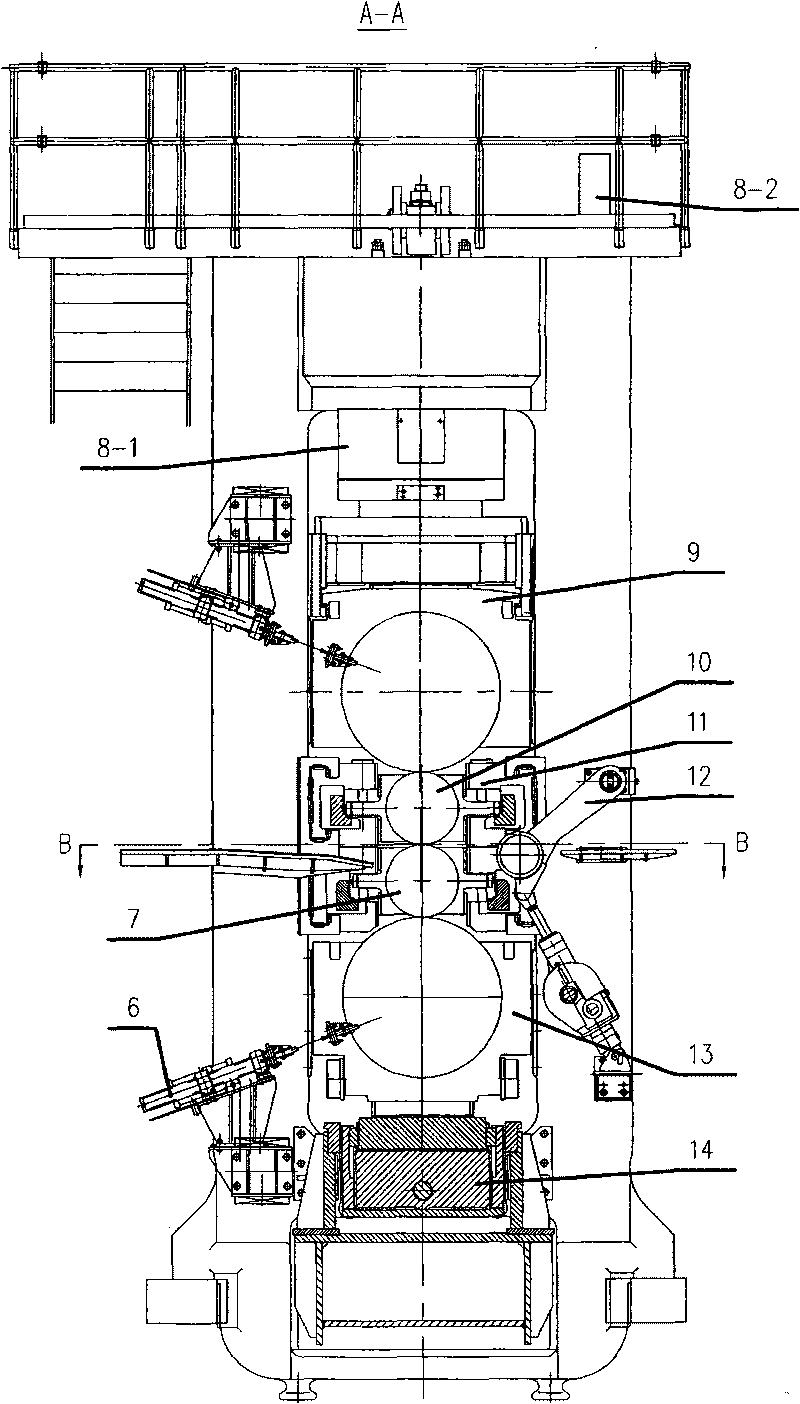

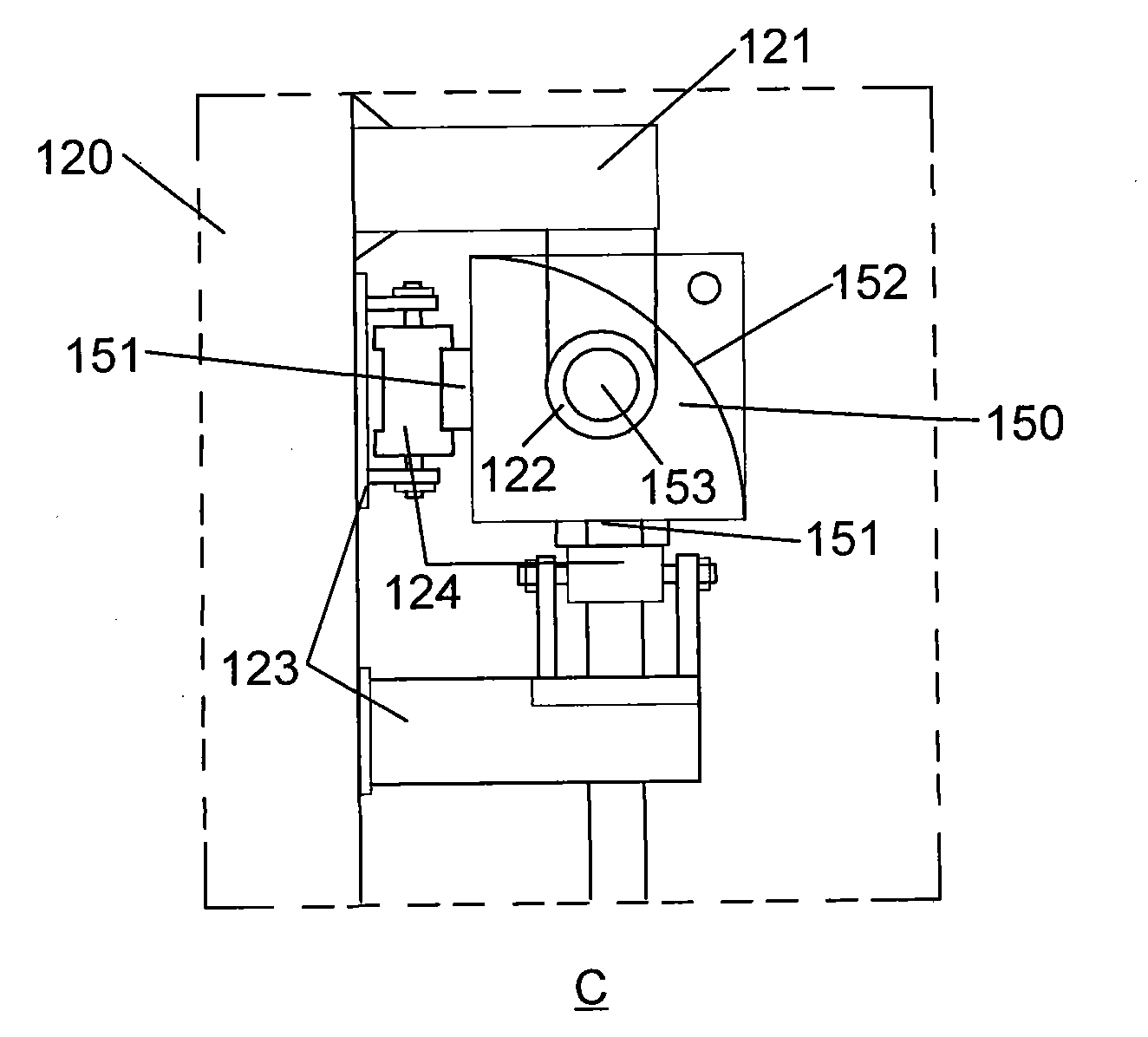

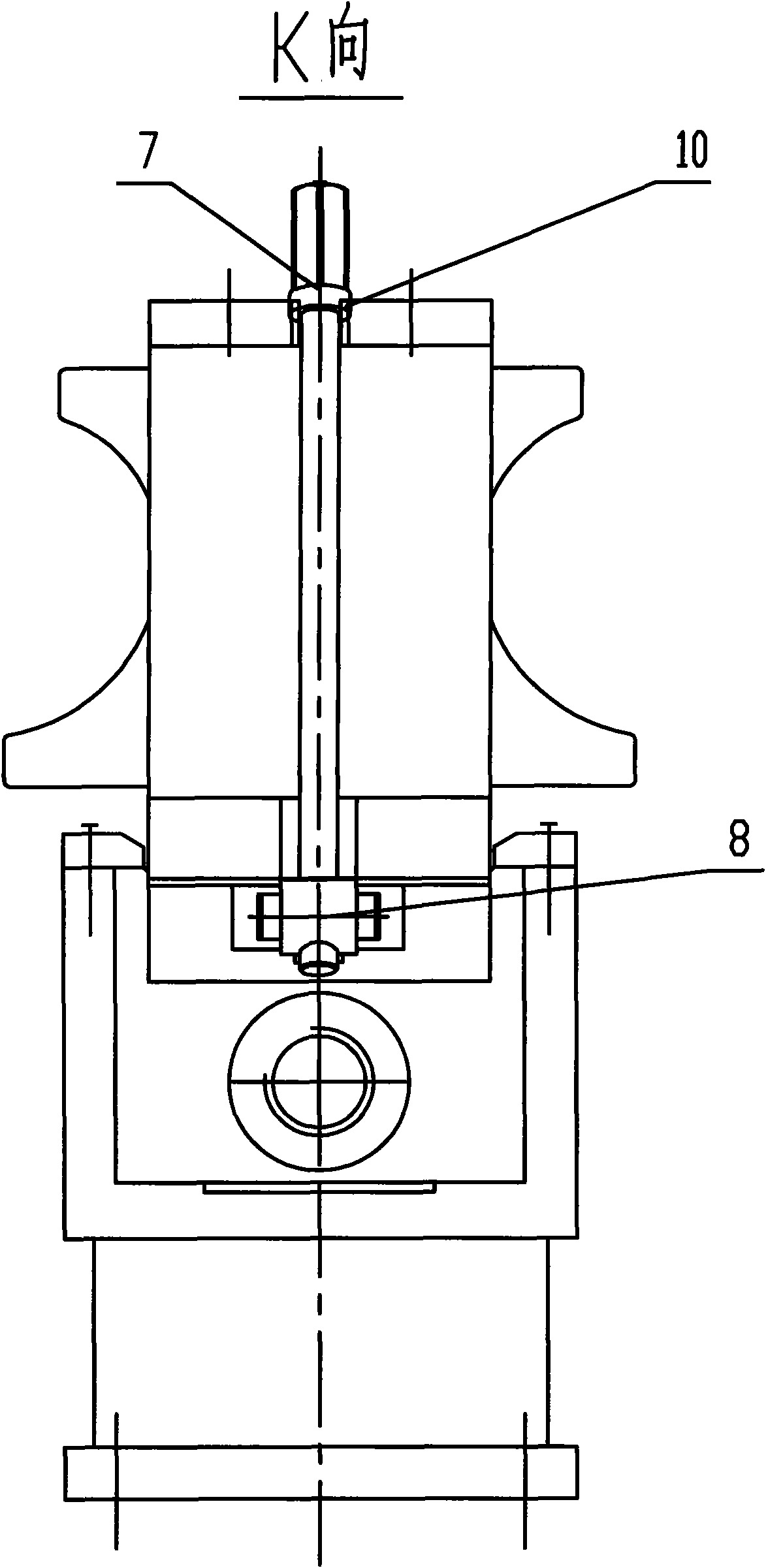

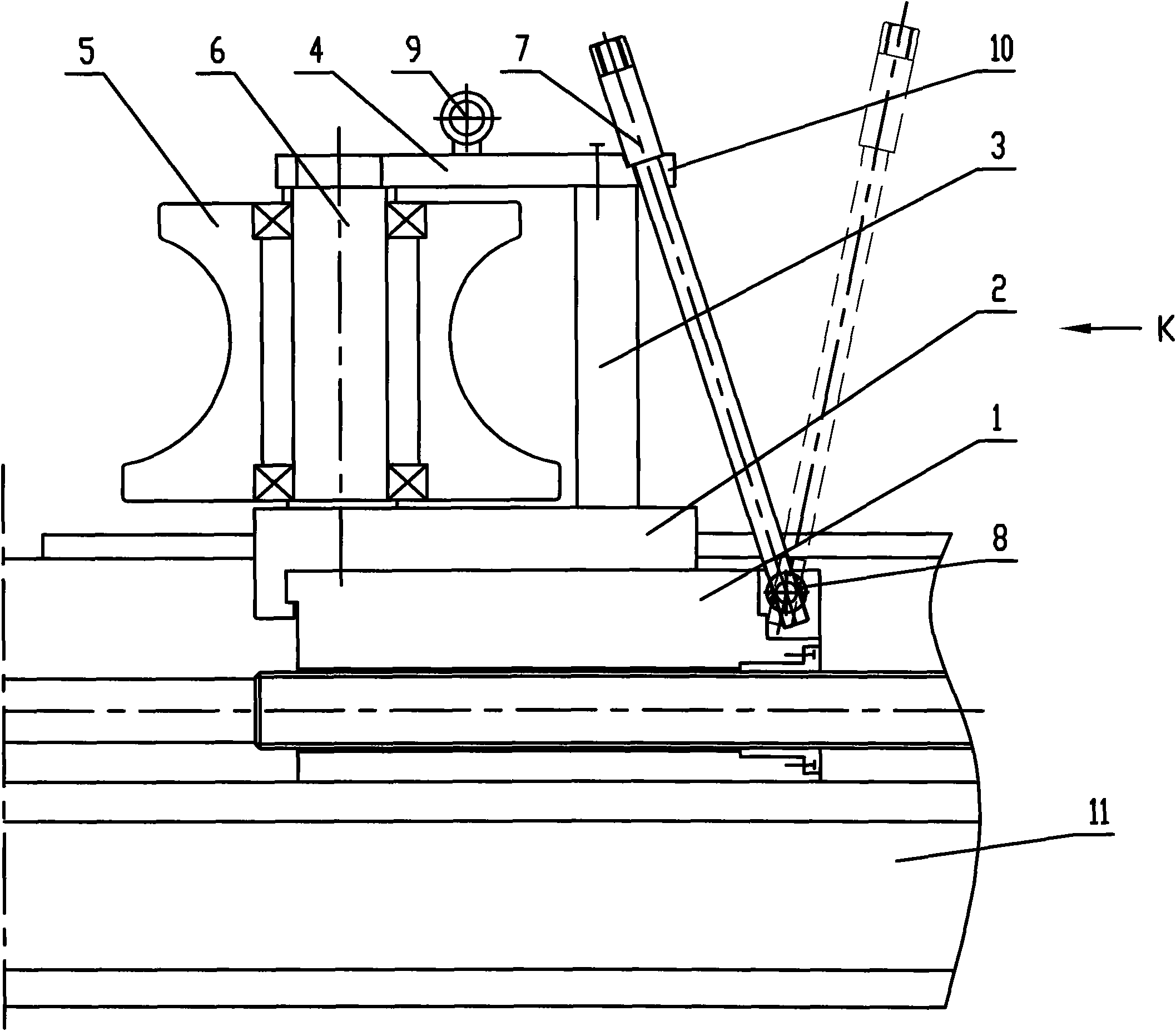

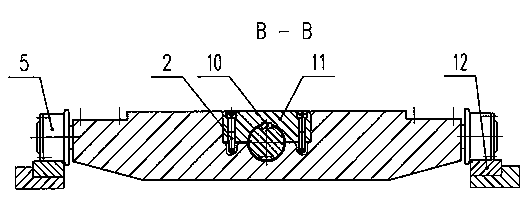

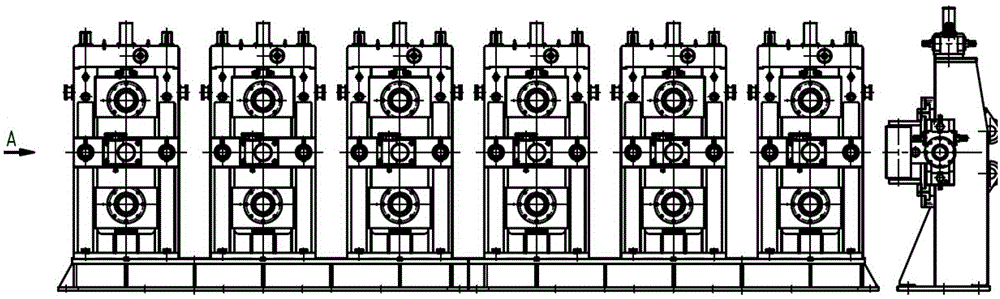

