Patents

Literature

203 results about "Battery fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

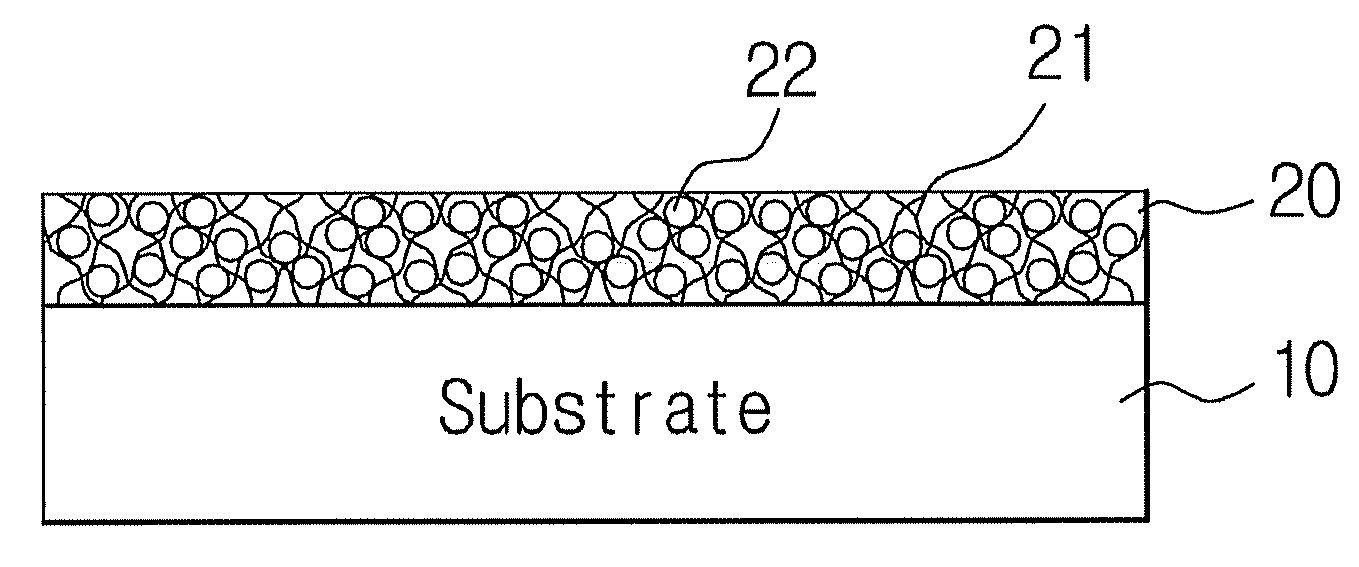

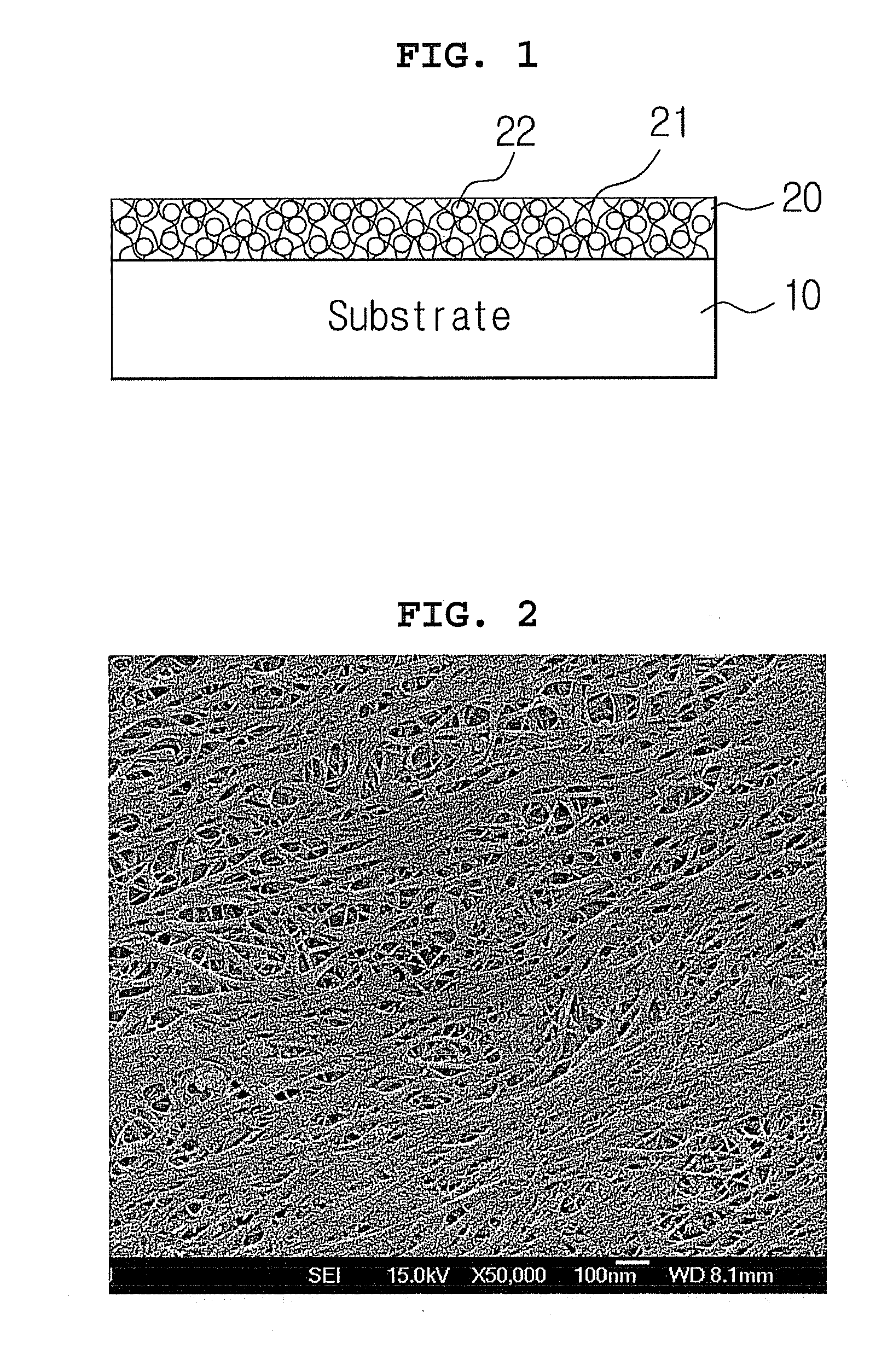

Transparent carbon nanotube electrode using conductive dispersant and production method thereof

ActiveUS20080088219A1Improve conductivityMaterial nanotechnologyConductive layers on insulating-supportsSolar cellTouchscreen

Disclosed is a transparent carbon nanotube (CNT) electrode using a conductive dispersant. The transparent CNT electrode comprises a transparent substrate and a CNT thin film formed on a surface the transparent substrate wherein the CNT thin film is formed of a CNT composition comprising CNTs and a doped dispersant. Further disclosed is a method for producing the transparent CNT electrode.The transparent CNT electrode exhibits excellent conductive properties, can be produced in an economical and simple manner by a room temperature wet process, and can be applied to flexible displays. The transparent CNT electrode can be used to fabricate a variety of devices, including image sensors, solar cells, liquid crystal displays, organic electroluminescence (EL) displays and touch screen panels, that are required to have both light transmission properties and conductive properties.

Owner:SAMSUNG ELECTRONICS CO LTD

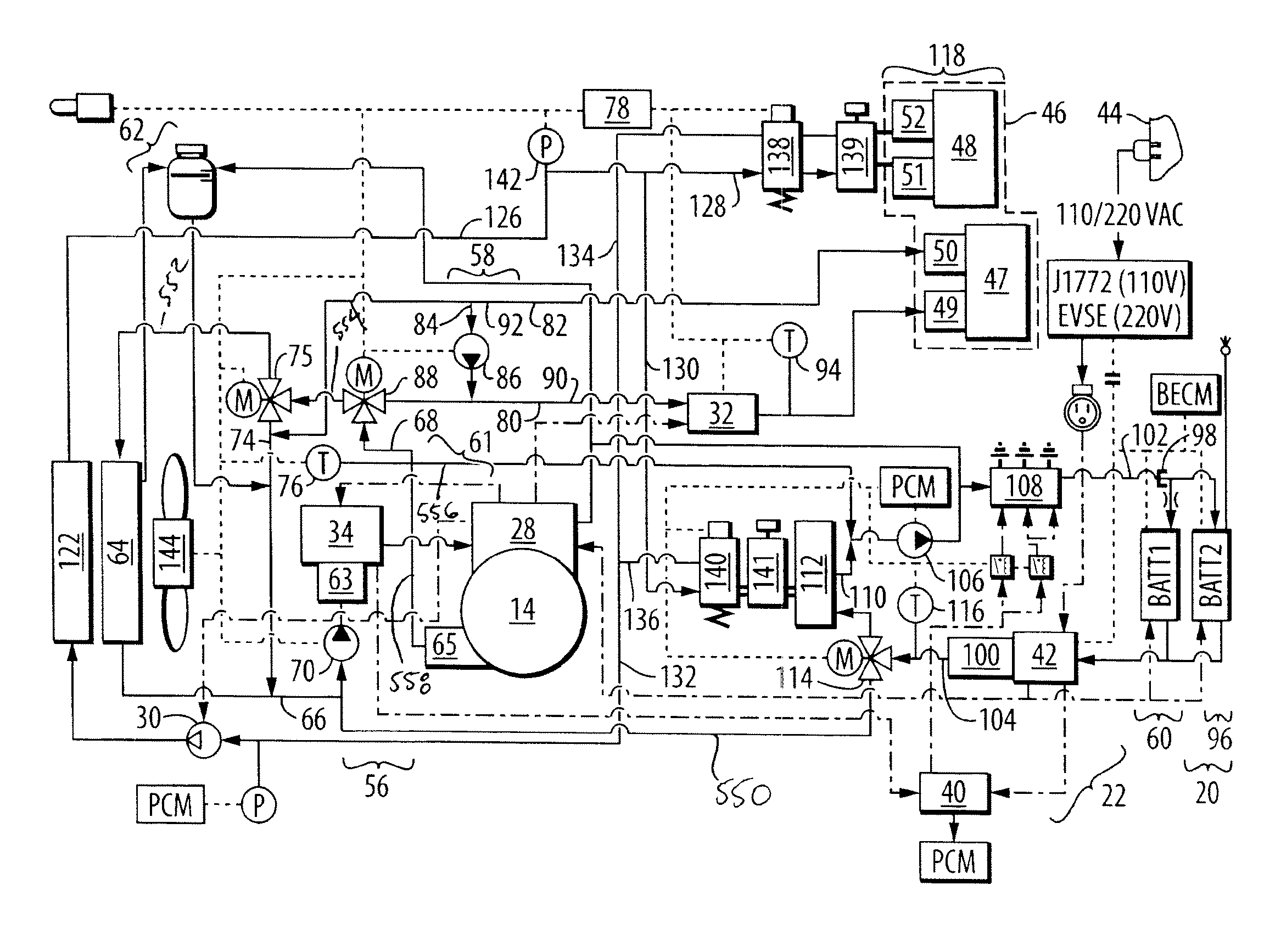

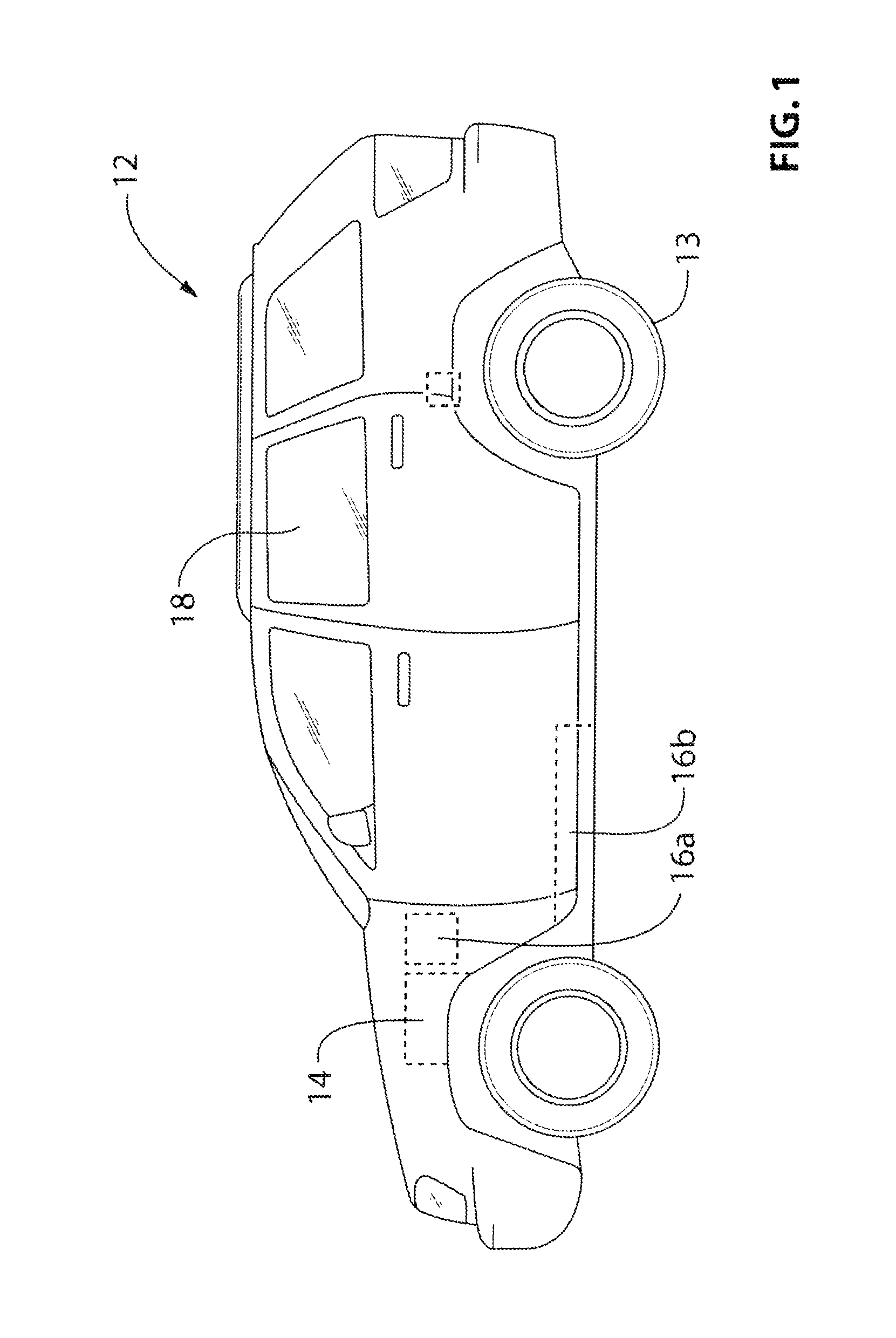

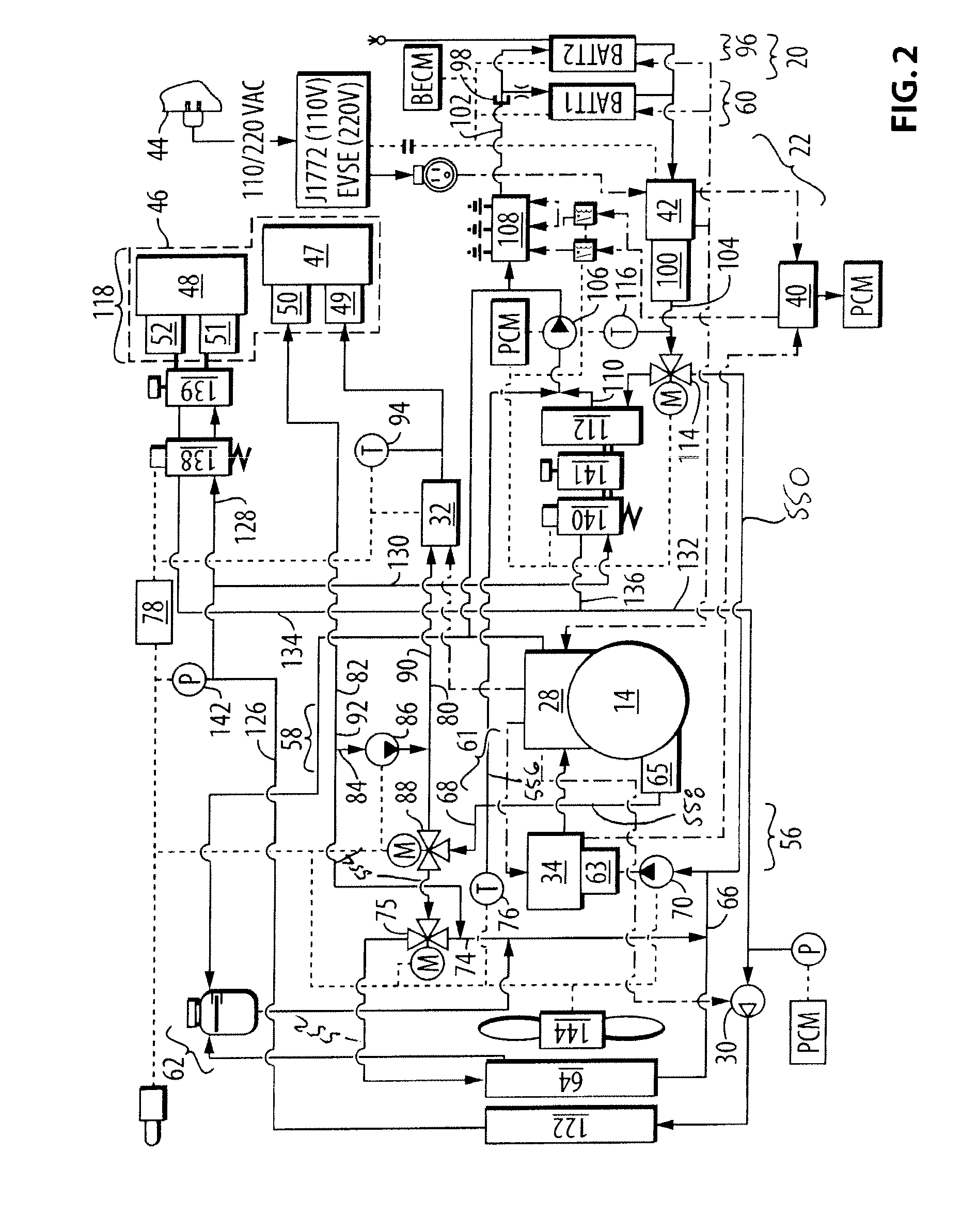

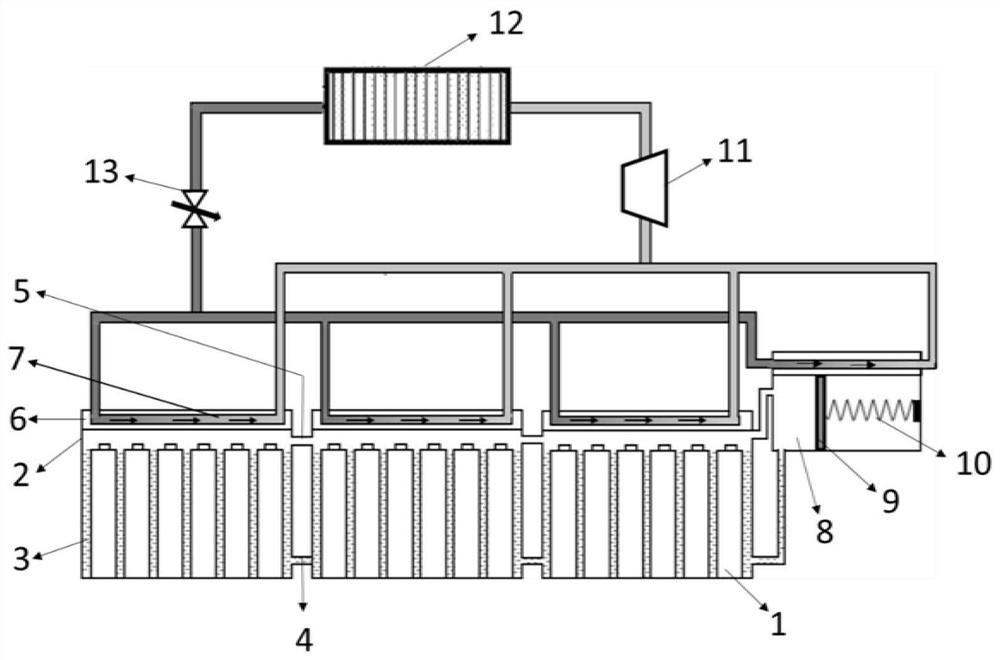

Vehicle with traction motor with preemptive cooling of motor fluid circuit prior to cooling of battery fluid circuit

A thermal management system for an electric vehicle includes a controller that carries out a method of cooling a battery of the electric vehicle. The method includes: a) when charging the battery using an external electrical source but prior to the temperature of the battery reaching a selected temperature, cooling a motor of the electric vehicle by a selected amount by circulating fluid between the motor and a radiator of the electric vehicle, and b) after step a) cooling the battery of the electric vehicle by circulating fluid between the battery, the motor and the radiator while charging the battery using the external electrical source.

Owner:MAGNA E CAR SYST OF AMERICA

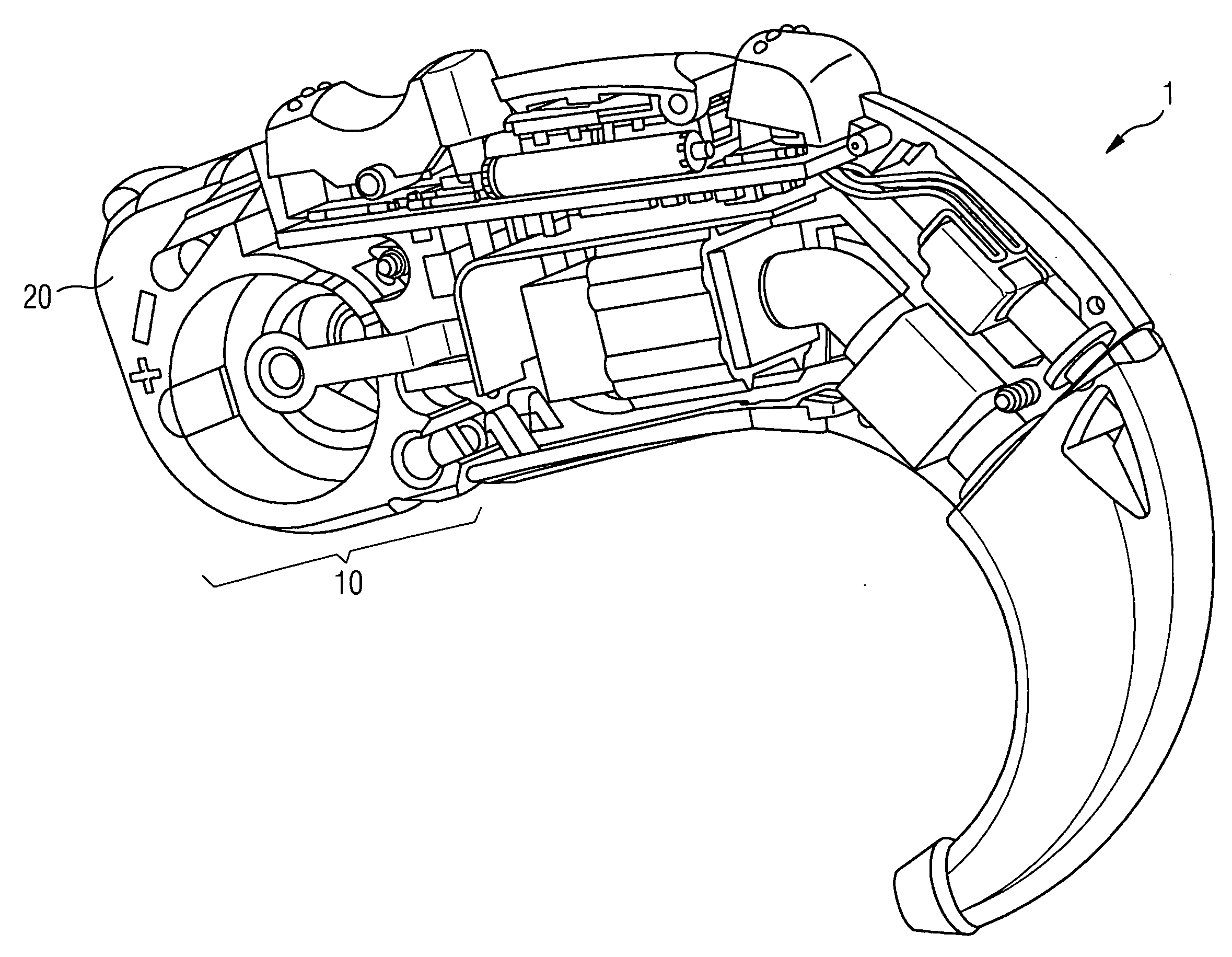

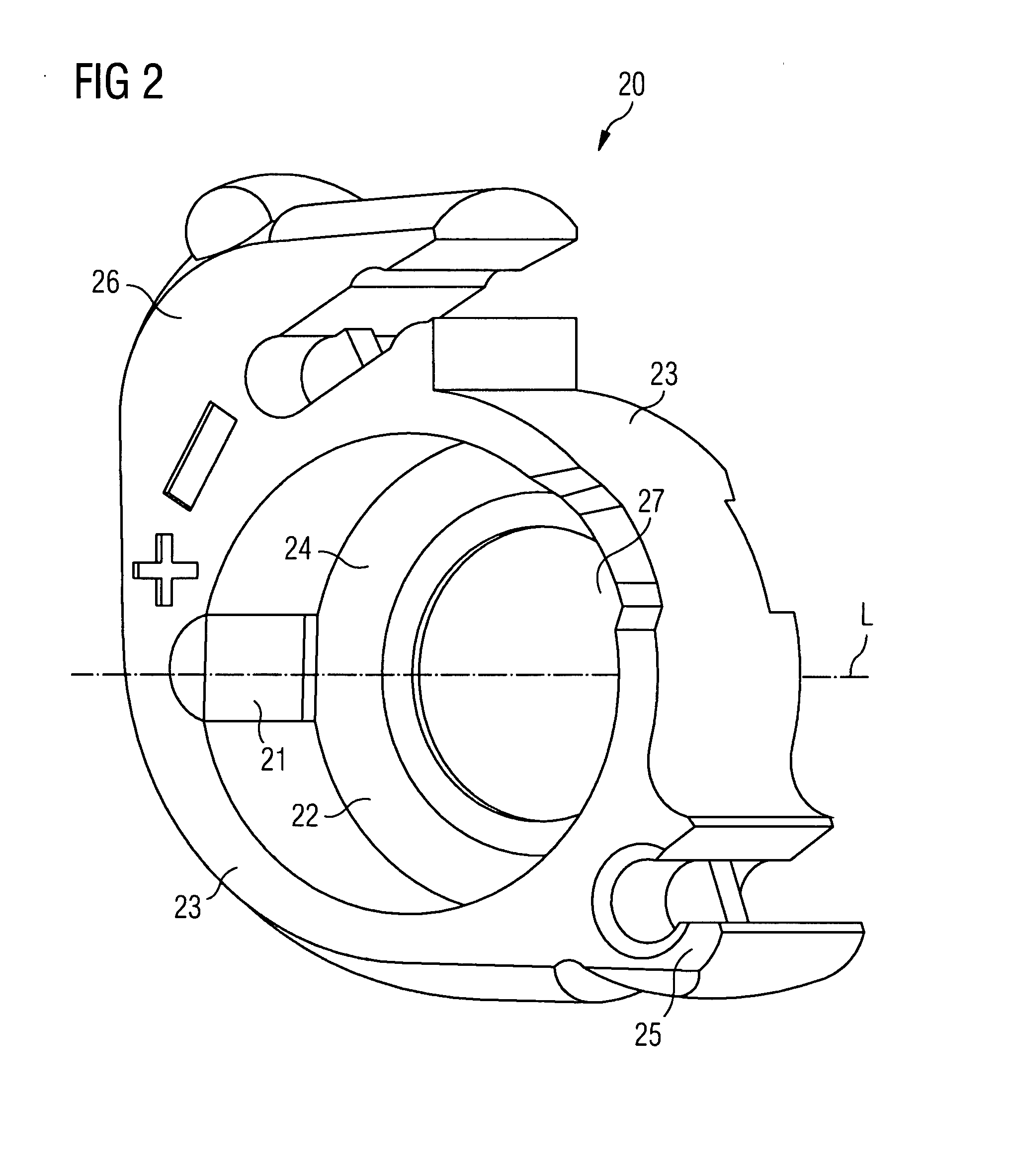

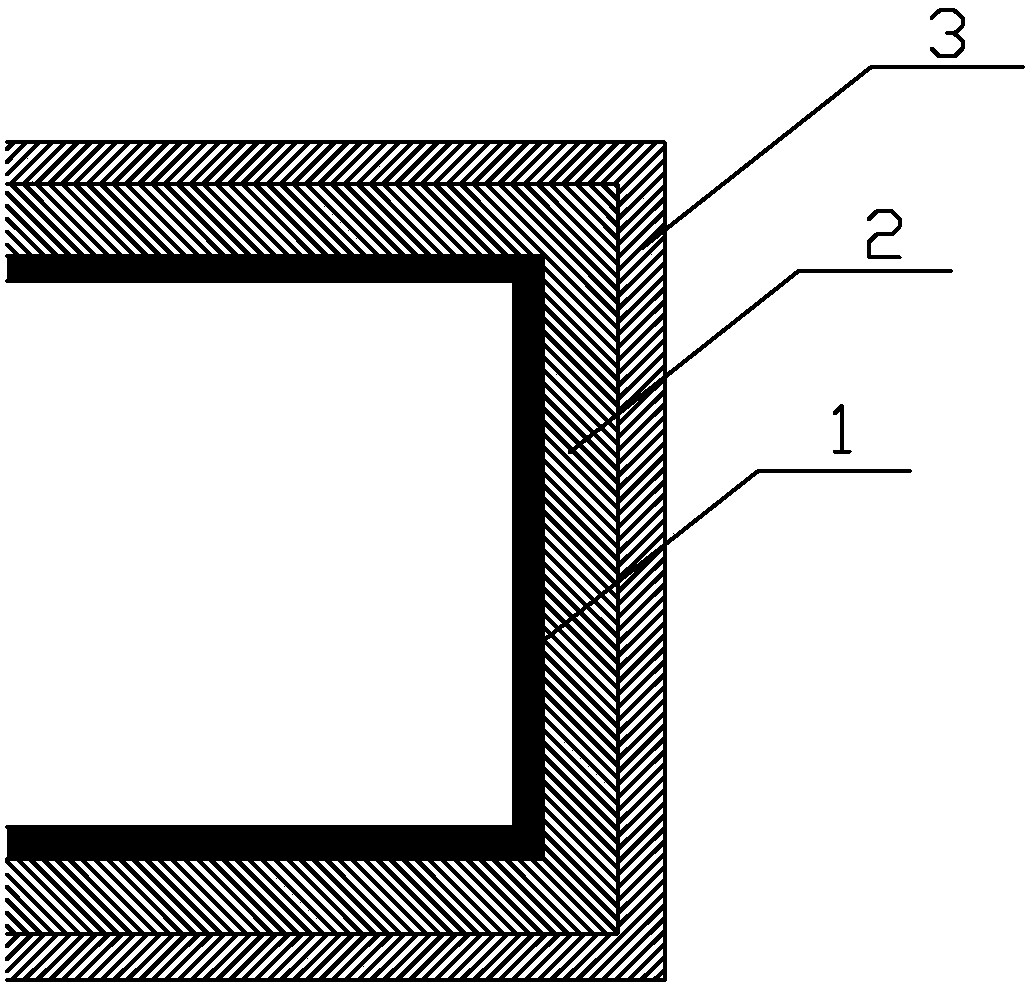

Hearing aid with a battery compartment

The invention relates to an electrical device with a battery compartment that all batteries can be accommodated therein and in the event that the battery dies, battery fluid is prevented from escaping into the interior of the electrical device. The battery compartment comprises a battery compartment casing which can be provided in or on an area of the electrical device, said battery compartment casing comprising a battery recess for accommodating a battery, with the battery being held in a predetermined position in the electrical device by a permanently magnetic area of the electrical device when the battery compartment casing is in a use position in or on the electrical device. The electrical device is in particular a hearing aid.

