Method for producing zinc powder and battery fluid from battery zinc anode waste and battery waste fluid

A technology of zinc anode and battery liquid, which is applied in the production of high-purity branched sheet metal zinc powder and the regeneration of battery waste liquid, can solve the problems of high use cost, difficulty in large-scale development, and large market influence, and achieves stable operation cost and improved Discharge amount, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

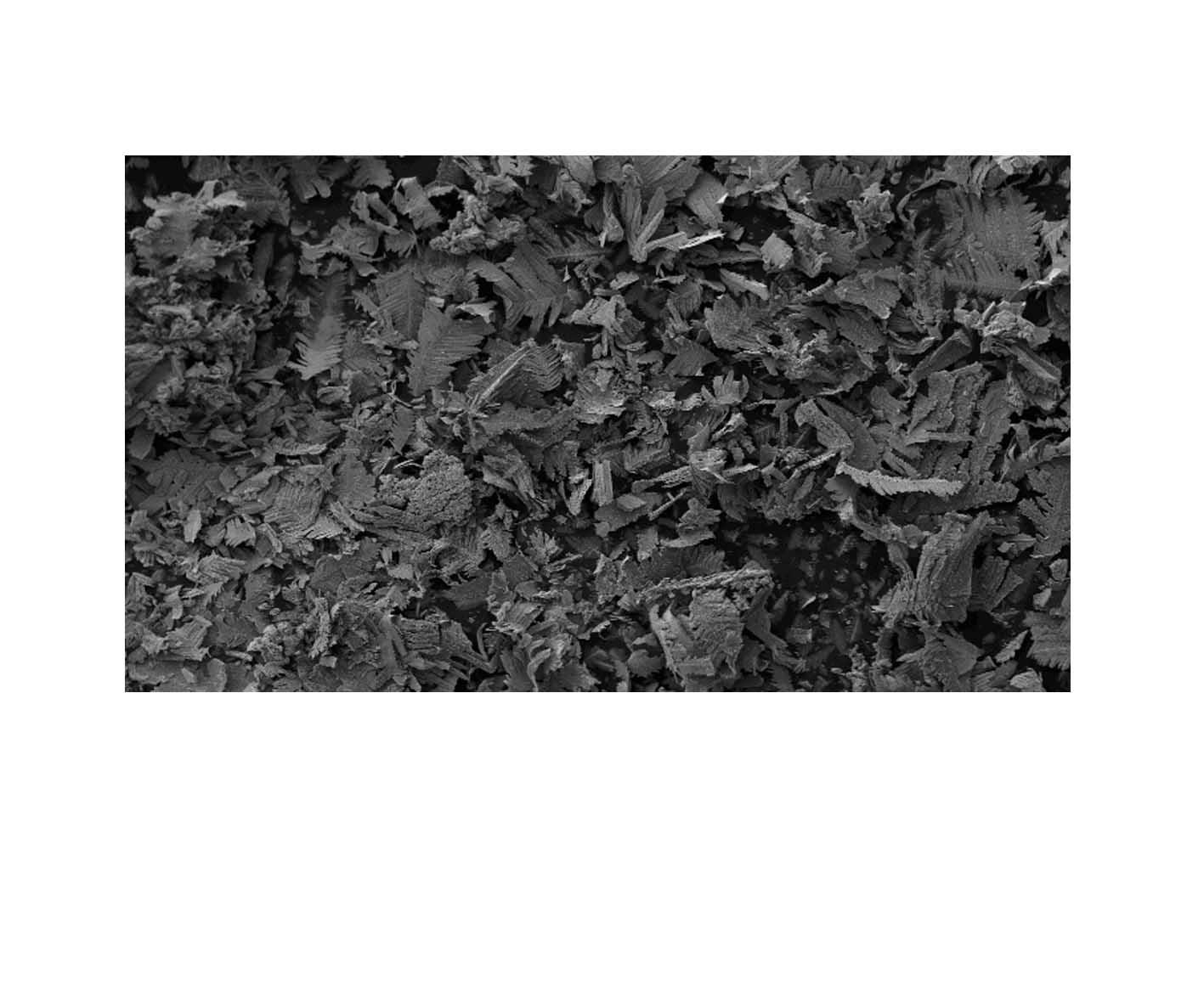

Image

Examples

Embodiment 1

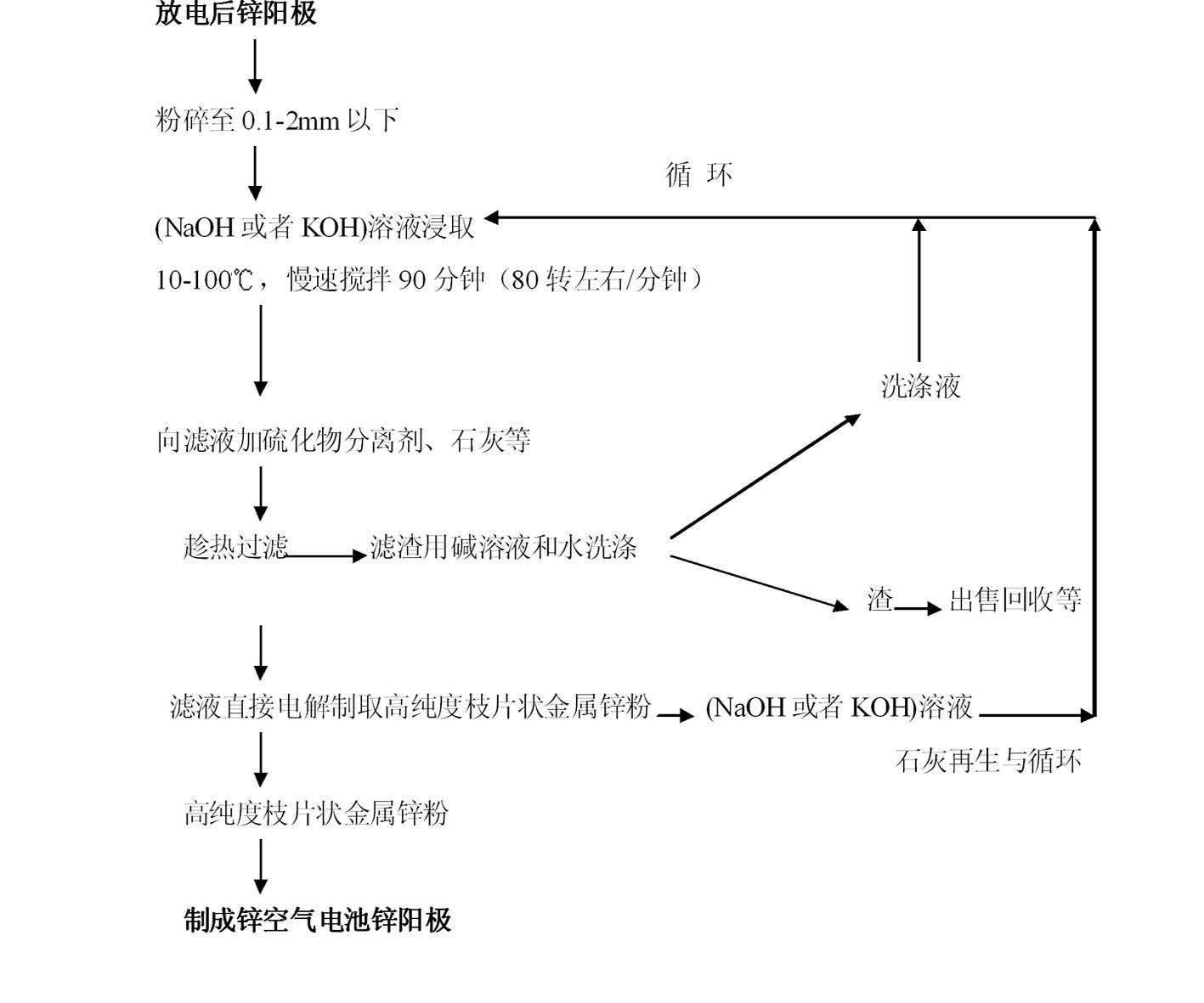

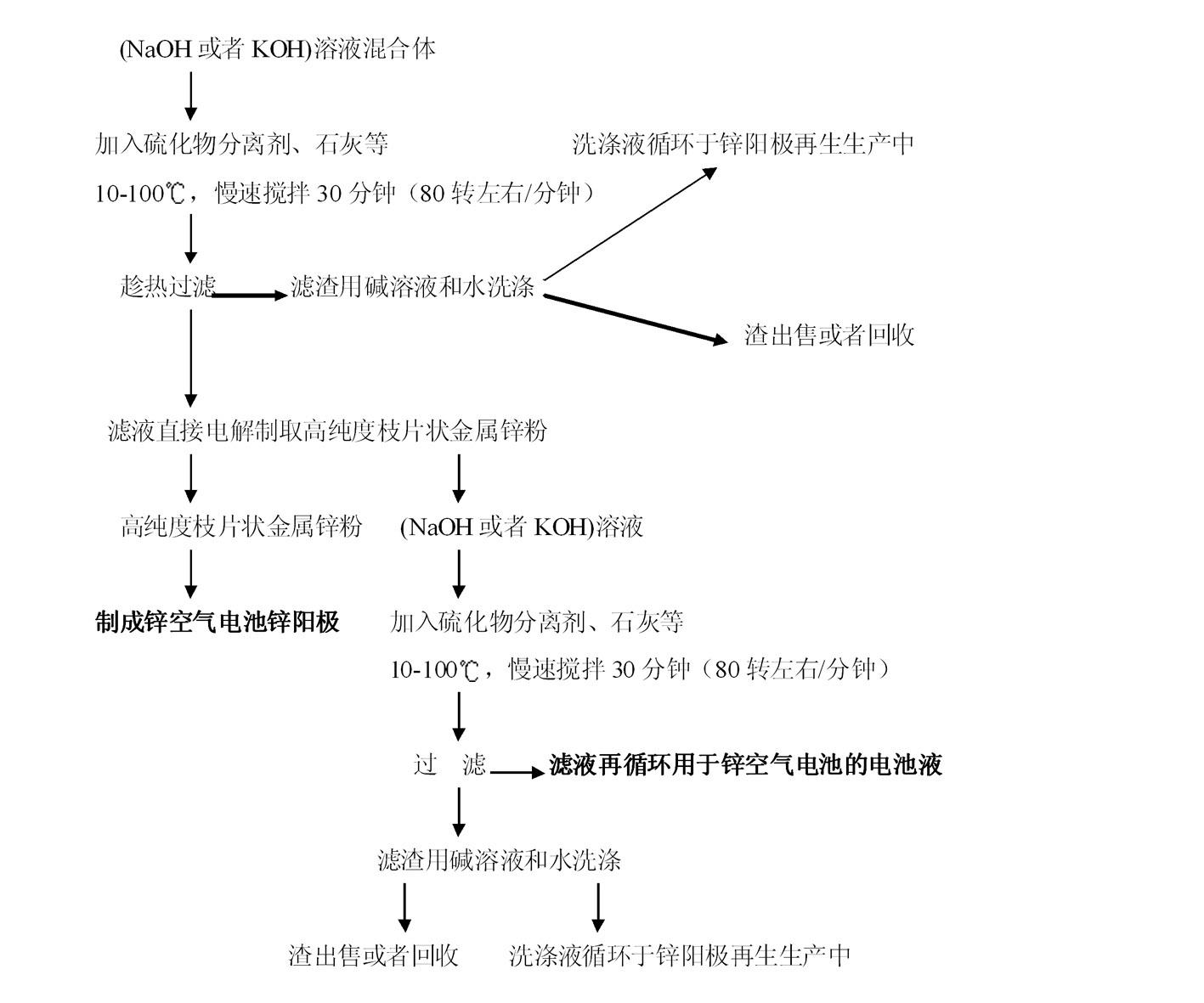

[0024] A method for producing high-metal zinc powder and battery liquid from battery zinc anode waste and battery waste liquid, the steps of which are:

[0025] a. A strong alkaline solution prepared according to the mass ratio of 1 part of NaOH and 99 parts of KOH, the total mass concentration of NaOH and KOH is 20%, to obtain a NaOH / KOH mixed solution;

[0026] b. First measure zinc-air battery waste: NaOH / KOH mixed solution with a solid-to-liquid ratio of 1:2, mix evenly to obtain raw materials, and then stir at 10 degrees Celsius for 3 hours;

