Patents

Literature

292results about How to "Temperature balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

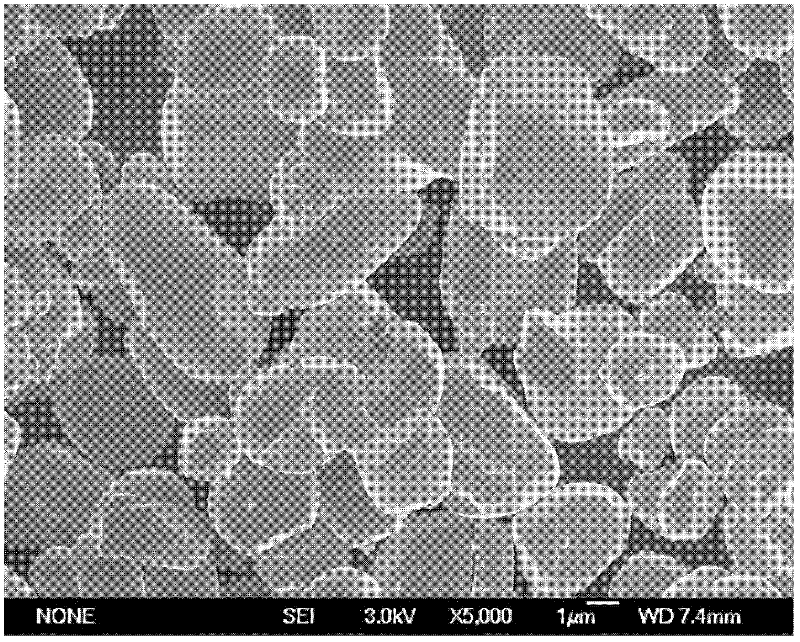

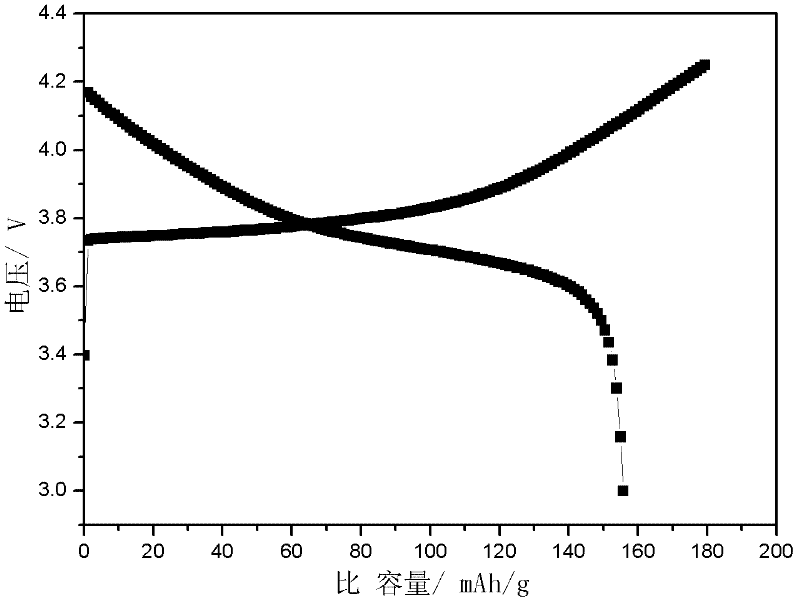

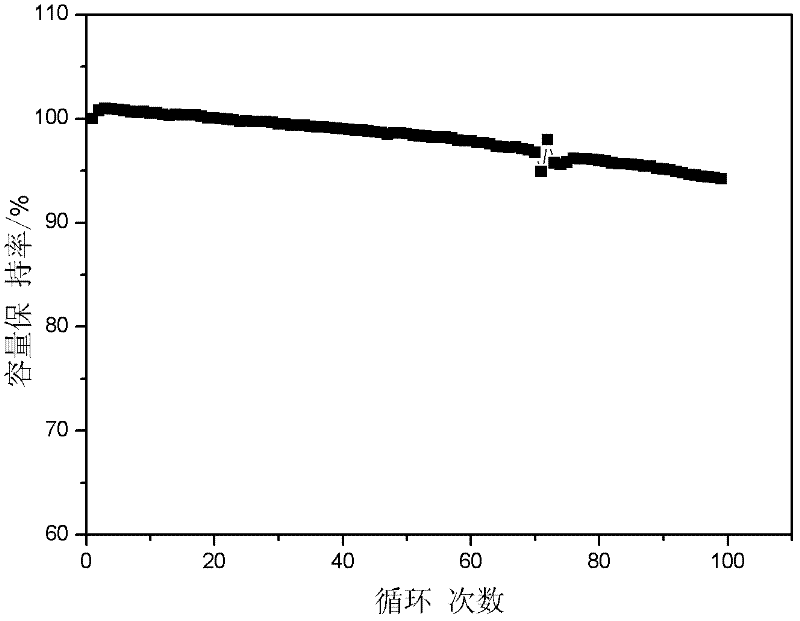

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

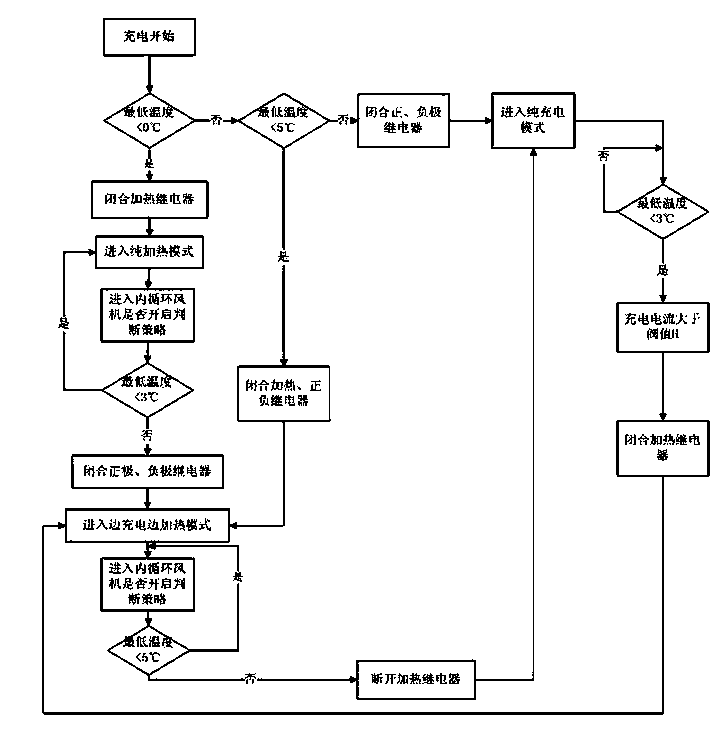

Charging method of power battery of electric vehicle

InactiveCN104393357AFast fullTemperature balanceSecondary cells charging/dischargingBatteriesPower batteryHeating time

The invention provides a charging method of a power battery of an electric vehicle. The charging method comprises the following steps: S1, detecting the maximal temperature and the minimal temperature of a battery, and judging whether the minimal temperature is lower than a first threshold temperature or not, if so, executing a step S2; if not, continuing to judge whether the minimal temperature is higher than a second threshold temperature or not, if so, executing a step S4, if not, executing a step S3; S2, entering a pure-heating mode; S3, entering a charging and heating mode; and S4, entering a pure-heating mode. According to the charging method of the power battery of the electric vehicle, provided by the invention, the power battery at low temperature is charged, the power battery enters different charging procedures according to the minimal temperature of the battery, namely, the pure-charging mode, the heating and charging mode and the pure-charging mode, so that the low-temperature charging and heating time can be shortened, and the rapid charging of the battery is ensured.