Owner:SIEMENS AUDIOLOGISCHE TECHN

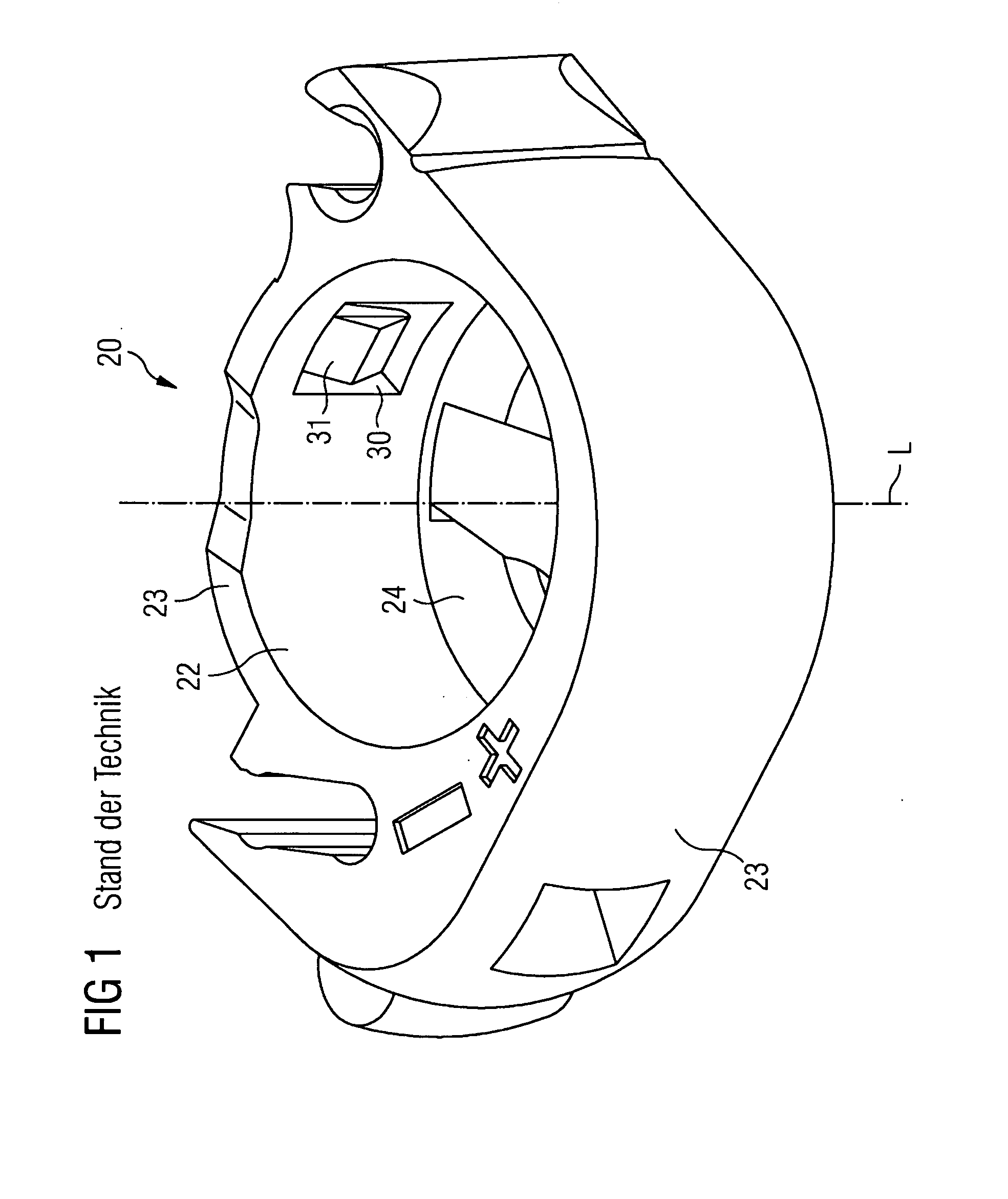

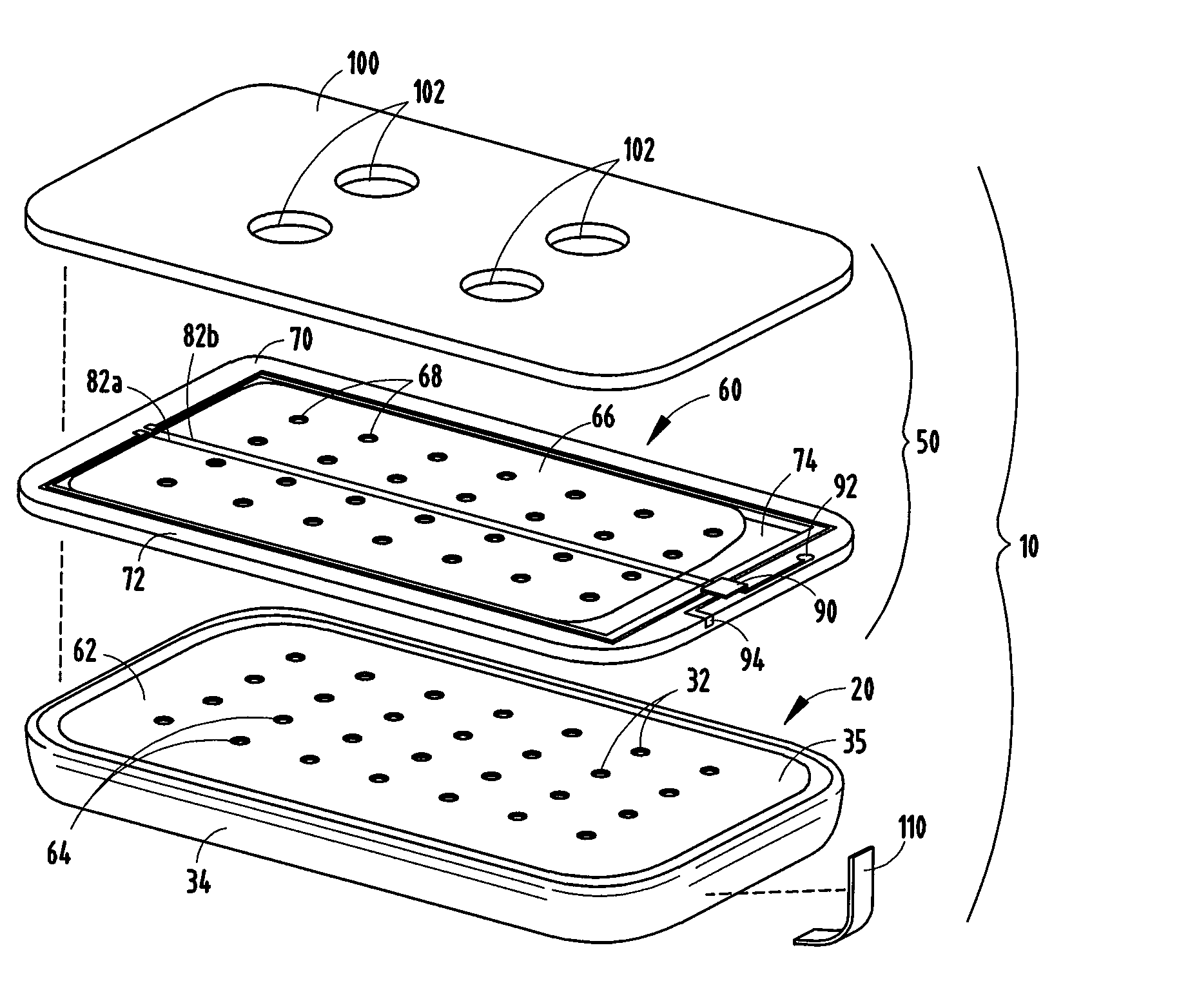

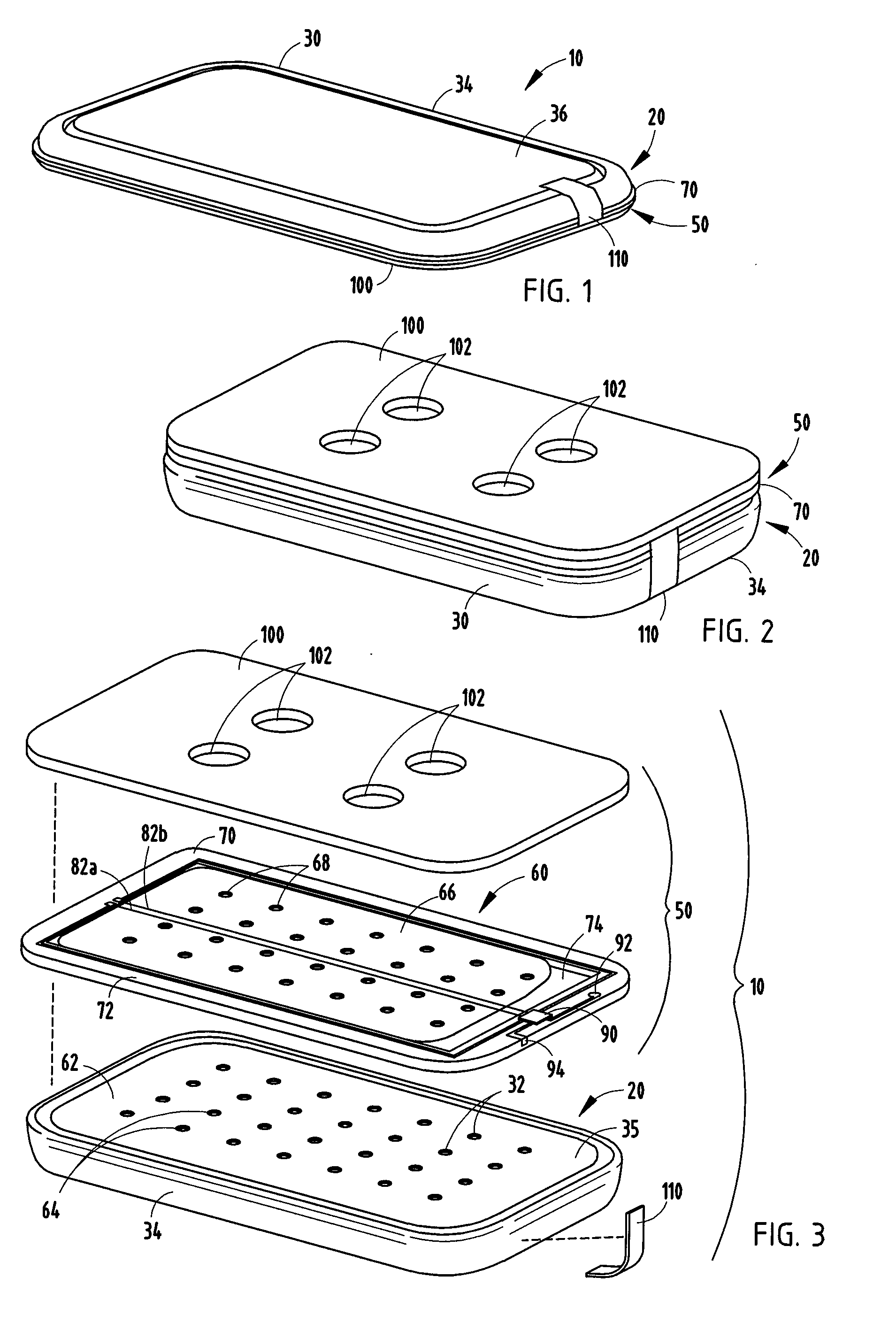

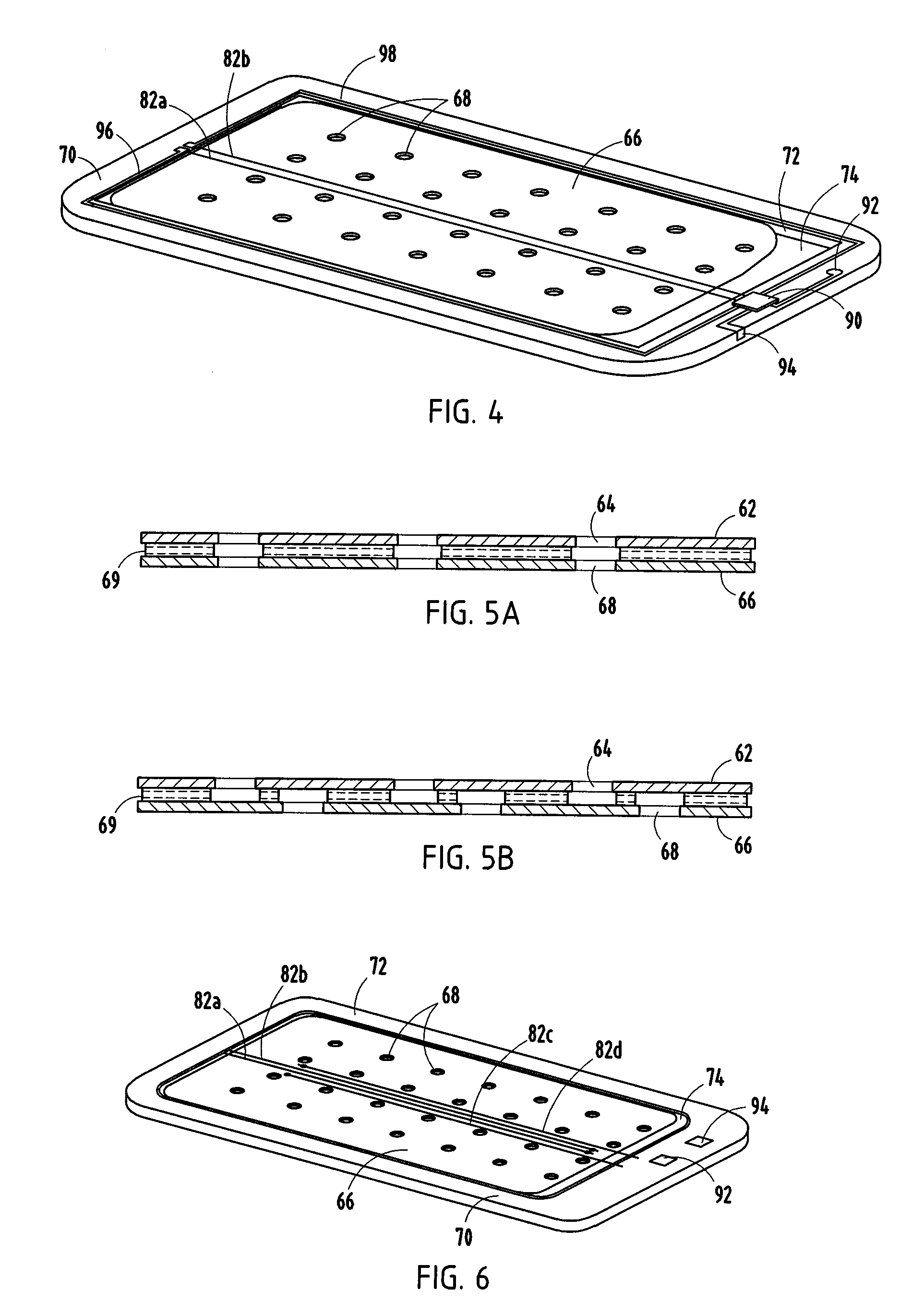

Battery fluid manager using shape memory alloy components with different actuation temperatures

A fluid consuming battery (10) is provided with a fluid regulating system (50) for regulating fluid entry into the battery. The battery (10) includes a fluid consuming cell (20) having a cell housing with fluid entry ports for the passage of a fluid into the cell housing. A first fluid consuming electrode and a second electrode are disposed within the cell housing. The fluid regulating system (50) includes a valve having a moving plate (66) disposed adjacent to a fixed plate (62). The moving plate and fixed plate both have fluid entry ports (68, 64) that align in an open valve position and are misaligned in a closed valve position. The fluid regulating system (50) also includes an actuator that may include one or more shape memory alloy (SMA) components (82a, 82b) for moving the moving plate (66) relative to the fixed plate (62) to open and close the valve.

