Fast roll changing device of vertical rolling mill

A roll changing device and vertical roll technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of complicated roll changing operation, high labor intensity, time-consuming and labor-intensive, etc., and achieve the design structure. Compact, labor-intensive, and easy-to-use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

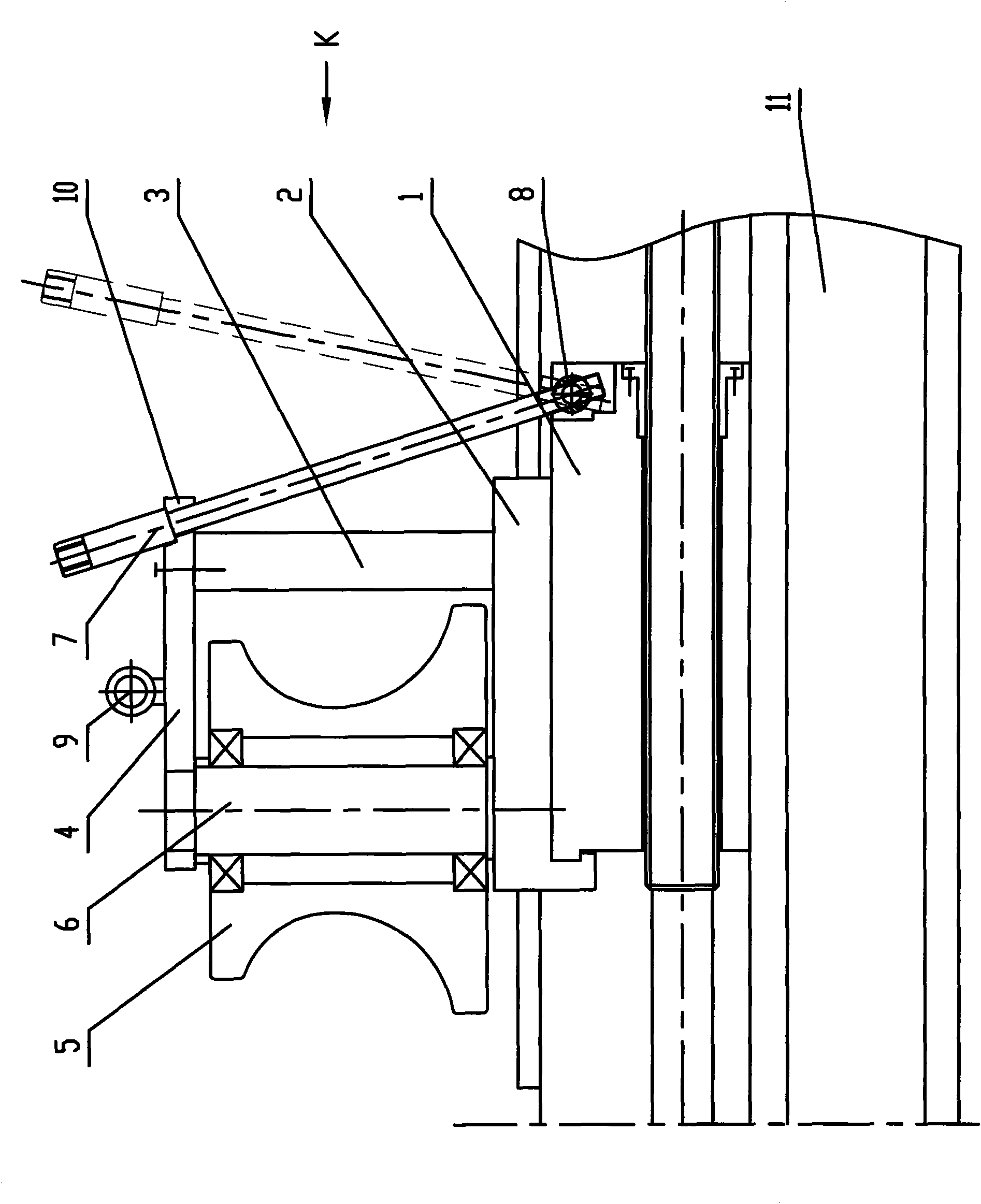

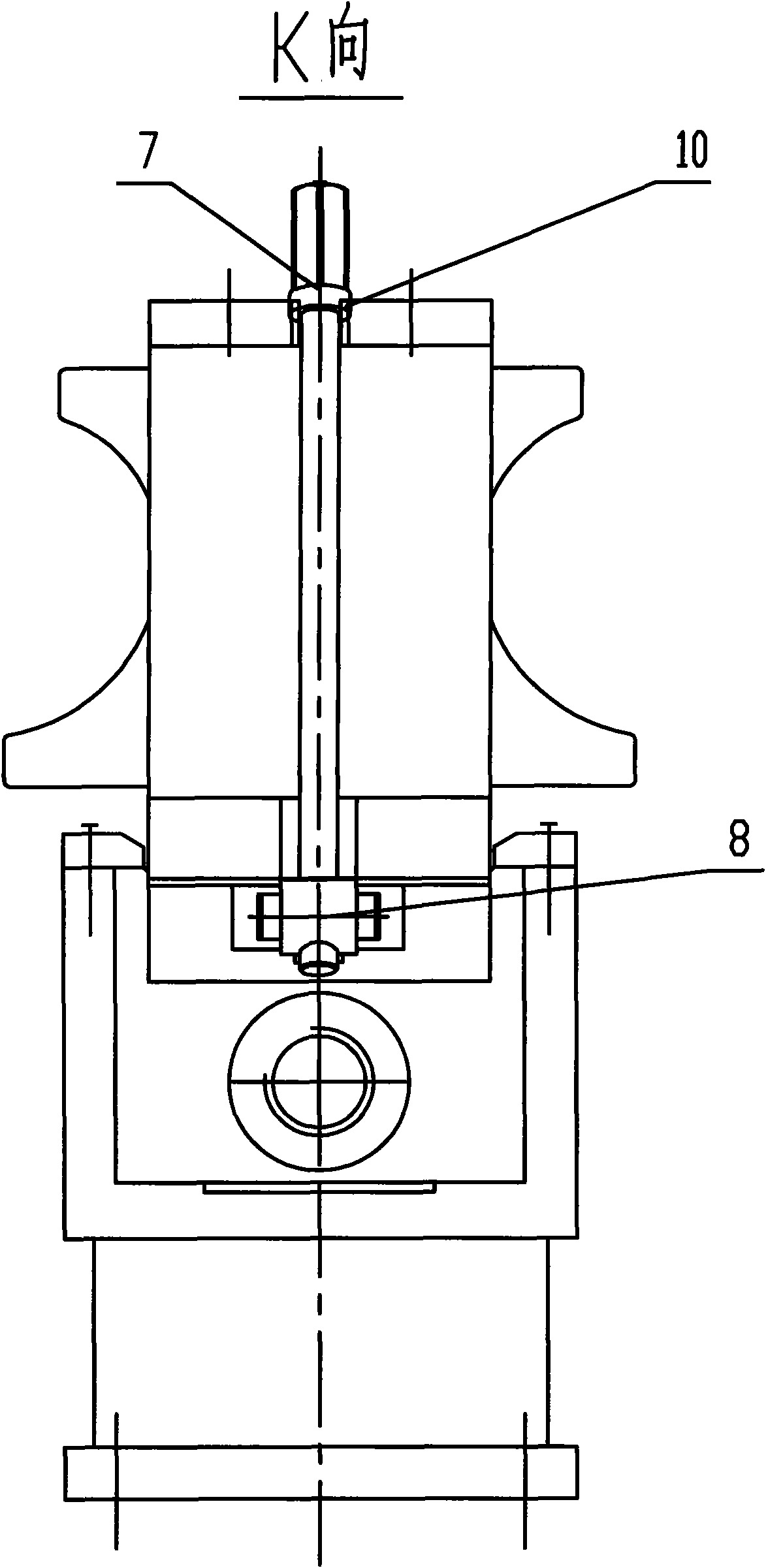

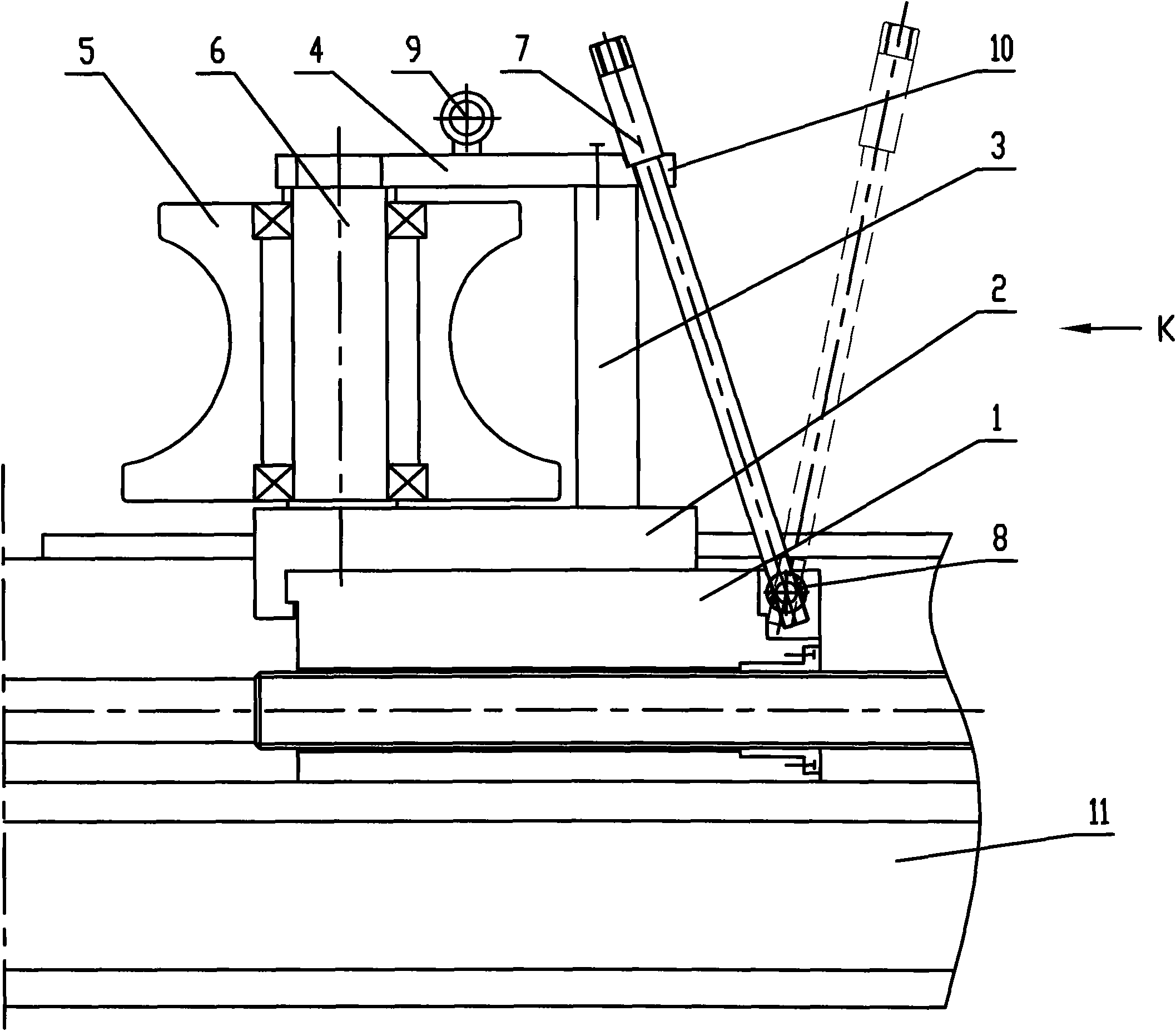

[0016] figure 1 , 2 Shown is the specific embodiment of the present invention, and it is to install 7 vertical rolling mills on the stand 11 of the roll forming equipment of rolling ∮ 76mm stainless steel pipe, and the quick changeover of the vertical rolling mills installed on each rolling mill Roller device; its structure includes: roller 5, roller shaft 6, and slider 1 vertically mounted on the slider 1, characterized in that a sliding roller is installed on the slider 1 corresponding to the position of each roller 5 The box removal mechanism, the sliding roller box removal mechanism is composed of a roller box frame, a pressing plate 4, a pull rod 7 and a screw nut 8, and is movable on the slider 1 and is composed of a bottom plate 2, a side vertical plate 3 and a pressing plate 4. Slider 1 slides the roller box frame composed of split parts, the bottom end of the roller shaft 6 equipped with the roll 5 is connected in the bottom plate 2, the top end of the roller shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com