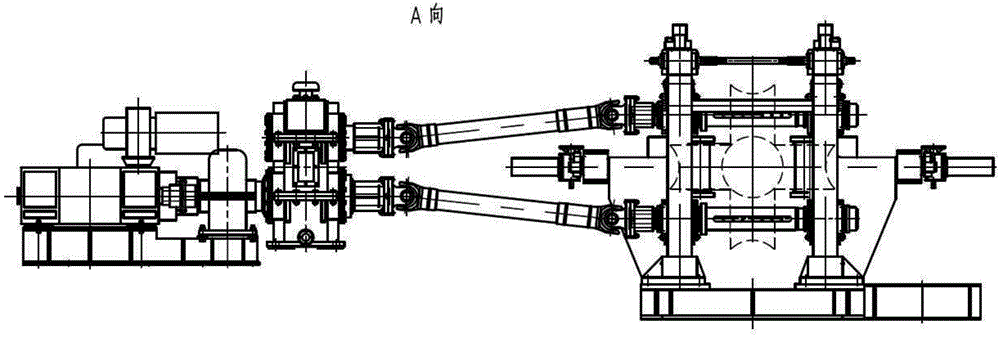

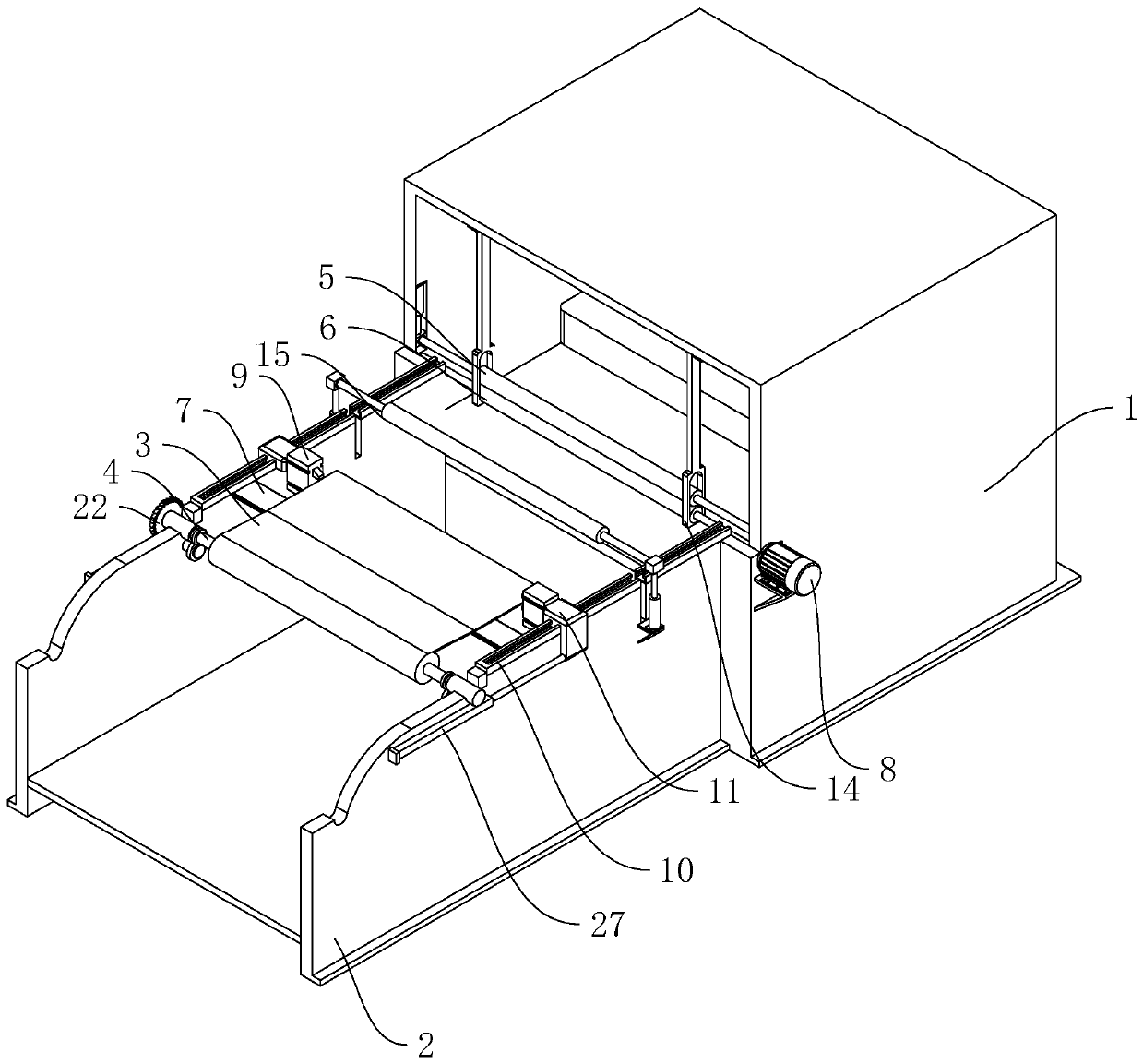

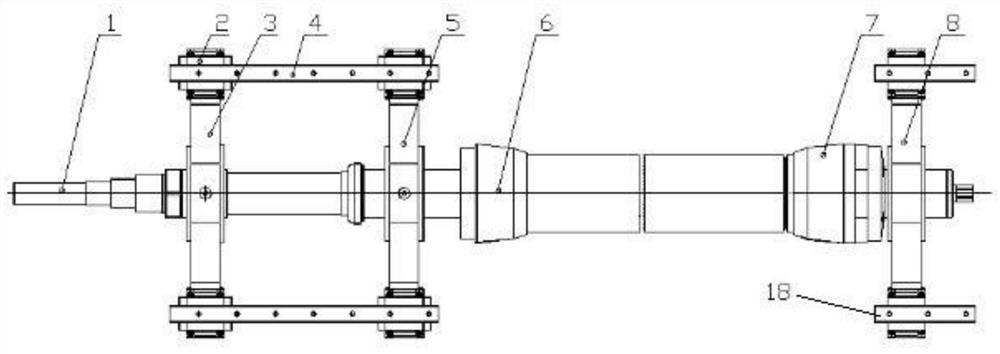

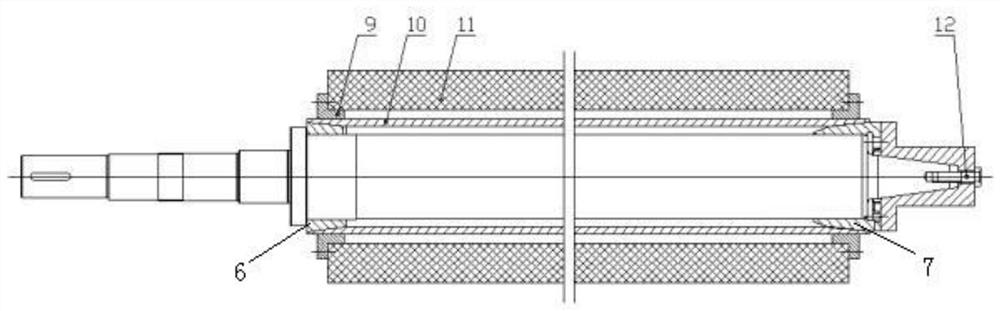

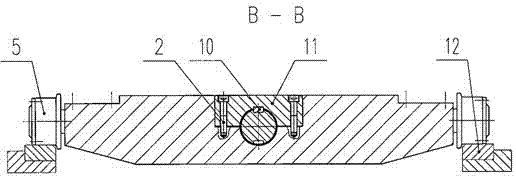