Owner:ENERGIZER BRANDS

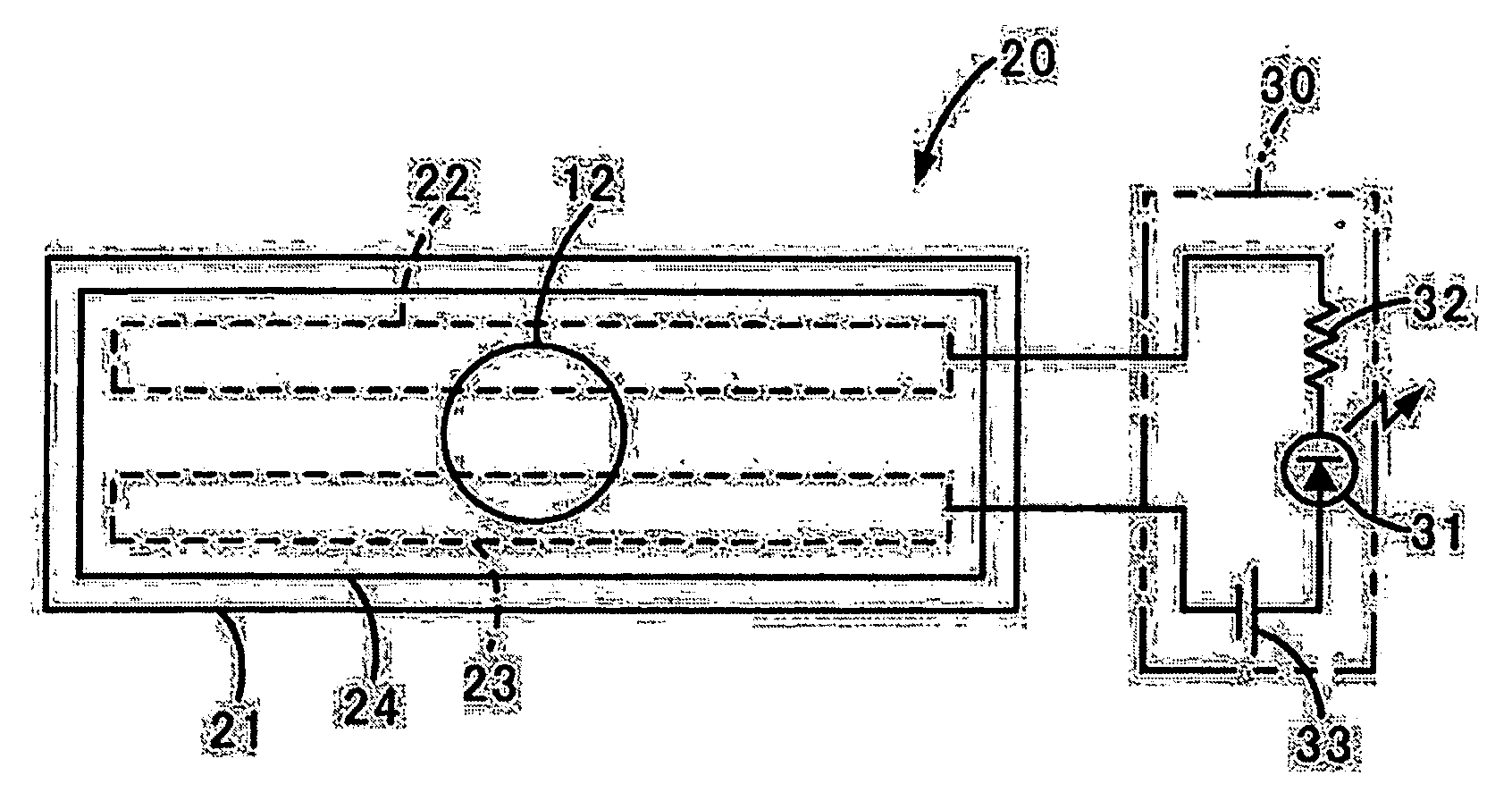

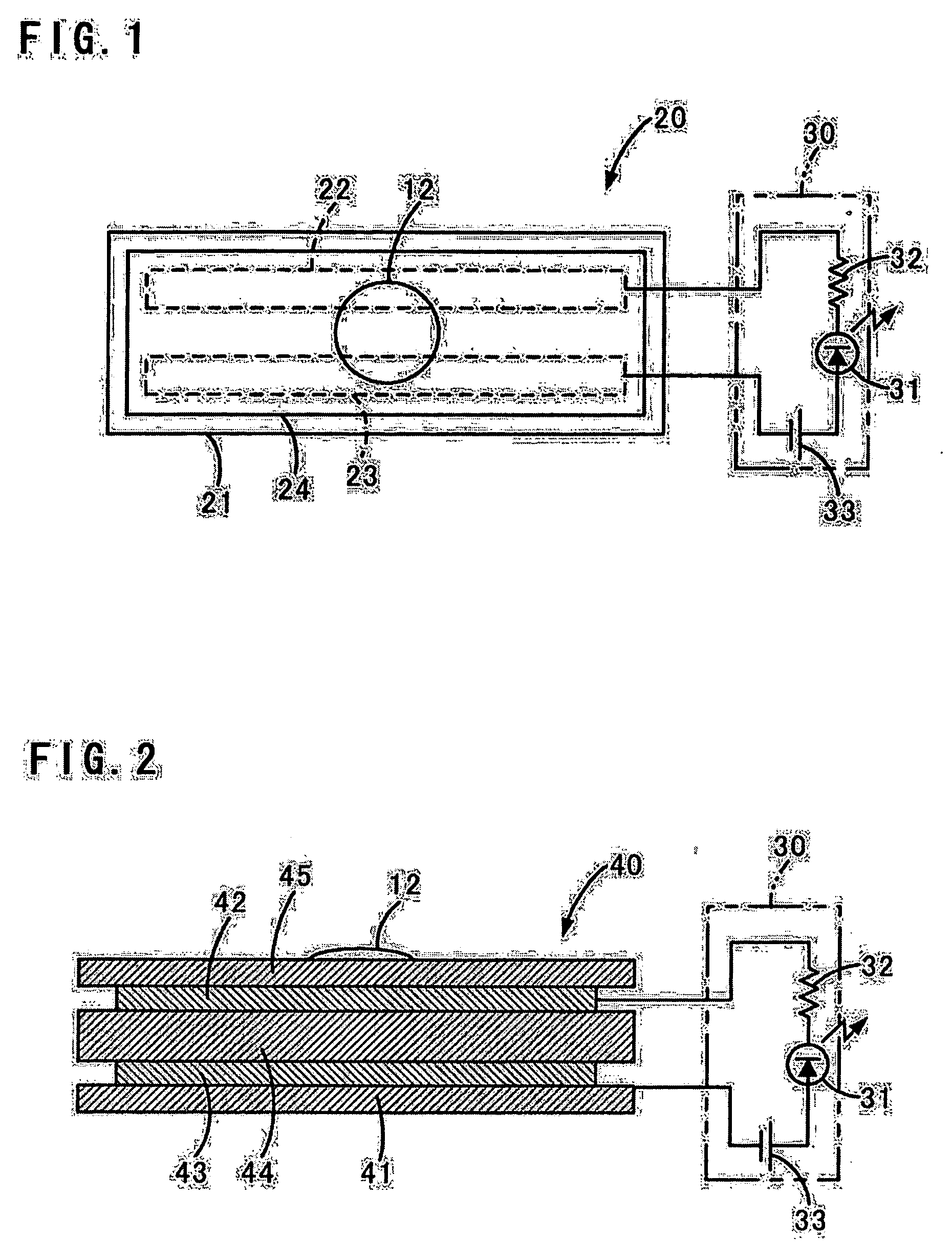

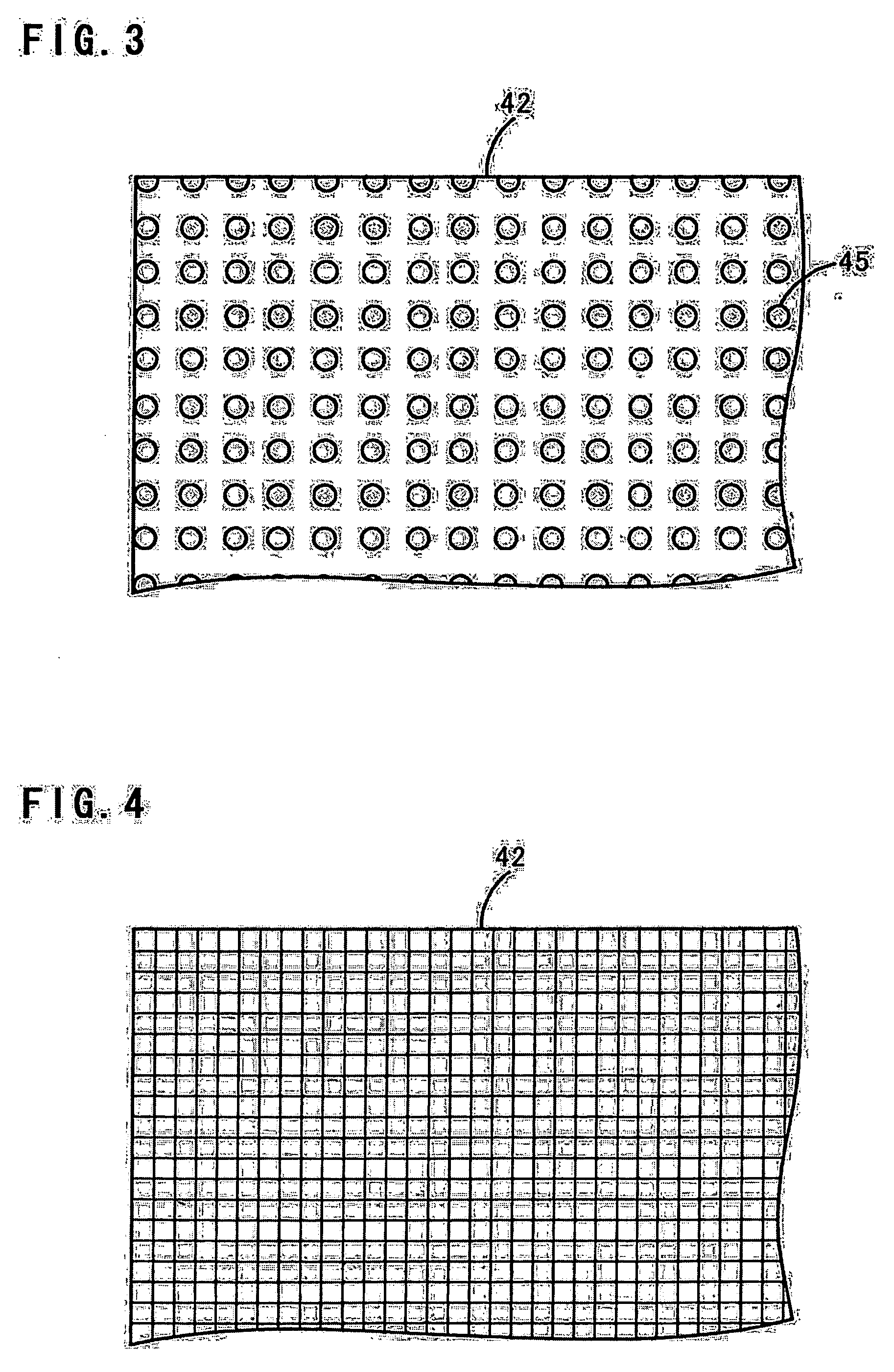

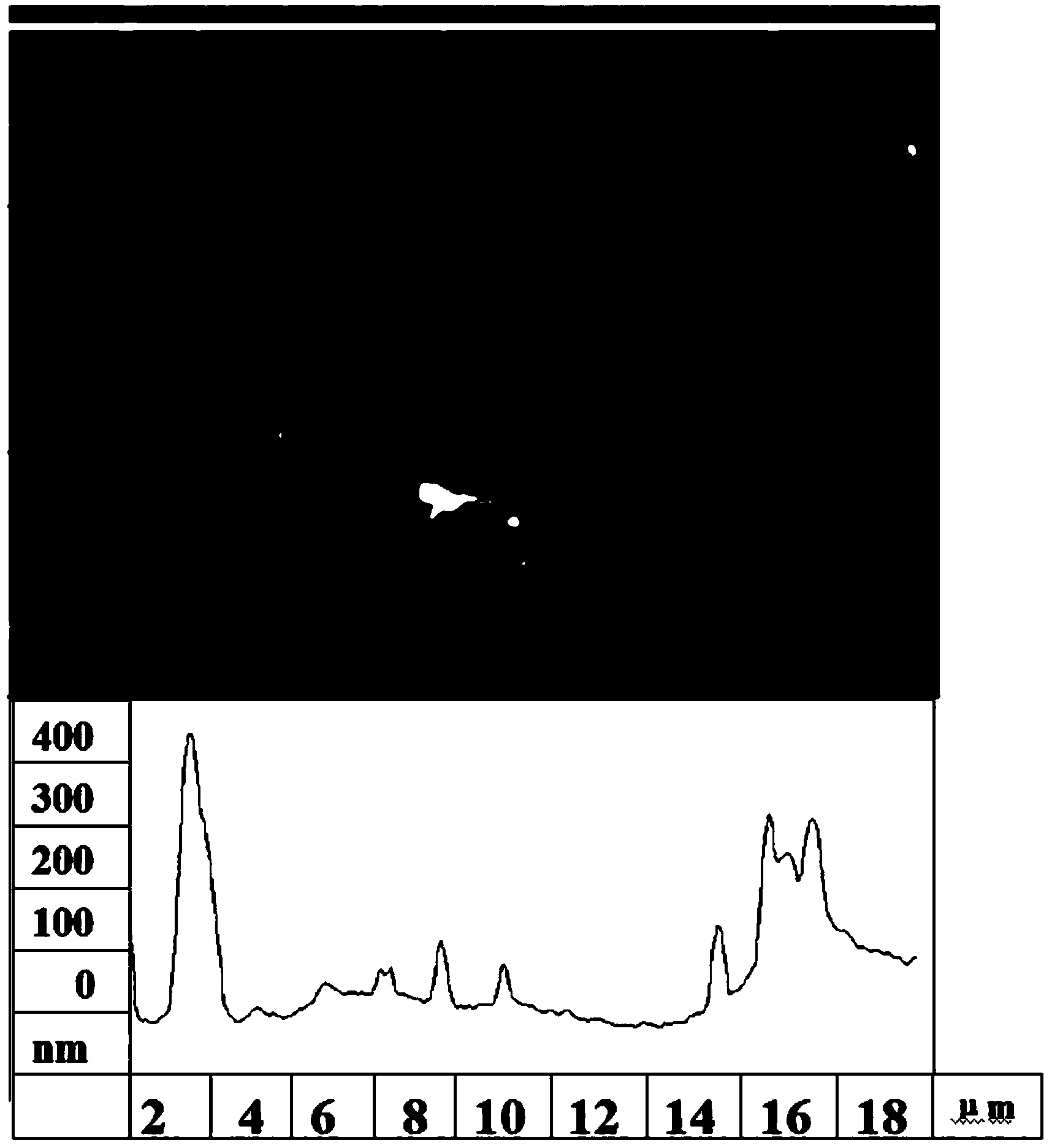

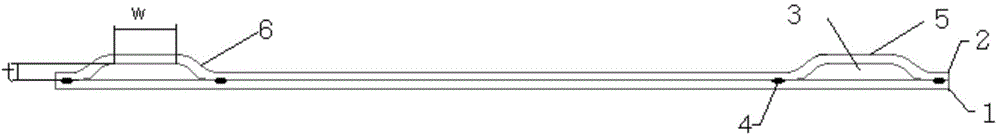

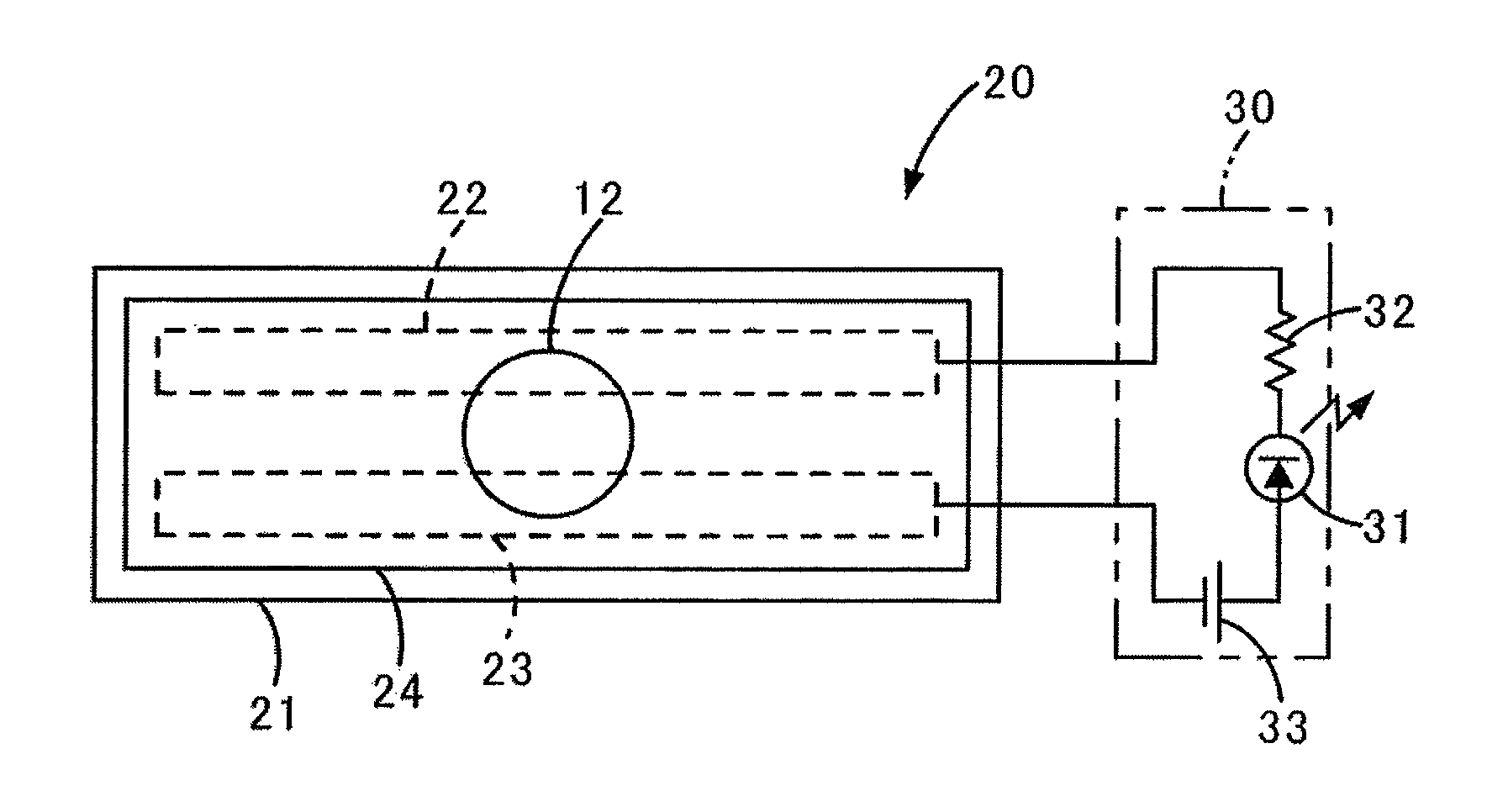

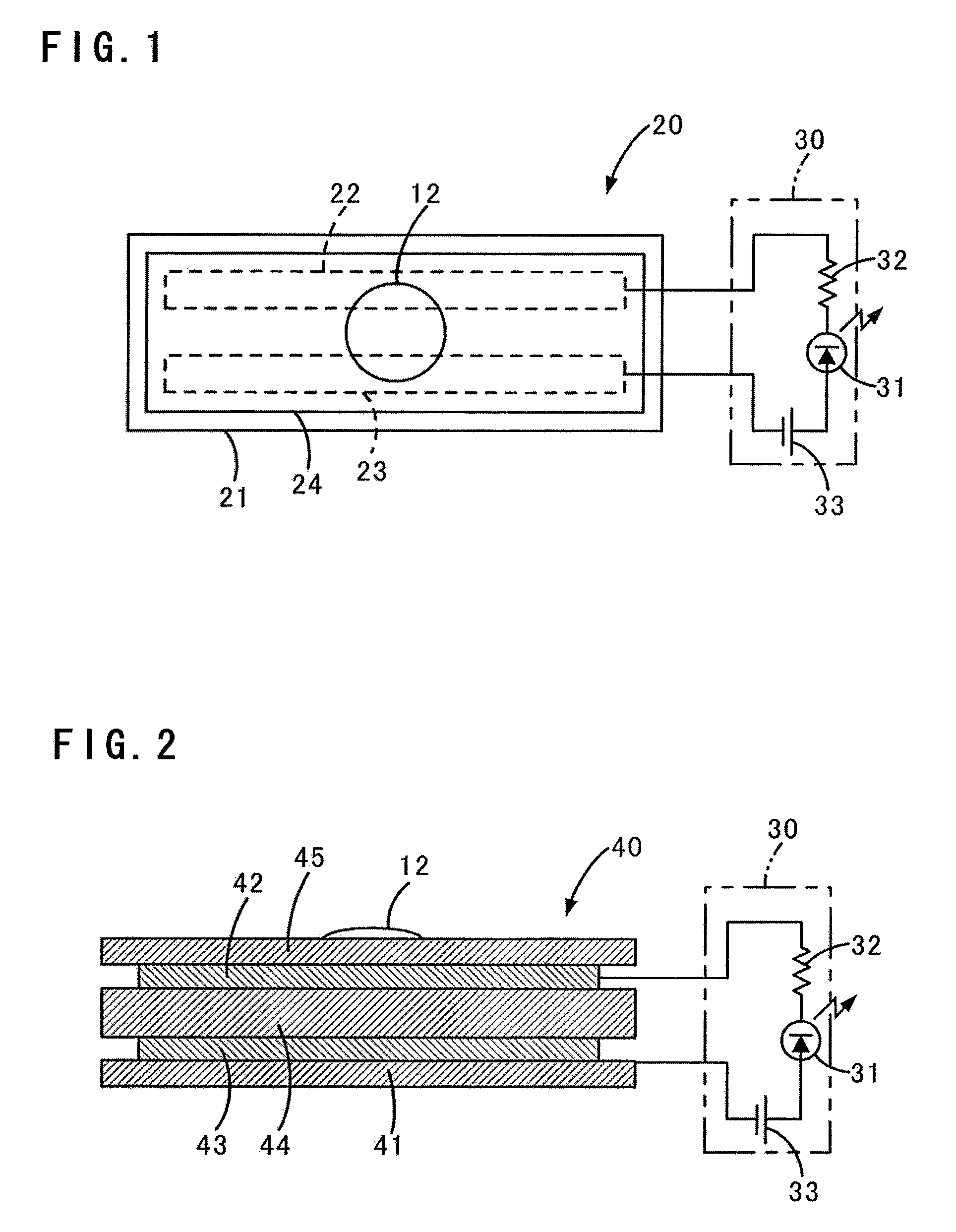

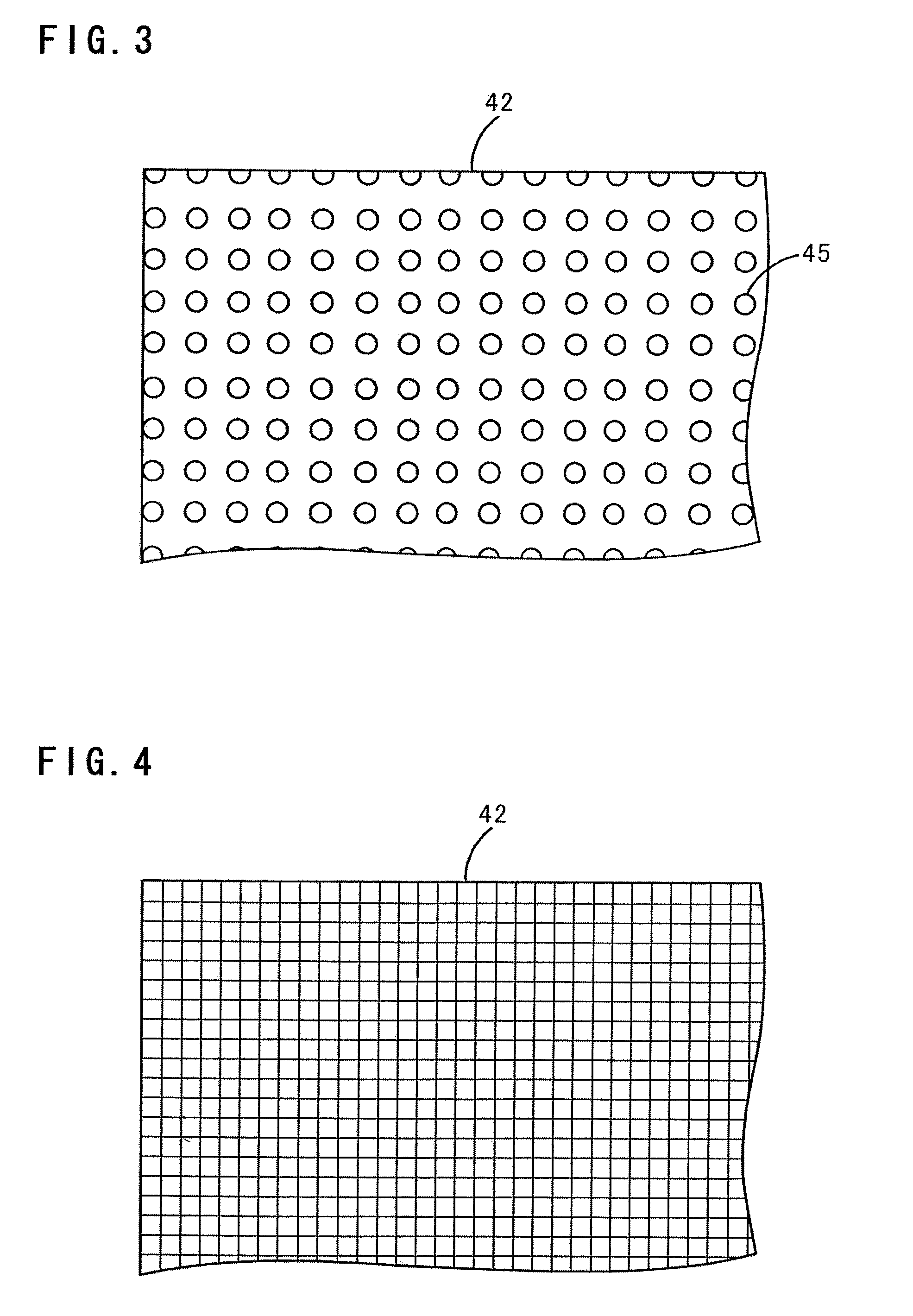

Acid Liquid Leakage Sensor

ActiveUS20070275296A1Quick checkEasy to adjustDetection of fluid at leakage pointLead-acid accumulatorsHigh resistanceEngineering

An acid liquid leakage sensor quickly detecting liquid leakage from a device, such as a battery or the like, containing an acid liquid includes a first conductive member, a second conductive member, and an electrically insulating material which establishes an electrically insulating state between these first and second conductive members. The electrically insulating material includes a macromolecular compound having a basic functional group, and an electrical insulation characteristic or high resistance characteristic that decreases upon reaction with an acid liquid. It is possible to detect leakage of acid liquid, such as battery fluid, by detecting the change of conductive state between the first conductive member and the second conductive member which accompanies a decrease of the electrical insulation characteristic or high resistance characteristic of the electrically insulating material, when acid liquid leaks out and drips down the electrically insulating material.

Owner:NTT FACILITIES INC +1

Composite flexible transparent electrode of copper nanowires and poly (3, 4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) and manufacturing method thereof

InactiveCN103440896AFix stability issuesImprove conductivityConductive layers on insulating-supportsOrganic conductorsComposite filmEthylenedioxy

The invention discloses a flexible transparent electrode and a manufacturing method of the flexible transparent electrode. The flexible transparent electrode is formed by compositing copper nanowires and poly (3, 4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) (PEDOT: PSS) to form a conducting layer and attaching the conducting layer to a transparent polymer substrate. The flexible transparent electrode and the manufacturing method of the flexible transparent electrode solve the problems that a copper nanowire film is poor in stability and large in roughness, and the combination force between the copper nanowire film and the flexible substrate is poor. A copper nanometer wire and PEDOT: PSS composite film has the advantages of being high in conductivity, high in light transmittance, good in flexibility and the like. The obtained flexible transparent electrode has good application value in image sensors, solar cells, liquid crystal displays, organic electroluminescence displays, touch screen panels and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

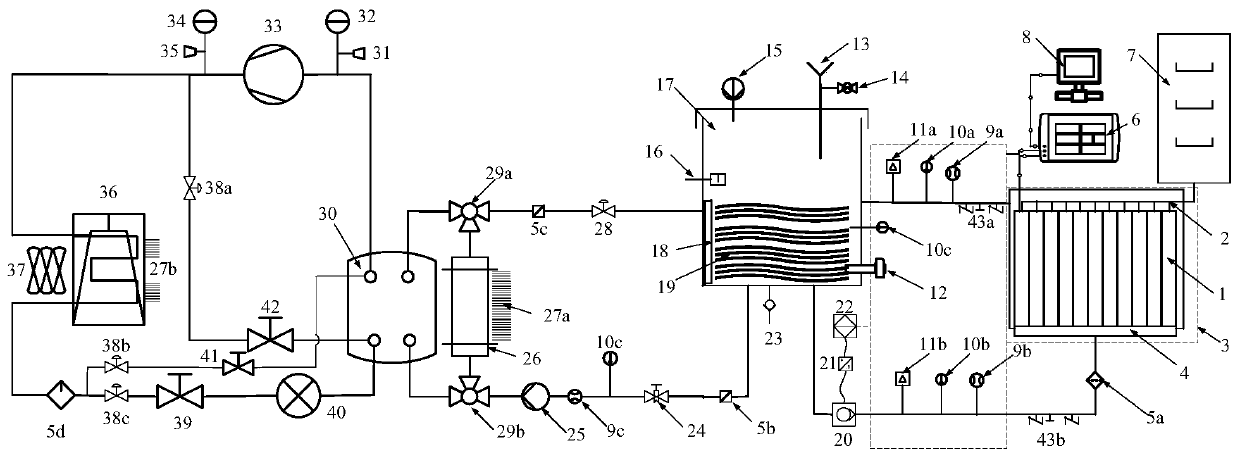

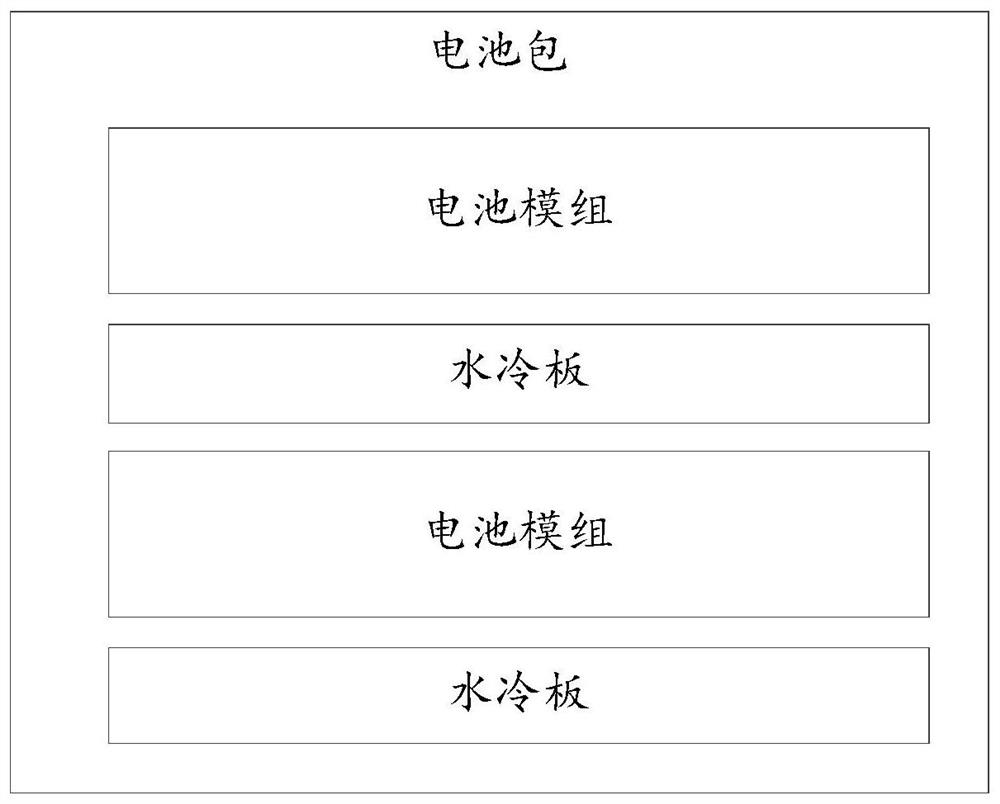

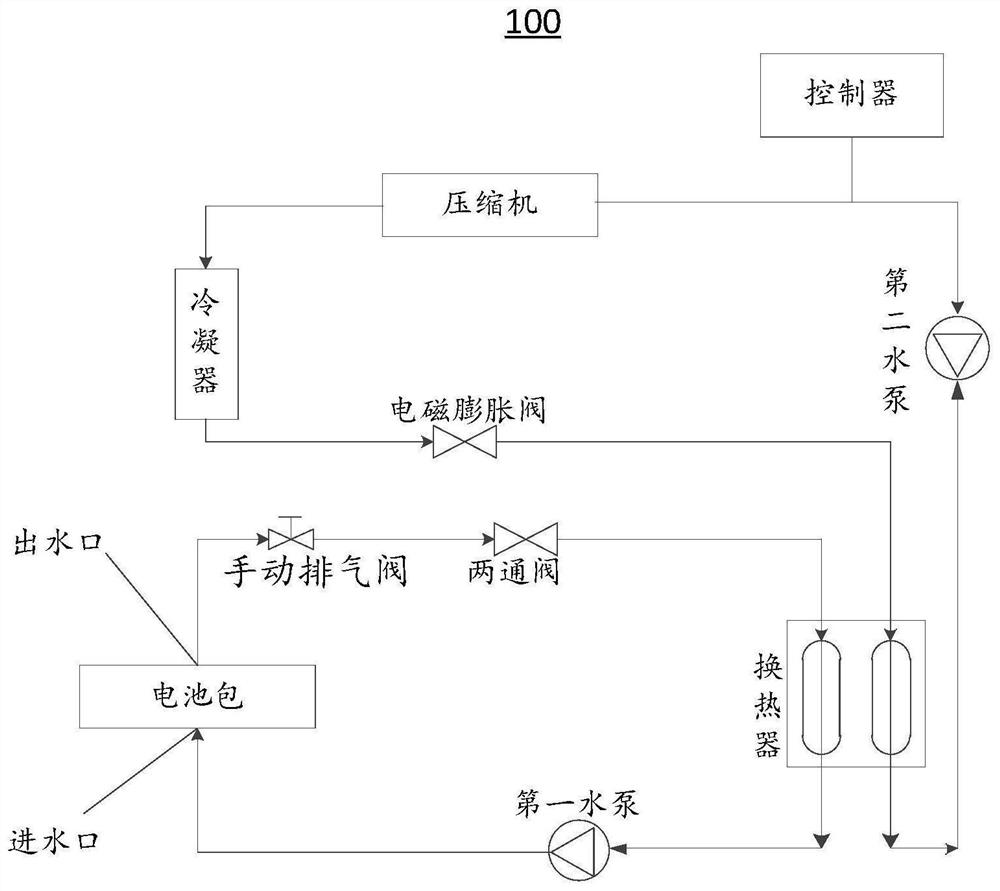

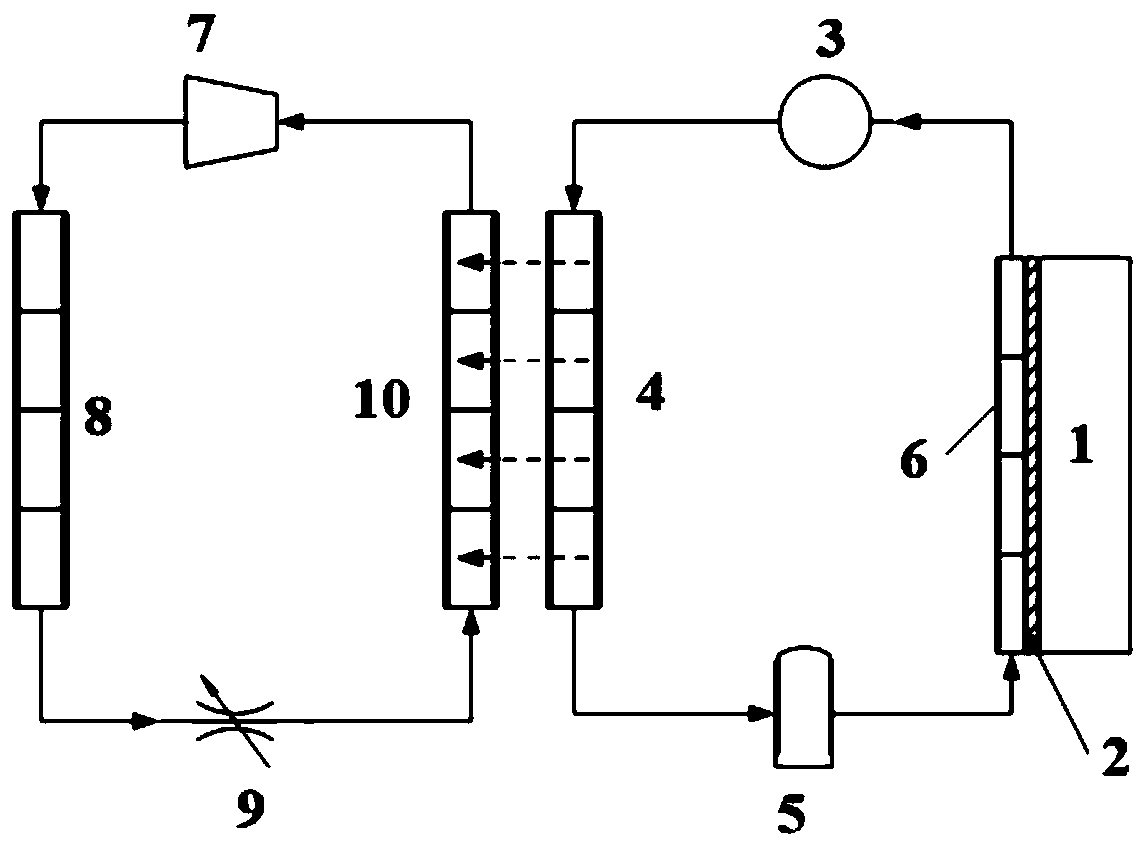

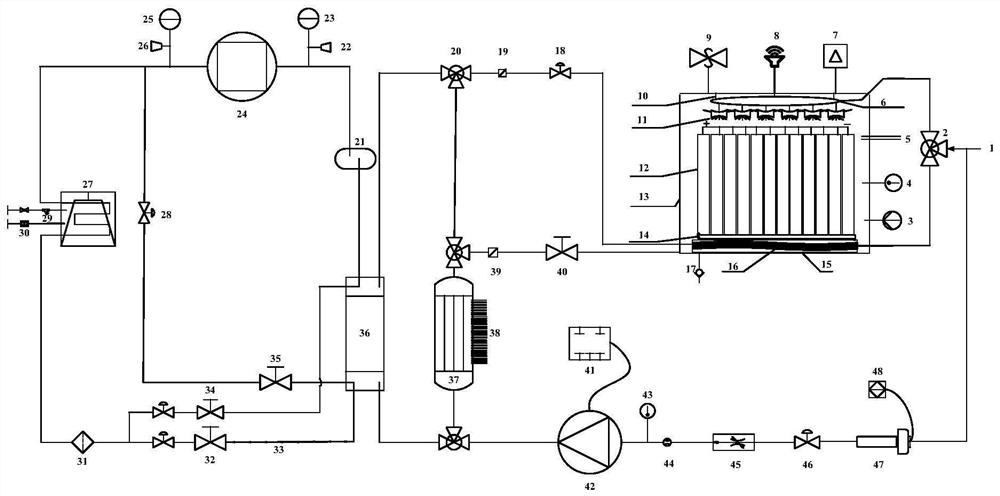

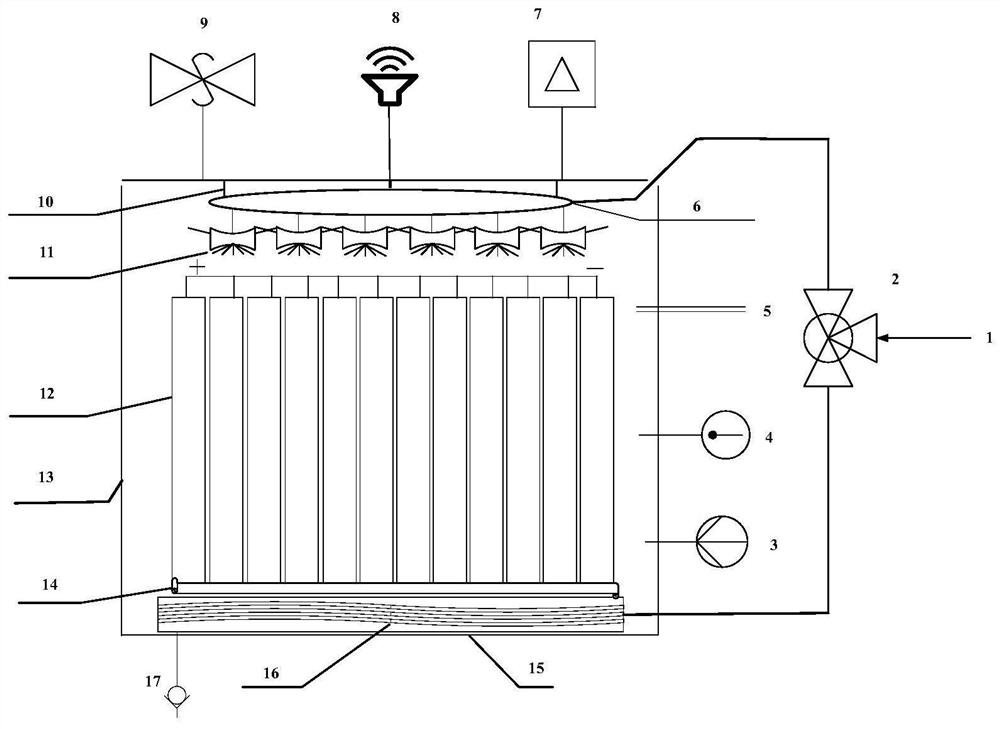

Liquid cooling dynamic heat management system for power supply

ActiveCN111403850AReal-time monitoring of operating parametersCompact structureCell temperature controlLiquid storage tankCirculator pump

