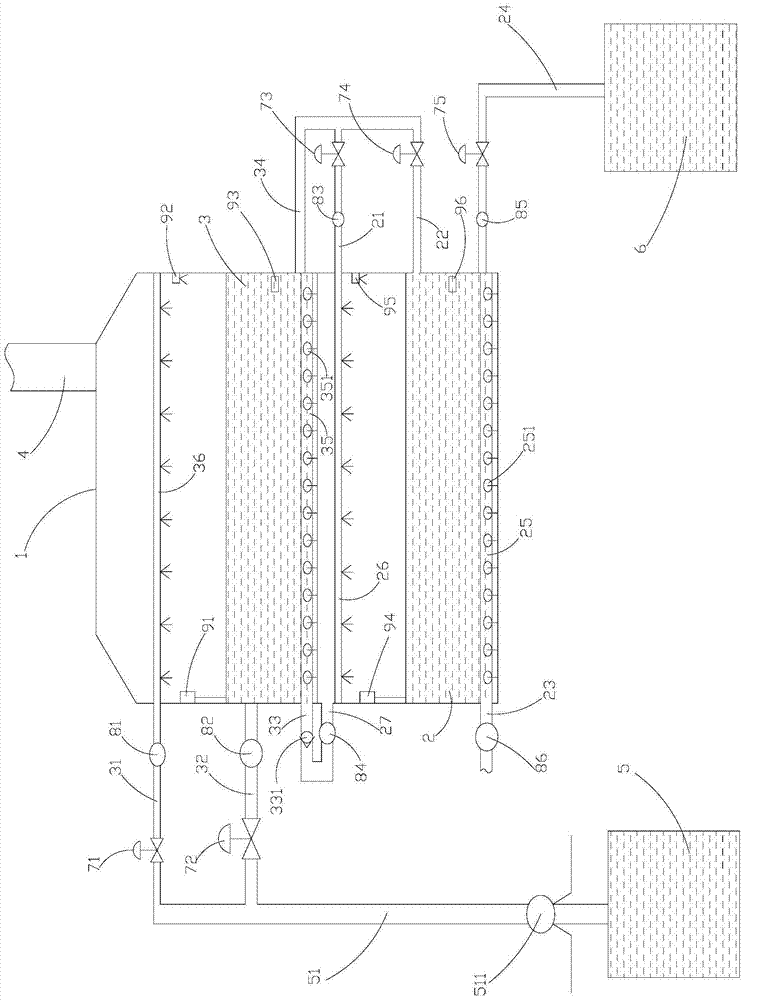

A flue gas multiple aeration desulfurization and denitrification system and control method

A technology of desulfurization, denitrification and aeration, which is applied in the direction of separation method, self-adaptive control, general control system, etc., can solve the problems of lower pH value of alkaline wastewater and high cost of alkaline wastewater treatment, and achieve the effect of reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

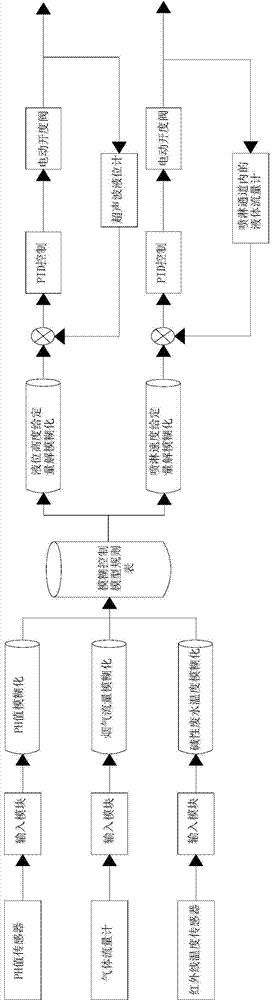

[0046] In order to fully react the alkaline wastewater with the sulfur oxides and nitrogen oxides in the flue gas, the discharged flue gas meets the emission standards. First, through a large number of experiments, the relationship between the temperature of the alkaline waste liquid, the pH value of the alkaline waste liquid, the liquid level of the alkaline waste liquid, the spraying speed of the alkaline waste liquid, the flow rate of the flue gas and the composition of the exhausted flue gas is obtained; On-line data analysis establishes a fuzzy control model; finally, the system monitors the temperature of alkaline waste liquid in the flue gas desulfurization and denitrification device of alkaline wastewater in real time, the pH value of alkaline waste liquid, and the change of flue gas flow rate, and controls the change of alkaline waste water. The height of the liquid level, the replacement of alkaline waste liquid, and the spraying speed of alkaline waste liquid can rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com