Owner:HUIZHOU EPOWER ELECTRONICS

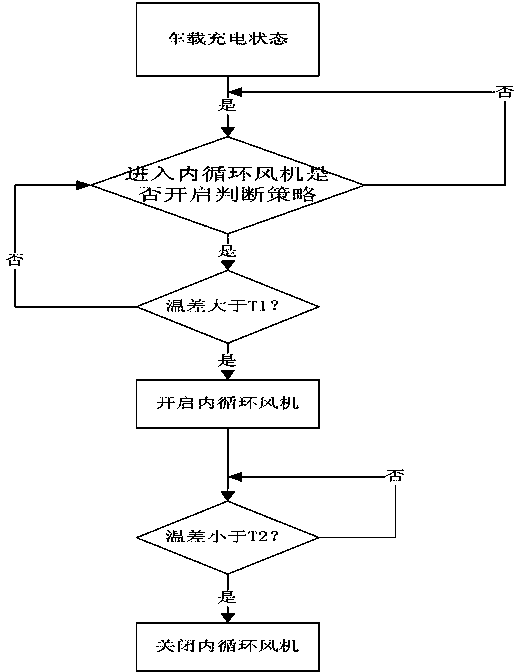

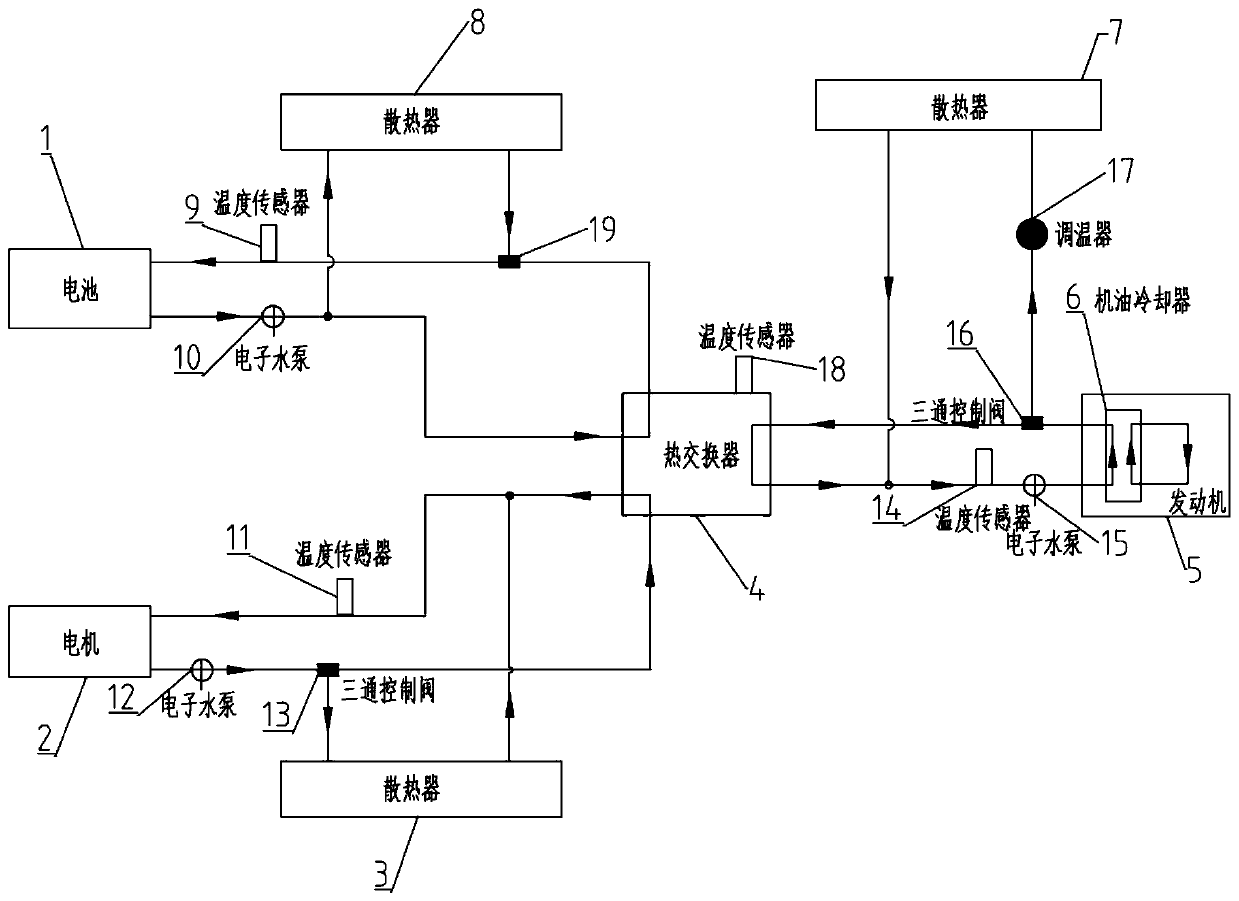

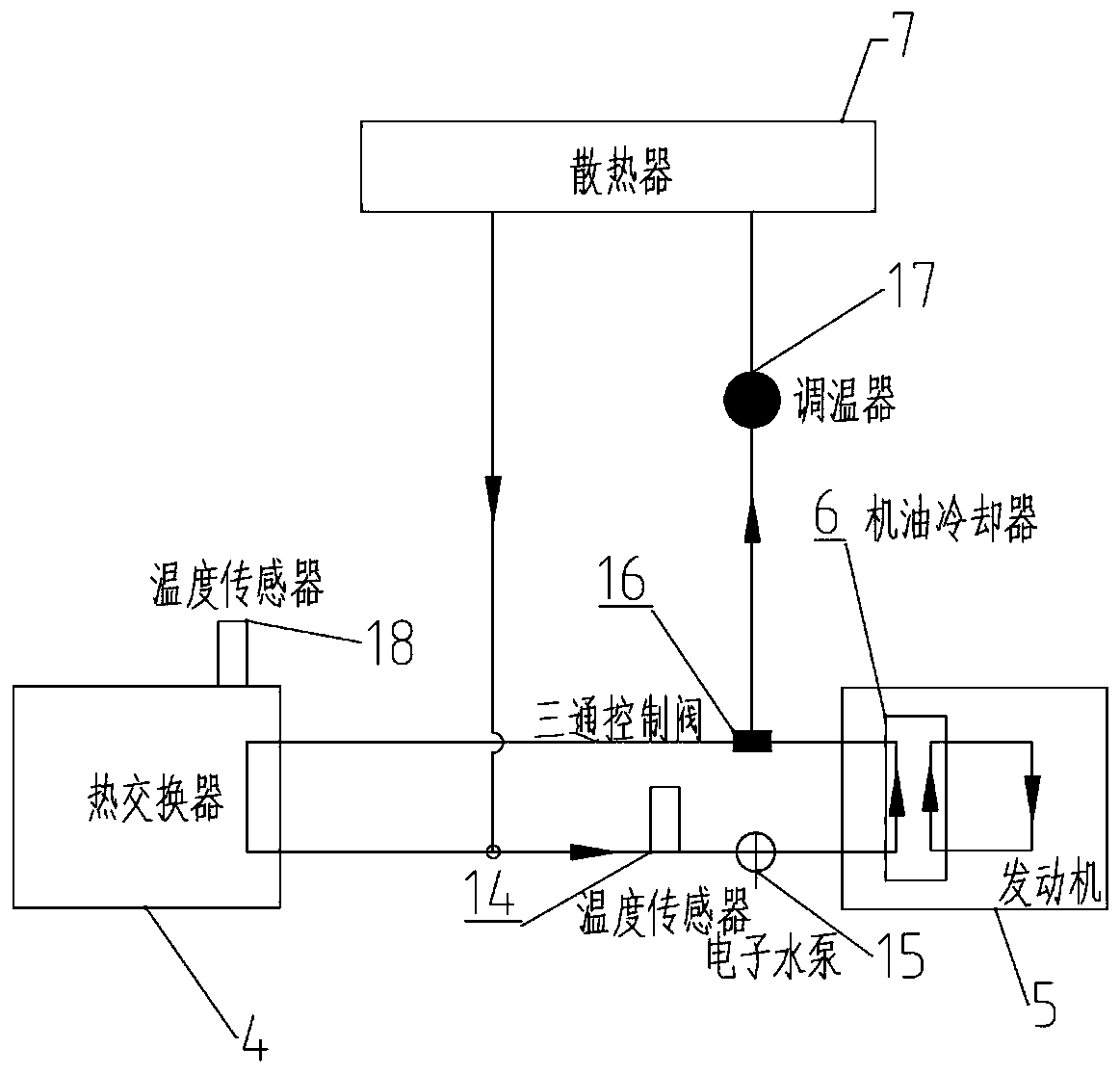

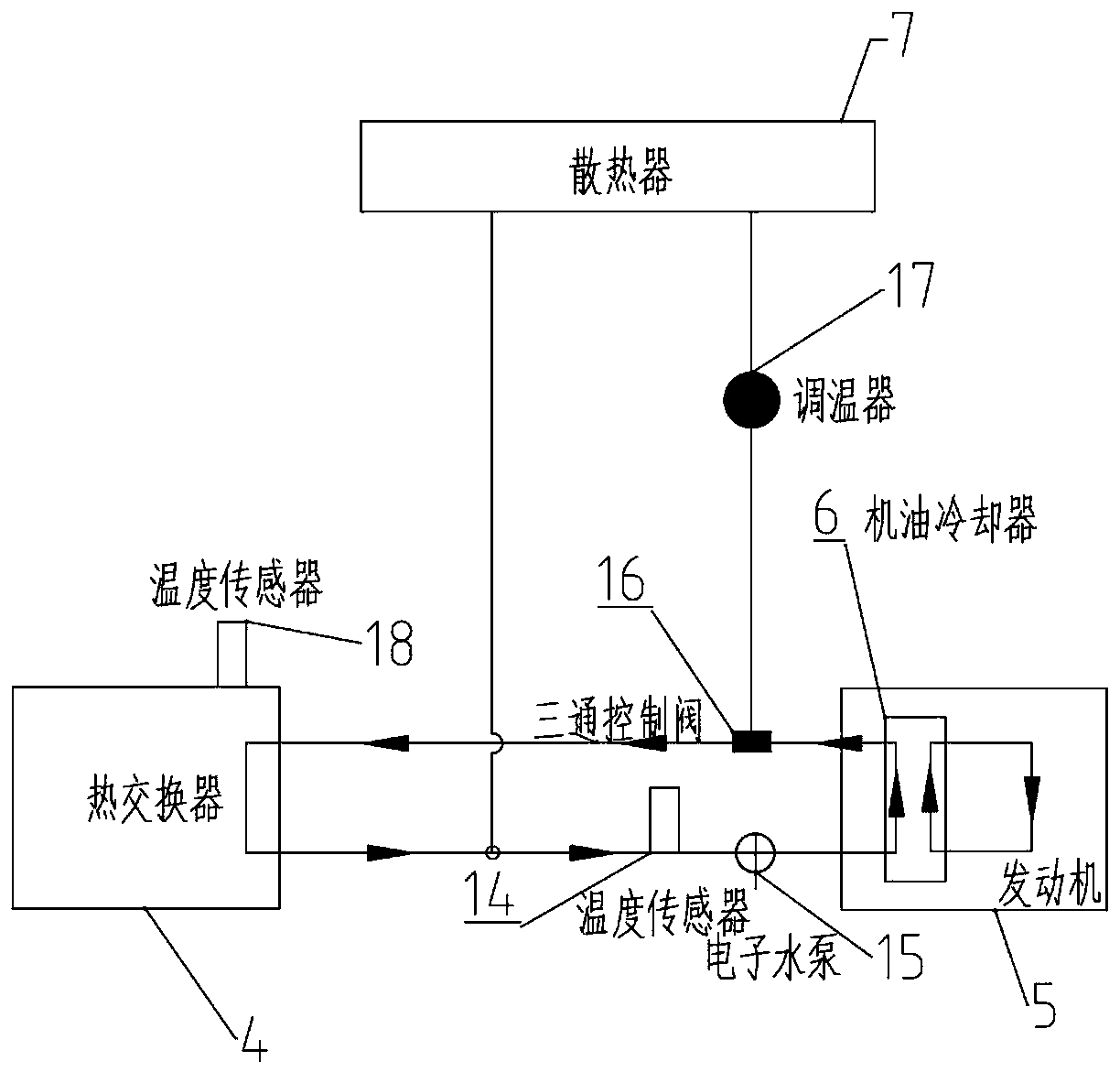

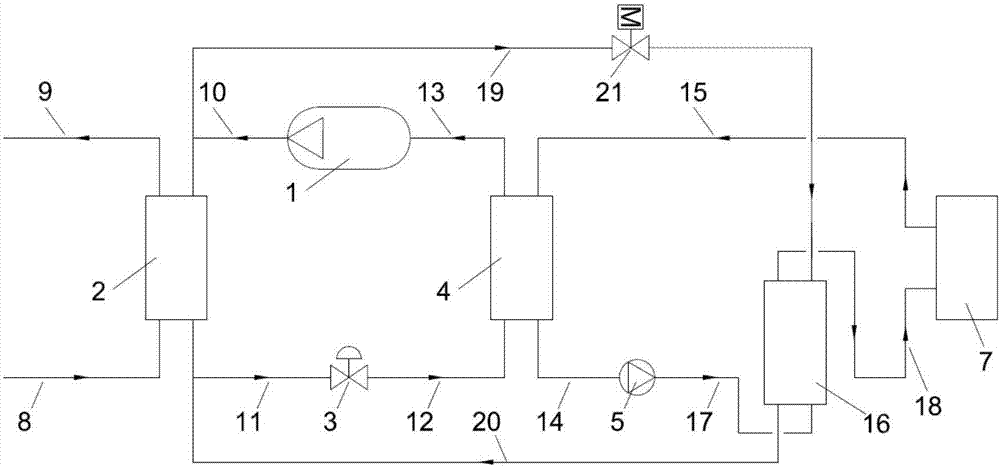

Plug-in hybrid electric vehicle heat management system

ActiveCN109795313AIncrease temperatureTemperature balanceVehicular energy storageBattery/fuel cell control arrangementOperating temperatureAutomotive engineering

The invention provides a plug-in hybrid electric vehicle heat management system. Relative independent systems in a plug-in hybrid electric vehicle such as an engine cooling system, a motor cooling system, a battery cooling system, a battery controller cooling system are integrated into an overall heat management system by an integrated heat exchanger. The integrated heat exchanger serves as a coreheat exchange structure, heat exchange of engine oil, engine cooling liquid, a battery cooling system, a battery controller cooling system and a motor cooling system is implemented by the aid of multiple cooling cycle paths, and optimal operating temperatures of systems are achieved. According to the system, waste heat generated by running of an engine, discharging of a battery and heat dissipation of the motor is sufficiently utilized, energy of the systems in a whole vehicle is reasonably cycled and utilized, so that energy is saved, and the efficiency of the whole vehicle heat management system is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

