Novel variable-roller-pitch connection shaft adjusting clamping mechanism

A technology of clamping mechanism and connecting shaft, which is applied in the field of metallurgical equipment and can solve the problems of wasting time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

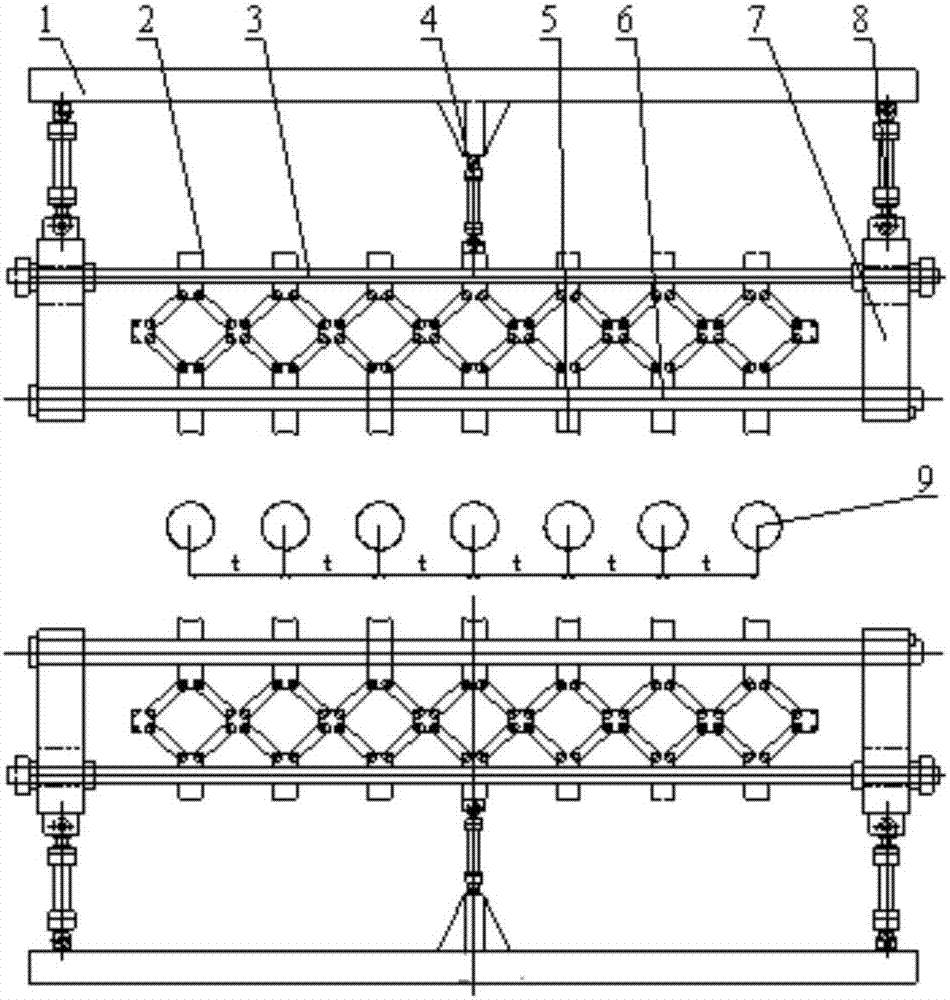

[0025] By adjusting the action of the oil cylinder 4, the position of the guide rod 3 is adjusted longitudinally, so as to drive the linkage mechanism 2 along the guide rod 3 and the synchronization shaft 6 to adjust the axial displacement synchronously. Since the compression head 5 is arranged under the linkage mechanism 2, So as to realize the synchronous adjustment of the center distance t.

Embodiment 2

[0027] The compression cylinder 8 is pressed downwards, thereby compressing the movable beams 7 on both sides, and the compression head 5 is compressed downward as a whole through the synchronization shaft 6. This mechanism has one set of upper and lower mechanism, and the two sets of mechanisms act at the same time. Through position control, the clamping mechanism 8 can flexibly hold the straightening roller flange in any position up and down, thereby minimizing the length. Time to replace the straightening roller. The position control of the compression cylinder 8 is easily realized in the field of hydraulic control.

[0028] The invention is mainly used to adjust the flange clamping mechanism of the variable roll distance straightening machine. When the center distance of the straightening machine changes, it can effectively change the center distance of the clamping mechanism and clamp the flange of the straightening roll so as to Quick roll change and precise positioning in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com