Graphite clamp for battery liquid cooling plate brazing and clamping method of thereof

A battery fluid and graphite technology, applied in manufacturing tools, welding equipment, auxiliary devices, etc., can solve problems such as high requirements for the clamping control of the liquid-cooled plate plane, the flatness of the brazing fixture cannot be guaranteed, and the surface flatness of the water-cooled plate is affected. , to shorten the time of clamping the fixture, facilitate the release of heat load, and improve the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

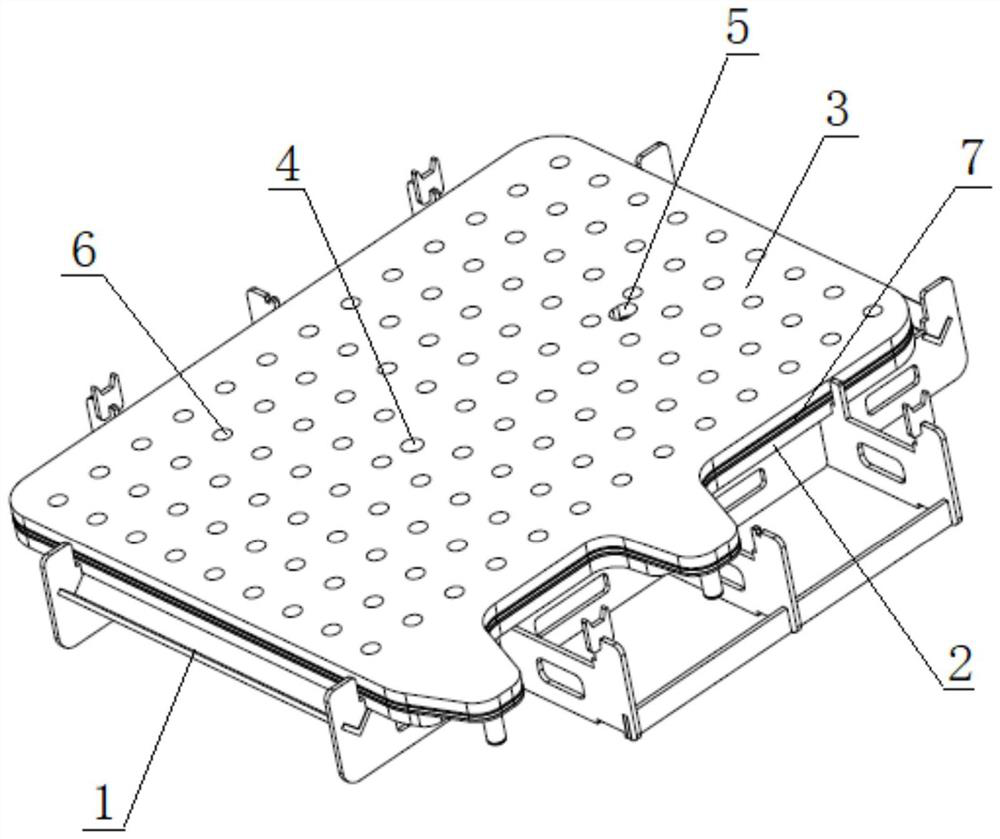

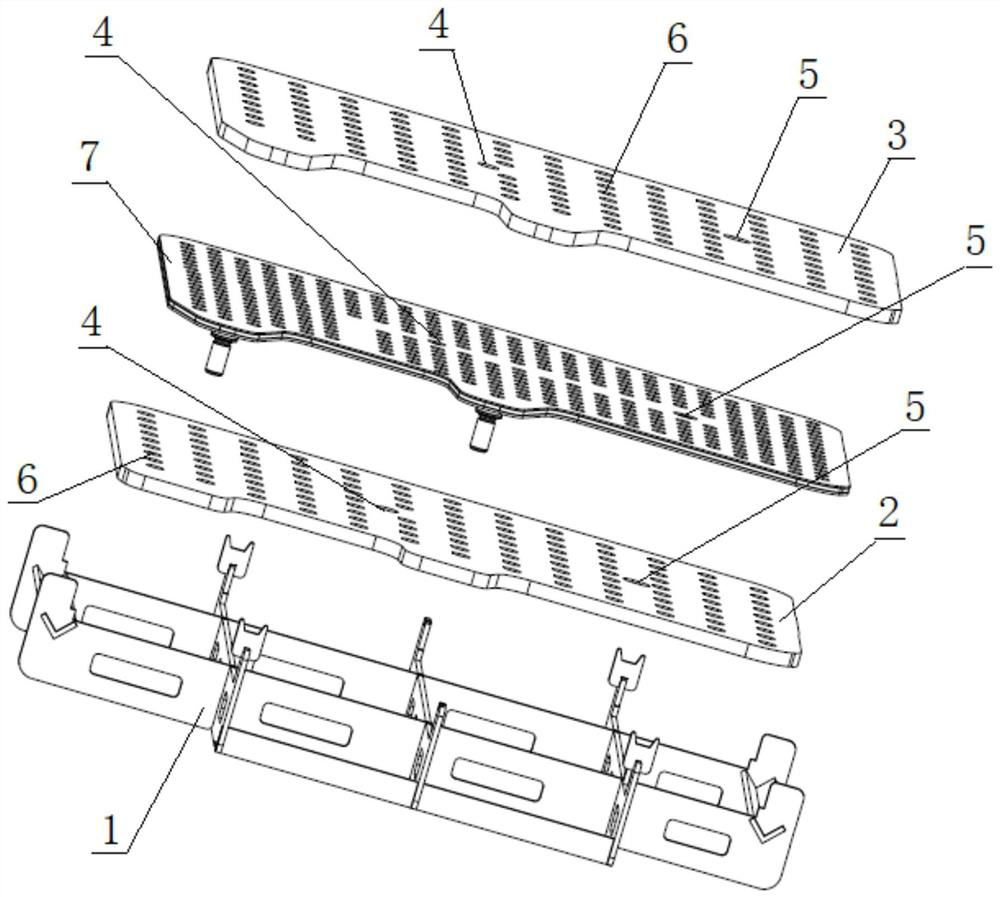

[0033] Such as figure 1 and figure 2 As shown, a graphite fixture for battery liquid cold plate brazing of the present invention includes a stainless steel bracket 1, the stainless steel bracket 1 is two horizontal and three vertical grids, and is welded by stainless steel with a thickness of 2mm. The stainless steel bracket 1 There is a groove space in the central area of the stainless steel bracket 1, and limit ribs are arranged around the groove space of the stainless steel bracket 1. A graphite bottom plate 2 is arranged on the groove space, and a graphite upper plate 3 is arranged above the graphite bottom plate 2. The graphite bottom plate 2 and the graphite upper plate Each plate 3 is provided with a first process positioning hole 4 and a second process positioning hole 5 corresponding to each other.

[0034] Wherein, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com