Liquid cooling dynamic heat management system for power supply

A dynamic thermal management, power battery technology, applied in secondary batteries, battery temperature control, circuits, etc., can solve the problems of limited heat exchange, difficult preheating function, uneven flow field, etc., to achieve intelligent control, The effect of avoiding energy loss and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

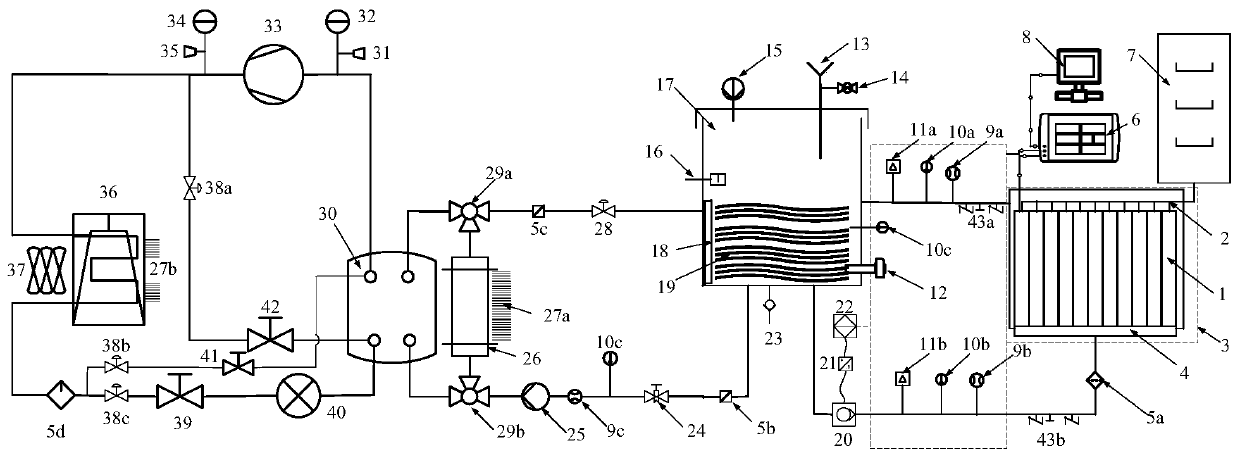

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] to combine figure 1 , a liquid-cooled dynamic thermal management system for a power battery, including a battery cell 1, a connecting row 2, a constant temperature and humidity box 3, a liquid cooling plate 4, dry filters 5a, 5b, 5c, 5d, a data collector 6, a charging and discharging Instrument 7, computer 8, flow sensor 9a, 9b, 9c, temperature sensor 10a, 10b, 10c, pressure sensor 11a, 11b, heater 12, filling funnel 13, filling regulating valve 14, liquid level sensor 15, liquid level Switch 16, liquid storage tank 17, thermal insulation cotton 18, coolant 19, external circulation pump 20, frequency converter 21, PLC controller 22, drain port 23, flow regulating valve 24, internal circulation pump 25, plate heat exchanger 26 , cooling fins 27a, 27b, manual valve 28, three-way reversing valve 29a, 29b, evaporator 30, low pressure protector 31, low pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com