The invention aims to provide a liquid cooling dynamic heat management system for a power battery. The system comprises a battery module, a liquid cooling plate, an outer circulating pump, a liquid storage tank, a multifunctional sensor, an inner circulating pump, a heater, a compressor, a condenser, an evaporator, a plate heat exchanger and a charging and discharging instrument, the system comprises a battery liquid cooling unit, a compressor unit refrigeration unit, a liquid cooling internal circulation unit, a liquid cooling external circulation unit, an environment simulation unit, a dataacquisition unit, a battery charging and discharging unit and the like. The multi-branch design can ensure that the system selects a proper heat management strategy to work according to the heat production power of the battery, dynamic monitoring and intelligent control of the whole power battery liquid cooling and heating management system are realized, and the energy consumption of the system can be greatly reduced.

Owner:HARBIN ENG UNIV

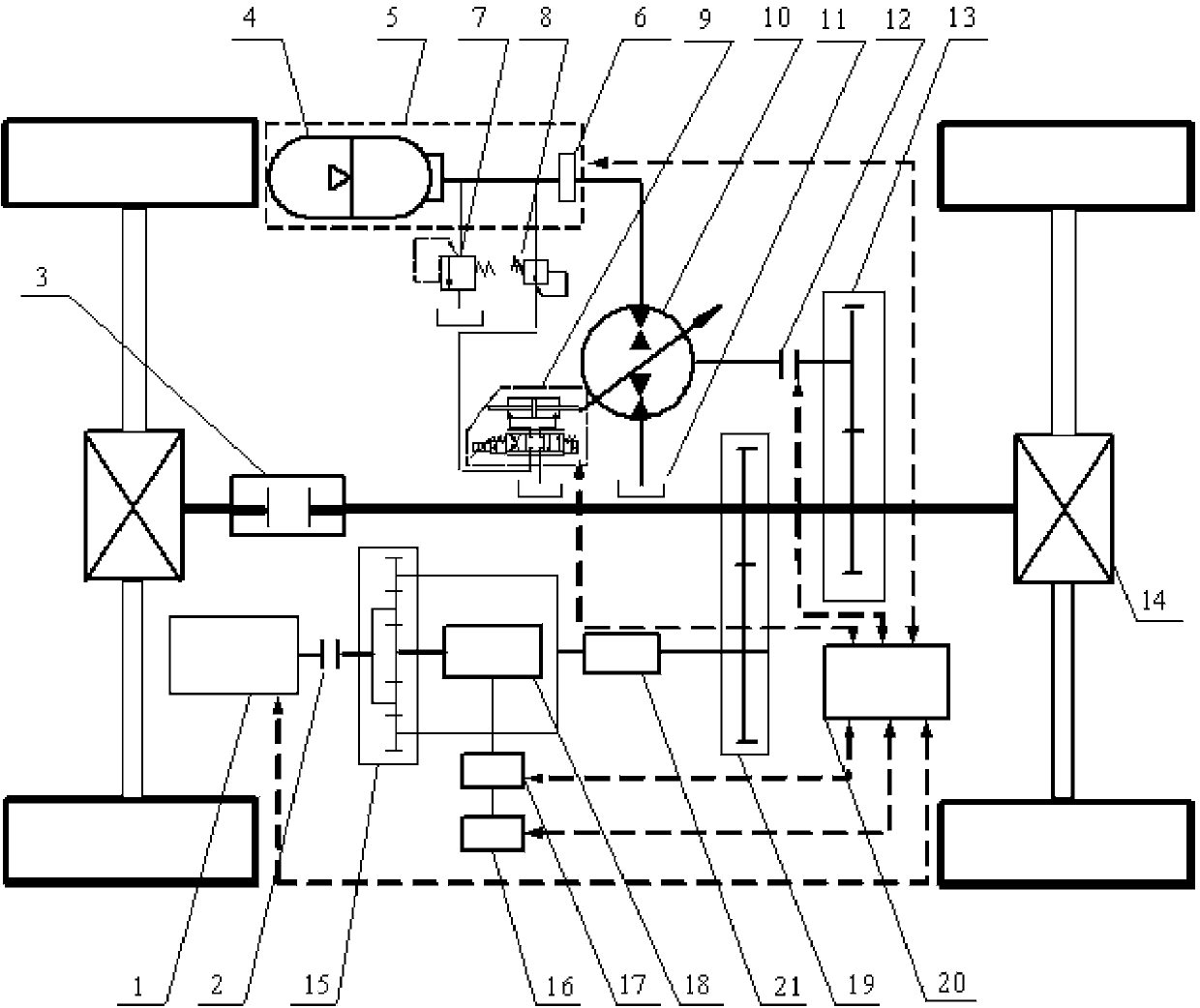

Oil electrohydraulic four-wheel drive hybrid power system and control method thereof

ActiveCN103738154AGuaranteed to workStable jobGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelHigh energy

The invention relates to an oil electrohydraulic four-wheel hybrid power system and the control method thereof. The oil electrohydraulic four-wheel hybrid power system has three power sources: an engine, a storage battery, and a hydraulic accumulator. The engine is successively mechanically connected with a clutch, an epicyclic train, a motor, a transmission and a gear train, an inverter is respectively connected with the motor and the storage battery, and a torque coupler is mechanically connected with an electromagnetic clutch and an output shaft of the hydraulic motor pump. A feed port of an overflow valve is communicated with an oil port of a hydraulic accumulator; a feed port of the hydraulic motor pump control assembly is communicated with an oil-out port of a pressure reducing valve. An oil tank is communicated with an oil-out port of the hydraulic motor pump, an oil-out port of the hydraulic motor pump control assembly, and an oil-out port of the overflow valve; an oil-out port of a two-way electro-hydraulic directional control valve is communicated with a feed port of the hydraulic motor pump. The oil electrohydraulic four-wheel hybrid power system has the advantages that the need of high power density and high energy density can be satisfied, the fuel economy of mobiles in different working situations, and the power performance of mobiles can be achieved.

Owner:TIANJIN ENG MACHINERY INST

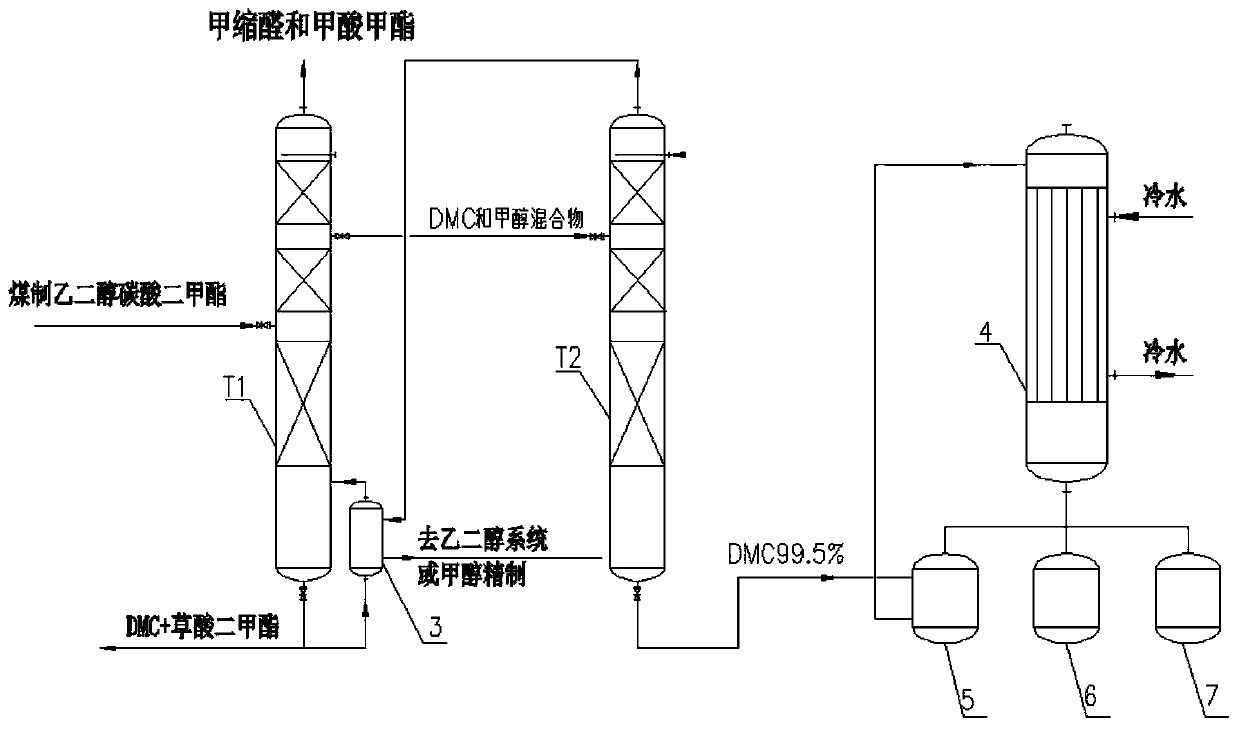

Process for refining battery fluid grade dimethyl carbonate through pressurization method coupled melt crystallization

ActiveCN109970565AControl reflux ratioControl timeOrganic chemistry methodsCarbonic/haloformic acid esters purification/separationMixed materialsBattery fluid

The invention relates to a process for refining battery fluid grade dimethyl carbonate from coal to ethylene glycol by-product dimethyl carbonate through pressurization method coupled melt crystallization. The process comprises the following steps: (1) materials are preheated: a coal to ethylene glycol product enters a normal-pressure T1 removal of light component tower, light components such as methylal and methyl formate are removed at the top of the T1 removal of light component tower, a part of dimethyl carbonate and dimethyl oxalate are removed at the bottom of the T1 removal of light component tower, side-draw produced methanol and DMC close to the upper part of a material inlet of the tower are mixed, and the mixed material enters a T2 pressurization tower; (2) a side-draw producedDMC azeotrope of the T1 tower enters the T2 pressurization tower, a DMC azeotrope with a DMC content of about 15-18% is obtained from the top of the pressurization rectification tower, and DMC with acontent of 99.5% or more is obtained from the tower kettle; and (3) dimethyl carbonate with a content of 99.5% enters a following film falling melt crystallization device, freezing is performed, sweating is performed, dissolving is performed, and therefore the battery fluid grade dimethyl carbonate with a content of 99.99% is obtained. The pressurization coupled melt crystallization separation process provided by the invention can remove more than 10 kinds of impurities in the coal to ethylene glycol by-product dimethyl carbonate, and the product quality reaches 99.99%, and the obtained dimethyl carbonate can be applied to prepare polycarbonate and a lithium battery fluid.

Owner:河北迈太特化工有限公司

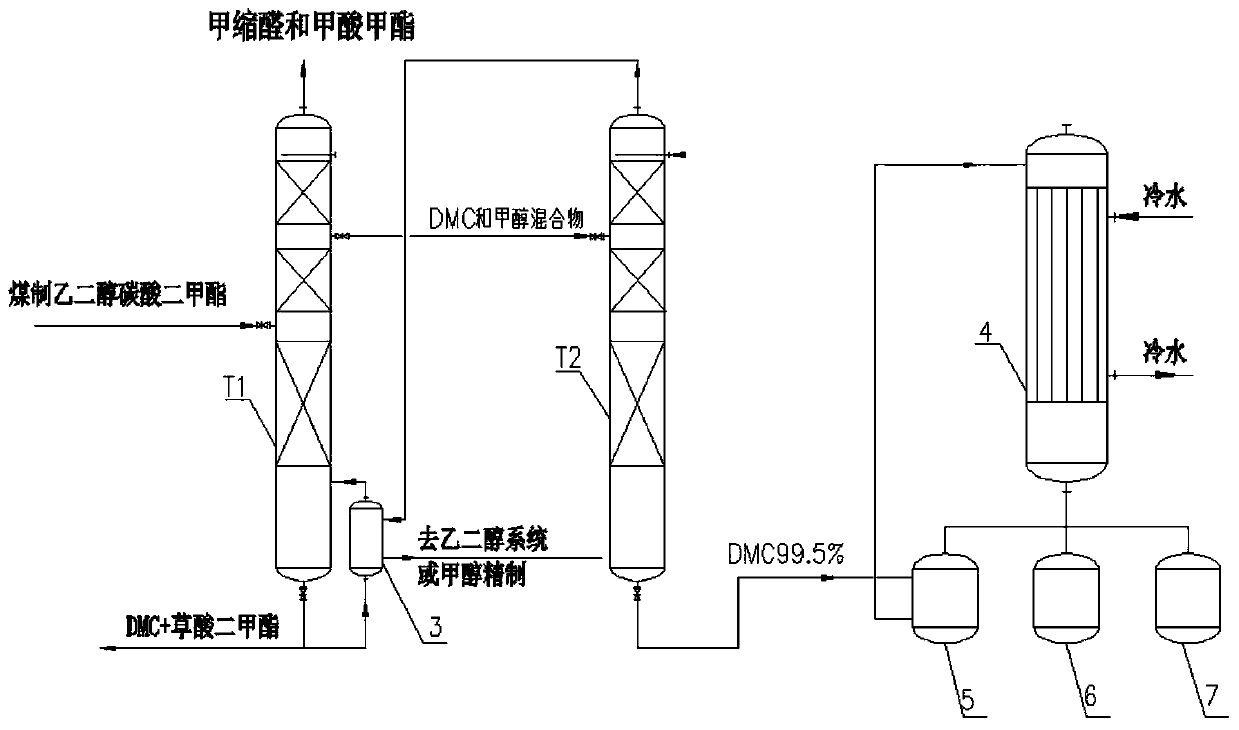

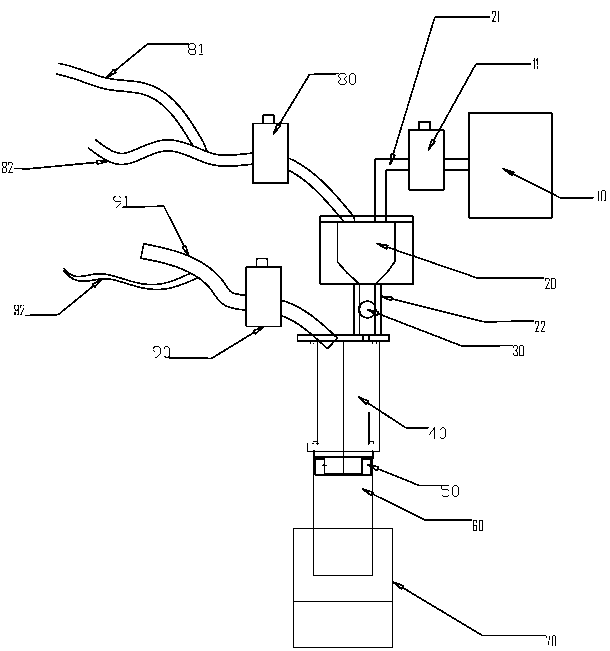

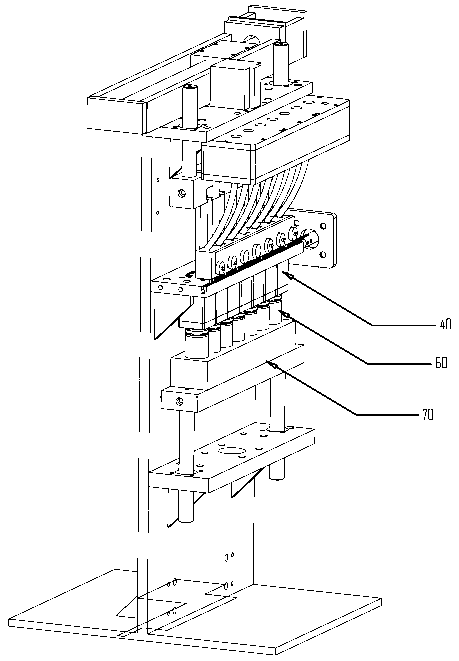

Battery fluid filling device and method

InactiveCN103236514AReduce wasteReduce volatilityCell component detailsElectrolytic agentEngineering

The invention is suitable for the field of battery production, and provides a battery fluid filling device and method. The battery fluid filling device comprises an upper fluid storage container, a lower fluid storage container, a fluid filling pump, a first vacuumizing pump and a second vacuumizing pump, wherein a first valve is arranged between the fluid filling pump and the upper fluid storage container, and a second valve is arranged between the upper fluid storage container and the lower fluid storage container. The battery fluid filling device also comprises a first air source connecting pipe and a second air source connecting pipe which are used for being connected with a dry air source, wherein a third valve is arranged among the first vacuumizing pump, the first air source connecting pipe and the upper fluid storage container, and a fourth valve is arranged among the second vacuumizing pump, the second air source connecting pipe and the lower fluid storage container. The battery fluid filling device is adopted in the battery fluid filling method. According to the battery fluid filling device and method provided by the invention, the fluid filling efficiency is improved, the production cost is lowered, the volatilization of electrolyte is reduced, and the safety is good.

Owner:江西佳沃新能源有限公司

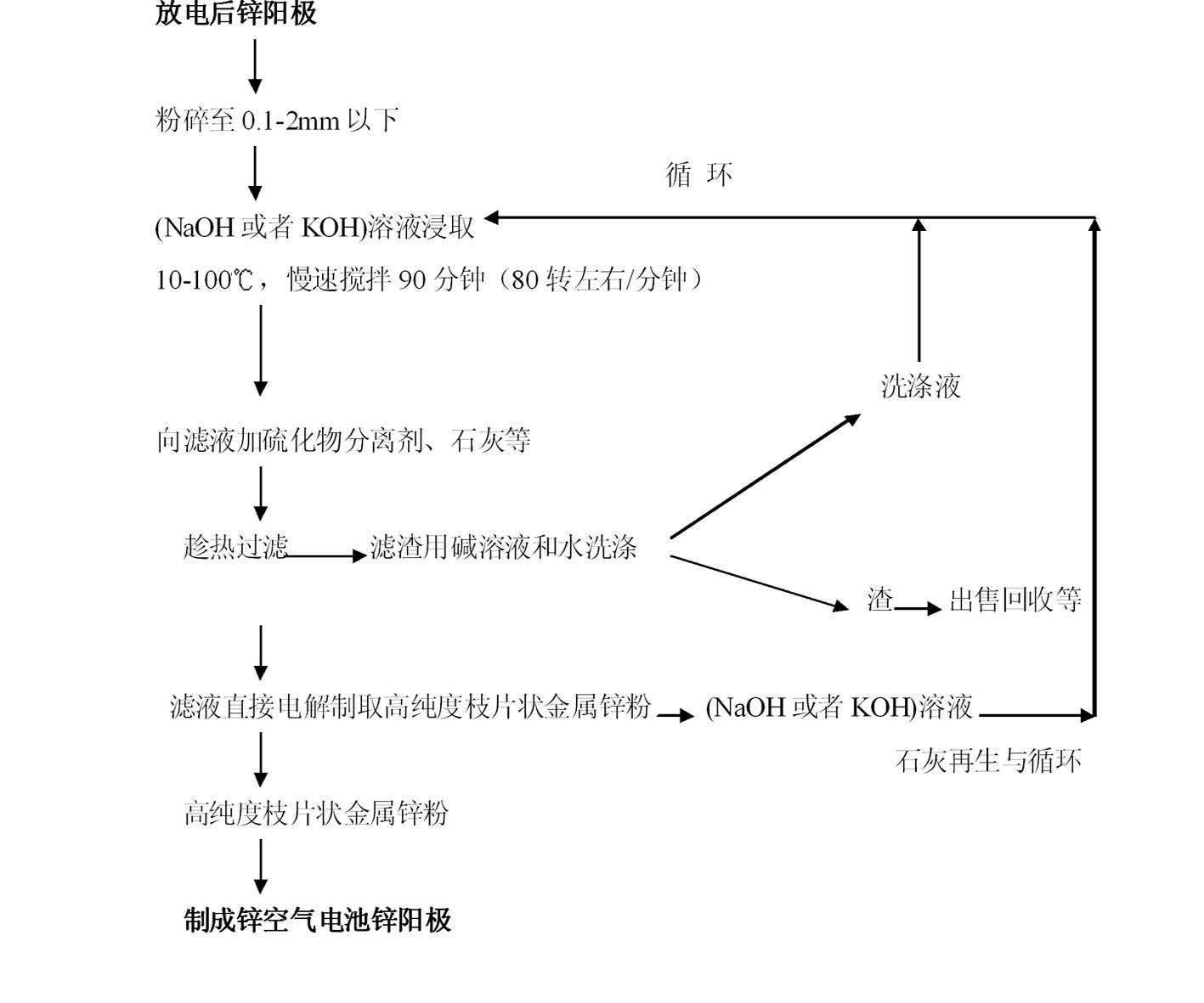

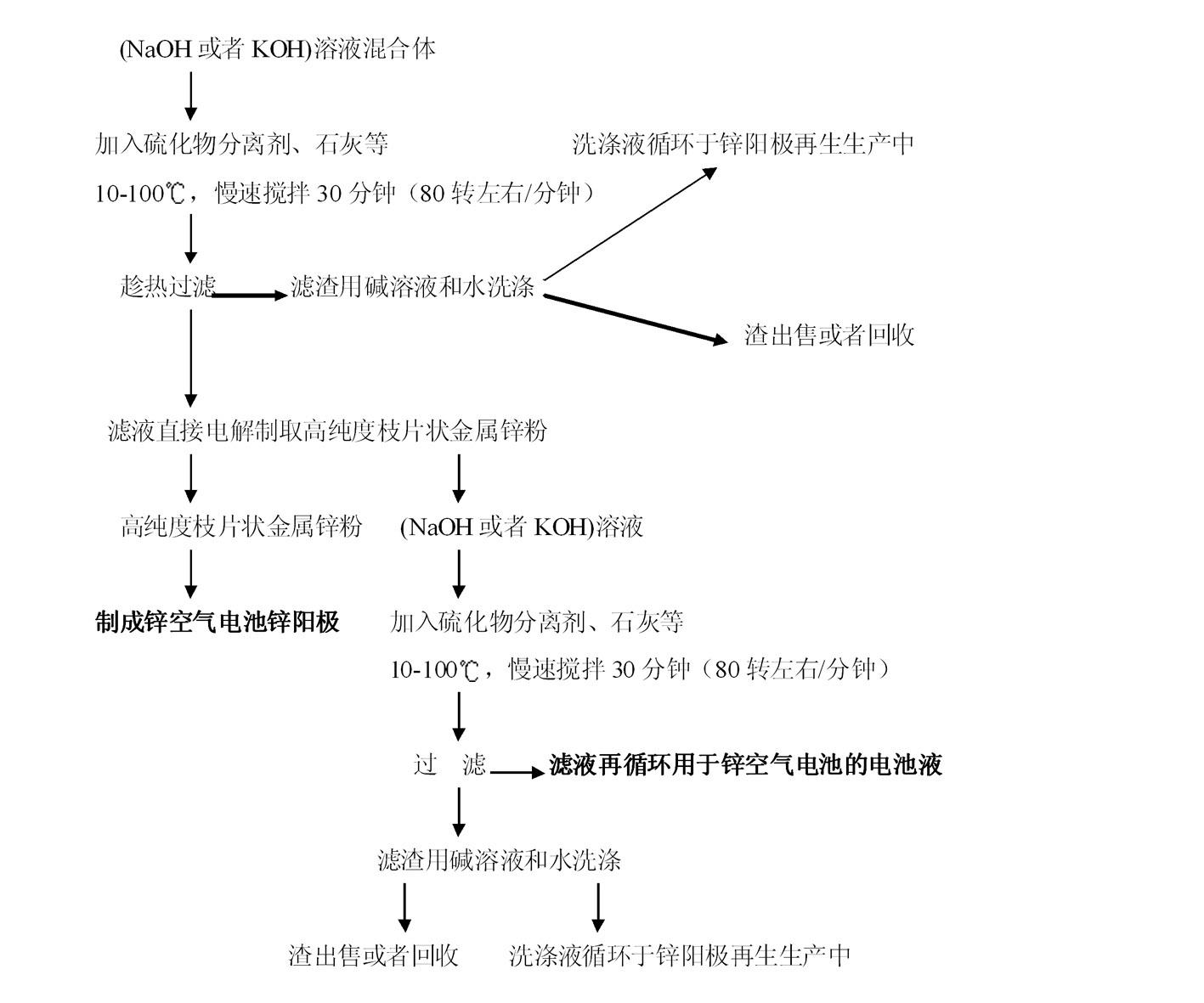

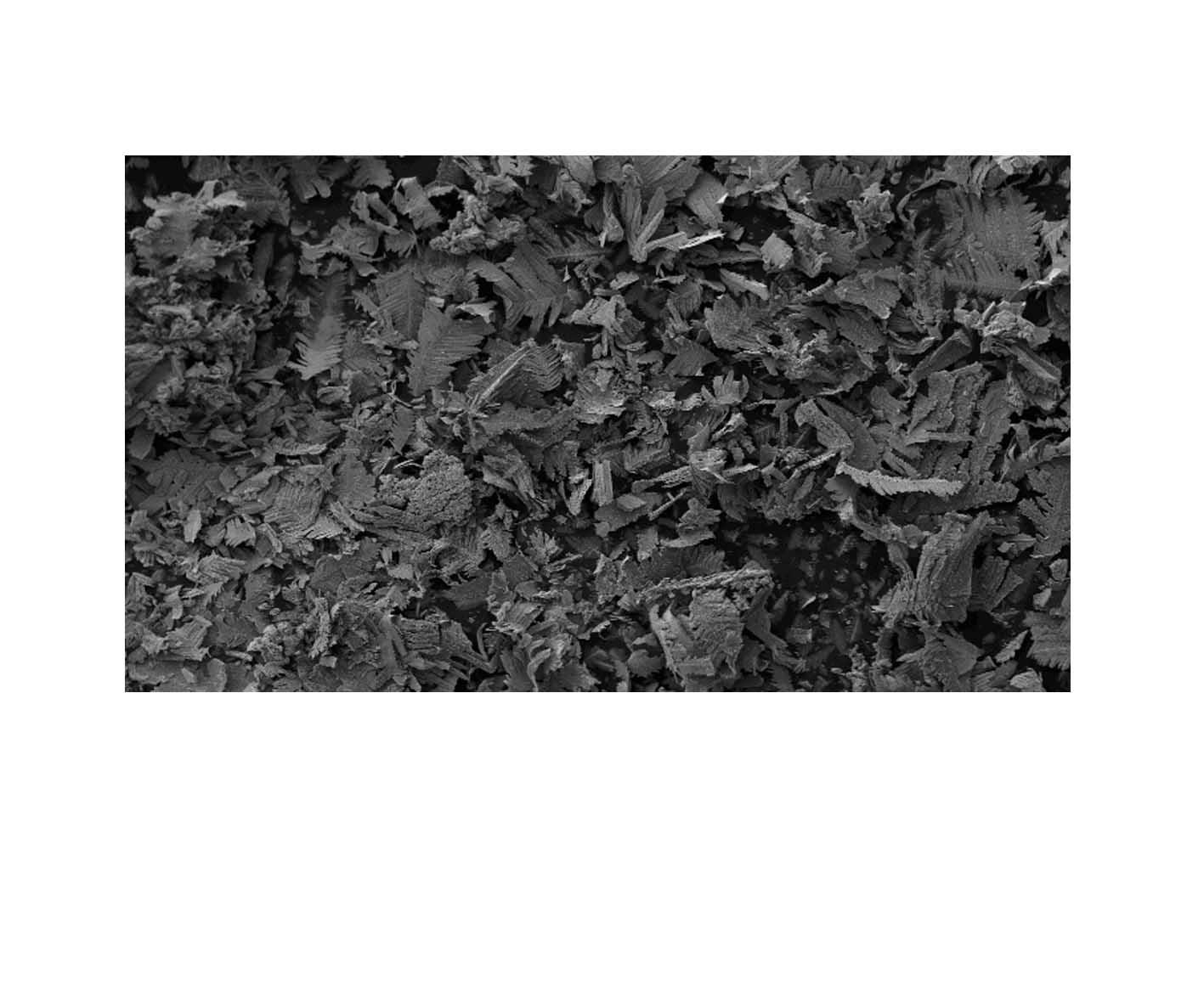

Method for producing zinc powder and battery fluid from battery zinc anode waste and battery waste fluid

InactiveCN102505076AIncrease surface areaStable running costPhotography auxillary processesProcess efficiency improvementSodium zincateElectrolysis

The invention discloses a method for producing zinc powder and battery fluid from battery zinc anode waste and battery waste fluid, which relates to the technical field of waste resource regeneration and processing. The method comprises the following steps: (a) 1-99 parts of NaOH and 99-1 parts of KOH are mixed to obtain a strong alkaline solution according to a proportion by weight; (b) NaOH / KOH mixed solution is uniformly mixed at a solid-to-liquid ratio of 1:(2-10) to obtain a leaching material; (c) the leaching material is mixed with zinc-air battery waste fluid to obtain zinc-air battery integrated mixed fluid; (d) sulfide is used for purifying and separating iron, copper and lead to obtain a sulfide purified solution; (e) lime regenerated alkali is used to react with the sulfide purified solution to obtain sodium zincate and potassium zincate solution suitable for electrolysis; (f) the sodium zincate and potassium zincate solution suitable for electrolysis obtained in step (e) is electrolyzed to obtain metal zinc powder; and (g) the lean solution is recycled after the electrolysis. The method of the invention sufficiently utilizes waste resources, and does not cause secondary pollution during the whole production process.