[0027] c. Mixing the leaching raw material prepared in step b with the zinc-air battery waste liquid to obtain a zinc-air battery integrated mixed liquid;

[0028] d. The iron, copper, and lead in the zinc-air battery integrated mixed solution prepared in the sulfide purification and separation step c are used to obtain a sulfide purification solution, the sulfide is sodium sulfide, and the amount of sulfide added is calculated ...

Embodiment 2

[0033] A method for producing high-metal zinc powder and battery liquid from battery zinc anode waste and battery waste liquid, characterized in that the steps are as follows:

[0034] a. A strong alkaline solution prepared according to the mass ratio of 99 parts of NaOH and 1 part of KOH, the total mass concentration of NaOH and KOH is 47.7%, to obtain a NaOH / KOH mixed solution;

[0035] b. First measure zinc-air battery waste: NaOH / KOH mixed solution with a solid-to-liquid ratio of 1: 10, mix evenly to obtain raw materials, and then stir at 100 degrees Celsius for 0.1h;

[0036] c. Mixing the leaching raw material prepared in step b with the zinc-air battery waste liquid to obtain a zinc-air battery integrated mixed liquid;

[0037] d. The iron, copper, and lead in the zinc-air battery integrated mixed solution prepared in the sulfide purification and separation step c are used to obtain a sulfide purification solution, the sulfide includes a composition of sodium sulfid...

Embodiment 3

[0042] A method for producing high-metal zinc powder and battery liquid from battery zinc anode waste and battery waste liquid, characterized in that the steps are as follows:

[0043] a. A strong alkaline solution prepared according to the mass ratio of 50 parts of NaOH and 50 parts of KOH, the total mass concentration of NaOH and KOH is 50%, to obtain a NaOH / KOH mixed solution;

[0044] b. First measure zinc-air battery waste: NaOH / KOH mixed solution with a solid-to-liquid ratio of 1:5.5, mix evenly to obtain raw materials, and then stir at 55 degrees Celsius for 2 hours;

[0045] c. Mixing the leaching raw material prepared in step b with the zinc-air battery waste liquid to obtain a zinc-air battery integrated mixed liquid;

[0046] d. The iron, copper, and lead in the zinc-air battery integrated mixed solution prepared in the sulfide purification and separation step c are used to obtain a sulfide purification solution. The sulfide is a composition of potassium sulfide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com