Oxidation ditch guide oxygen increasing device

An aeration device and oxidation ditch technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as deterioration of circulation capacity, small oxygenation function, and inability to adjust oxidation ditch , to reduce the loss of micro-bubbles on the surface, increase the oxygenation capacity, and solve the effect of sludge settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

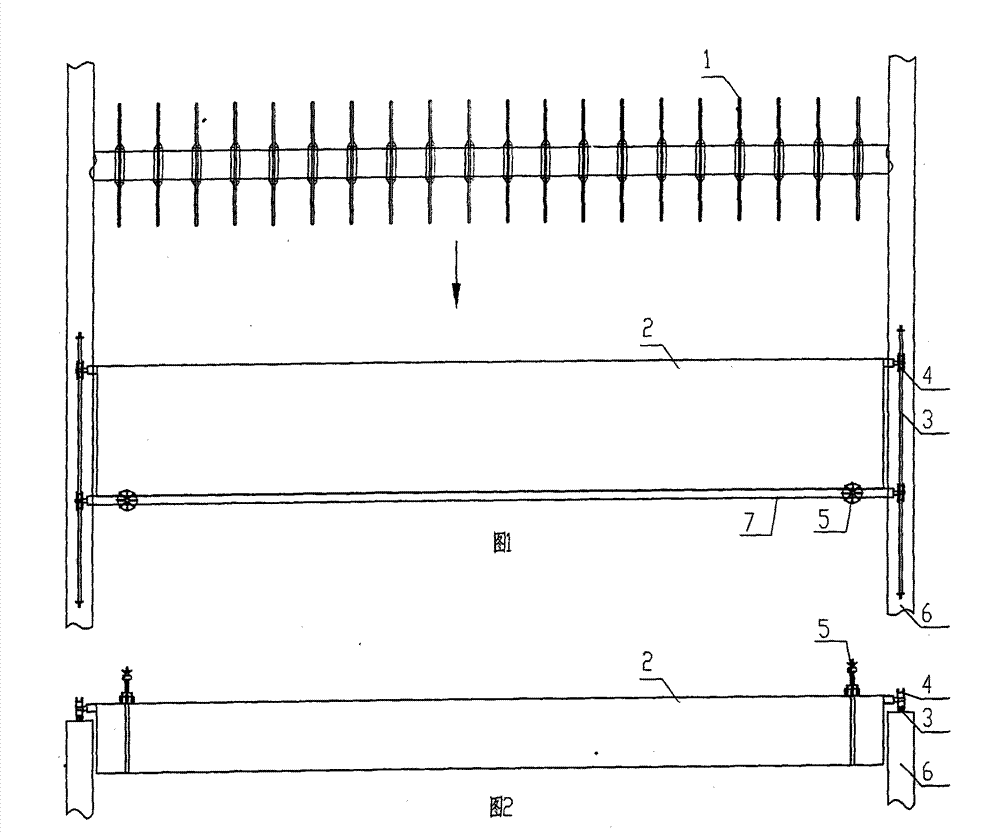

[0028] Embodiment 1: see figure 1 , 2 , the oxidation ditch is equipped with the deflector of the present invention, and the top surface of the oxidation ditch pool wall 6 downstream of the rotary aeration device 1 is provided with a track 3, and the flat deflector 2 is hinged through the upper end, and the two ends are arranged on the guide wheel 4. On the track 3, it is driven by a motor to move back and forth (it can also be manually pulled). There is also a movable shaft 7 supported on the track of the wall surface of the downstream ditch, on which two motor hoists 5 (also can be manual hoists) are arranged on the left and right, for lifting and lowering the lower end of the deflector, and adjusting the inclination of the deflector 2 angle. The oxidation ditch is equipped with a real-time on-line water flow rate and depth measuring instrument and a dissolved oxygen measuring instrument (not shown in the figure), and the measurement data is fed back to the computer to co...

Embodiment 2

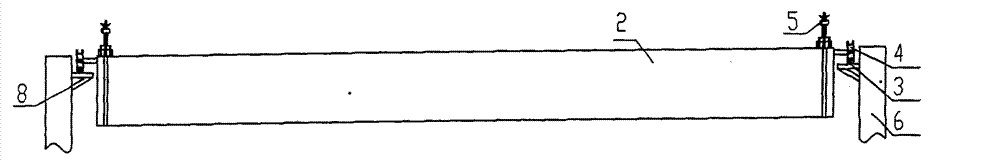

[0029] Example 2: see image 3 , as in Example 1, a track support frame 8 is arranged on the water surface of the side surface of the oxidation ditch wall 6, and the deflector is rested on the side surface of the oxidation ditch pool wall.

Embodiment 3

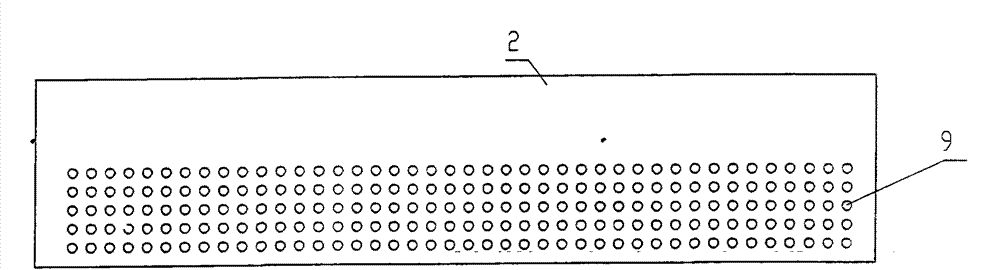

[0030] Embodiment 3: see Figure 4 , As in Embodiment 1 or 2, the water part of the deflector 2 has a circular through hole 9, and the through hole has a cutting effect on air bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com