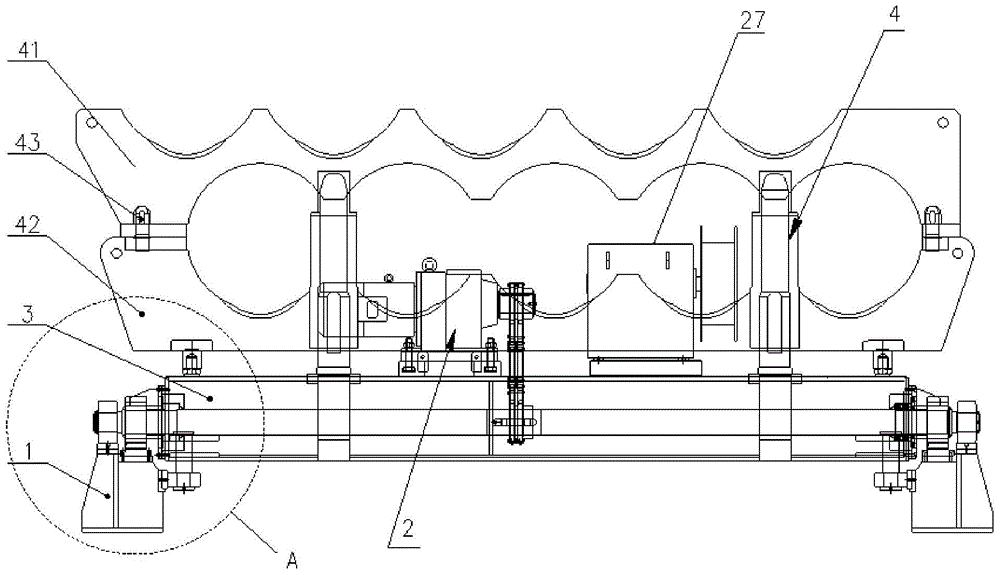

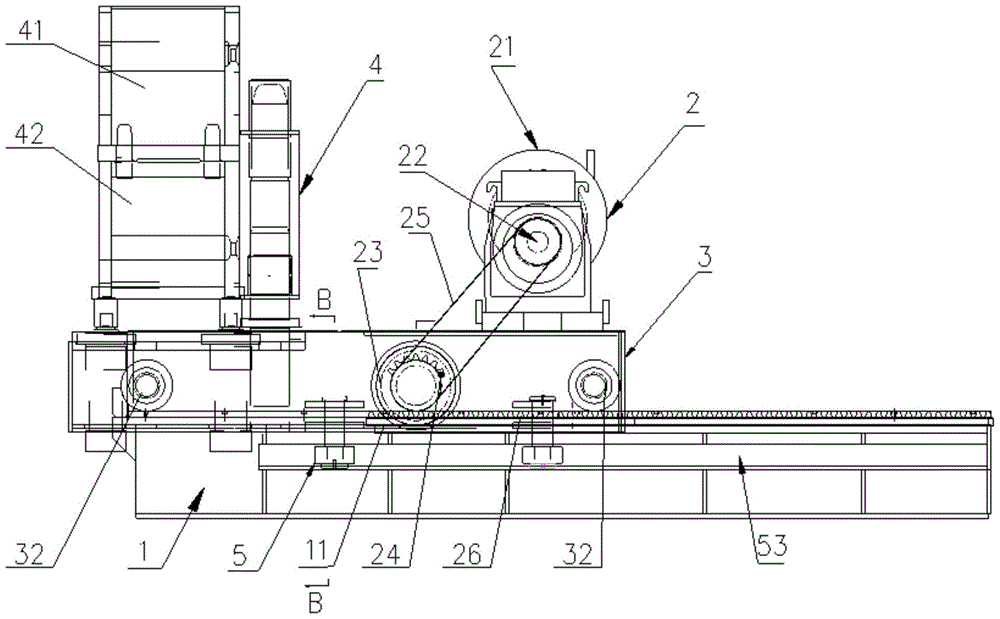

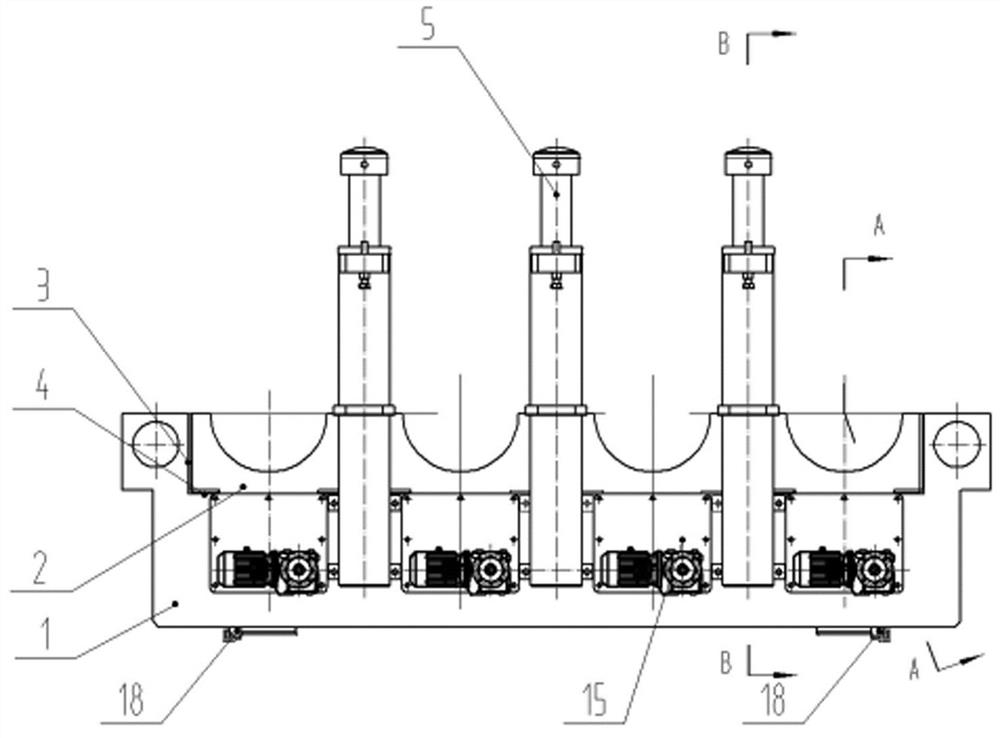

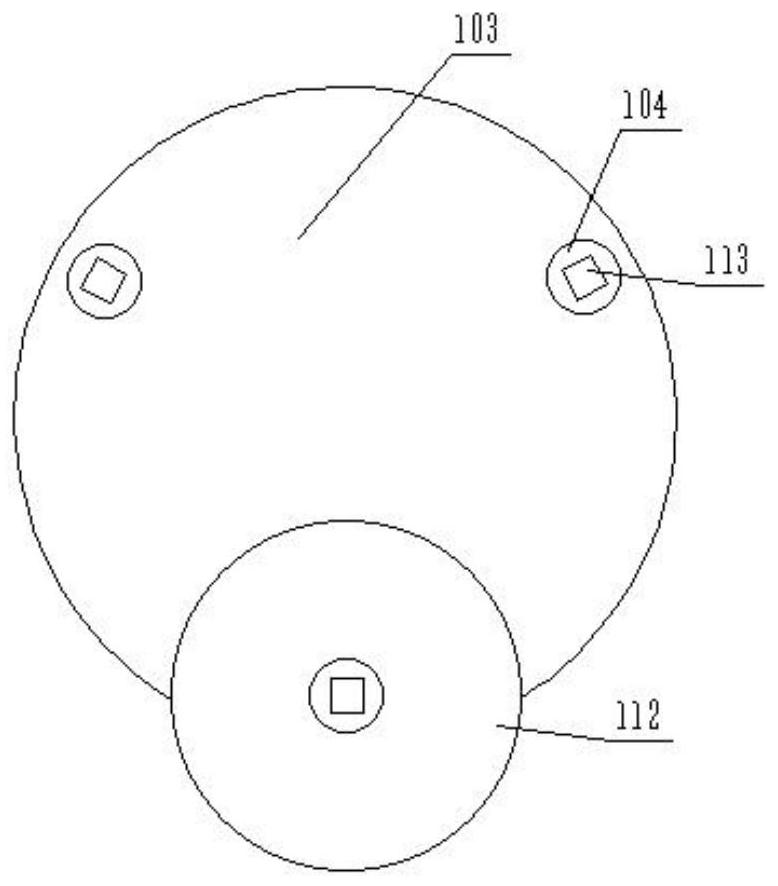

Rough rolling vertical roller mill

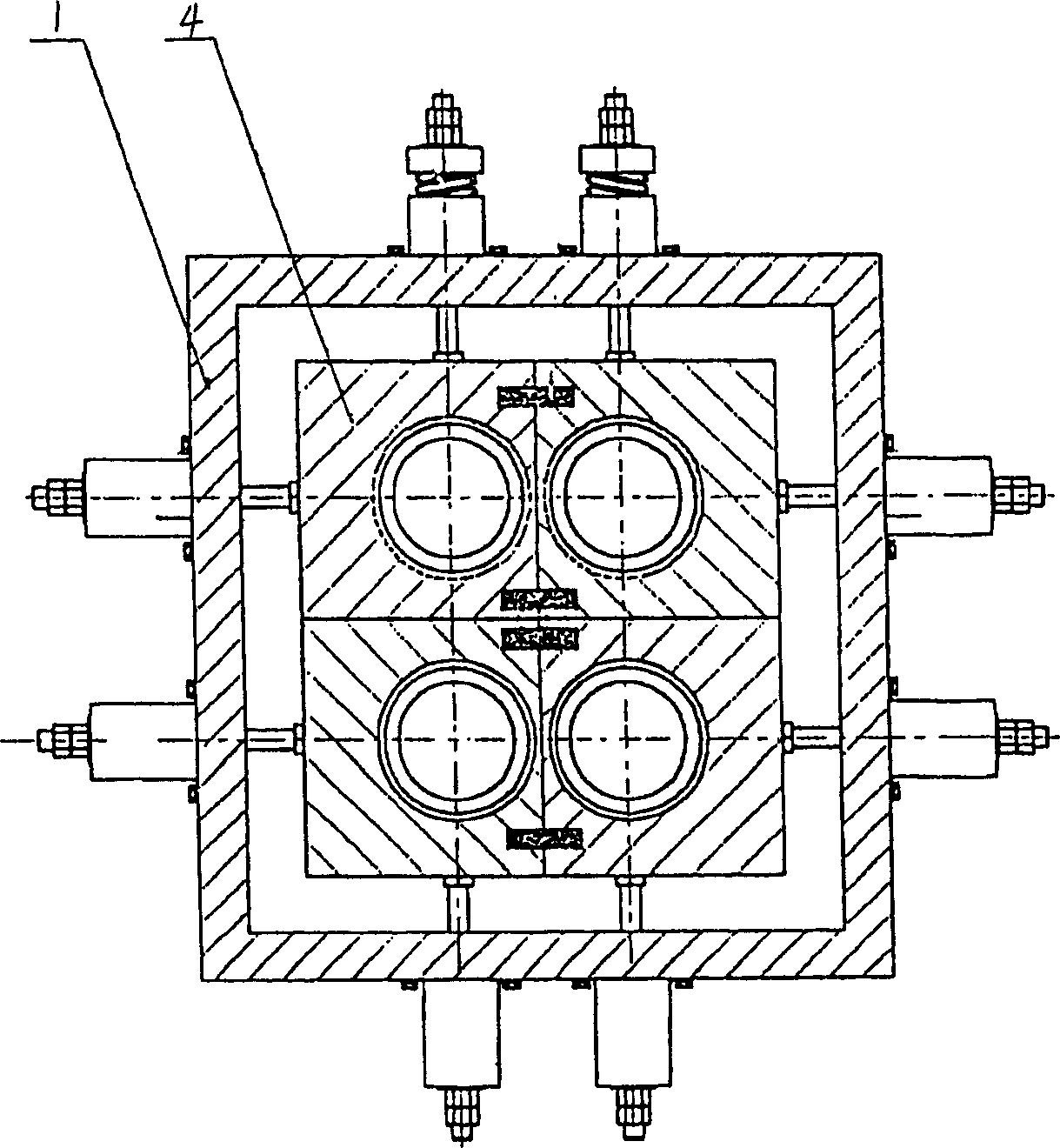