Owner:昆明同越科技开发有限公司

Acid-resistant epoxy resin embedding agent and preparation method thereof

InactiveCN101100594AImprove acid resistanceMeet the needs of useOther chemical processesCell sealing materialsEpoxyResin embedding

An acid-resisting epoxy-resin pouring agent and its production are disclosed. The pouring agent consists of epoxy-resin 100 proportion, anhydride 60-100 proportion, trivalent chrome complex 0.5-5.0 proportion and tertiary amine 0.3-3.0 proportion. The process is carried out by surface drying at room temperature for 4-6 hrs and curing less than 25 deg. C for 7 days or less than 80 deg. C for 2-3 hrs. The shearing strength for ABS plastic and lead is greater than or equal to 5 MPa, the acid absorptive rate is less than or equal to 0.7% at 80 deg. C in 40% sulfuric acid battery liquor. It has no acid creep and leakage. It can be used for pouring materials or acid-resisting coatings under high-temperature or high-acidity condition.

Owner:HEILONGJIANG INST OF PETROCHEM

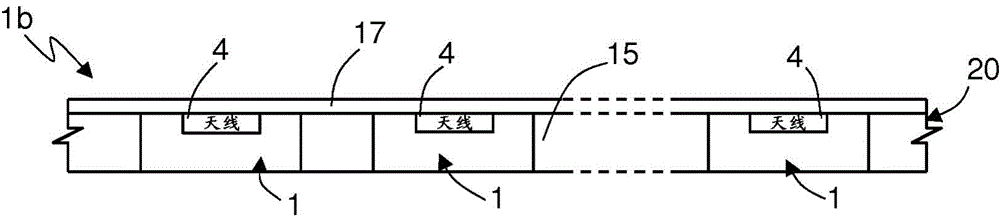

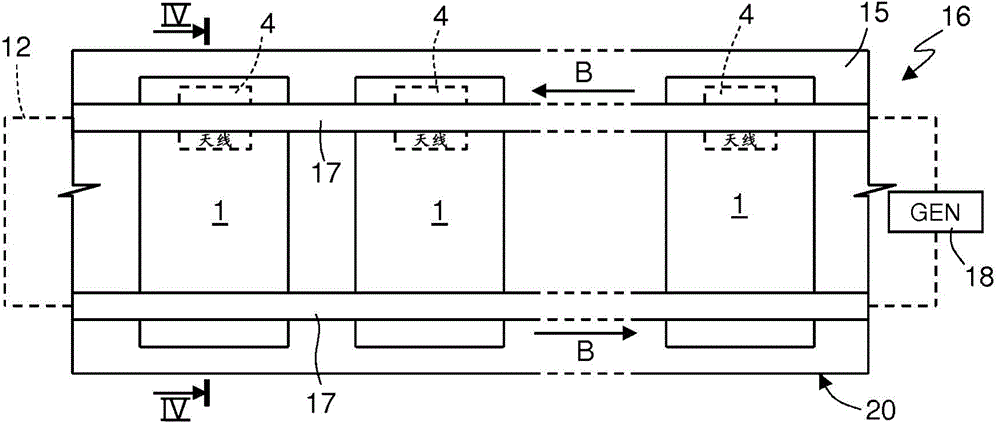

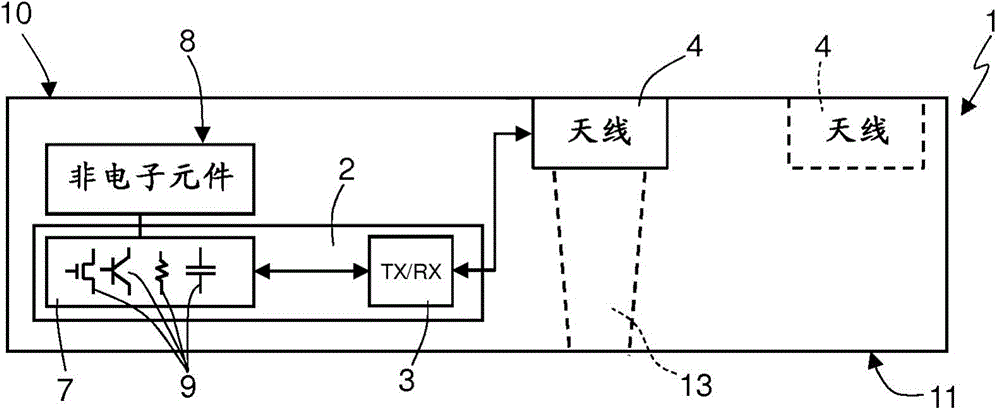

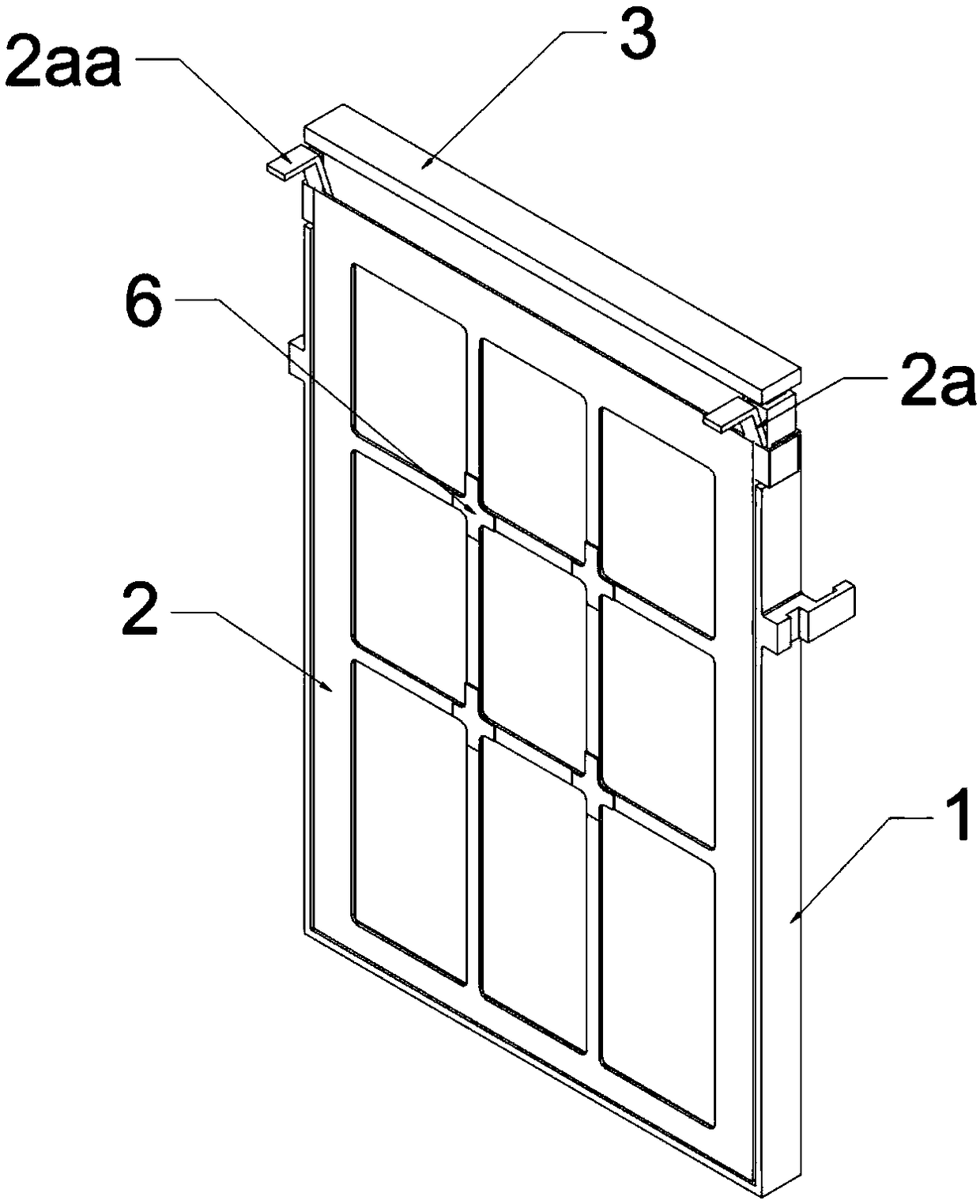

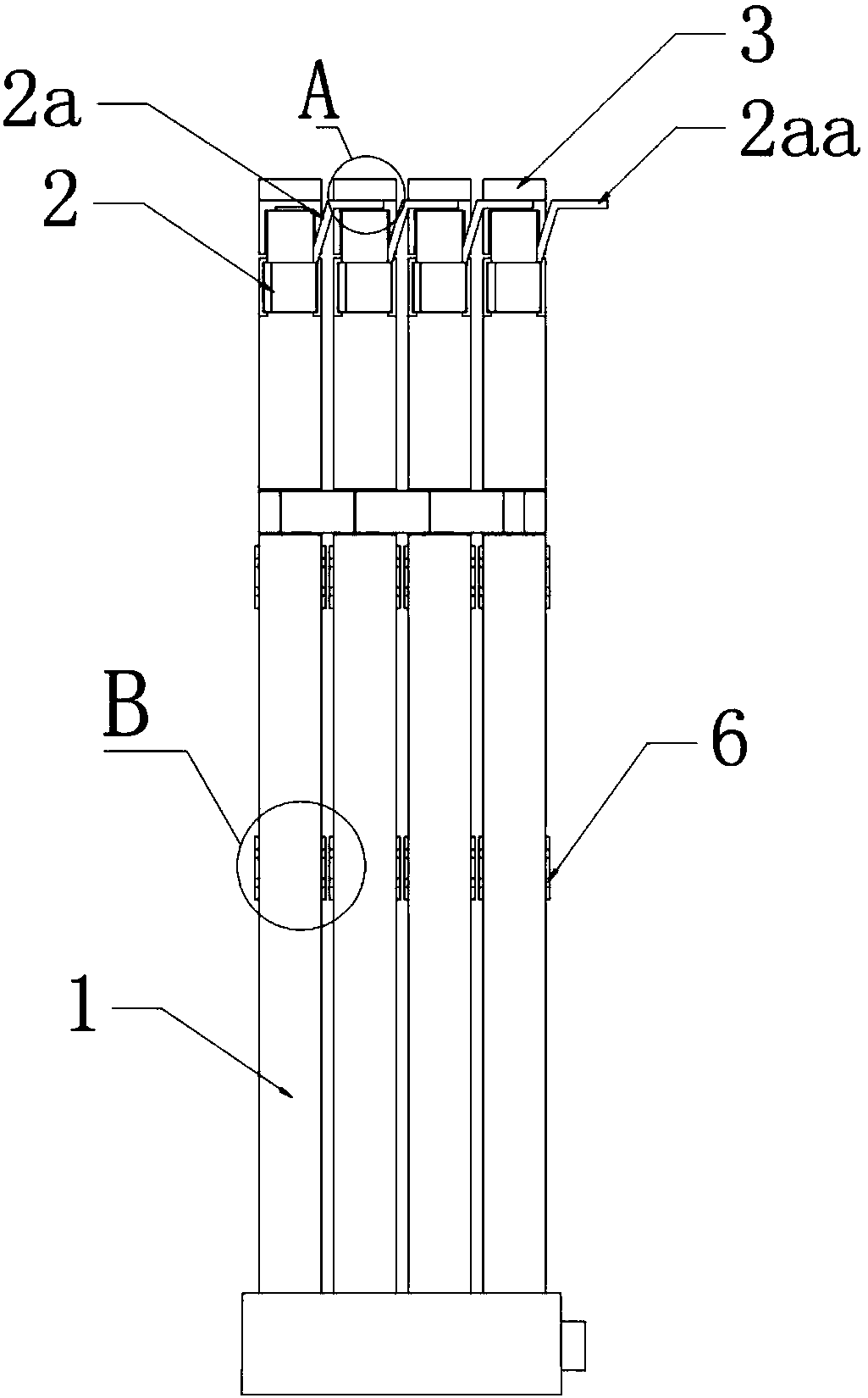

Network of electronic devices assembled on flexible support and communication method

An embodiment of a network of electronic devices is formed on a flexible substrate by a plurality of electronic devices assembled on the flexible substrate. The electronic devices have an embedded antenna for mutual coupling of a wireless type. Each electronic device is formed by a chip or a complex system integrating a transceiver circuit coupled to the embedded antenna and a functional part coupled to the transceiver circuit and including at least one element chosen in the group comprising: a sensor, an actuator, an interface, an electrode, a memory, a control unit, a power-supply unit, a converter, an adapter, a digital circuit, an analog circuit, an RF circuit, a microelectromechanical system, an electrode, a well, a cell, a container for liquids. The flexible support may be a substrate of plastic material that incorporates the electronic devices or a garment having smart buttons that house the electronic devices.

Owner:STMICROELECTRONICS SRL

Novel monomer aluminum air battery

InactiveCN108258370AEasy to replaceAvoid short circuitFuel and primary cellsMiniaturizationElectrode Contact

The invention discloses a novel monomer aluminum air battery. An aluminum electrode plate is inserted into a battery fluid chamber; a negative electrode plate is arranged on the aluminum electrode plate; positive electrode plates are arranged on the battery fluid chamber; the positive electrode plates cover front and rear surfaces of the battery fluid chamber; a plurality of bosses made of insulating materials are arranged on front and rear surfaces of the positive electrode plates; a conductive lead-out strip is connected onto each positive electrode plate; the negative electrode plate serving as a sealing cover plate of the battery fluid chamber is arranged at the upper end of the aluminum electrode plate; two ends of the negative electrode plate extend outwards to form a negative electrode contact section; an elastic piece is arranged on the battery fluid chamber below the negative electrode contact section. According to the air battery disclosed by the invention, a connection formbetween monomer batteries is improved, and compared with conduction in the prior art, the air battery in the invention is simpler in operation and processing technology, the operation is more convenient and more feasible during replacement of the aluminum electrode plate, and a failure risk is greatly reduced; due to the arrangement of the bosses, a condition of positive electrode contact short circuit is avoided, and swelling in opposite directions is offset, so that the overall structure of the battery pack is compact, and miniaturization is facilitated.

