Manufacturing method of x80 pipeline steel straight seam welded pipe

A technology of a straight seam welded pipe and a manufacturing method, which is applied in the manufacture of straight seam submerged arc welded pipes and the manufacture of X80 pipeline steel straight seam welded pipes, can solve the problems of low overall performance of welded joints and reduced impact toughness of welding heat affected zone, etc. The effect of reducing the energy of the inner bead line, increasing the energy of the welding line, and ensuring the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

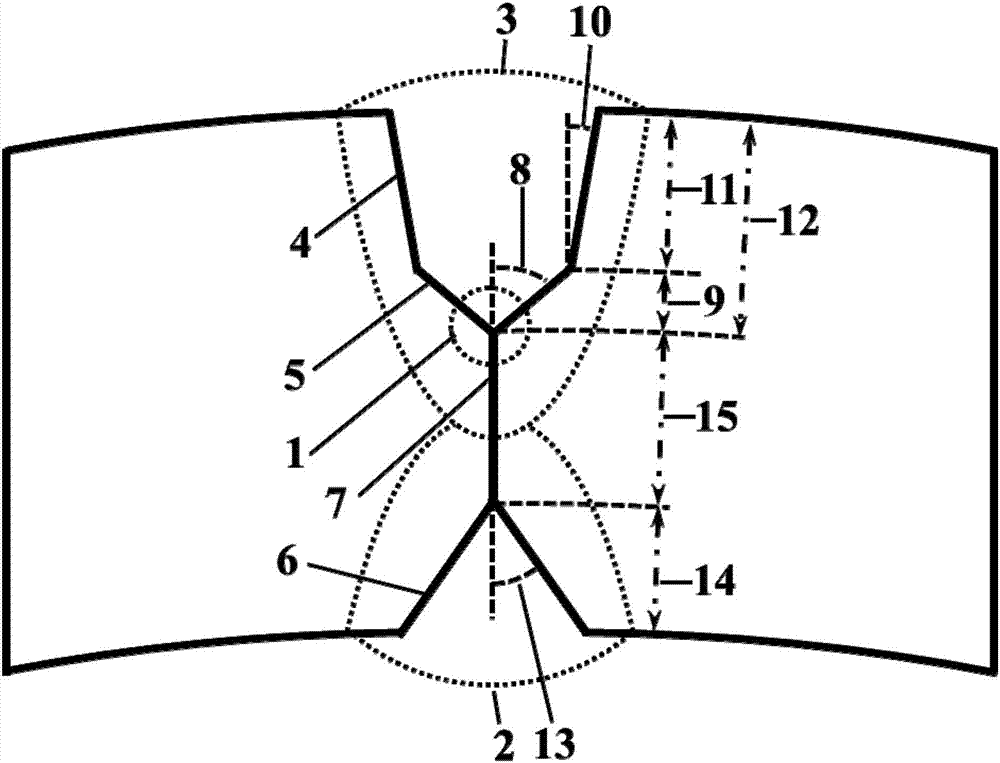

[0023] Such as figure 2 As shown, the manufacturing method of X80 pipeline steel longitudinal welded pipe adopts the X80 pipeline steel plate with a wall thickness of 21.4mm and a width of 4485mm, and its chemical composition (weight percentage) is as follows: C 0.04~0.07, Si 0.15~0.25, Mn 1.68 ~1.78, Nb 0.04~0.05, Ti 0.01~0.02, Cu 0.12~0.22, Cr 0.20~0.28, Mo 0.10~0.20, Ni0.10~0.20, P<0.015, S<0.005, N<0.006, Fe is the balance ;To make X80 pipeline steel straight seam welded pipe with a pipe diameter of Φ1422mm, the process steps are as follows:

[0024] 1. Preparation process: including X80 pipeline steel plate leveling, steel plate loading and welding arc strike plate.

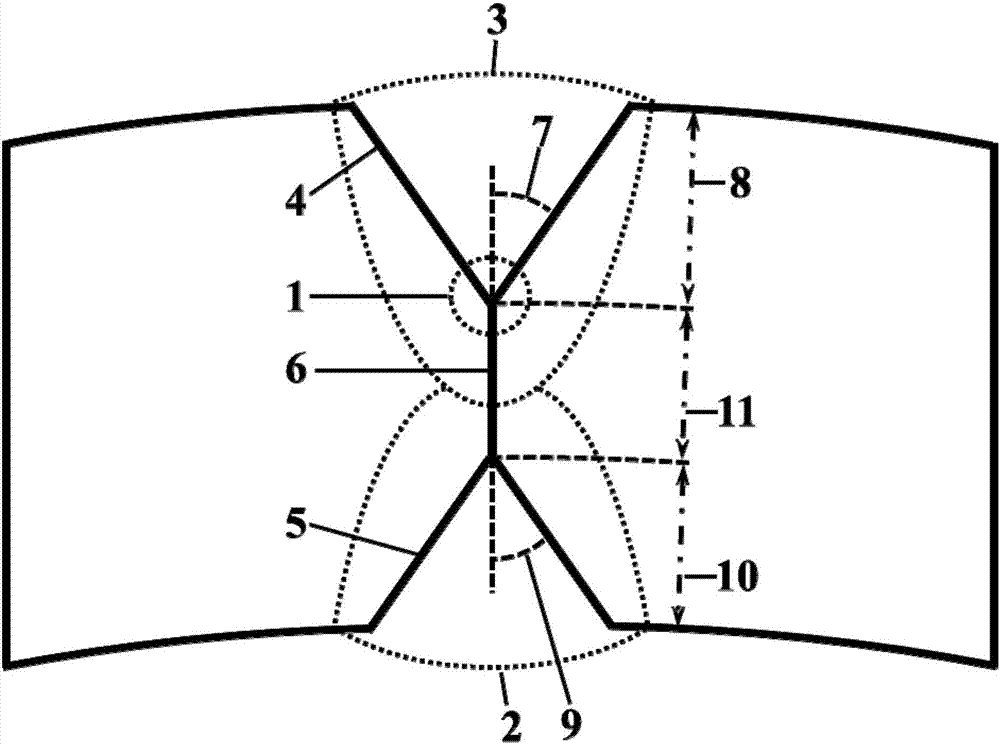

[0025] 2. Edge milling: rough milling first, milling off the width of the plate edge by 5-10mm; then fine milling, as attached figure 2 As shown, the groove on the outer side of the pipe wall is the outer groove, the groove on the inner side is the inner groove 6, and the straight edge between the two gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com