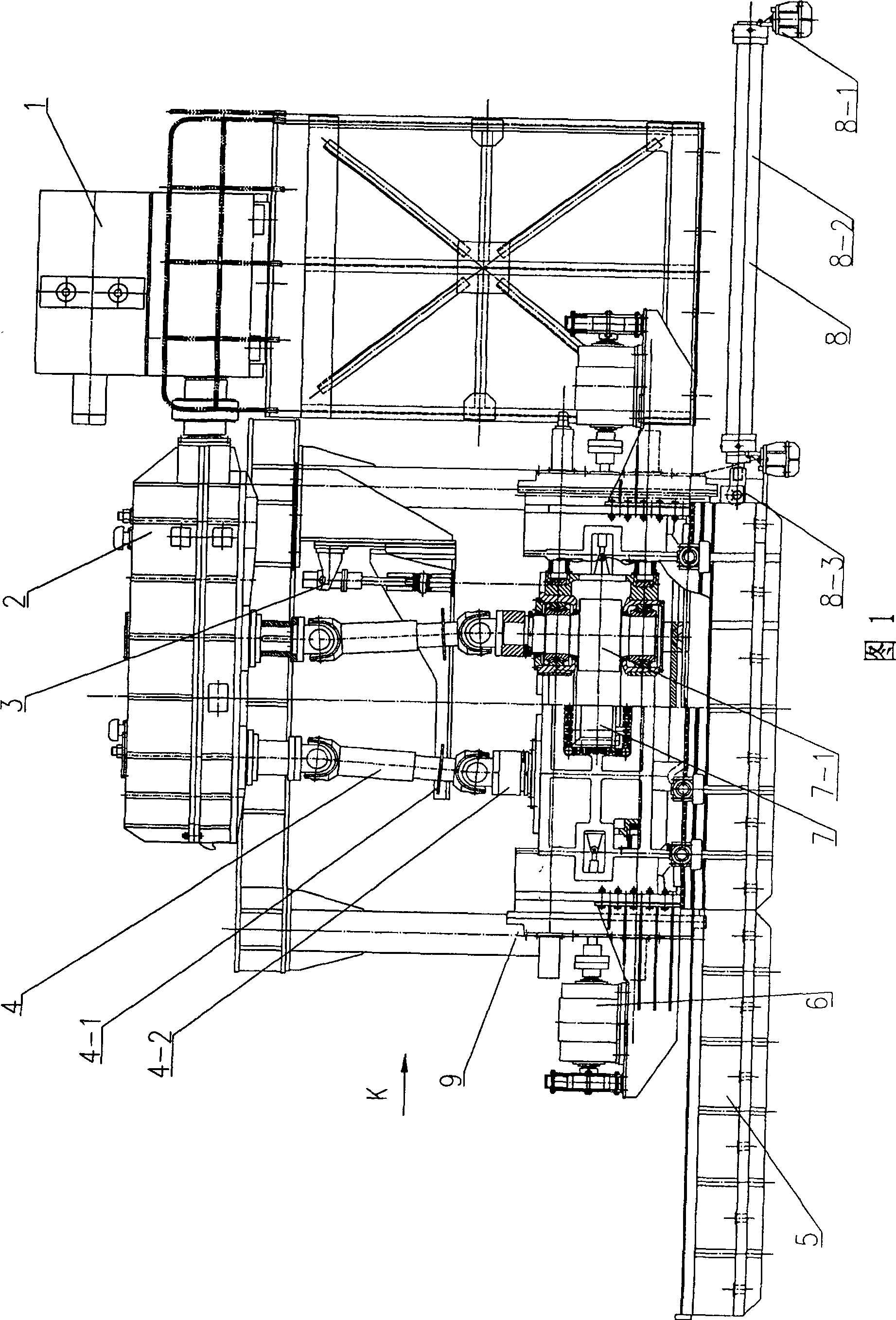

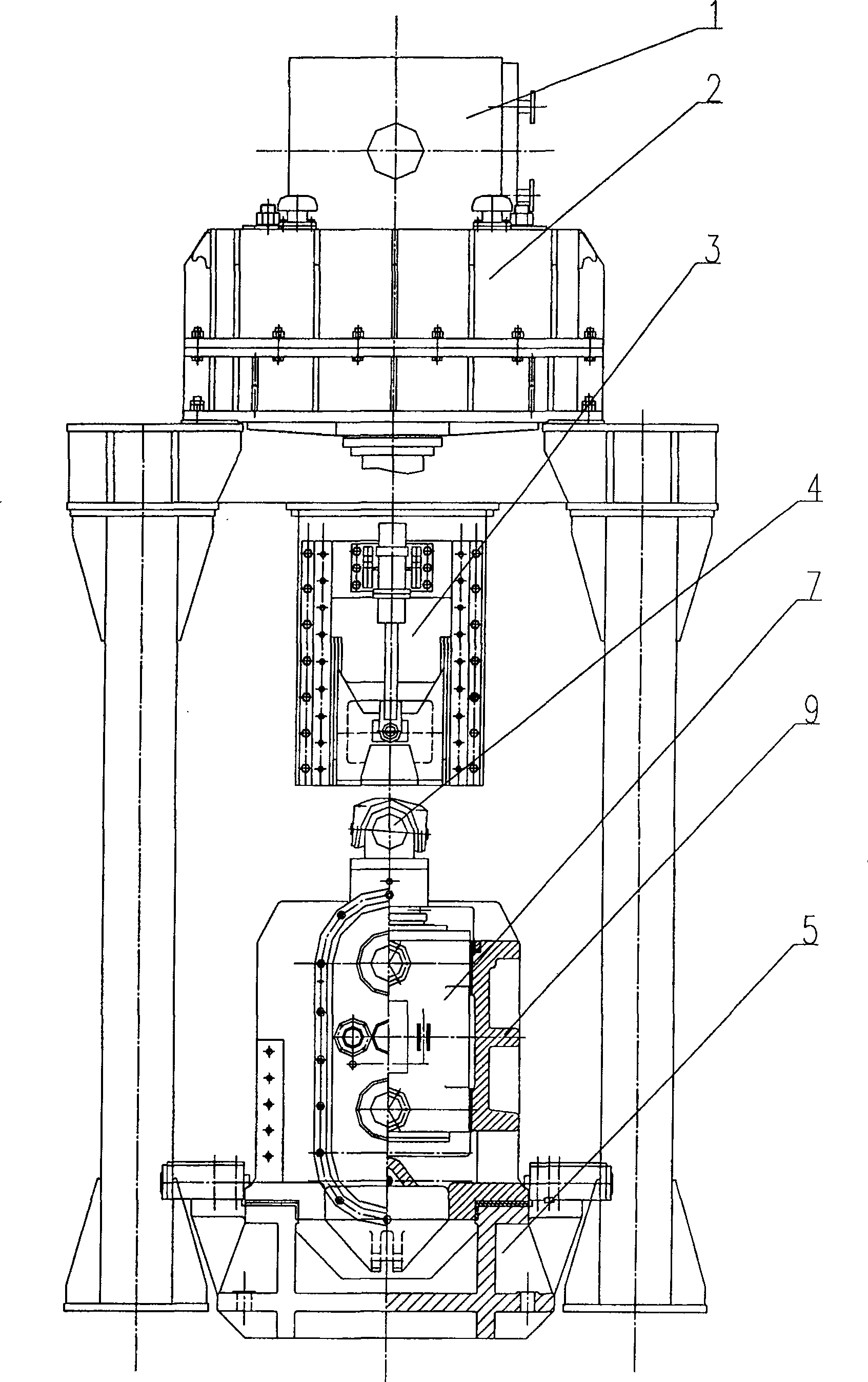

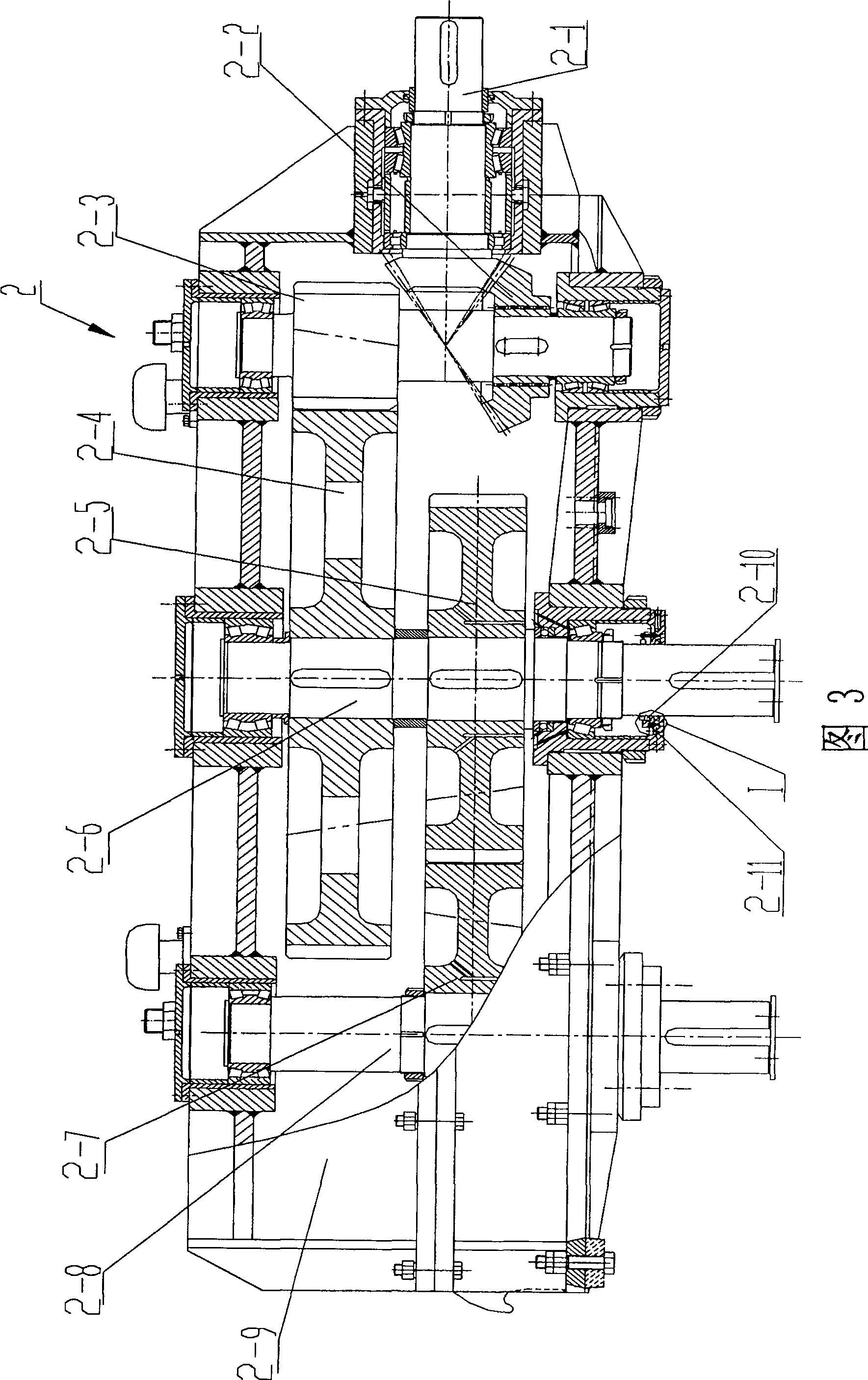

InactiveCN100469471CEasy to adjustQuick roll changeMetal rolling stand detailsRolling mill drivesCouplingGear wheel