Owner:CHONGQING DINKING POWER MACHINERY

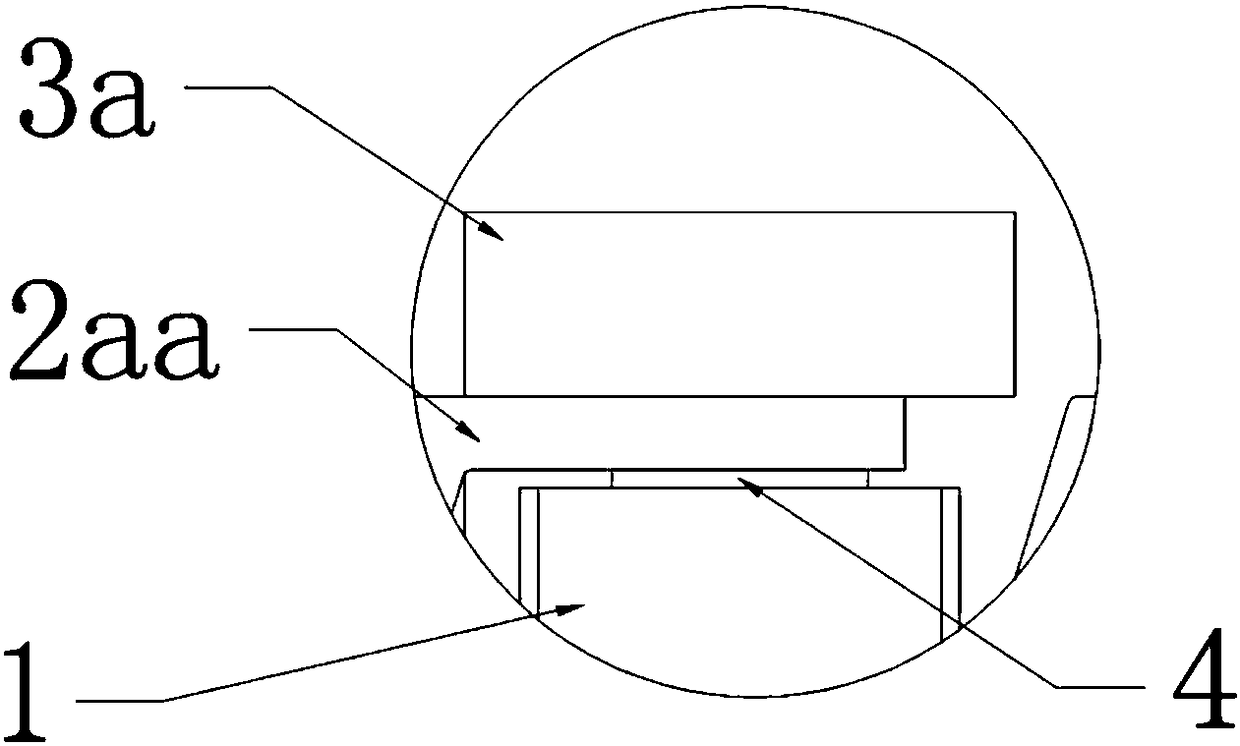

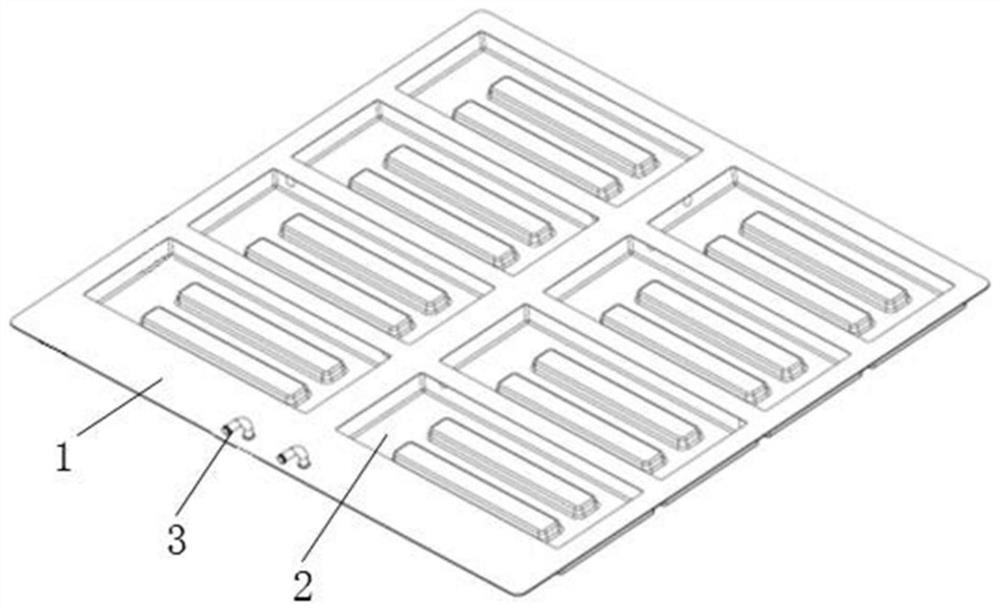

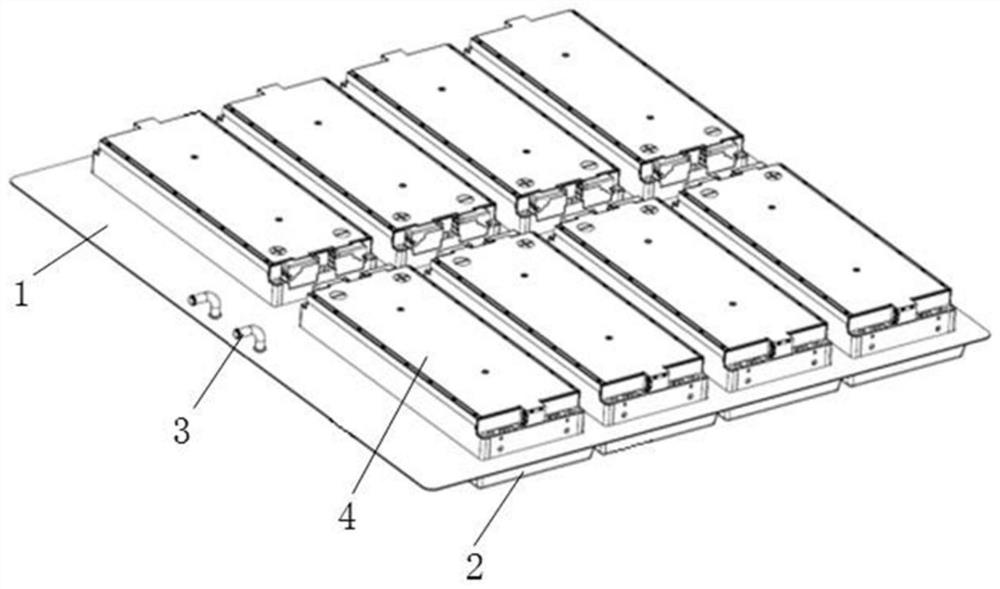

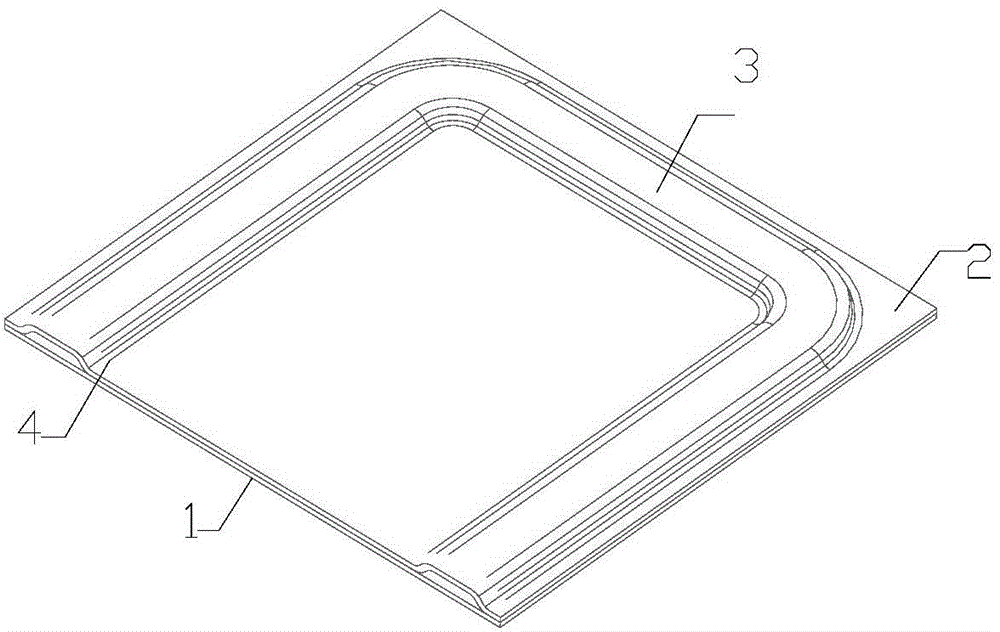

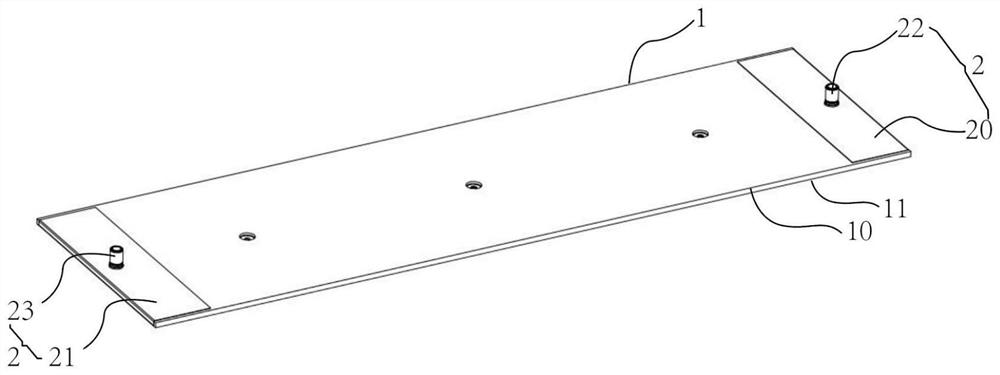

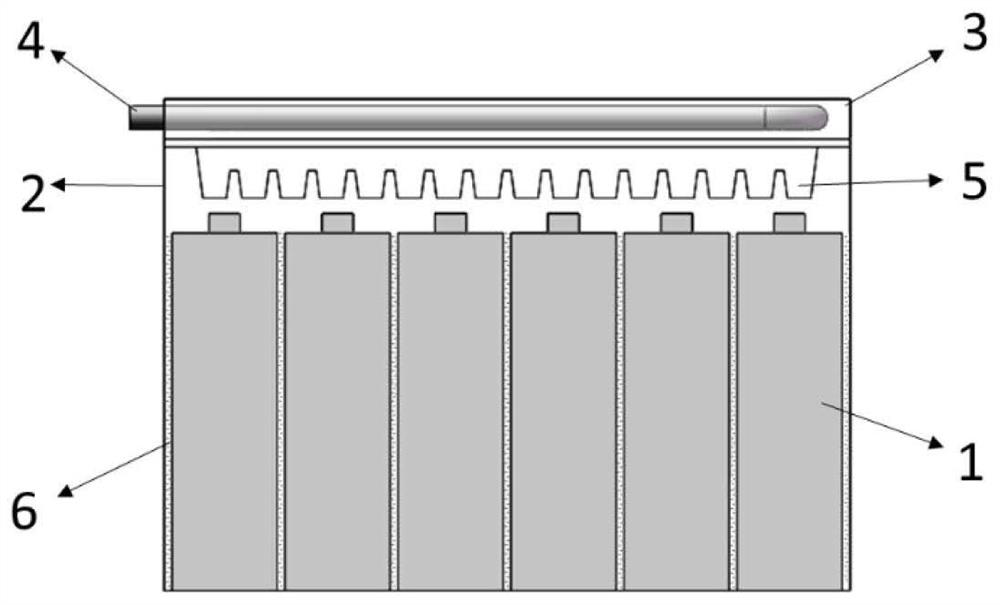

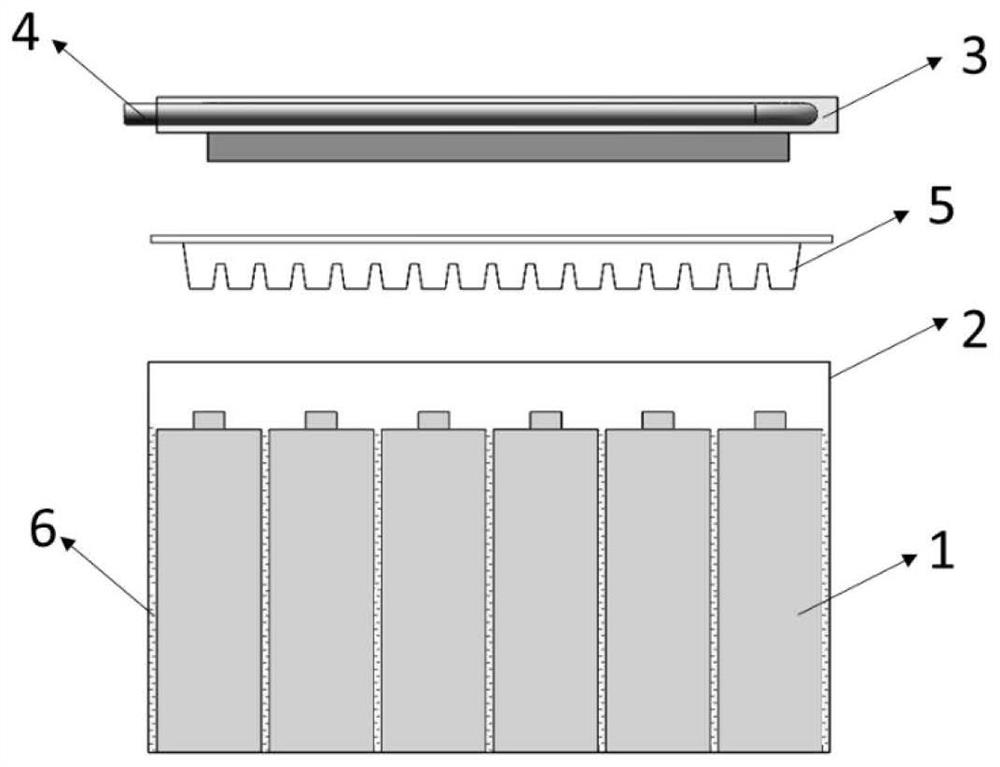

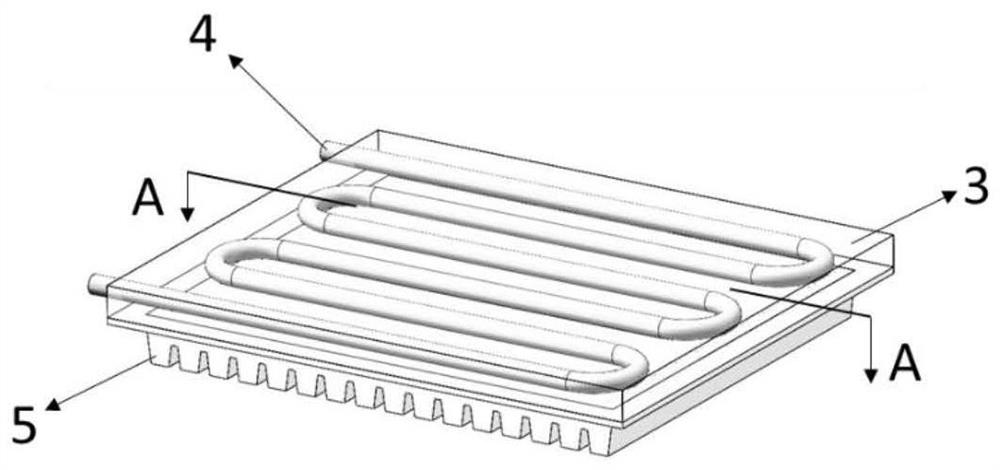

Battery liquid cooling plate assembly, battery assembly and vehicle

InactiveCN112701383ARealize thermal management functionFixedSecondary cellsHeat managementStructural engineering

The invention discloses a battery liquid cooling plate assembly, a battery assembly and a vehicle, and belongs to the field of battery safety, the battery liquid cooling plate assembly comprises a liquid cooling plate upper plate, a liquid cooling plate lower plate and a cooling liquid joint, a cooling flow channel is formed between the liquid cooling plate upper plate and the liquid cooling plate lower plate, the liquid cooling plate lower plate is provided with a plurality of cooling grooves; a plurality of openings are correspondingly formed in the liquid cooling plate upper plate, the plurality of openings and the plurality of grooves are arranged in a one-to-one correspondence manner, and the battery modules are partially fixed in the cooling grooves through the openings and are in sealed connection with the liquid cooling plate upper plate; at least one circulating hole is formed in the groove wall of each cooling groove, and the multiple cooling grooves are communicated through the circulating holes; the cooling liquid joint is arranged on the liquid cooling plate upper plate and communicated with the cooling flow channel, and the cooling groove located in one side of the cooling liquid joint is communicated with the cooling flow channel. The battery liquid cooling plate assembly is simple in manufacturing process, low in requirement for arrangement space and high in applicability, semi-immersed cooling of the battery module is achieved, and heat management of the battery module can be effectively achieved.

Owner:CHINA FIRST AUTOMOBILE

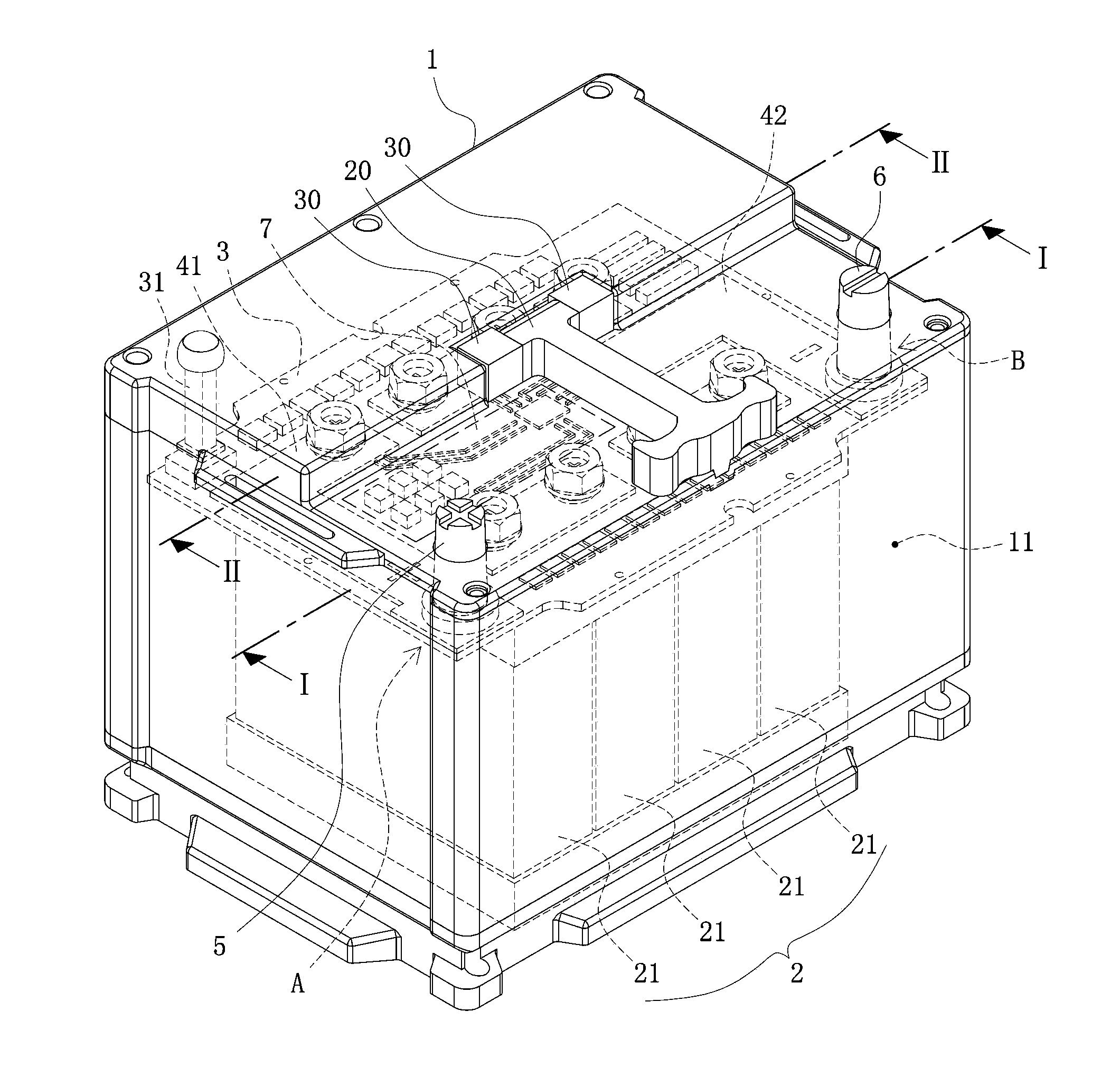

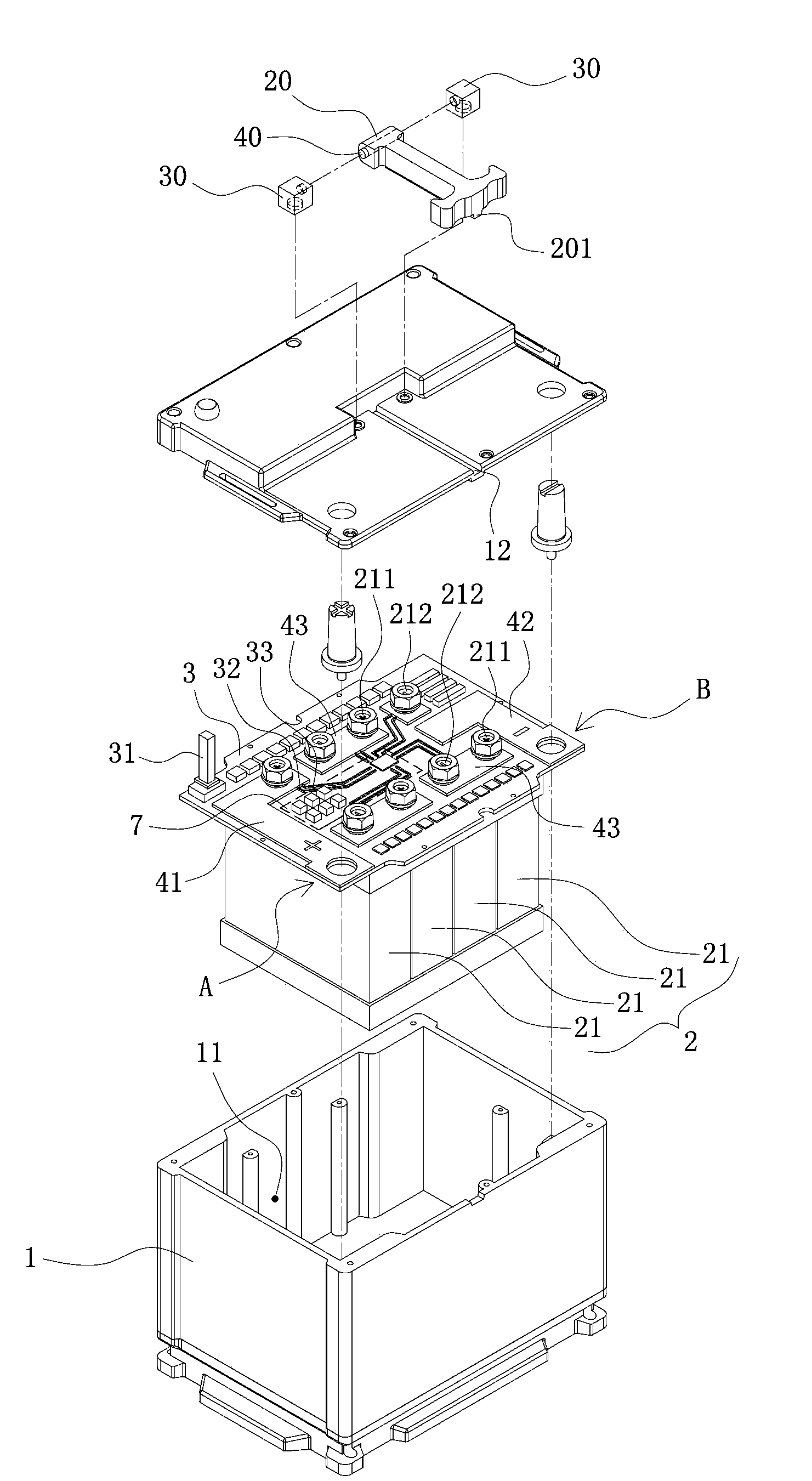

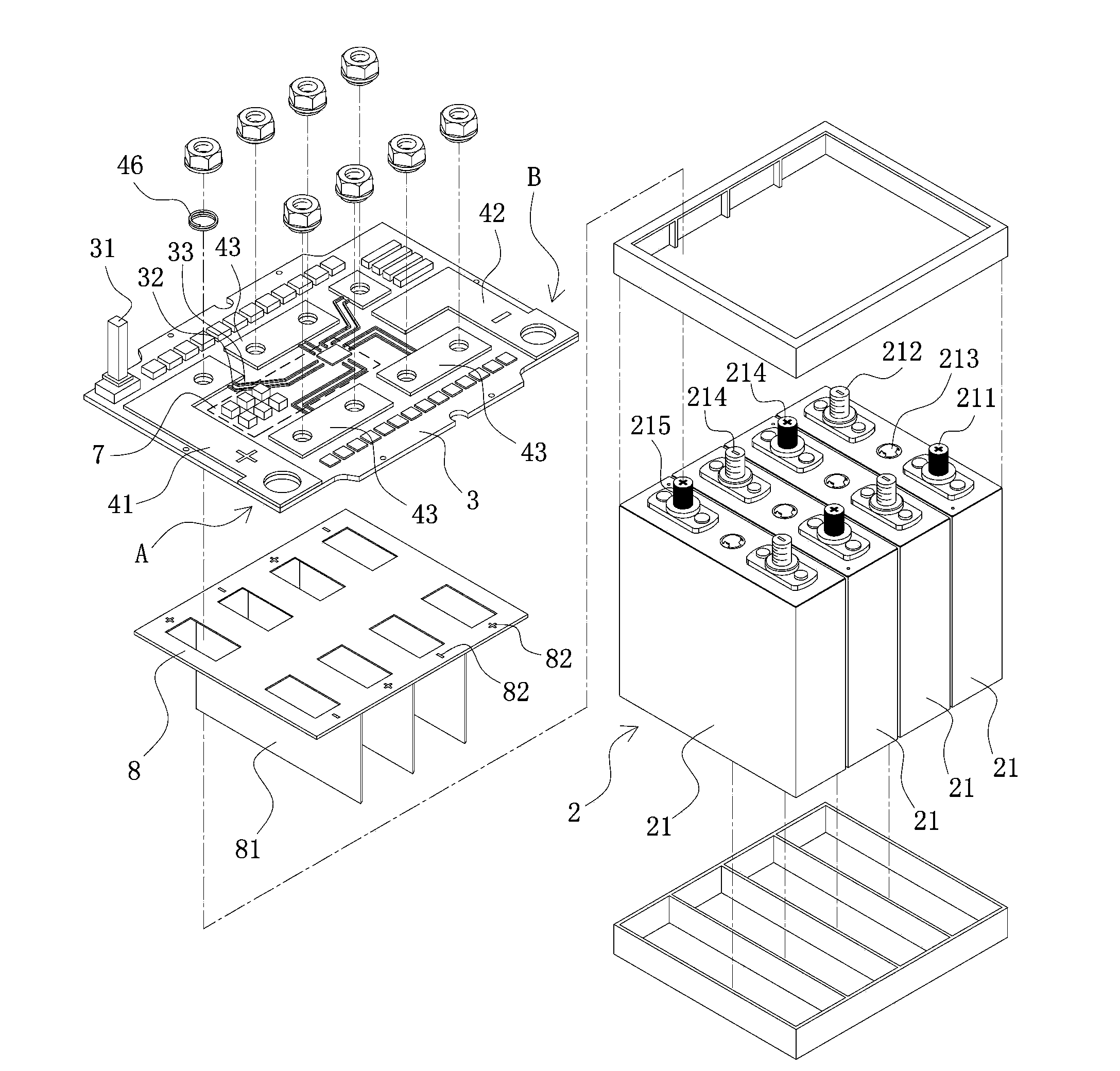

Modularization battery

ActiveCN103840221ASolve the problem of being unable to withstand continuous discharge of large currentsLower assembly costsBatteries circuit arrangementsBattery isolationElectricityElectrical battery

The invention aims to provide a modularization battery capable of greatly reducing a reject ratio and shortening production hours. The technical scheme is that the modularization battery comprises a battery case, an electrical storage device, a monitoring circuit board for monitoring the voltage and the temperature of each storage battery, a metal conducting layer set, a positive pole pile head, a negative pole pile head and a battery management system, wherein the thickness of the metal conducting layer set is larger than that of a printed circuit of the monitoring circuit board. The monitoring circuit board further comprises a reset button which reboots the battery management system to force each storage battery to continue to supply power when each storage battery of the battery management system is excessively low in electricity, and the battery management system judges the situation and stops supplying electricity. A cover plate capable covering a safety relief valve to prevent the monitoring circuit board form being eroded by a leaked battery fluid is arranged between the electrical storage device and the monitoring circuit board.

Owner:FORMOSA PLASTICS TRANSPORT CORP

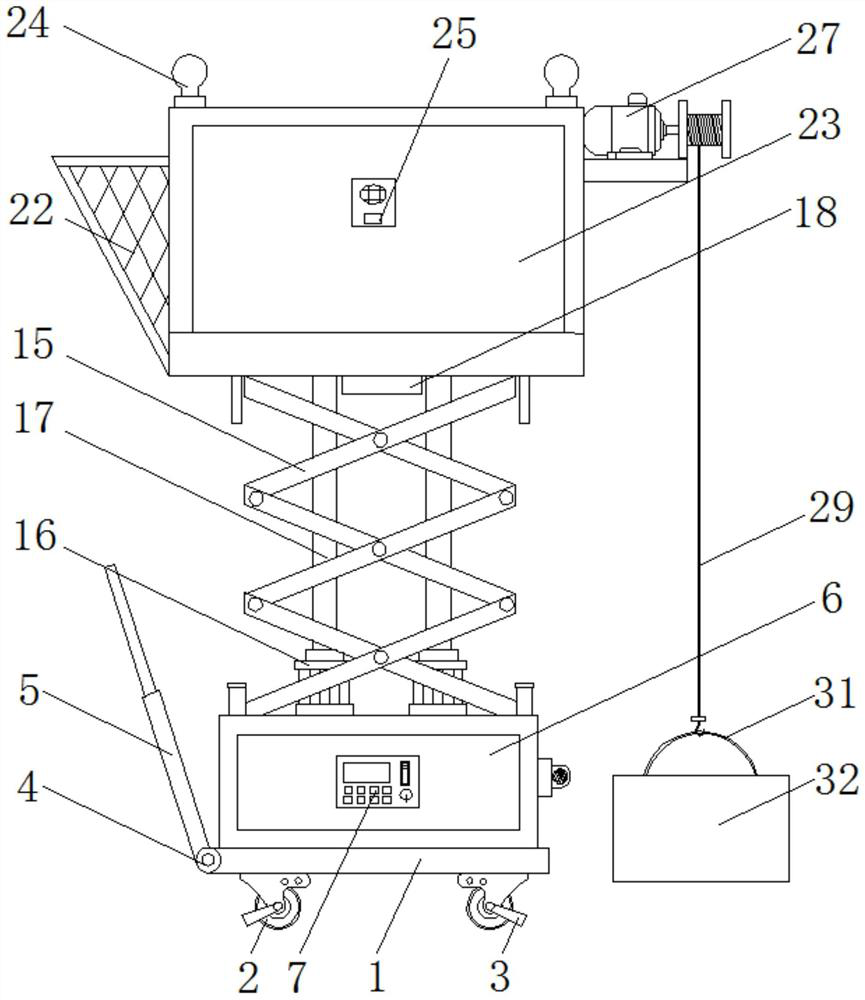

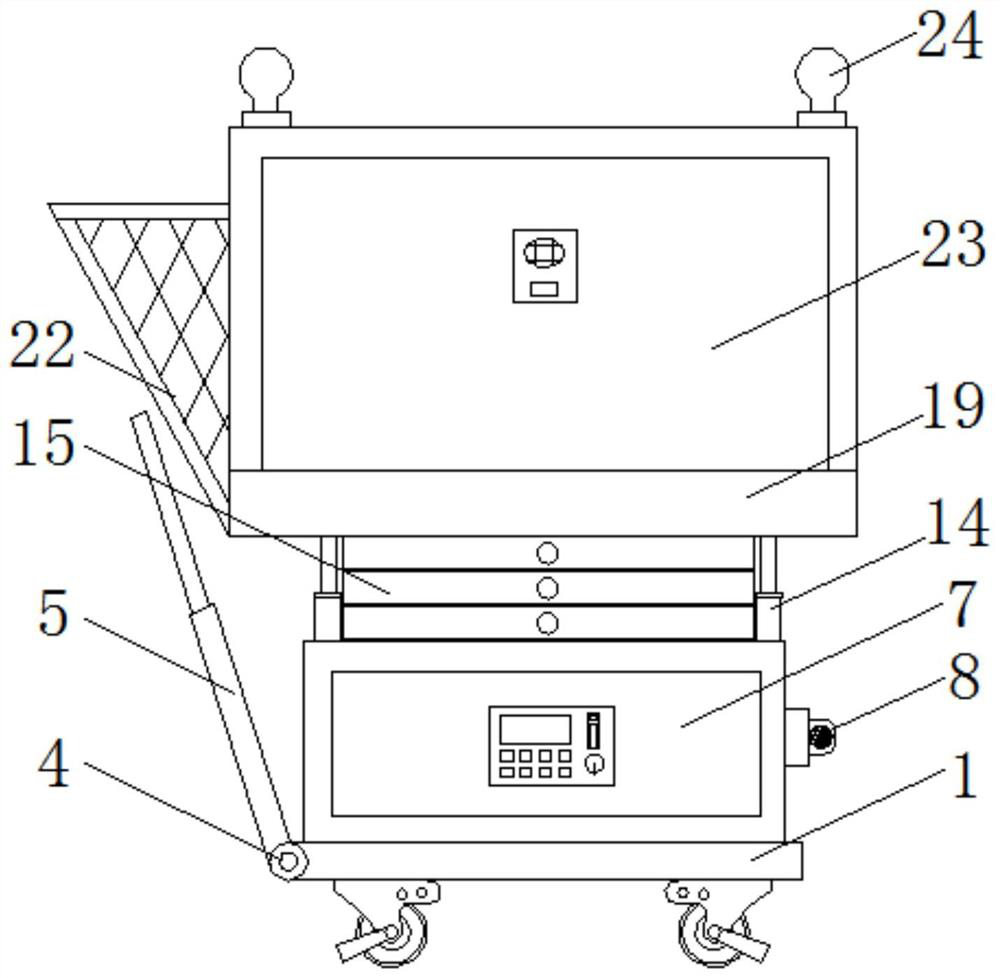

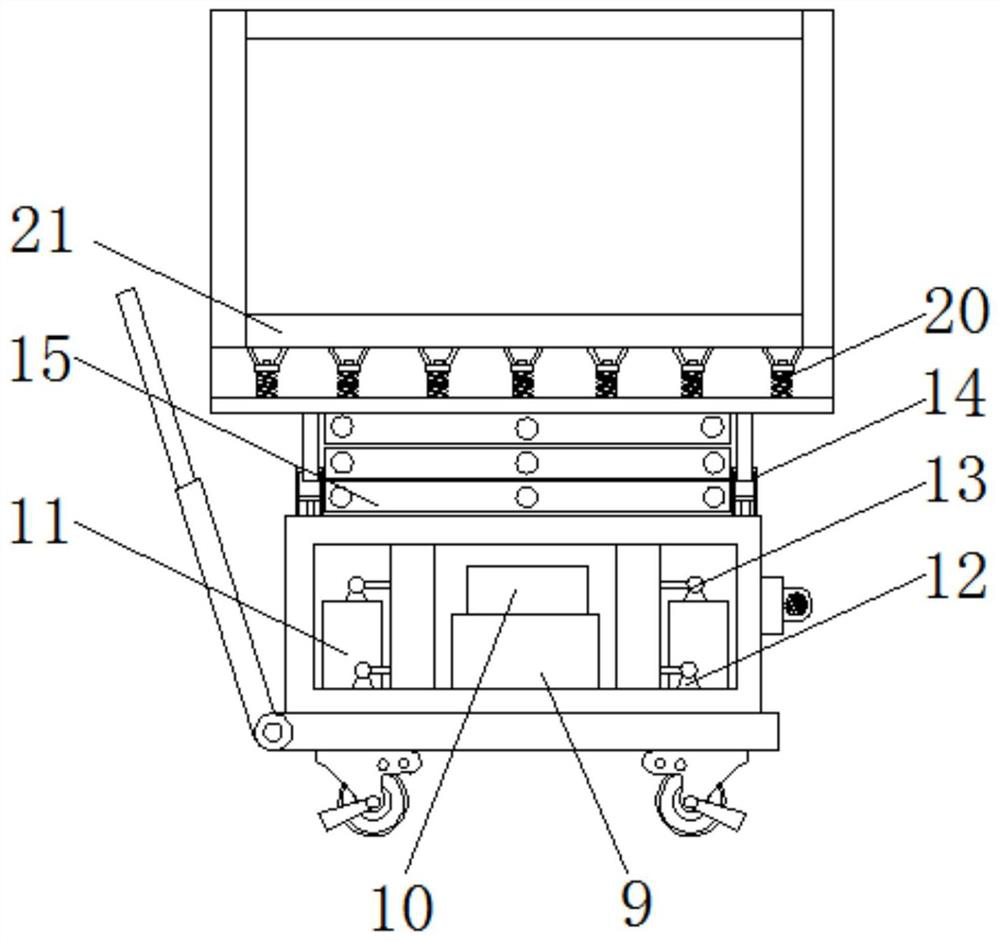

High-safety elevator for building external wall construction

ActiveCN113173540AImprove securityImprove protectionSafety devices for lifting equipmentsWinding mechanismsHydraulic cylinderArchitectural engineering

The invention discloses a high-safety elevator for building external wall construction. The high-safety elevator comprises a base, a telescopic pull rod, a control panel, a storage battery, hydraulic oil tanks, positioning mechanisms, hydraulic cylinders, gravity sensors, a load plate, an illuminating lamp, a supporting plate, a steel wire rope and a feeding box; rolling wheels are fixedly connected to the lower portion of the base; the telescopic pull rod is rotationally connected with the base through a rotary shaft; the control panel is arranged on the outer side of an elevator body; the storage battery is arranged in the elevator body; the hydraulic oil tanks are arranged on the two sides of the storage battery; the positioning mechanisms are arranged on the two sides of the upper portion of the elevator body; and the hydraulic cylinders are arranged on the upper portion of the elevator body. The high-safety elevator for building external wall construction is provided with an anti-falling protective net and a damping mechanism, the anti-falling protective net effectively prevents personnel falling accidents in the using process, the damping mechanism can reduce vibration generated during ascending and descending to a certain extent, and the accidents such as falling and falling caused by shaking of workers are avoided.

Owner:苏州贝曼重工有限公司

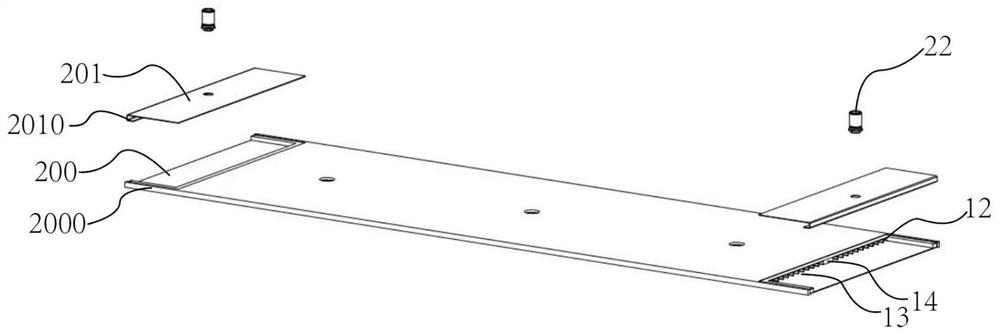

Liquid-cooled plate for battery, preparation method of liquid-cooled plate, battery module, battery pack and electric vehicle

ActiveCN105789728AGuaranteed StrengthImprove cooling effectSecondary cellsEngineeringElectric vehicle

The invention discloses a liquid-cooled plate for a battery, a preparation method of the liquid-cooled plate, a battery module, a battery pack and an electric vehicle. The liquid-cooled plate comprises a lower liquid-cooled plate, a locally deforming upper liquid-cooled plate and a runner, wherein the runner is formed by surrounding of the upper liquid-cooled plate and the lower liquid-cooled plate through local deformation of the upper liquid-cooled plate; and the edge of a deformed part of the upper liquid-cooled plate is connected with the lower liquid-cooled plate in an atom binding manner. The liquid-cooled plate for the battery can have the advantages of being relatively light in weight, relatively simple in structure and relatively good in connection strength and sealing property, and can be obtained without a runner punch forming step.

