A liquid discrete microfluidic chip and its application method

A microfluidic chip and liquid technology, applied in the field of microfluidics, can solve problems such as cumbersome operation steps, difficulty in integration and automation, and influence on analysis and detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

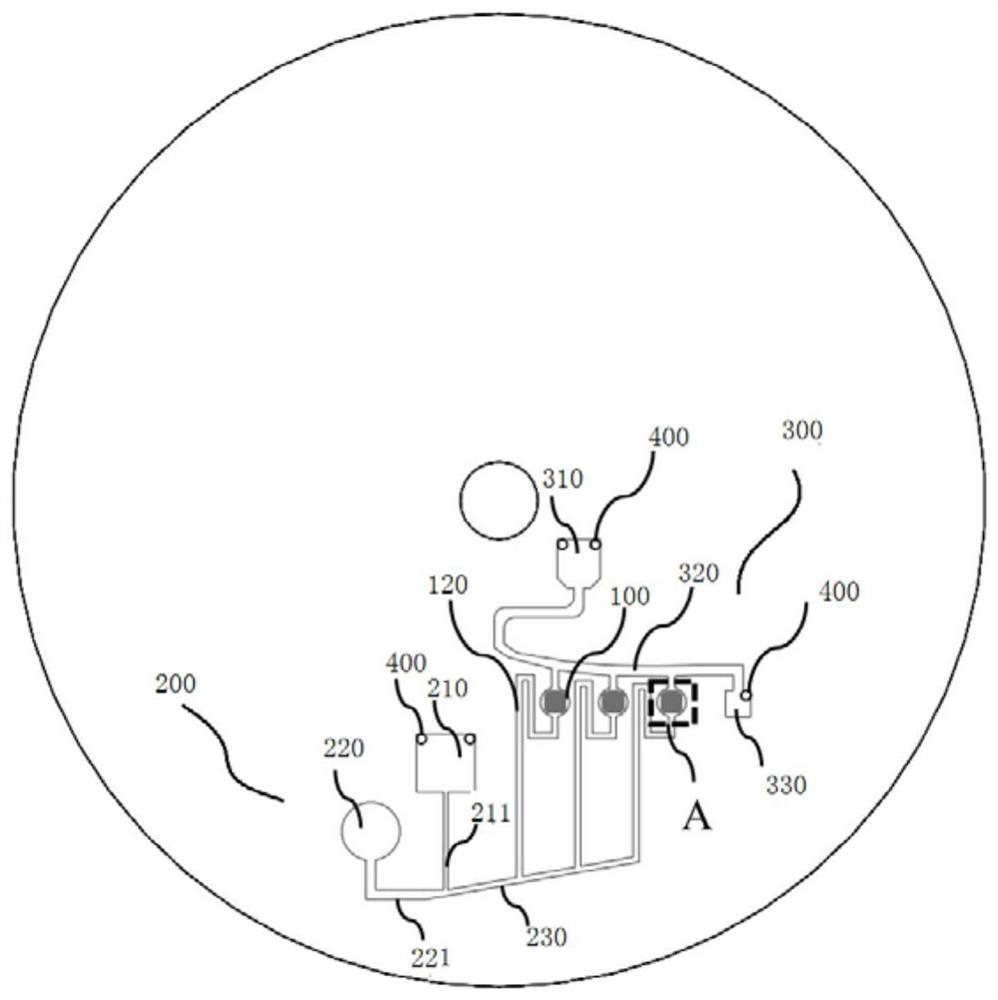

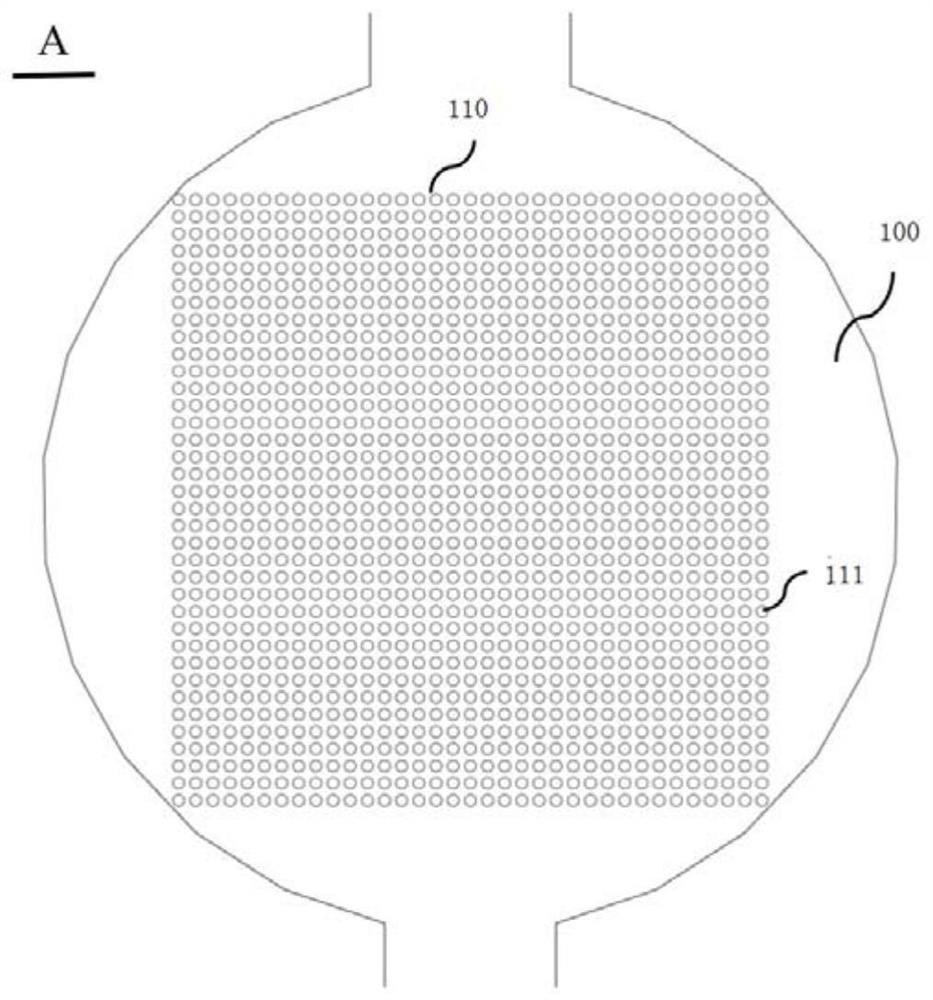

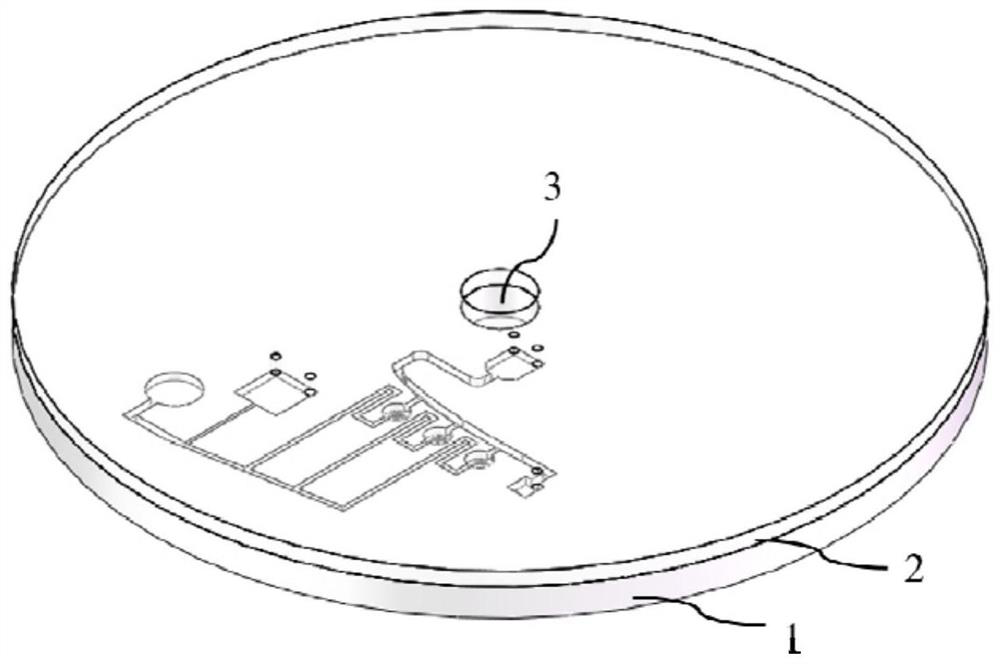

[0068] In this embodiment, the microfluidic chip of the present invention is described in detail by taking the application in the field of digital PCR as an example. The microfluidic chip is a centrifugal microfluidic chip with four sets of discrete units symmetrically arranged (one of which is shown in the figure), and each discrete unit includes a distribution unit 300 , three reaction tanks 100 , and a liquid pumping unit 200 . The distribution unit 300 includes a first liquid tank 310 , a distribution channel 320 and a waste liquid tank 330 . Wherein, the distribution channel 320 is connected to three reaction tanks 100 , each of the three reaction tanks 100 is connected to the liquid pumping unit 200 through the capillary channel 120 . The reaction tank 100 has a micro-reaction well array 110 composed of 20,000 micro-reaction wells 111 . The shape of the micro-reaction pool 111 is circular, the draft angle is 6°, the volume capacity is 0.1 nanoliter, the aspect ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com