The invention relates to a vertical mill for rough rolling, for which, a main transmission combined speed reducer is an integral structure, the output axles of which are two output gear axles arranged vertically; a main transmission motor is connected with the main transmission combined speed reducer through a coupling; the two output gear axles extending vertically under the main transmission combined speed reducer are connected with a cross cardan axis, a sleeve at the low end of the cross cardan axis is connected with a roller flat a roller mechanism arranged on a guide rail seat; the two sides of the roller mechanism are connected with a side holddown device, for which DC motor drives a gear and a transmission nut structure; a hydraulic roll-changing lifter is arranged on a frame under the main transmission combined speed reducer, and a roll-changing shift-out mechanism is arranged on the side of the guide rail seat. The invention has the advantages that the transmission rigidity and the service life are improved, and the transmission requirements of large torque can be met; the quick roll changing can be realized, the online roll changing time is greatly shortened, and the productivity is improved; being combined with a flat rolling machine, the invention can produce blanks with different specifications and decrease the processing cost.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

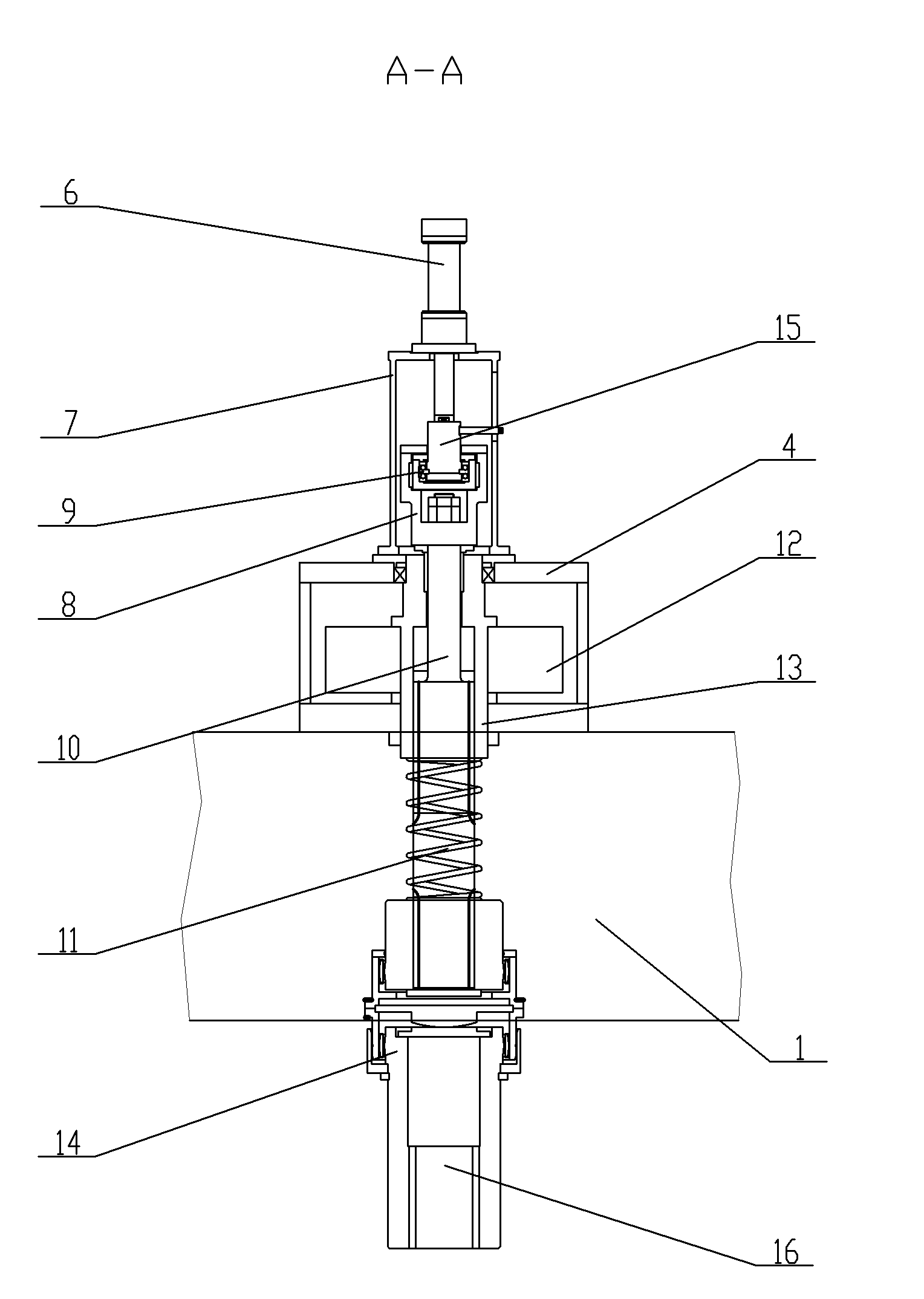

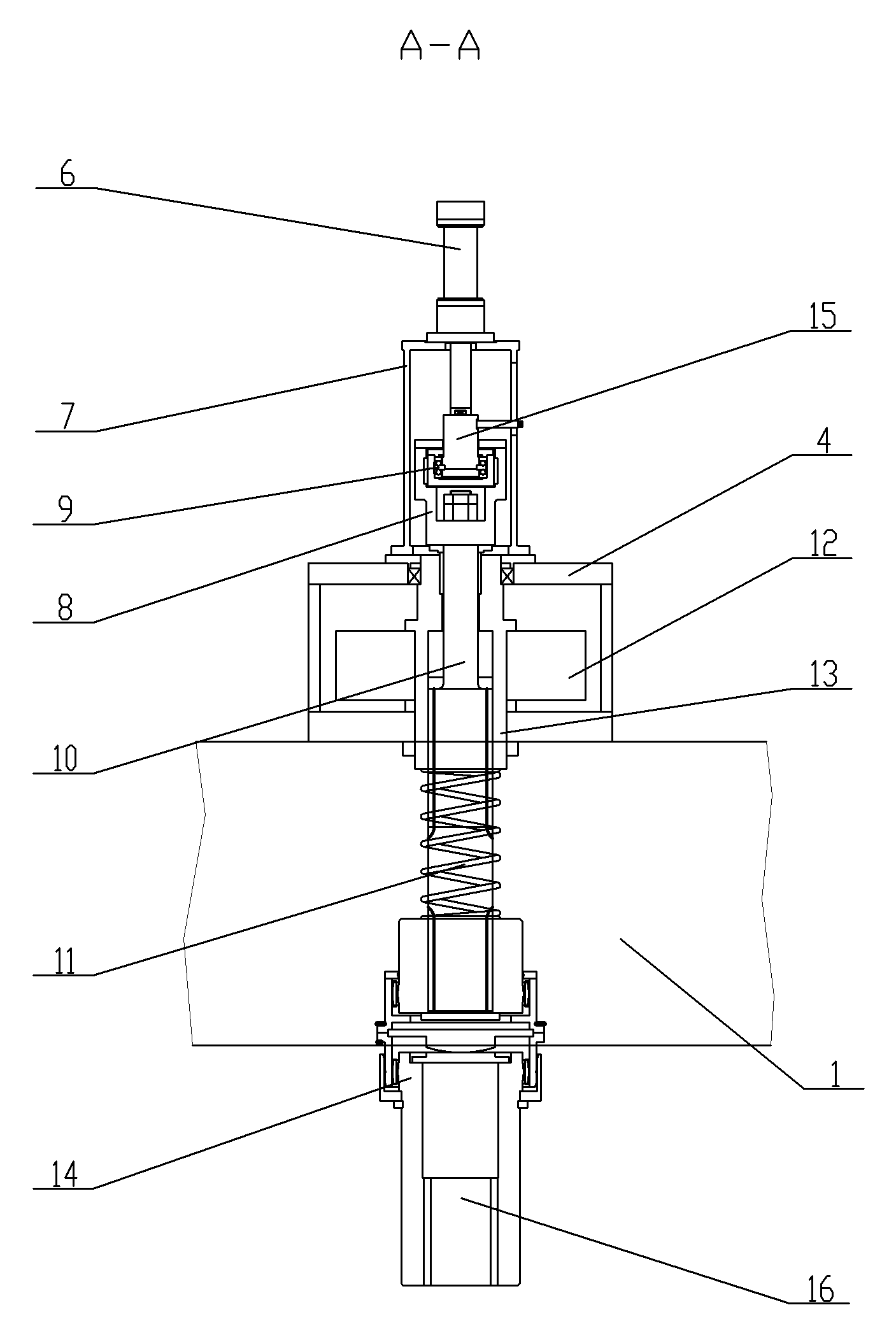

Vertical transmission device for vertical roller of rolling mill

InactiveCN101985133ADo not rotate to ensureRealize active transmissionMetal rolling stand detailsRolling mill drivesHydraulic cylinderCoupling

The invention relates to a vertical transmission device for a vertical roller of a rolling mill. The device is characterized in that: a beam opposite to a vertical roller shaft on each side is provided with the vertical transmission device for the vertical roller, which consists of a motor base, a motor, a coupling, a reduction box, a roller change mechanism of a hydraulic cylinder elevating spline shaft, a spring and a shaft coupling; an output shaft of the reduction box is a spline shaft; the upper and lower shaft ends of the spline shaft extend out of the reduction box; the upper shaft endof the spline shaft is connected with the roller change mechanism of the hydraulic cylinder elevating spline shaft; a spline shaft section in the reduction box is connected with a spline sleeve; the outer side of the spline sleeve is connected with a gear; the bottom end of the spline sleeve extends out of the bottom of the reduction box; the spring and the shaft coupling are arranged on a splineshaft section below the spline sleeve; and the upper section of the vertical roller shaft is connected to the inside of the shaft coupling. The device has the characteristics that: the device has a reasonable design and a compact structure, realizes active transmission of the vertical roller, can balance stress of a horizontal roller and the vertical roller in the rolling processes, has high steel pipe rolling and molding quality, is extremely convenient to use, a roller is convenient to change rapidly, and the like.

Owner:DALIAN SAGE GROUP

Roll changing device of horizontal and vertical rolling mill

PendingCN114130830AQuick roll changeImprove roll changing efficiencyMetal rolling stand detailsMetal rolling arrangementsSpare parts managementStructural engineering

The invention discloses a roll changing device of a horizontal and vertical rolling mill, and belongs to the technical field of roll changing of rolling mills. The roller replacing device comprises a trolley, a roller replacing hydraulic cylinder and a bolt mechanism, a piston rod of the roller replacing hydraulic cylinder is connected with the bolt mechanism, the front end of the bolt mechanism is connected with the trolley, a roller replacing bolt cylinder and a plunger rod are arranged on the surface of the bolt mechanism, and a guide positioning block is further arranged on the surface of the bolt mechanism. One end of the bolt mechanism is connected with the movable base, and a rolling mill body is installed on the surface of the movable base. The roller replacing device is used for roller replacing operation of a fixed type horizontal and vertical rolling mill train, rapid roller replacing of horizontal rolling and vertical rolling can be achieved, and the roller replacing efficiency is high; the roller replacing device has the advantages of being simple and reliable in structure and convenient to maintain, the roller replacing device can be rapidly moved in and out of the rolling mill body and the movable base, meanwhile, the requirement for rapid roller replacing operation of flat rolling and vertical rolling is met, main body structures can be interchanged and universally used, spare part specifications are reduced, and spare part management is convenient.

