Propeller structure and rapid developing and shaping method

A propeller and structure technology, which is applied in the field of propeller structure and rapid development and shaping, can solve the problem of pitch positioning operation not being able to adjust the propeller, and achieve the effect of saving mold opening cost and mold opening time, convenient and rapid operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

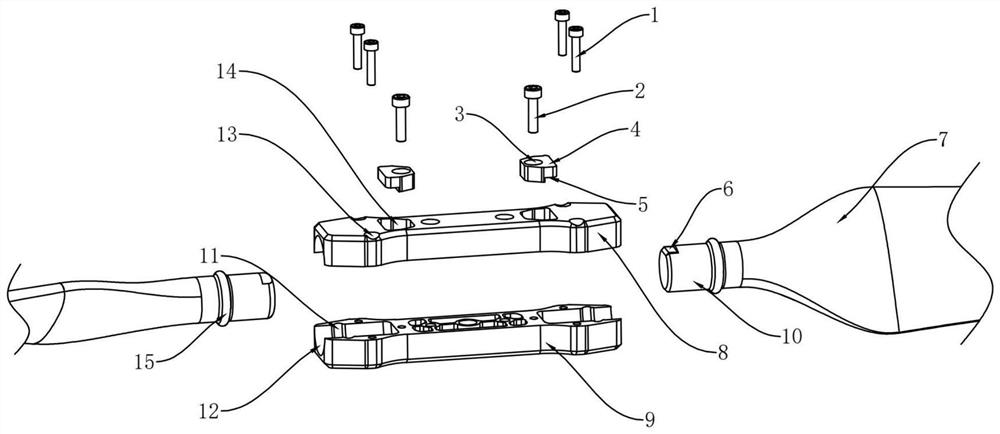

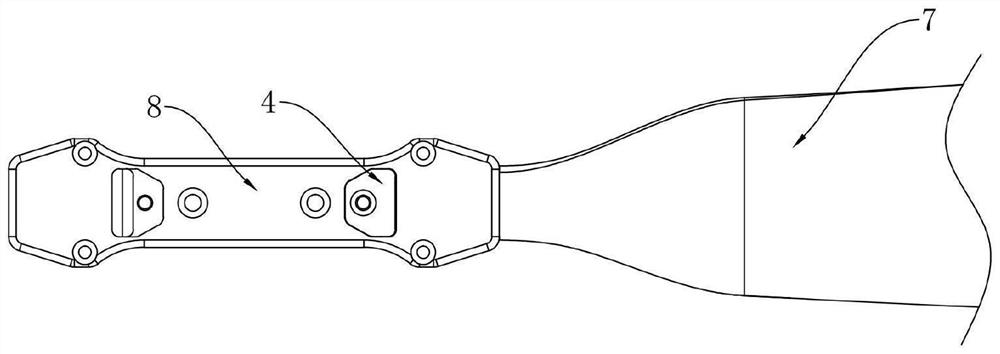

[0038] A specific embodiment of the present invention is shown in the accompanying drawings, a propeller structure includes a blade 7 and a propeller clip; also includes a plurality of positioning blocks 4 with mating surfaces 5 with different inclination angles;

[0039] Both sides of the paddle clip are provided with accommodating holes for accommodating the paddle 7 , and the paddle clip is provided with a positioning hole 14 for installing the positioning block 4 , and the positioning hole 14 communicates with the accommodating hole , the positioning block 4 is detachably arranged in the positioning hole 14;

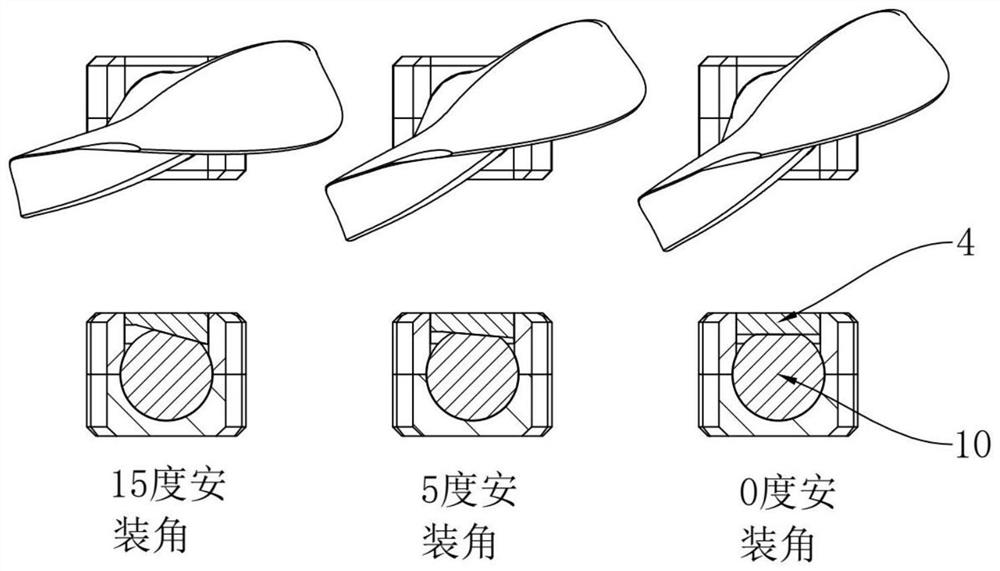

[0040] A positioning shaft 10 is provided at one end of the paddle clip that is matched with the accommodating hole, and a positioning shaft 10 is provided on the positioning shaft 10 to cooperate with the mating surface 5 of the positioning block 4 to realize the radial positioning of the positioning shaft (restrict the rotation of the positioning shaft). Limit surf...

Embodiment 2

[0046] A method for developing and shaping a propeller structure, the method comprises the following steps

[0047] 1. In the initial manufacturing stage of the project, prepare at least 2 to 3 sets of blade plans and make samples (several plans are the preferred main plans, using different local airfoils, chord length distribution, and blade tip designs), each The solutions all integrate the same positioning shaft structure at the root in advance, and make several sets of propeller clips with different installation lengths and several sets of positioning blocks with different angles. Propeller clips with different lengths are assembled with the same blade, and the maximum diameter of the blade can be adjusted, which can quickly realize the scheme verification of different blade lengths in a short period of time. The positioning blocks of different angles can quickly realize the installation and positioning of the blades with different pitches. Both can adjust the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com