Floating type equipment for enclasping spindle nose

A floating, equipment technology, applied in metal processing equipment, metal rolling, metal rolling stands, etc., can solve the problems of affecting the speed of roll changing, inconvenient roll changing, etc., and achieve simple structure, convenient maintenance, and quick change Roller effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

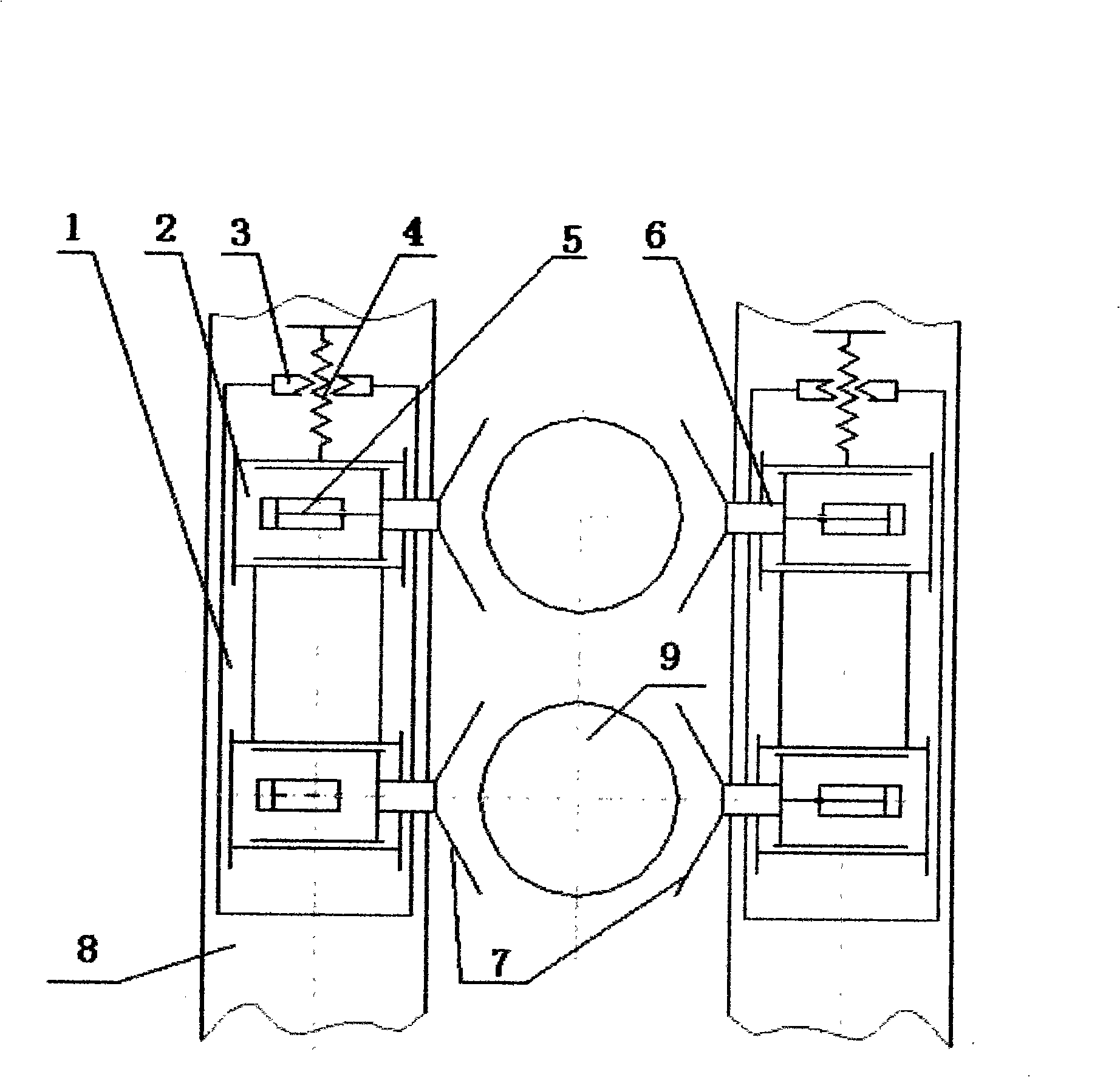

[0010] Such as figure 1 As shown: the vertical sliding guide rail 1 is fixed on the left and right sides of the transmission window of the rolling mill stand 8, and there are two vertically moving sliders and the horizontal guide rail 2 on the vertical sliding guide rail 1; the upper end of the vertical sliding guide rail 1 is fixed with a lifting nut 3; The lower end of the lifting screw 4 is fixed on the vertical moving slider and the horizontal guide rail 2; the lifting nut 3 is connected with the lifting screw 4; the lifting screw 4 moves up and down along the lifting nut 3 to drive two vertical moving sliders and the horizontal guide rail 2 Move up and down; the vertical moving slider and the horizontal guide rail 2 are respectively connected with the holding cylinder 5, the piston rod 6 is connected with the holding V-shaped block 7, and the piston rod 6, the holding V-shaped block 7, the vertical moving slider and the horizontal The clamping mechanism formed by the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com