Owner:HUATIAN ENG & TECH CORP MCC

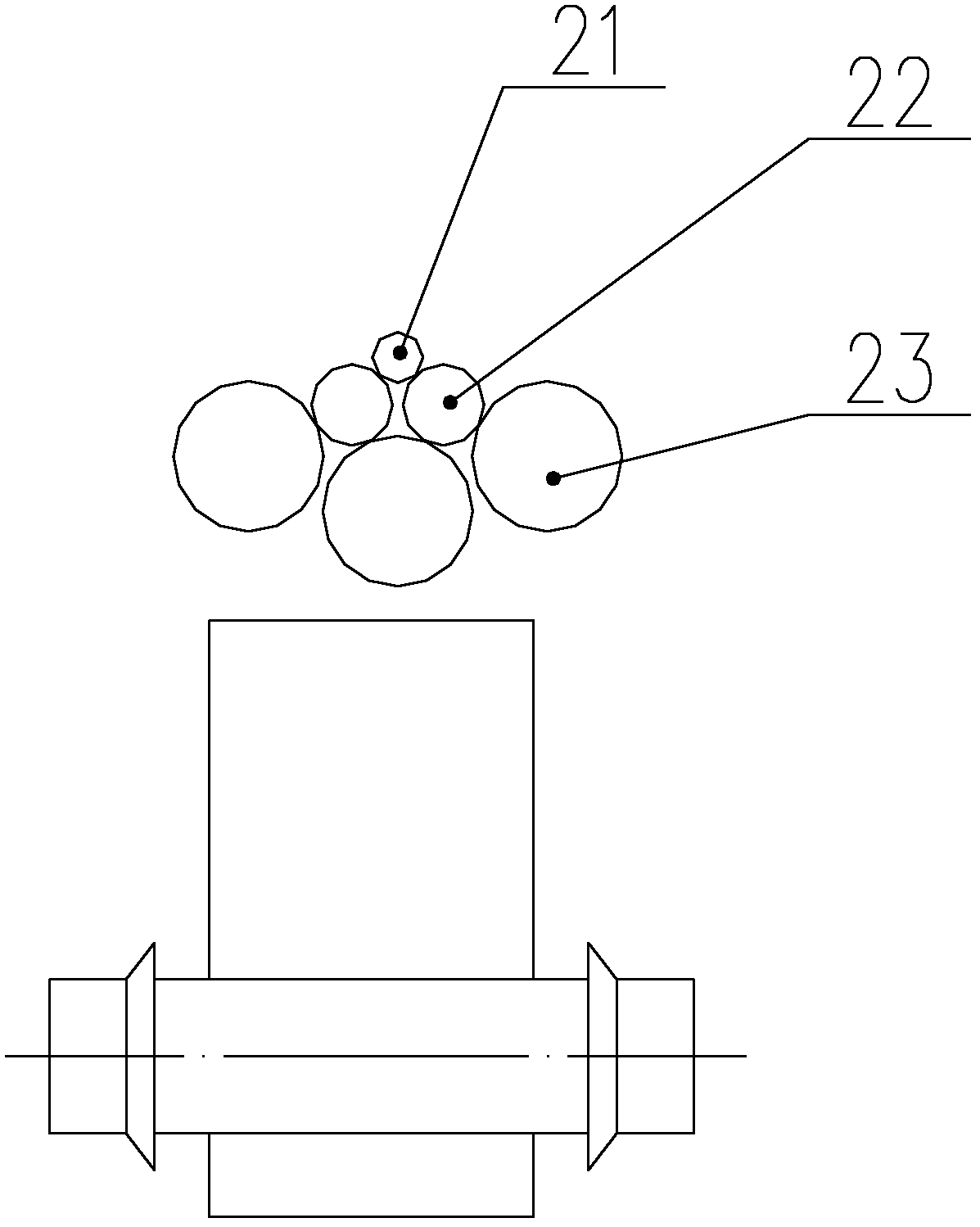

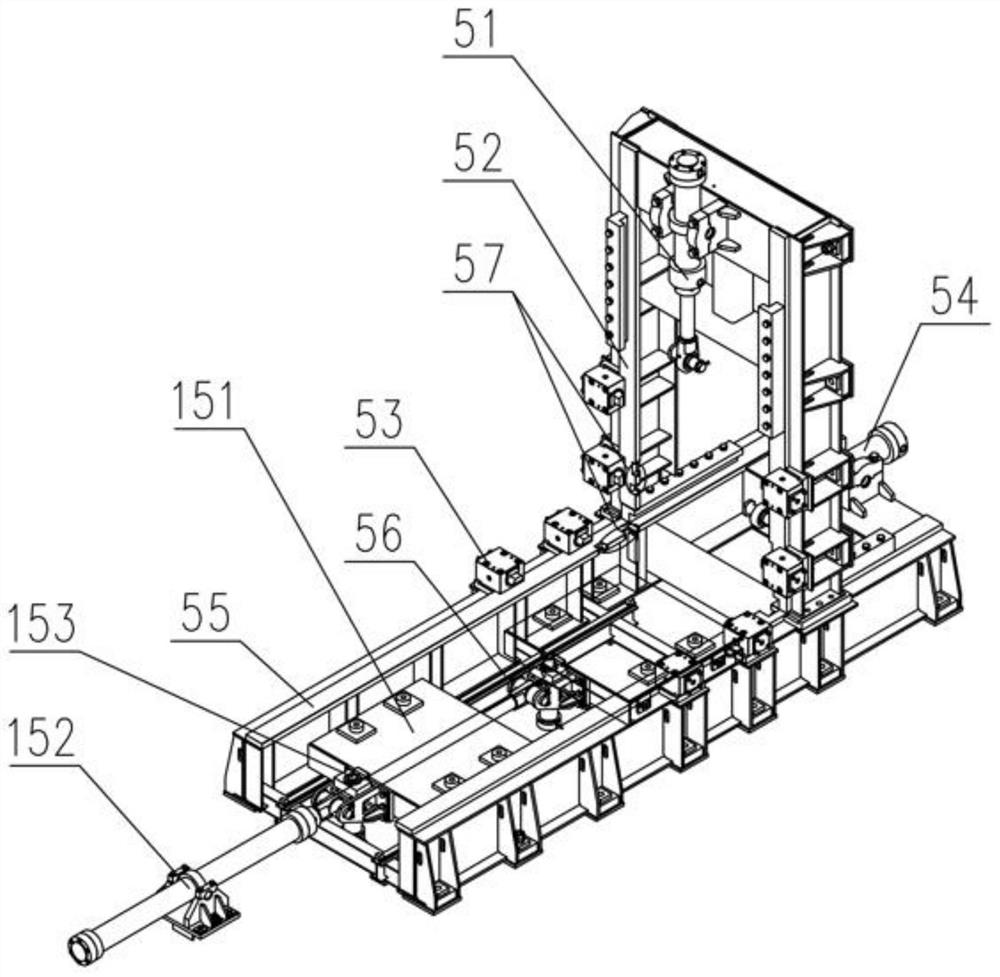

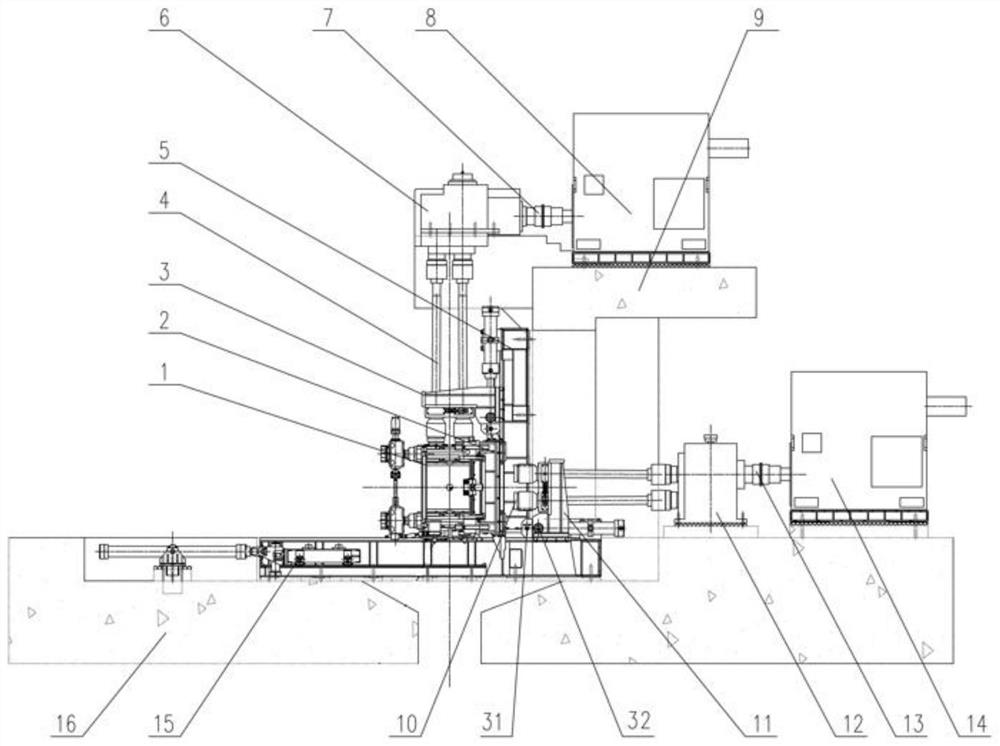

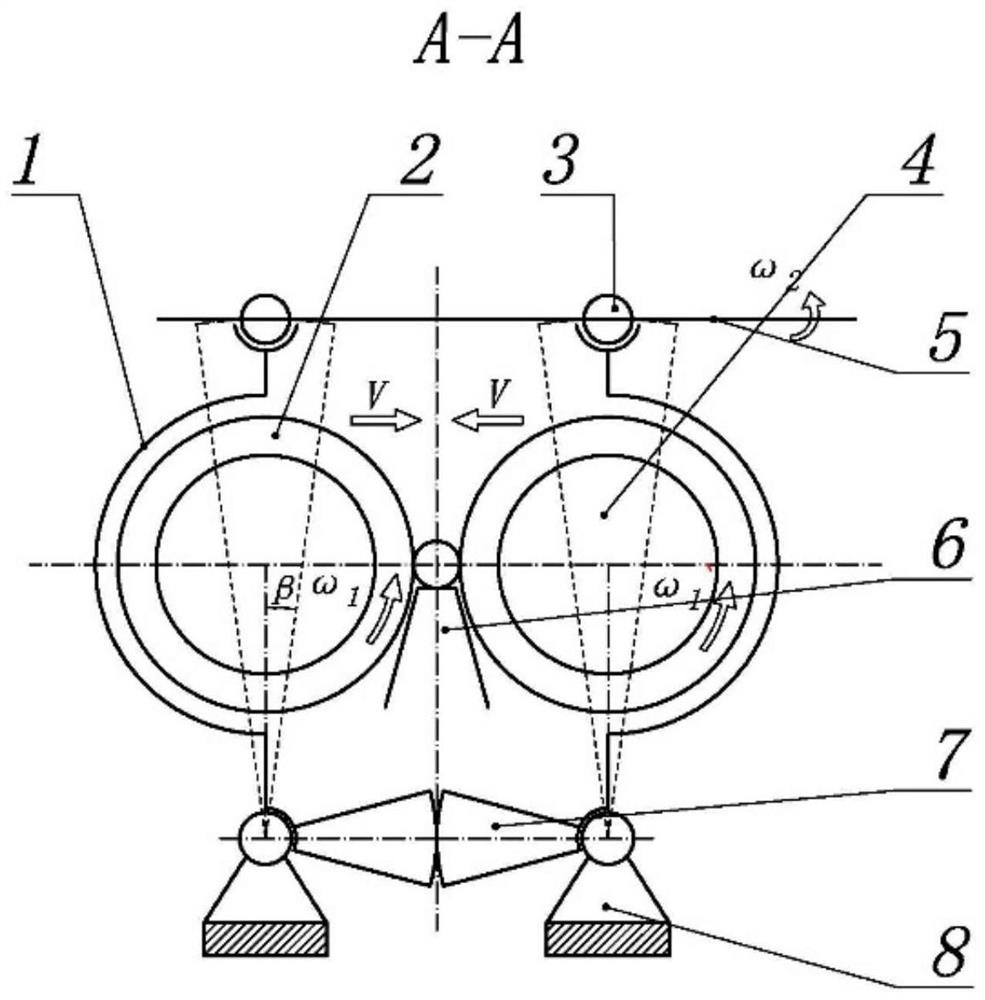

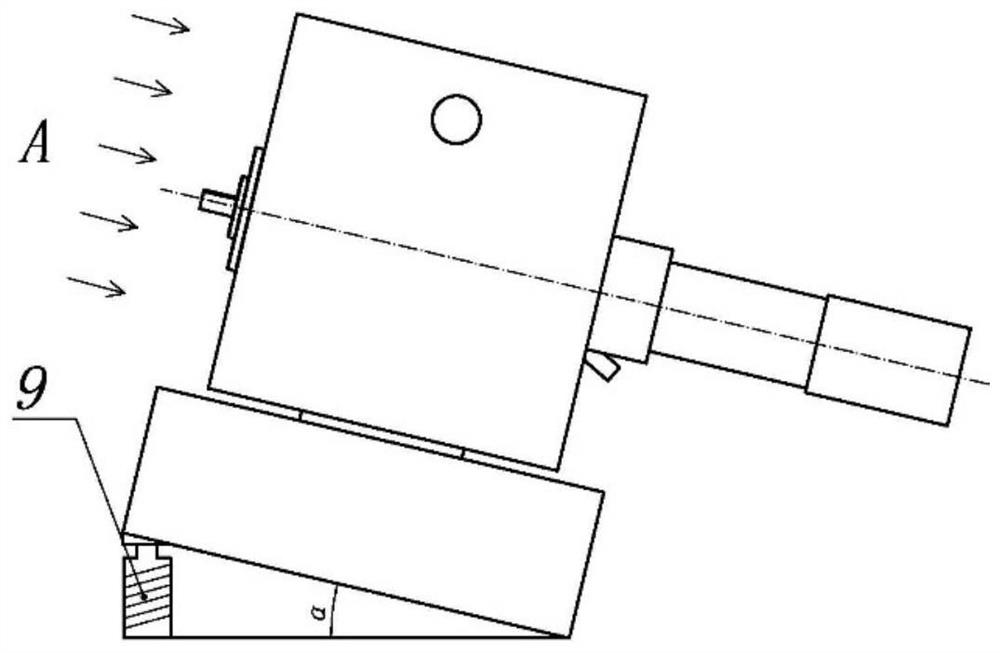

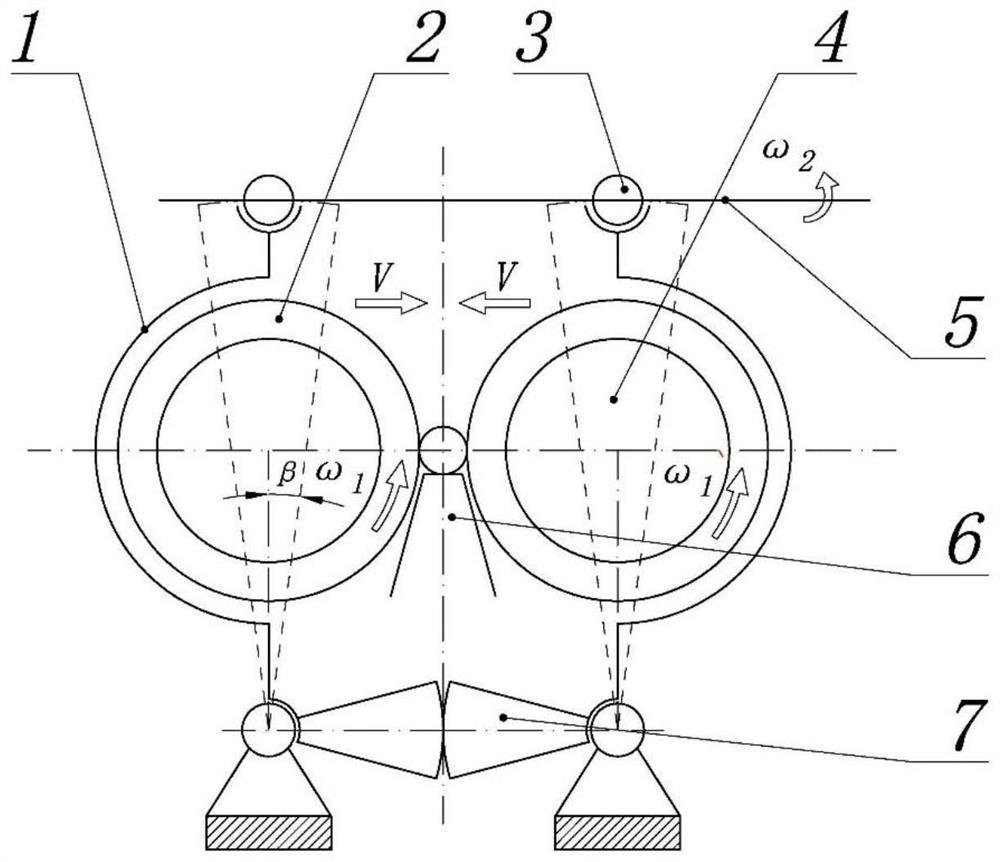

Inclined precise cross wedge rolling forming device

ActiveCN114798718AFast deliveryLow costMetal rolling stand detailsMetal rolling arrangementsRack unitRolling mill

The invention relates to the technical field of metal plastic forming equipment, and provides an inclined precise cross wedge rolling forming device which is characterized in that rack units are symmetrically mounted on a base; the guide plate feeding units are symmetrically mounted above the base; the left and right molds are coaxially fixed by left and right shaft systems respectively; the driving unit is coaxially mounted on the shaft system unit to drive the mold to rotate; the roller spacing adjusting unit is installed above the rolling mill in a penetrating mode, and the die spacing is adjusted by controlling the opening and closing degree of a rack. The synchronous units are symmetrically mounted below the rolling mill to ensure synchronous opening and closing of the two racks; the lifting inclination unit provides the inclination angle needed by the rolling mill by controlling the lifting height. A blank reaches a designated position through the guide plate feeding unit, the roller spacing is adjusted through the roller spacing adjusting unit, and the driving unit provides rolling power to roll the blank into a product in a cross wedge mode. The device has the advantages of high rolling precision, convenience in die replacement, high automation degree and the like, can realize quick feeding and discharging by utilizing the dead weight of a rolled piece, remarkably improves the production efficiency, and has a wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Six-roller mill

ActiveCN101549354BHigh dimensional accuracyExtended service lifeMetal rolling stand detailsRolling equipment maintainenceEngineeringStrip steel

The invention relates to cold mill machinery, in particular to a six-roller mill which belongs to the forming technical field. In the invention, an axial locking device and supporting rollers are connected and installed at the operation sides of the upper part and the lower part of a housing; a supporting roller balancing device is connected with an upper supporting roller; a hydraulic pressing fine adjustment device is installed at the bottom of the housing, and a lower supporting roller is directly placed on the top of the hydraulic pressing fine adjustment device; an axial moving device isinstalled outside the transmission side of the housing and connected with a middle roller through another axial moving device; an axial moving locking device is installed on a bowed roller block at the transmission side; and a roller system compensating device is installed at the upper part of the housing. The invention improves the dimensional precision of cold-rolled steel strip products and improves the automatic degree in the production process; the device pressing mechanism has simple structure and compact arrangement and improves the service life of bearings; and the roller replacement is fast, flexible, stable, reliable and convenient in operation. The six-roller mill is suitable for rolling steel strip products such as straight carbon steel, quality carbon steel, low alloyed steel,stainless steel, and the like.

Owner:CISDI ENG CO LTD

Solar water tank end cap sealing tape applicator

A sticking machine for a sealing tape of an end cover of a solar water tank adopts the structure that a shaft seat and a bearing are mounted in a base thereof; a rotating shaft is mounted in the bearing; the upper end of the rotating shaft is fixed on a center of a lower bottom of a round rotating disc; the end cover of the water tank is fixedly mounted on the round rotating disc; a bracket bottom rod and a vertical rod are mounted on one side below the base; a cross arm is movably fixed at the upper end of the vertical rod through a bolt; the front end of the cross arm is fixed with a sealing tape reel mounting rack; a fixing shaft is mounted on the mounting rack