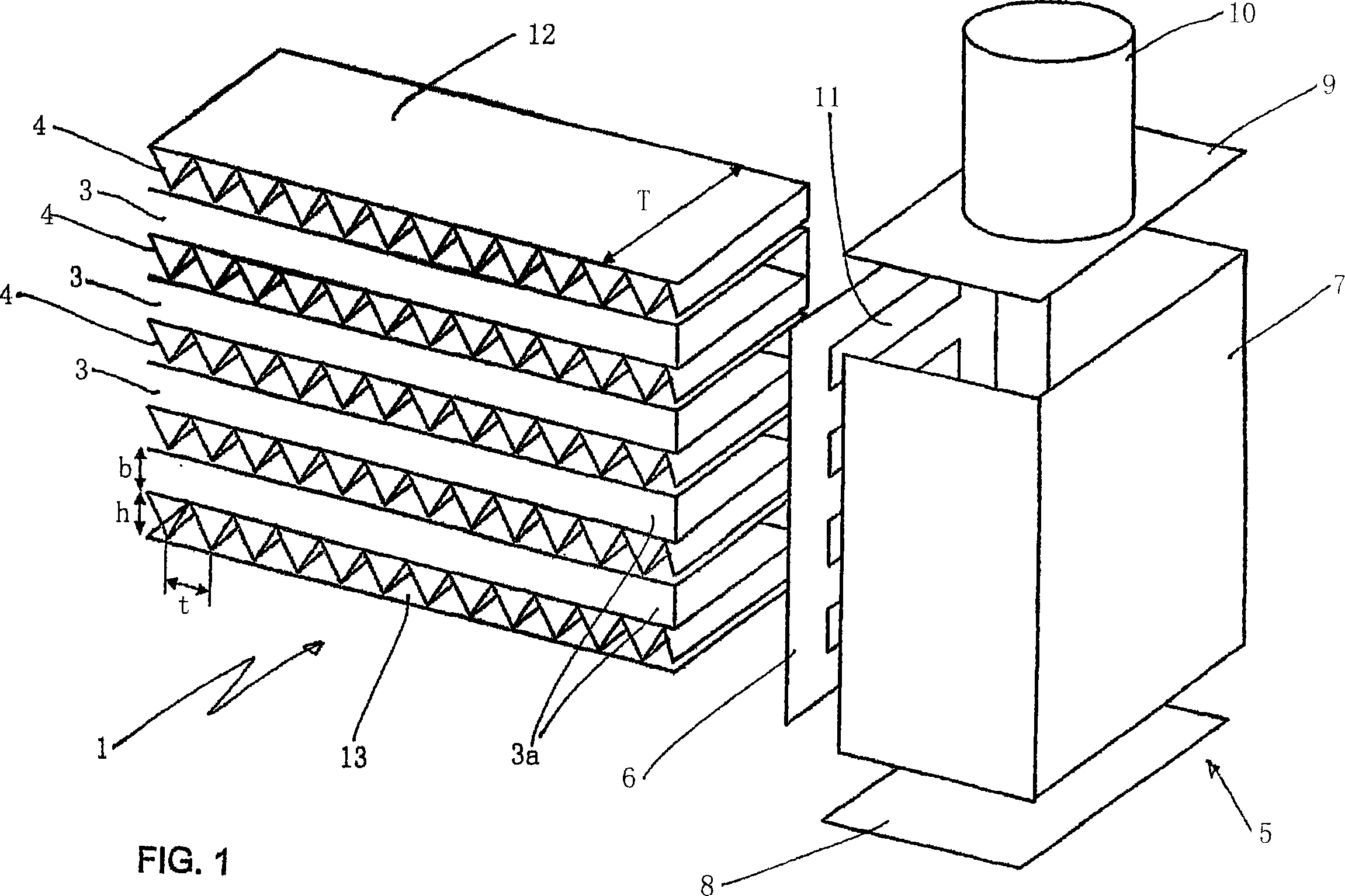

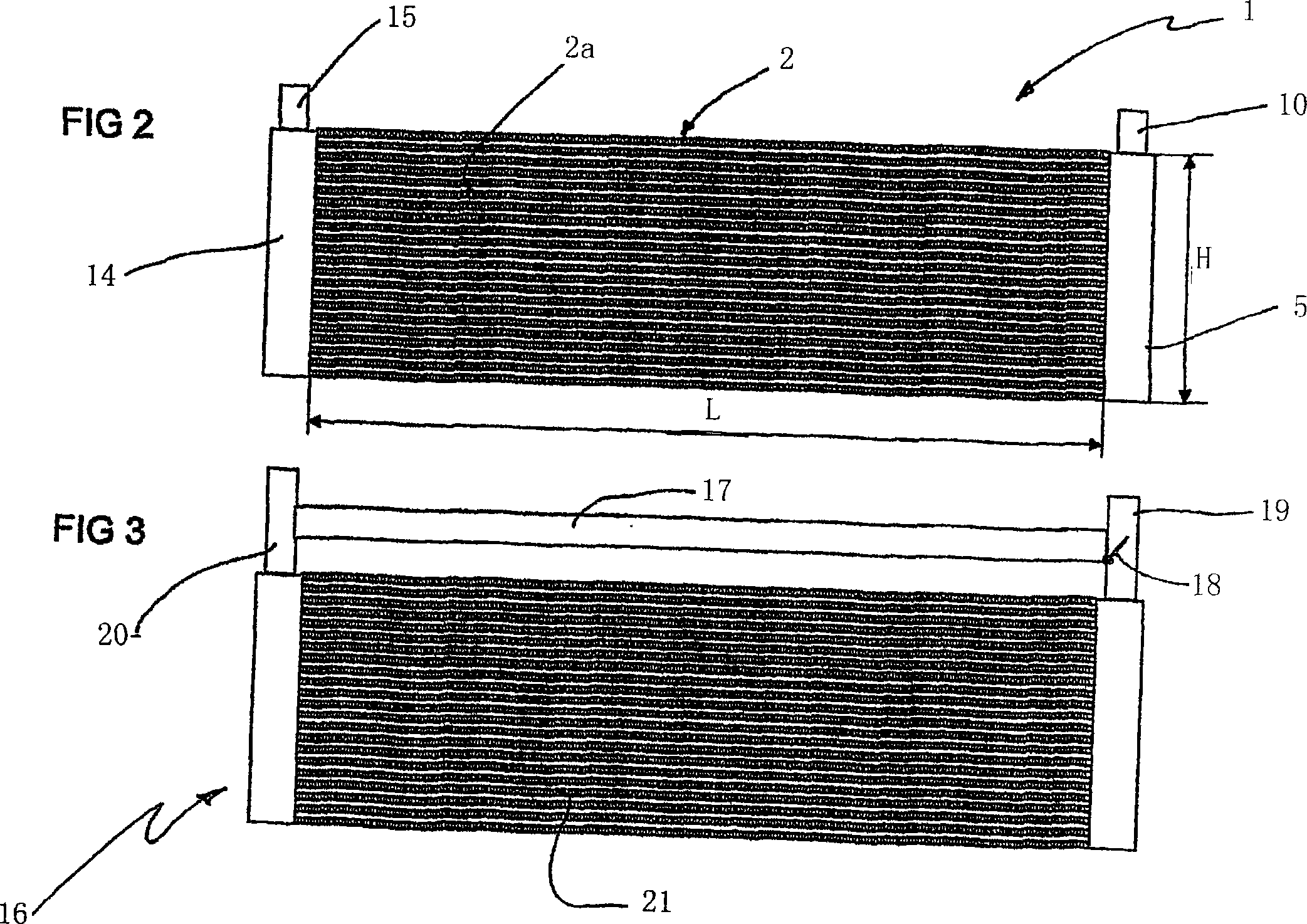

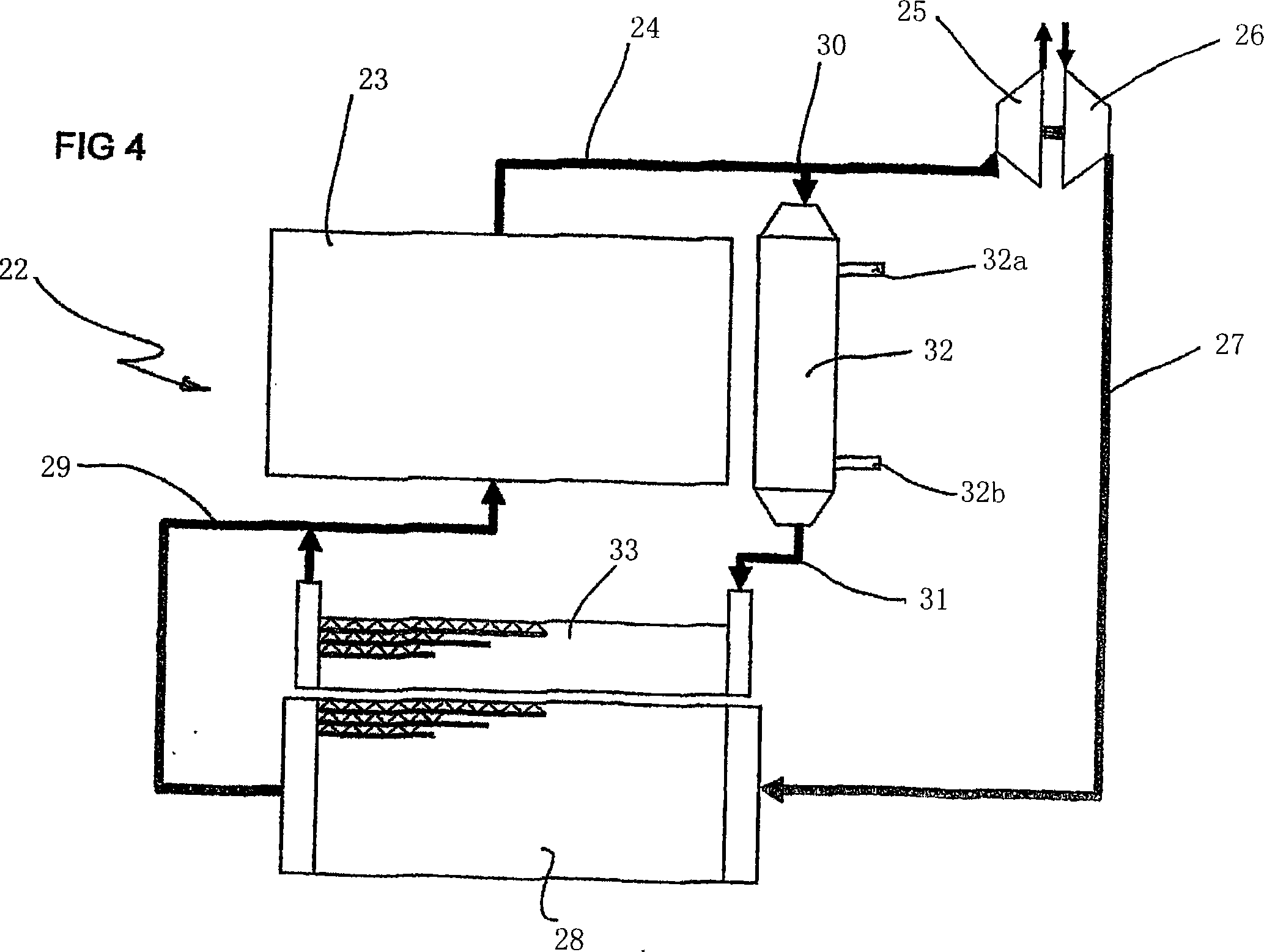

Air-cooled exhaust gas heat exchanger, in particular exhaust gas cooler for motor vehicles

InactiveCN101072976AIncrease powerCompact structureInternal combustion piston enginesStationary conduit assembliesViewpointsImaging processing

To provide an image processing method which easily constructs an indoor space model of high reality in a virtual