Owner:BYD CO LTD

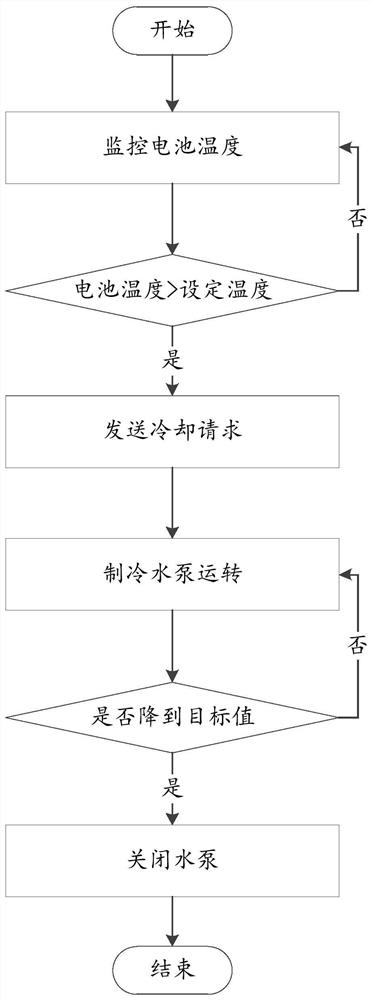

Temperature control method and device and electronic equipment

InactiveCN111969280AReduce consumptionAvoid imperfectionSecondary cellsPower batteryTemperature control

The embodiment of the invention provides a temperature control method and device and electronic equipment, and relates to the technical field of power batteries. The embodiment of the invention provides a temperature control method and device and electronic equipment. The method comprises the steps of: after acquiring the battery temperature of a battery pack in a battery liquid cooling system andthe temperature of a cooling medium in the battery liquid cooling system, obtaining a preset temperature adjustment strategy corresponding to the battery temperature according to the battery temperature, and adjusting the temperature of the battery pack according to the temperature adjustment strategy and the temperature of the cooling medium, so that the imperfection that only the battery temperature is used as the threshold value is avoided, and the energy consumption is effectively reduced.

Owner:HAIMA AUTOMOBILE CO LTD +1

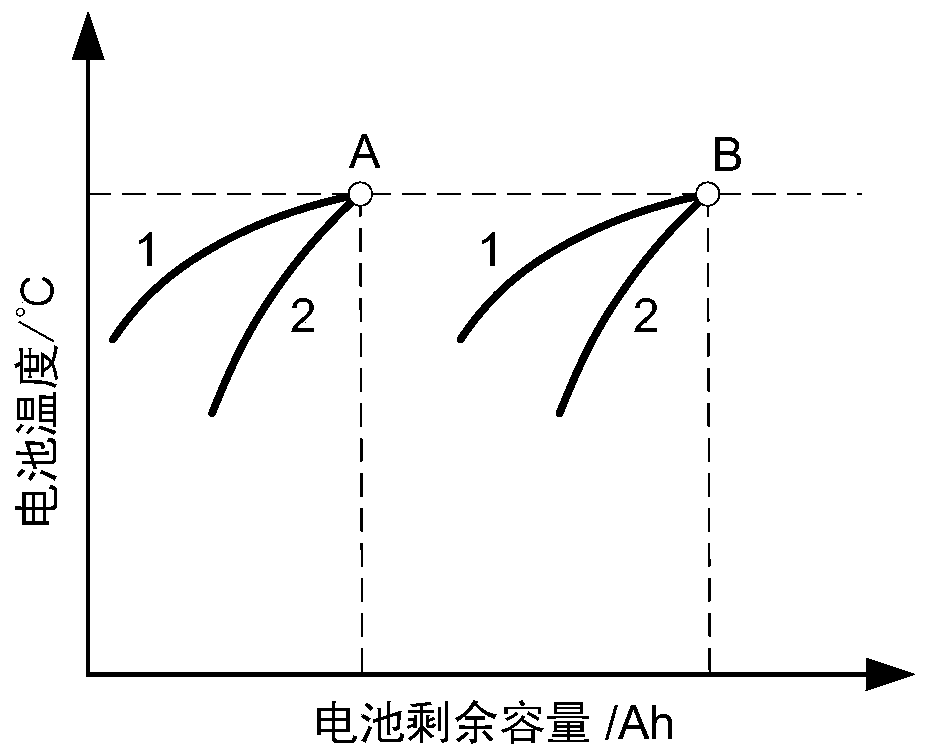

Real-time refrigerating capacity calculation method of electric vehicle power battery liquid cooling system and control thereof

ActiveCN111244568AGood temperature control effectImprove adaptabilityCapacitance measurementsSecondary cellsElectrical batteryElectric vehicle

The invention discloses a real-time refrigerating capacity calculation method of an electric vehicle power battery liquid cooling system and control thereof. The refrigerating capacity required by a battery refrigerating system at the current t moment is calculated through formulas (1) and (2), then the rotating speed of a compressor is adjusted according to the corresponding relation between therotating speed of the compressor and the refrigerating capacity, and the refrigerating capacity required by a battery at the current t moment is achieved. According to the refrigerating capacity method of the liquid cooling system provided in the invention, the factors such as the temperature of the battery, the heating power, the SOC of the battery and recession are actually considered, the obtained refrigerating capacity has better adaptability compared with a traditional method, and the temperature control capacity of the liquid cooling system can be remarkably enhanced. According to the refrigeration control system, the refrigerating capacity can be automatically adjusted according to the dynamic change of the thermal load of the battery in the running process of the electric vehicle,so that the liquid cooling system runs at the minimum power under the condition of meeting the heat dissipation requirement of the battery, the energy consumption of the liquid cooling system is remarkably reduced, and the endurance mileage of the electric vehicle is increased.

Owner:深圳威铂驰热技术有限公司

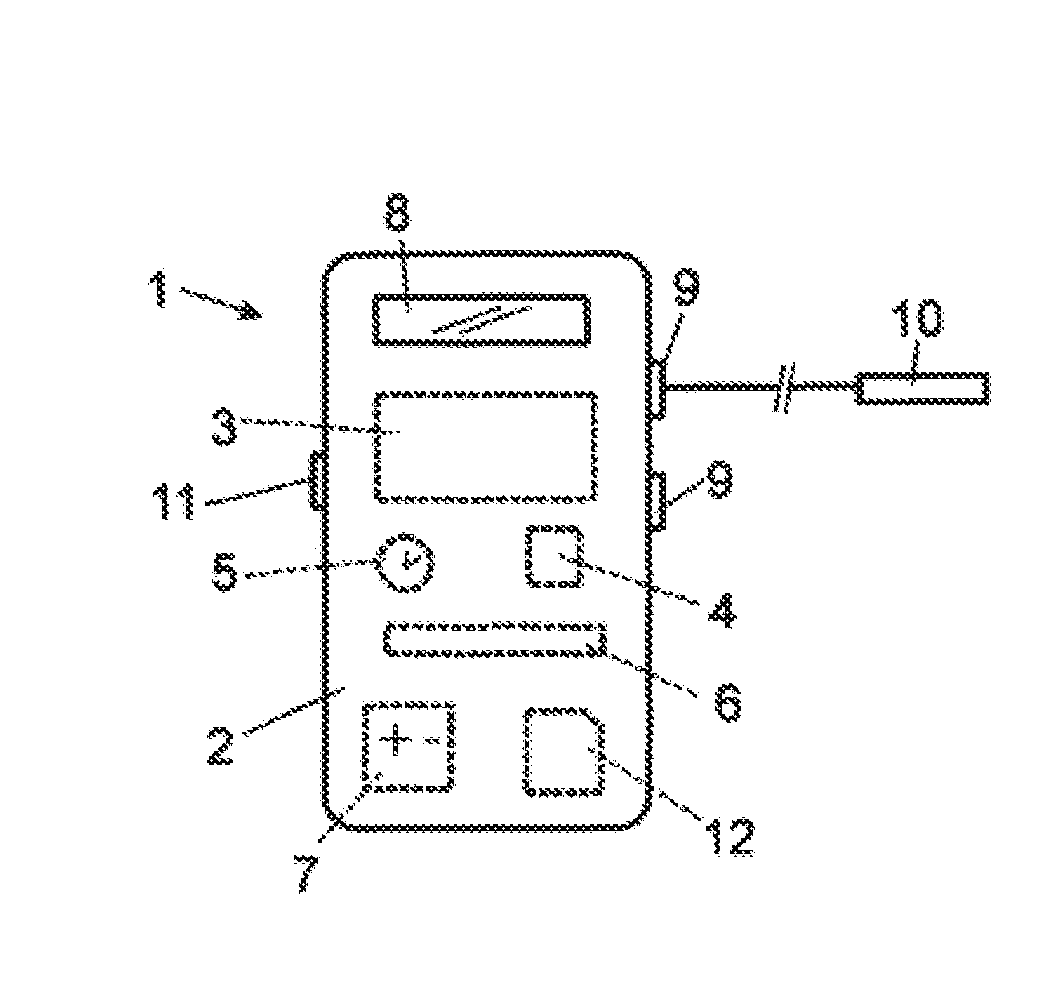

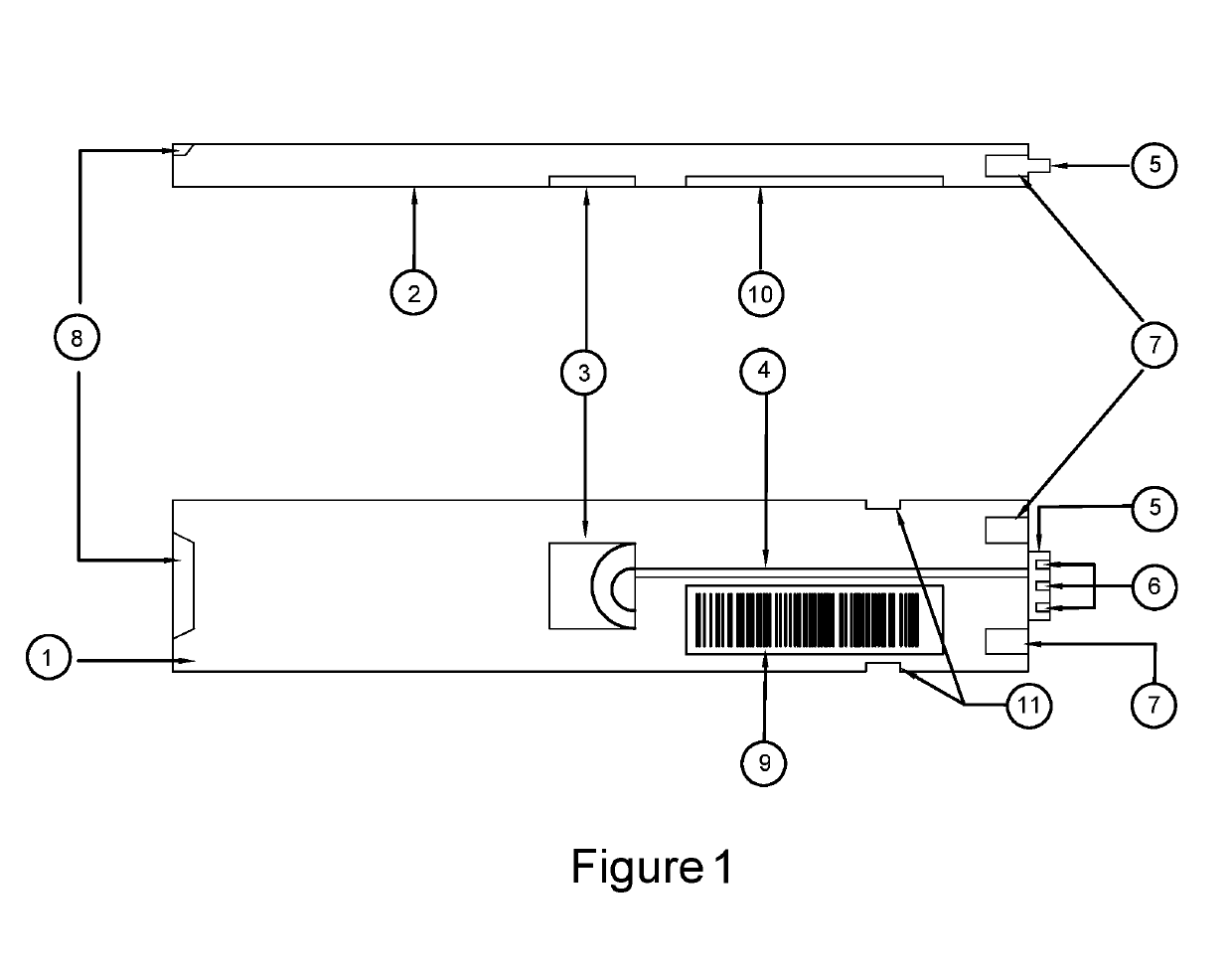

Data recorder system for monitoring and tracking in the dispatch and transportation of goods requiring specific values to be maintained and method for achieving said monitoring and tracking

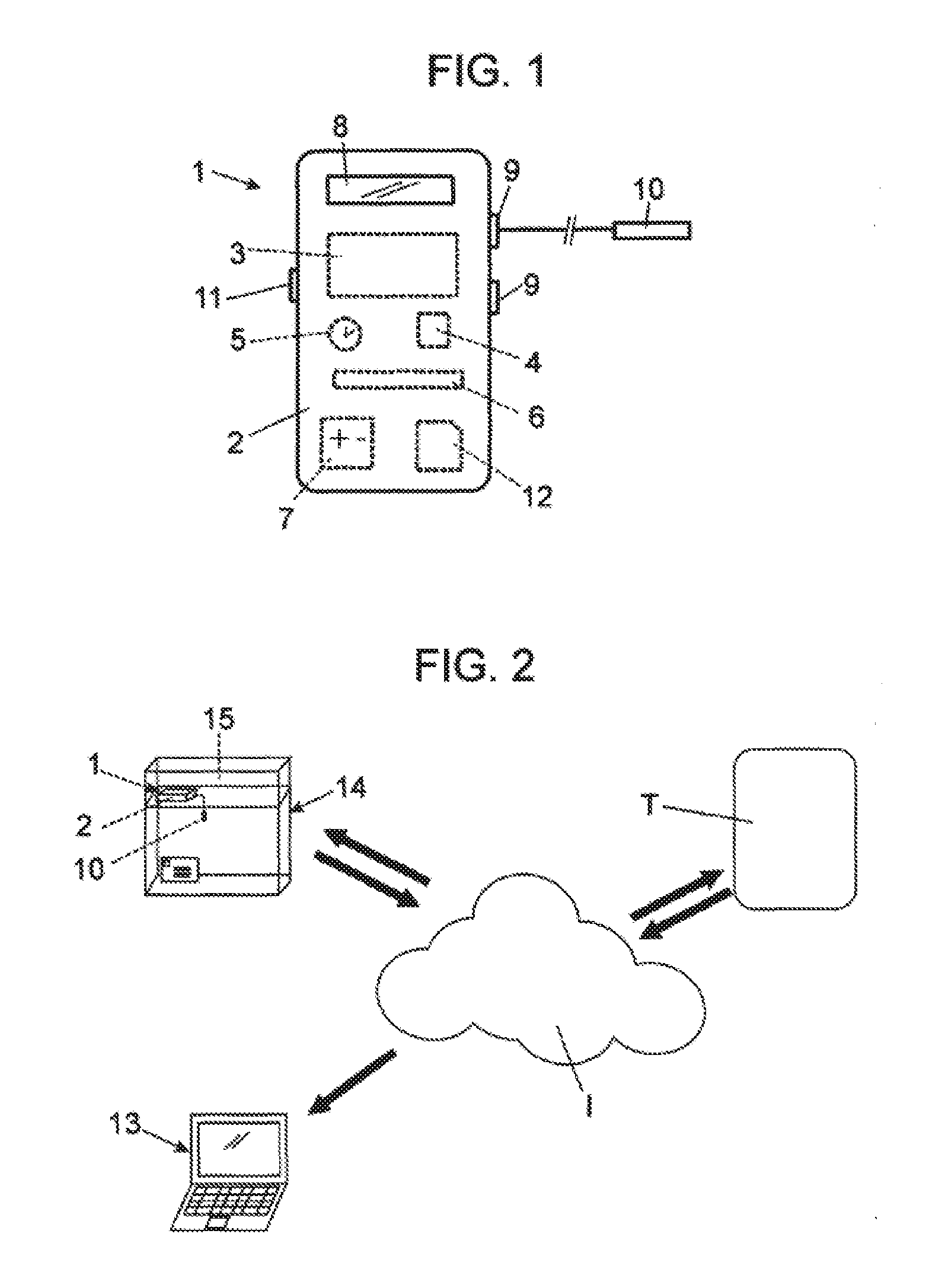

The invention concerns a device for recording data for monitoring and tracking the dispatch and transportation of goods requiring specific values to be maintained, and method for achieving said monitoring and tracking, which incorporates an electronic board with microprocessor (3), GPS (4), clock (5), memory card (6), power-supply battery (7), LCD read screen (8) and connectors (9) for coupling probes (10) for sensing temperature, moisture level or other parameters, being provided with a wireless communication card (12) with a GSM / GPRS 3G system, with roaming, suitable for use of the Internet communications service (I) of the IoT or “Internet of things” (T) offered by telephony operators for gaining access to a URL for storage of sensor data offered by said service

Owner:PARA EL INTERNET DE LAS COSAS

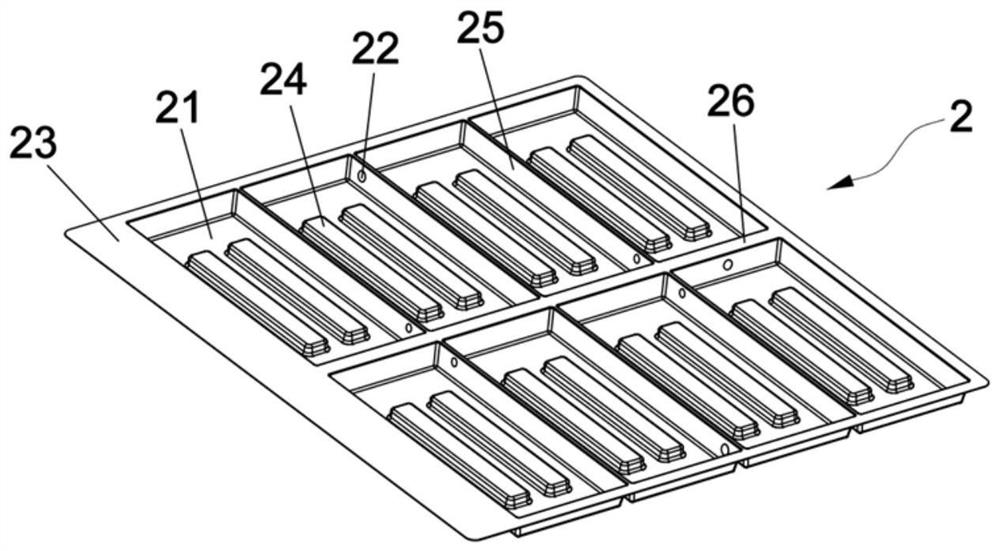

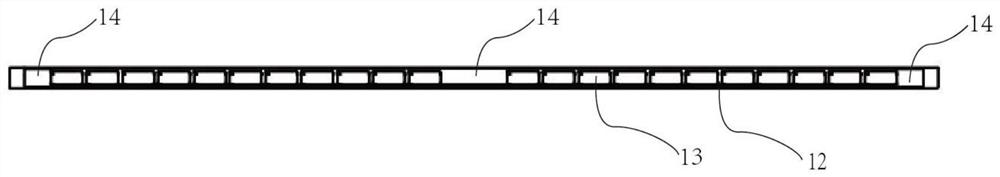

Battery liquid cooling plate structure and automobile battery

InactiveCN111952691AImprove cooling effectSimple processSecondary cellsAutomotive batteryEngineering

The invention relates to a battery liquid cooling plate structure and an automobile battery. The battery liquid cooling plate structure comprises a liquid cooling plate main body and a liquid inlet and outlet structure. The liquid cooling plate main body comprises an upper cooling plate and a lower cooling plate arranged side by side up and down, a plurality of partition plate ribs arranged between the upper cooling plate and the lower cooling plate at intervals, and a cooling cavity between the upper cooling plate and the lower cooling plate is divided into a plurality of cooling flow channels by the plurality of partition plate ribs. The liquid inlet and outlet structure comprises a liquid inlet plate structure and a liquid outlet plate structure which are arranged at the two ends of theliquid cooling plate body respectively, a liquid inlet cavity communicated with one end of the cooling flow channel is formed in the liquid inlet plate structure, and a liquid outlet cavity communicated with the other end of the cooling flow channel is formed in the liquid outlet plate structure; a liquid inlet head communicated with the liquid inlet cavity is arranged on the liquid inlet plate structure, and a liquid outlet head communicated with the liquid outlet cavity is arranged on the liquid outlet plate structure. According to the present invention, the processing technology of the battery liquid cooling plate is simplified, so that the liquid cooling plate meets the design requirement of light weight, and meanwhile, the cooling and heat dissipation performance of the liquid cooling plate is improved.

Owner:东风时代(武汉)电池系统有限公司

Acid liquid leakage sensor

ActiveUS8088331B2Quick checkEasy to adjustDetection of fluid at leakage pointLead-acid accumulatorsHigh resistanceElectricity

Owner:NTT FACILITIES INC +1

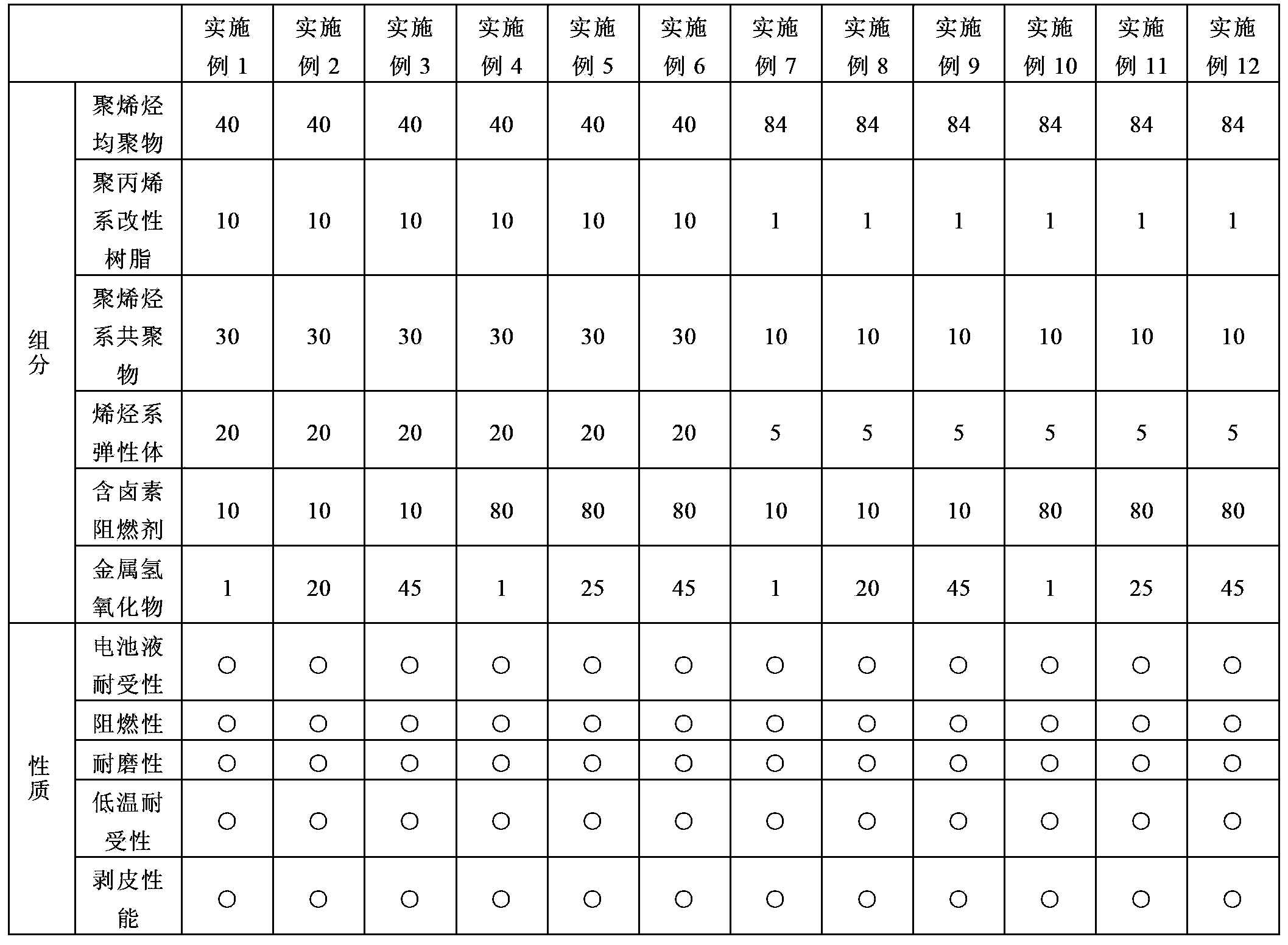

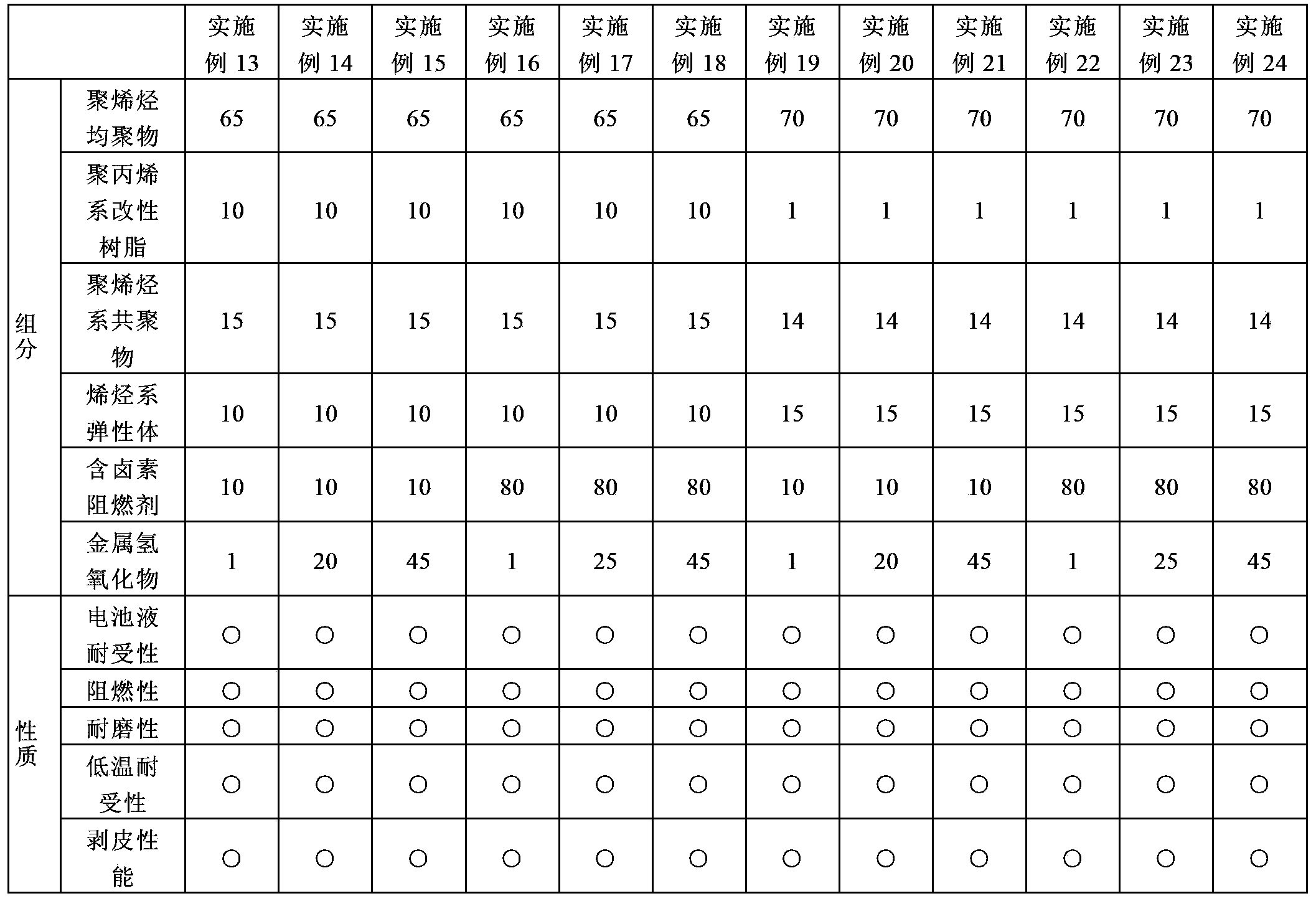

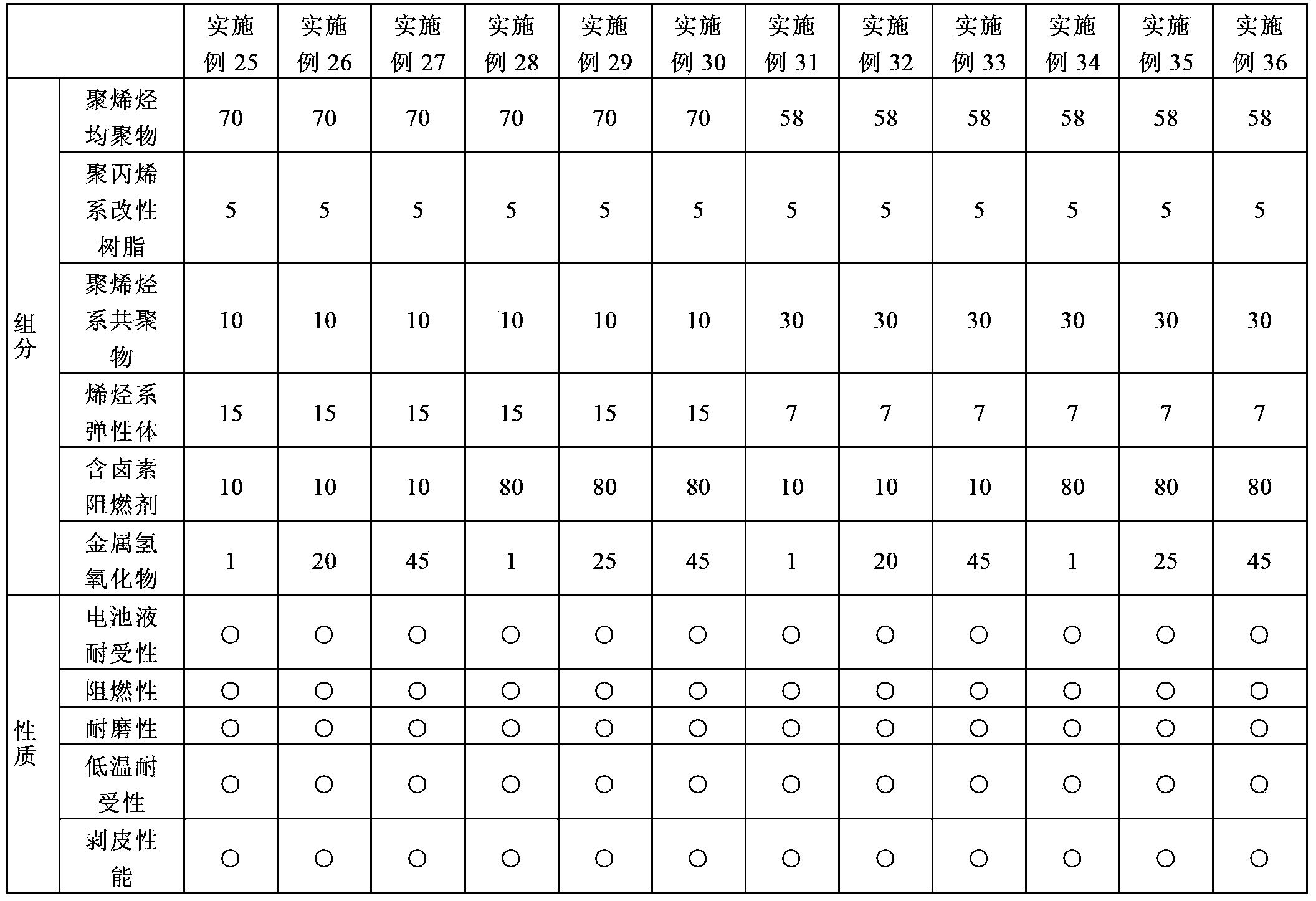

Fireproof material of housing of storage battery

InactiveCN108059834AHigh temperature resistantLight weightElectrical equipmentRubber layered productsFiberPolymer science