positioned at the upper end of the center of the round rotating disc; a sealing tape reel fixing tray is sleeved on the fixing shaft; a sealing tape reel is mounted in the sealing tape reel fixing tray; a fixing element is mounted in the middle of the cross arm; a lateral positioning wheel with a tape, a pressing wheel and a height positioning wheel are mounted on the fixing element; and the sealing tape is stuck on the upper mouth edge of the inner side of the end cover of the water tank. Due to the adoption of the technical scheme, the accuracy and quality in tape sticking are greatly improved, the tape sticking is quick, the reel replacement is quick, and the working efficiency is greatly improved.

Owner:YUNNAN YUXI TAIBIAO SOLAR ENERGY EQUIP

Polisher spindle device and roll changing method

PendingCN112123170ARealize reciprocating vibration functionQuick changeGrinding wheel securing apparatusGrinding carriagesCustomer requirementsPolishing

The invention relates to a polisher spindle device and a roll changing method. A second driving mechanism drives whole support mechanisms and a spindle body on the support mechanisms to move on a guide rail along the axial direction of the spindle body, and sliding blocks connected to the bottoms of the support mechanisms move on the guide rail, so that the spindle body and a polishing roll on thespindle body are vibrated in a reciprocating mode, and the problem that chromatic aberration, attractiveness and the like appearing on the surface of a polished aluminum alloy plate are difficult tomeet customer requirements is solved; a supporting and limiting structure is located between each two adjacent support mechanisms, a locking part is disassembled firstly, then the support mechanism onone side is disassembled, finally, the polishing roll is taken out while the supporting and limiting structure is disassembled, a new polishing roll is changed, then the supporting and limiting structure is installed, and the support mechanism and the locking part on one side are installed, so that rapid changing of the polishing roll is achieved; and the spindle device with the structure achieves the characteristics of high-frequency reciprocating oscillation and rapid roll changing of the spindle device.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

ptfe ultrafine filtration membrane production biaxial stretching equipment

ActiveCN112936834BReduce the temperatureQuick edgeDomestic articlesFlat articlesFiltration membraneLaboratory oven

Owner:SHANDONG SENRONG PLASTIC IND TECH

Roller body mounting structure on steel belt processing line

PendingCN114472516AQuick roll changeImprove the efficiency of roll changeMetal rolling stand detailsMetal rolling arrangementsStructural engineeringSteel belt

The roller body mounting structure comprises supporting arms, a lower roller assembly, an upper roller assembly and a first lifting mechanism, the two supporting arms are oppositely arranged on the two sides of the steel belt conveying direction, each supporting arm is provided with a containing groove, and the lower roller assembly comprises a lower roller base installed at the inner bottom end of the containing groove in a liftable mode; the upper roller assembly comprises an upper roller base installed at the top end in the containing groove in a lifting and sliding mode, a plurality of grooves are formed in the top face of the lower roller base or the bottom face of the upper roller base, protrusions matched with the grooves are correspondingly arranged on the bottom face of the upper roller base or the top face of the lower roller base, and the first lifting mechanism is used for driving the upper roller base to ascend and descend. And the top surface of the upper roller seat is matched on the top wall of the accommodating groove or the bottom surface of the upper roller seat is matched with the top surface of the lower roller seat through the bulges and the grooves, so that the upper roller seat and the lower roller seat are pulled out together in the axial direction through external force during roller replacement. The upper roller seat and the lower roller seat can be conveniently pulled out together, roller replacement is achieved, and the roller replacement efficiency is improved.

