Inclined precise cross wedge rolling forming device

A technology of cross wedge rolling and inclined type is applied in the field of inclined precision cross wedge rolling forming device, which can solve the problems of slow discharge efficiency and high cost, and achieve the effects of high production efficiency, low cost and short force transmission route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

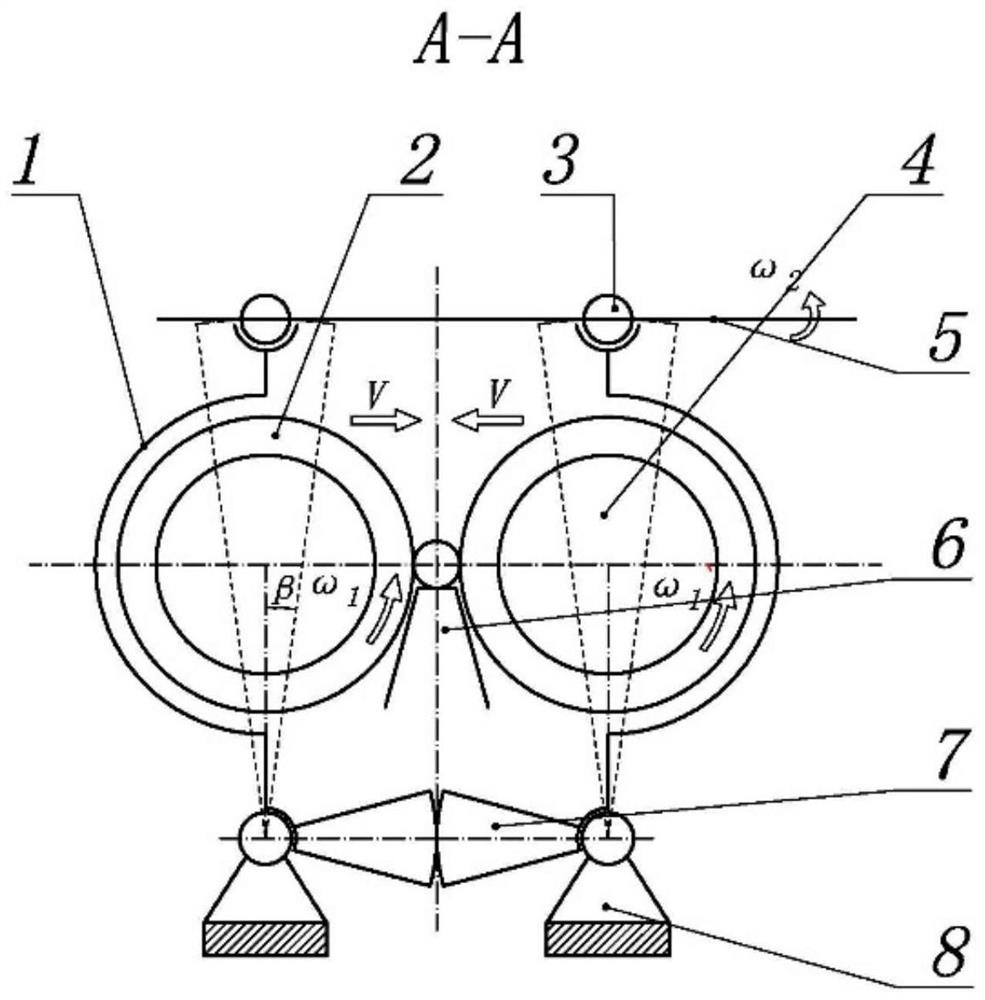

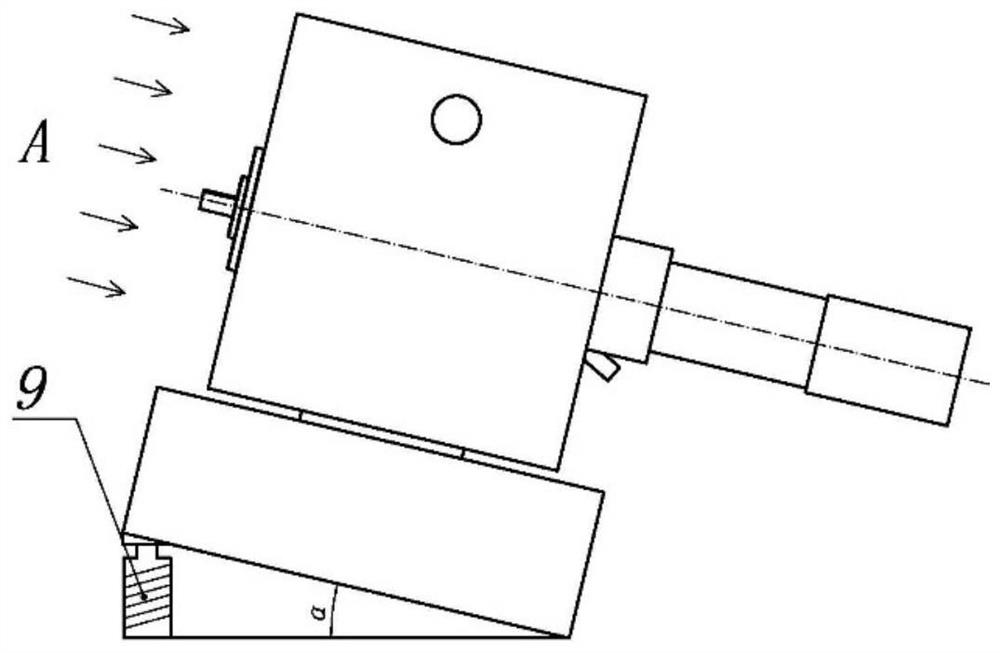

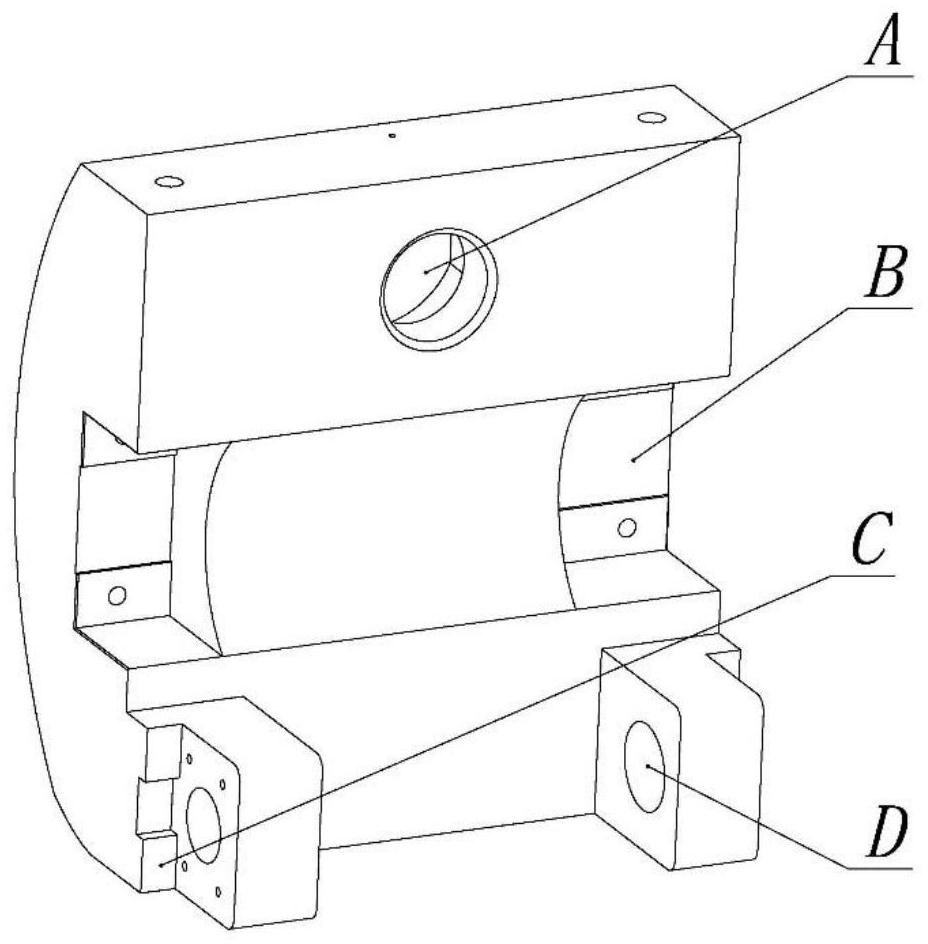

[0045] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be considered isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in the various drawings represent the same features or components, which may be used in different embodiments.

[0046] In the following embodiments, for the convenience of description, the two frames are expressed as left frame and right frame; the two shaft systems are expressed as left shaft system and right shaft system; the two molds are expressed as left mold and right mold. It should be noted that the distinction between left and right here is only a distinction between relative positions, and can also be distinguished b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com