The invention belongs to the field of materials, and relates to a fireproof material of a housing of a storage battery. The housing comprises a metal layer, a polypropylene plastic layer and a ceramicsilicone rubber layer which are sequentially arranged from inside to outside, wherein the ceramic silicone rubber layer is prepared from the following raw materials in parts by weight: 100 parts of silicone rubber, 20-60 parts of ceramic preparing filler, 5-15 parts of a fluxing agent, 0.2-1.5 parts of a platinum catalyst, 2-8 parts of hydroxyl silicone oil, and 2-4 parts of a vulcanizing agent;and the ceramic preparing filler is a mixture of alumina silicate fibers and needle aedelforsite based on the mass ratio of (15-25): (30-40). A plurality of materials are matched with one another to jointly construct the material of the housing of the storage battery; the outermost ceramic silicone rubber layer ensures high fireproofing performance of the storage battery; in case of fire at the outside, the ceramic silicone rubber can be converted into a ceramic body with a dense structure for preventing outside fire from invading to cause combustion of inside materials, and moreover, the riskthat battery fluid leaks from a damaged vessel to cause explosion can be avoided.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

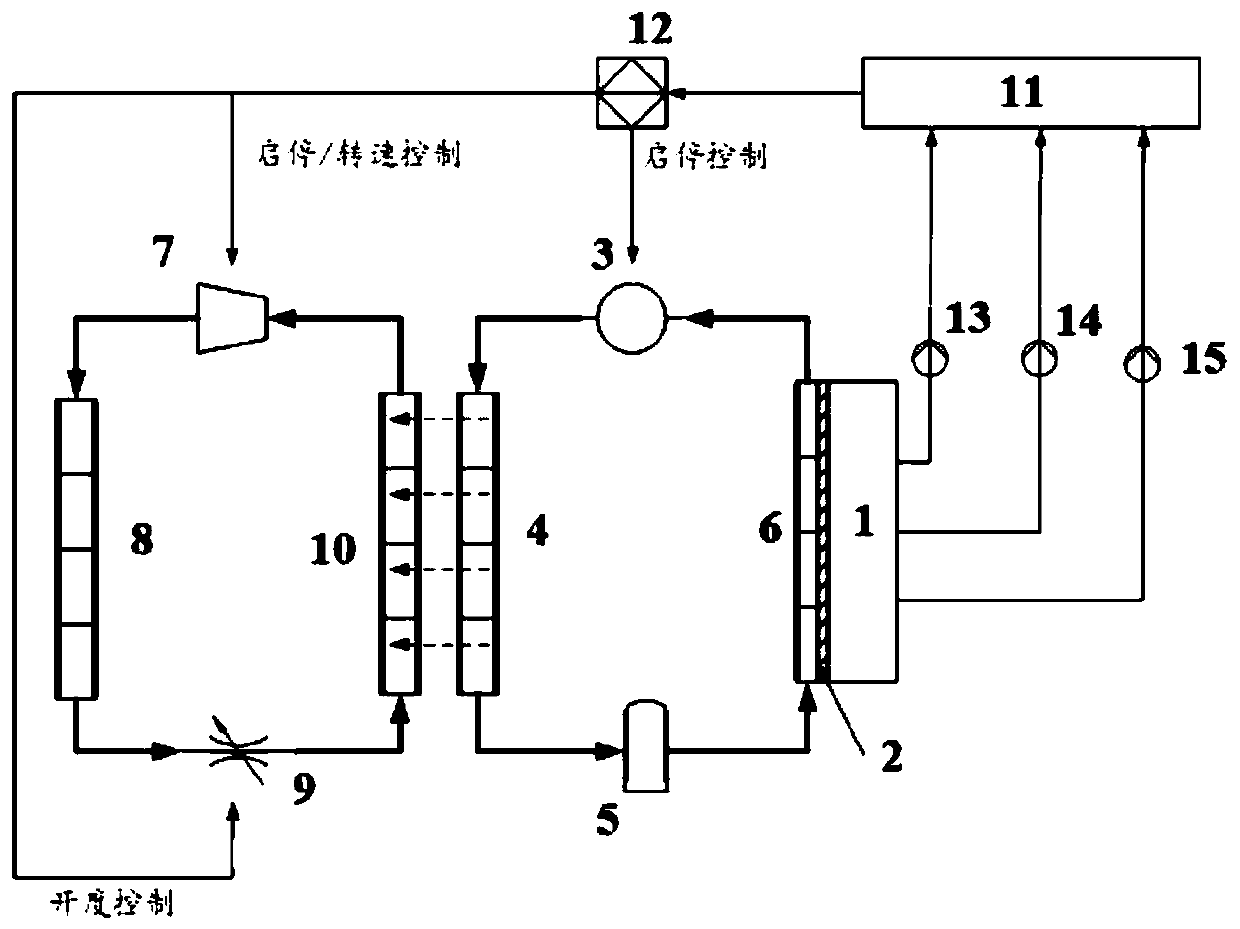

Integrated power battery thermal management system with cooling and fire extinguishing functions

InactiveCN112721736AHighly integratedHigh utility valueElectric devicesCompression machines with non-reversible cyclePower batteryCirculator pump

The invention aims to provide an integrated power battery thermal management system with cooling and fire extinguishing functions. A compressor, a condenser, a dry filter, a refrigeration electromagnetic valve, a capillary tube and an evaporator are sequentially connected to form a compressor unit refrigeration unit; a manual valve and a liquid spraying electromagnetic valve are led out from the front of the refrigerating electromagnetic valve to form a spraying branch; a manual valve and a thermal electromagnetic valve are led out from a pipeline between the compressor and the condenser to form a thermal bypass branch; a first three-way connecting valve, a water absorption filter and a regulating valve are connected to a liquid outlet of a liquid cooling plate in the battery liquid tank to form a liquid cooling branch, and the second three-way connecting valve, the water absorption filter and the liquid return electromagnetic valve are connected to a liquid return port of the sealed battery liquid tank to form a liquid fire extinguishing branch; the circulating pump, the temperature sensor, the flow sensor, the flow regulating valve, the diaphragm valve and the heater are sequentially connected to form a liquid cooling circulating unit. Cooling and fire extinguishing functions are integrated, the space utilization rate of the system can be increased, and the safety performance of the whole thermal management system is enhanced.

Owner:HARBIN ENG UNIV

Two-phase immersed battery liquid cooling system with multiple modules sharing one constant-pressure device

PendingCN111883878AImprove stabilityStable temperatureSecondary cellsCell component detailsPower batteryThermodynamics

The invention belongs to the technical field of power batteries, and provides a two-phase immersed battery liquid cooling system with multiple modules sharing one constant voltage device. The heat generated by the battery in the working process is dissipated by vaporization of the fluorinated liquid on the surface of the battery, the vaporized fluorinated liquid is condensed on the surface of theupper cover plate of the box body and in the air storage chamber, and the heat released by condensation is absorbed by a cooling working medium in the cooling coil, so that the highest temperature ofthe battery and the temperature difference between different battery monomers are effectively controlled. Compared with a traditional two-phase immersed battery liquid cooling device, the liquid cooling device has the following advantages that the pulse pressure in the box body is buffered by utilizing the position movement of the piston in the air storage chamber, so that the box body does not need to bear the pulse pressure load, and the stability of the system is improved; in addition, the condensation rate of the fluorinated liquid steam changes along with the change of the heat productionrate of the battery, so that the temperature and the pressure in the battery box body can be controlled to be basically stable.

Owner:DALIAN UNIV OF TECH

Electric cable

ActiveCN103443872AMeet low temperature toleranceRubber insulatorsInsulated cablesElastomerPolyolefin

Owner:YAZAKI CORP

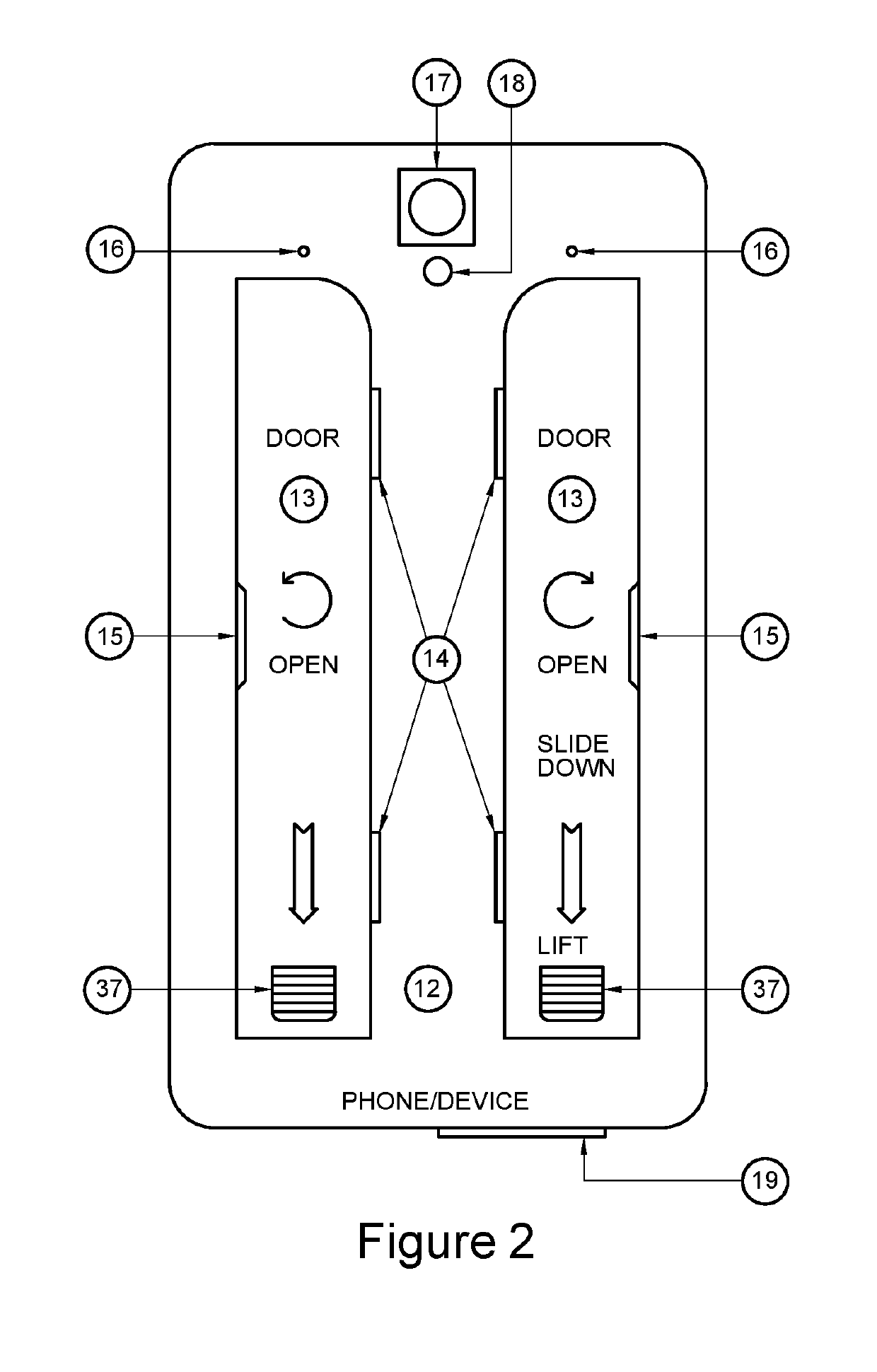

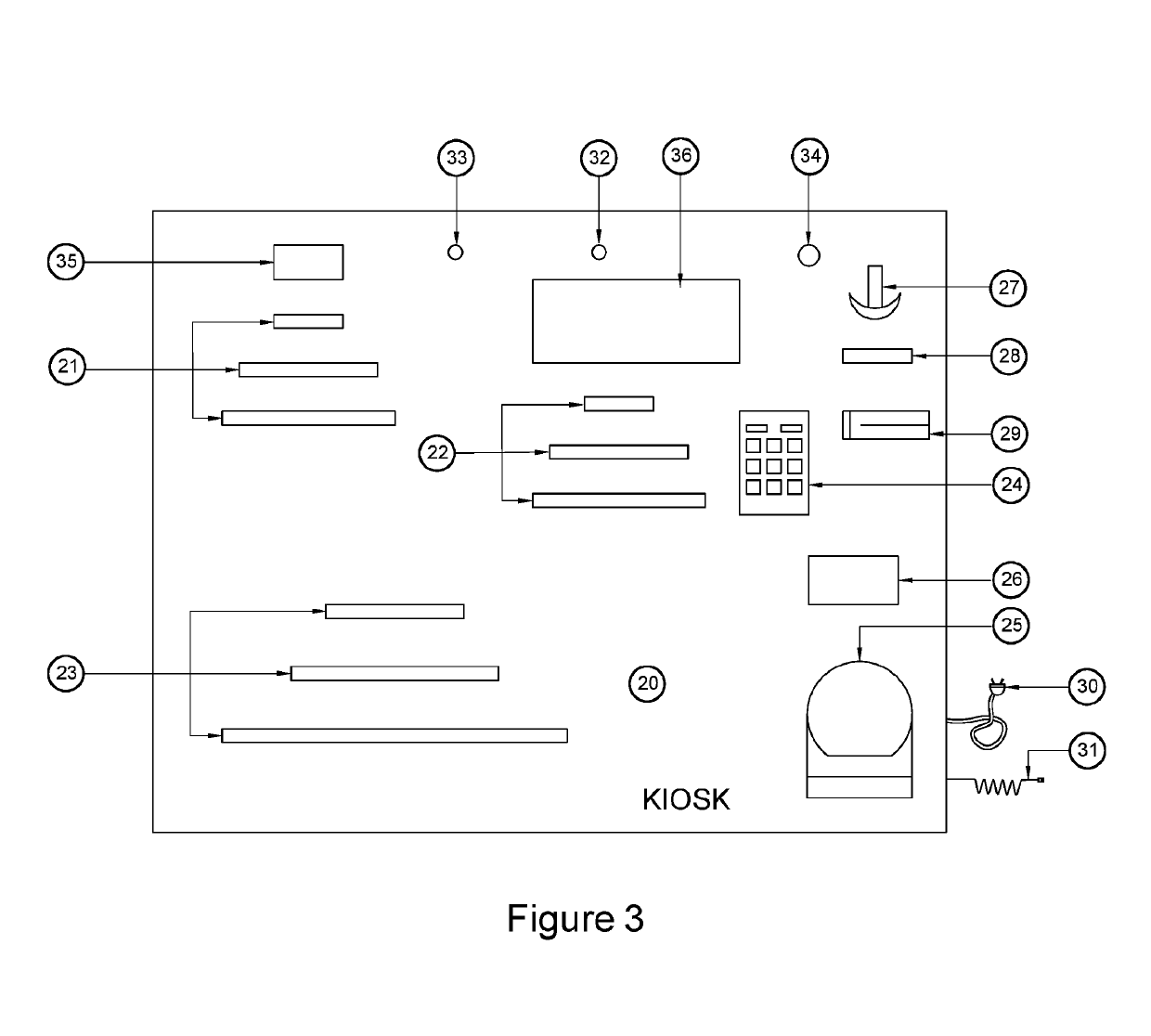

Rechargeable devices and kiosks for same

ActiveUS20190333037A1Easy to identifyPrevent tamperingCells structural combinationPayment architecturePaymentElectrical battery

A system for enabling electrical devices to exchange either battery or battery fluids or reagents that supply the energy for the battery or device with new recharged batteries or battery fluids or reagents for use in equipment including vehicles, excavating and earthmoving equipment, tractors and agricultural equipment or aircraft, smaller devices such as mobile phones, telecommunication devices and portable computers. This system involves handling and billing systems to ensure this is all done and that satisfactory payment to the supplier parties is achieved. The system involves packaging reagents such as enzymes, anodes, gases, etc. in sealed systems in order to ensure their integrity or having control over the delivery and retrieval and internal use systems to ensure the reagent is kept secure and uncontaminated.

Owner:RAYNER DIGNAN

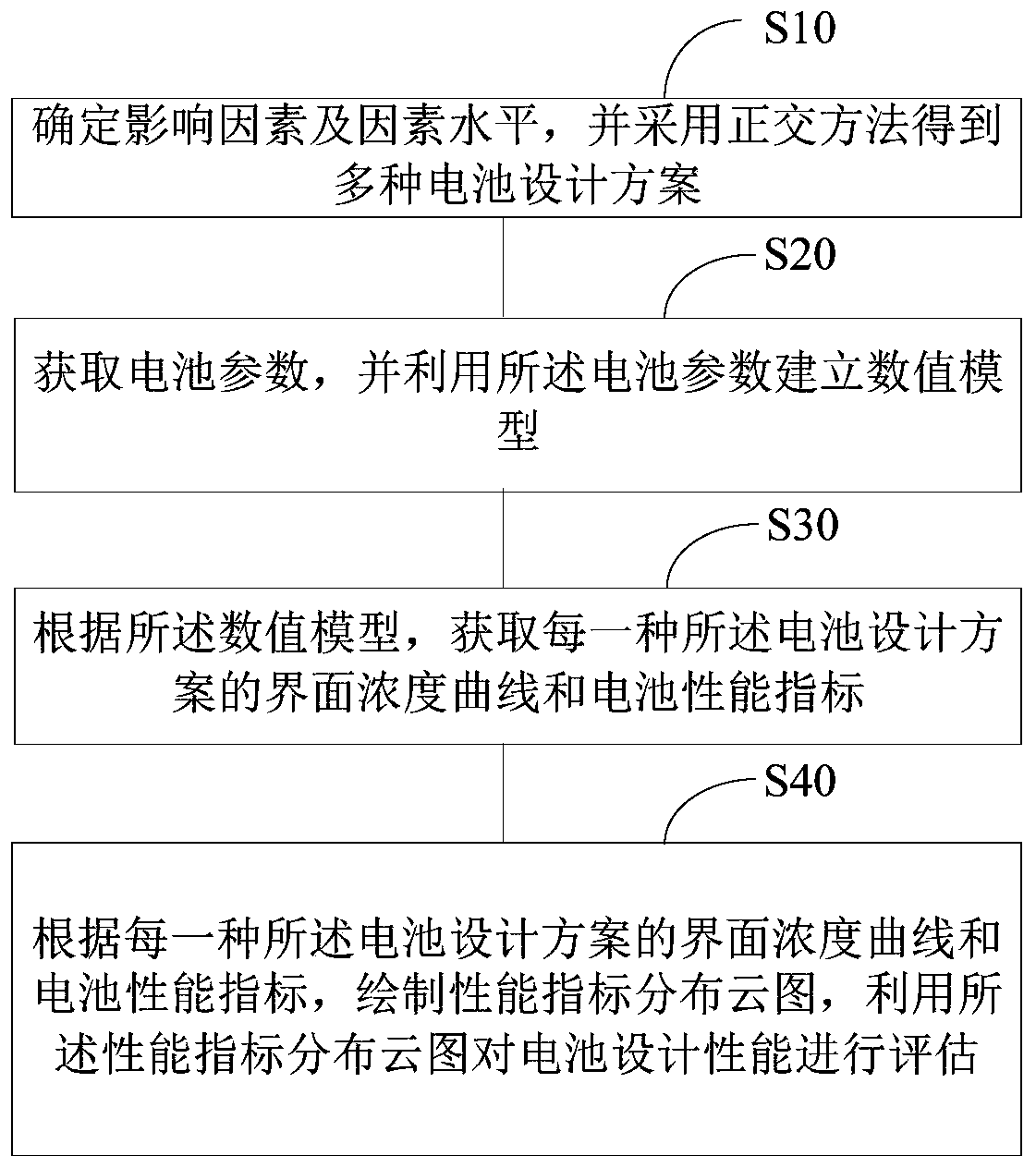

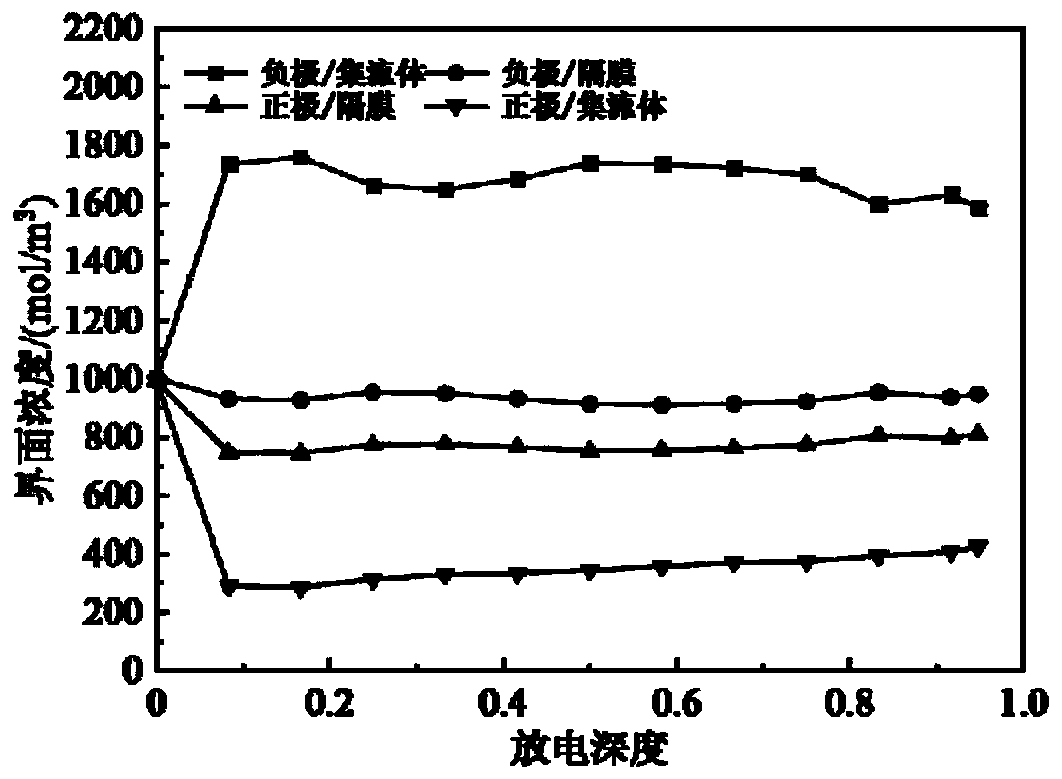

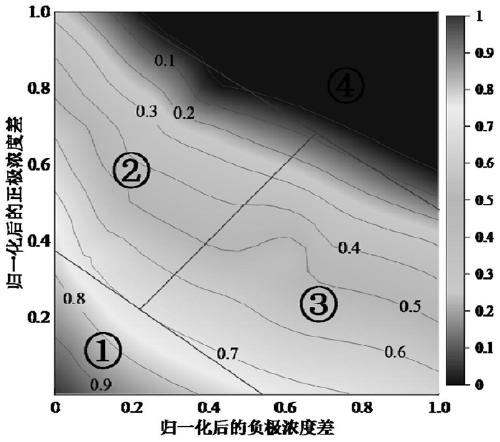

Battery design method, method for evaluating battery design and computer equipment

ActiveCN111475956ADesign pros and consSmall scaleDesign optimisation/simulationSecondary cells servicing/maintenanceElectrical batterySimulation

The invention relates to a battery design method, a method for evaluating battery design and computer equipment. The method for evaluating battery design comprises the steps of: acquiring a pluralityof battery design schemes through determining influence factors and factor levels and employing an orthogonal method; acquiring battery parameters, and establishing a numerical model by utilizing thebattery parameters; and acquiring an interface concentration curve and a battery performance index of each battery design scheme according to the numerical model, further drawing a performance index distribution cloud chart, and evaluating battery design performance by utilizing the performance index distribution cloud chart. According to the method for evaluating battery design, the particle sizeand kinetic parameters of the active substance during battery design are generally set values, the solid-phase transmission difference is small, the thickness, porosity and other design parameters mainly influence the liquid-phase transmission performance of the battery, and the electrolyte concentration difference is caused by liquid-phase transmission, so that the advantages and disadvantages of the battery design are evaluated through utilizing the concentration features, the value range of the design parameters is narrowed, the calculation resources are saved, and the optimization time isshortened.

Owner:TSINGHUA UNIV

Two-phase immersed battery liquid cooling device for storing energy by utilizing phase change material

PendingCN111864304AReduce cooling energy consumptionImprove battery lifeSecondary cellsCell component detailsPower batteryThermodynamics

The invention belongs to the technical field of power batteries and provides a two-phase immersed battery liquid cooling device for storing energy by using a phase change material. Fins are filled with the phase-change materials so that when an electric automobile runs for a short distance, heat released by a power battery can be absorbed only by the phase-change materials in the fins, a cooling system does not need to be opened, and cooling energy consumption during short-distance running of the electric automobile is reduced. When the electric automobile runs for a long distance, the phase-change materials in the fins can be firstly used for absorbing heat generated by the power battery, when the phase-change materials are completely melted, the cooling system is started to cool the battery and the phase-change materials, cooling energy consumption is minimized in the whole process, and the endurance mileage of the electric automobile in the long-distance running process is greatly increased.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com