Owner:ZHAOQING HONGWANG METAL IND

Rapid supporting roller changing mechanism for plate strip rolling mill

ActiveCN103406358BQuick roll changeEasy maintenance and operationMetal rolling stand detailsMetal rolling arrangementsEngineeringPiston rod

The invention relates to a rapid supporting roller changing mechanism for a plate strip rolling mill. The rapid supporting roller changing mechanism comprises a supporting roller hook (3) and a connecting shaft (8) and is driven by an oil cylinder (6). The rapid supporting roller changing mechanism is characterized in that the connecting shaft (8) is fixed on the supporting roller hook (3) through a bearing and a bearing gland (14), the cross section of the middle of the connecting shaft (8) is in a flat shape with two symmetrically-scraped sides, a shaft hole (18) and an opening both corresponding to the connecting shaft (8) are formed at one end of an oil cylinder connector (9), the diameter of the shaft hole (18) is not less than the section diameter of the connecting shaft (8), a gap at the opening of the end portion of the shaft hole (18) is larger than the distance between two symmetric planes of the connecting shaft (8) and smaller than the section diameter of connecting shaft (8), the piston rod (19) of the oil cylinder (6) is detachably connected at one end of the oil cylinder connector (9), and the oil cylinder connector (9) is fixed on a frame (4) with wheels (5). The rapid supporting roller changing mechanism has the advantages that convenience in operation and maintenance is realized, roller changing time is saved, and auxiliary rolling time is reduced.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Fast roll changing device of vertical rolling mill

ActiveCN101954379BImprove installation accuracyCompact designMetal rolling stand detailsMetal rolling arrangementsEngineeringUltimate tensile strength

The invention relates to a fast roll changing device of a vertical rolling mill, belonging roll-type forming mill trains. The fast roll changing device of the vertical rolling mill is characterized in that a slide block which corresponds to each roll in position is provided with two sliding roll-box removing mechanisms; each sliding roll-box removing mechanism comprises a roll-box rack, a pull rod and a screw; the slide block is movably provided with the roll-box rack which consists of a base plate, a side vertical plate and the press plate and slides along the slide block; the bottom end of a roll shaft is connected into the base plate, and the top end of the roll shaft is connected into the press plate; a locking groove is arranged in the center of the press plate positioned at one side of the side vertical plate; the screw is articulated with the outer side of the lower part of the roll-box rack which corresponds to the locking groove in position; the center of the screw is in female connection with the bottom end of the pull rod; and the pull rod is clamped and locked in the locking groove of the roll-box rack by twisting a step positioned on the top segment of the pull rod. The invention not only has compact, simple and practical design structure and can fast change the rolls and greatly reduce the labor intensity, but also has the advantages of high production efficiency, convenient operation, very convenient use, and the like.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

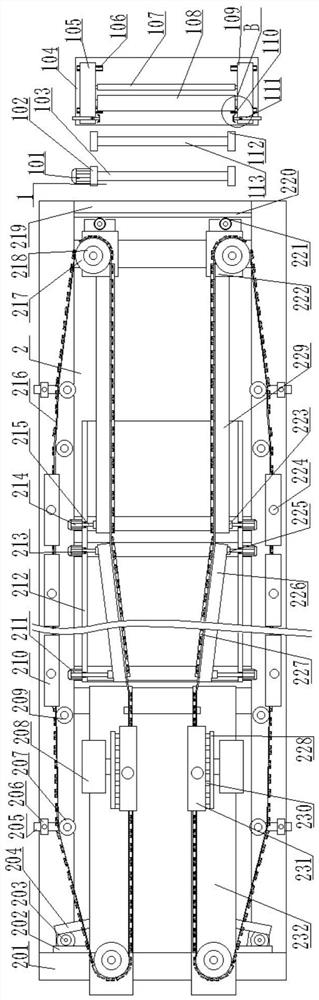

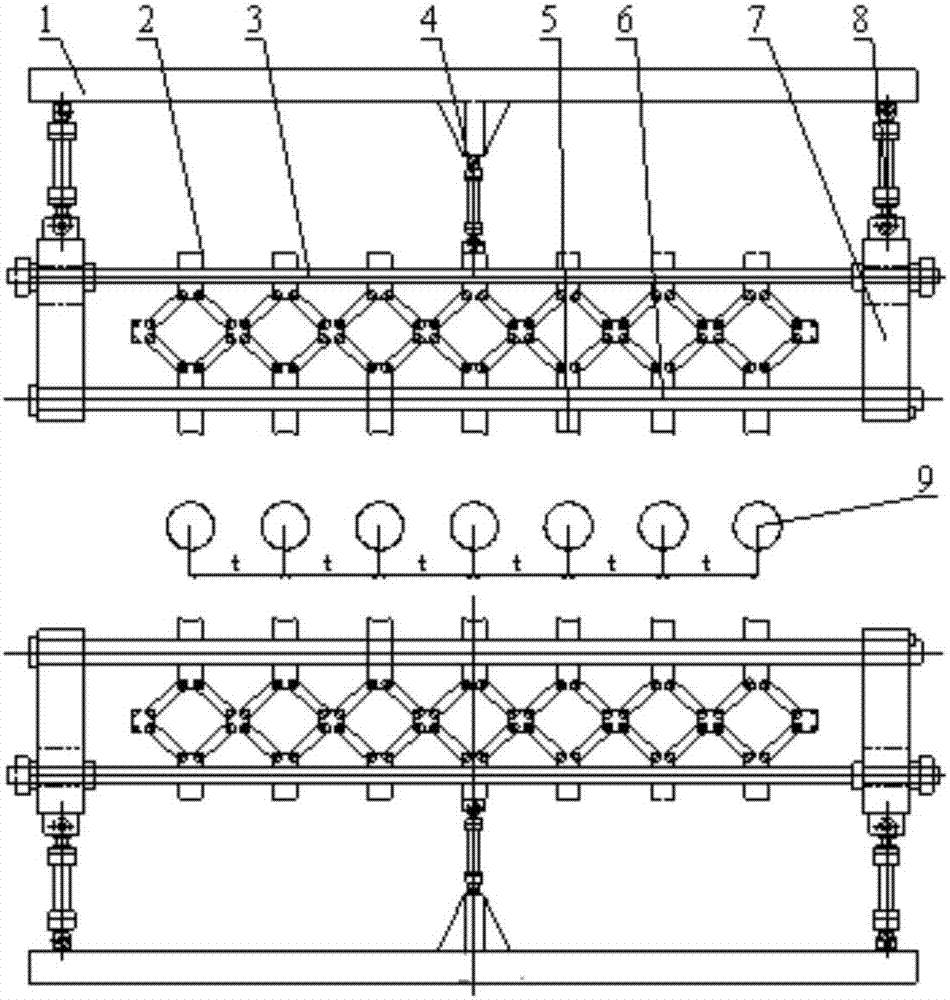

Cantilever type parallel roll leveler roll changing device

The invention is suitable for the field of rolled steel straightening and provides a roll changing gear for a cantilever-type parallel roll straightening machine. The roll changing gear comprises track frames, a transmission mechanism and a roll changing car; the roll changing car is provided with bracket elevator mechanisms; the roll changing car moves on the track frames through the transmission mechanism. According to the roll changing gear provided by the invention, multiple pairs of roll sleeves and straightening rolls on brackets can be accurately and simultaneously centered; the roll changing mode is simple and fast; the roll changing gear is also suitable for long-distance crossing and driving roll changing of the roll changing car.

Owner:WISDRI ENG & RES INC LTD

Forming device capable of achieving precise cross wedge rolling

ActiveCN114589199AIncrease stiffnessShort power transmission pathMetal rolling arrangementsEngineeringStructural engineering

The invention relates to the technical field of metal plastic forming equipment, and provides a forming device capable of achieving precise cross wedge rolling. The guide plate feeding units are symmetrically mounted above the base about the central axis; the left and right dies are coaxially fixed by the left and right shaft systems respectively; the driving unit is coaxially installed on the shaft system unit and drives the mold to rotate. The roller spacing adjusting unit is installed above the rolling mill in a penetrating mode, and the die spacing is adjusted by controlling the opening and closing degree of a rack. The synchronous units are symmetrically installed below the rolling mill, and synchronous opening and closing of the two racks are guaranteed. A blank reaches a designated position through the guide plate feeding unit, the roller spacing is adjusted through the roller spacing adjusting unit, and the driving unit provides rolling power to roll the blank into a needed product in a cross wedge mode. The precise cross wedge rolling device has the advantages of capability of realizing precise cross wedge rolling, high rolling mill rigidity, convenience in die replacement, compact structure, high production efficiency and the like, can be used for precise cross wedge rolling forming of small and medium-sized shaft parts, and has a wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

A roll changing base of a multi-line pass section steel straightening machine

The invention belongs to the technical field of metallurgical equipment, and in particular relates to a roll changing base of a multi-line pass type steel straightening machine, including a base, a roll changing seat, a side slide plate, a slide plate, guide seat assembly, guide ring one, guide ring two, and thread lining sleeves, gears, lock nuts, end caps, left bearings, right bearings, gear shafts, spacers, geared motor mounts, geared motors, backing plates, bushings and wedges. The present invention is capable of simultaneously straightening multiple steel profiles, and the multi-line profile steel straightening machine realizes the function of quick roll change without using a special spreader; at the same time, through the axial adjustment function of the straightening roll system, the traditional The axial adjustment device of the straightening machine can realize the rapid roll change of the multi-line pass section steel straightening machine without using a special spreader, so it has the advantages of simple structure, light equipment weight, small investment and low production cost. The invention is used for changing rolls of a straightening machine.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel variable-roller-pitch connection shaft adjusting clamping mechanism

A novel variable-roller-pitch connection shaft adjusting clamping mechanism comprises mechanism bodies in vertical symmetry. Straightening rollers are arranged between the mechanism bodies. Each mechanism body comprises a horizontal base, a guide rod and a synchronous shaft, wherein an adjustment oil cylinder is arranged at the center of the space between the base and the guide rod, compression oil cylinders are arranged at the two ends of the space between the base and the guide rod, a connection mechanism is arranged between the guide rod and the synchronous shaft, the connection rod mechanism is driven by the adjustment oil cylinders to conduct axial movement along the guide rod and the synchronous shaft for synchronous adjustment, the compression oil cylinders are arranged on moving beams, the moving beams are located at the ends between the guide rod and the synchronous shaft, the straightening rollers are provided with straightening roller spline flanges, and the synchronous shaft is provided with compression heads used for tightly holding the straightening roller spline flanges. The novel variable-roller-pitch connection shaft adjusting clamping mechanism is flexible in adjustment and greatly saves centering time and effort during roller replacement of a straightening machine.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

ptfe high strength film production device

The invention relates to a PTFE high-strength film production device, which includes a stretcher and an uncoiling mechanism arranged at its feeding end. The stretcher includes a frame and an oven. Conveyor chain, the return end of the conveyor chain is outside the oven, and there are multiple cooling boxes outside the return end of the conveyor chain, each cooling box is connected with a suction pipe, the suction pipe is connected with a cooling fan, and the conveyor chain at the front end of the oven The outside of the process end is provided with a secondary cooling box, and the front and rear sides of the secondary cooling box are provided with blowing pipes facing the conveying chain, and the blowing pipes are connected with a blower. The present invention arranges the return end of the conveying chain on the expander outside the oven, and then cooperates with the cooling box arranged at the return end of the conveying chain to reduce the temperature of the conveying chain and improve the quality of product expansion through air suction.

Owner:SHANDONG SENRONG PLASTIC IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com