space and provides a person, who wants to buy a house, with more realistic VR pictures, and also provide a program therefor. Actual pictures of an indoor space photographed with a plurality of photographing devices are obtained, and the obtained actual pictures are compared with virtual pictures obtained by viewing the virtual model of the same indoor model from virtual viewpoints to compute a correlation between the actual pictures and the virtual model. Then, the surface area of the virtual model for mapping the textures of the actual pictures is designated, and the partial areas of the actual pictures after conversion of their forms are mapped to the surface area. Then, the VR images obtained by viewing the virtual model after the texture mapping from arbitrary viewpoints are generated and displayed on a display device.

Owner:BEHR GMBH & CO KG

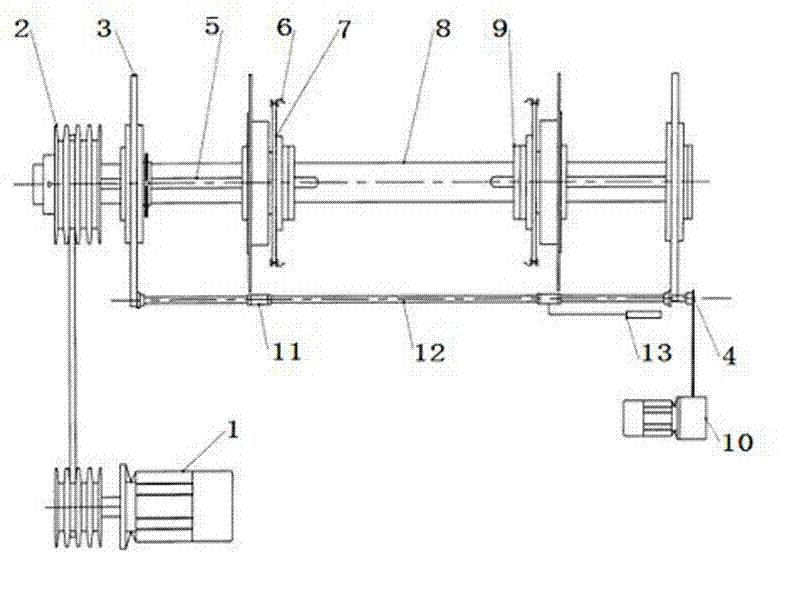

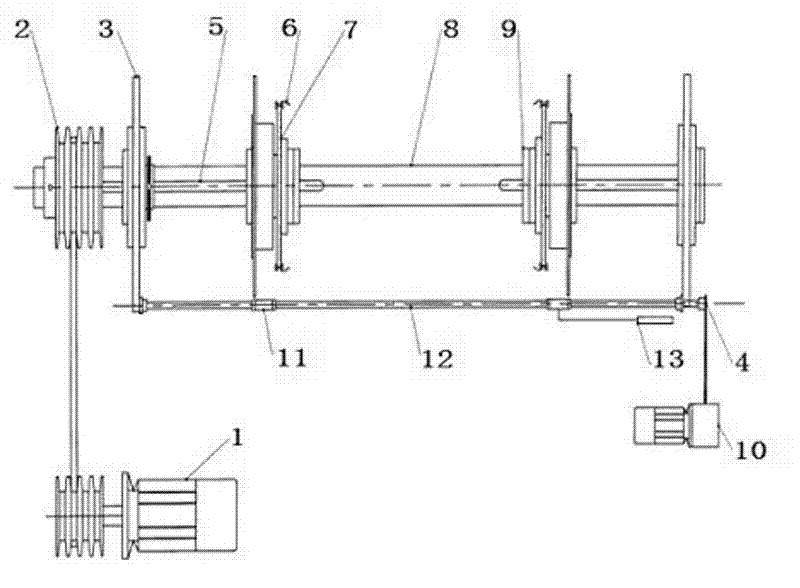

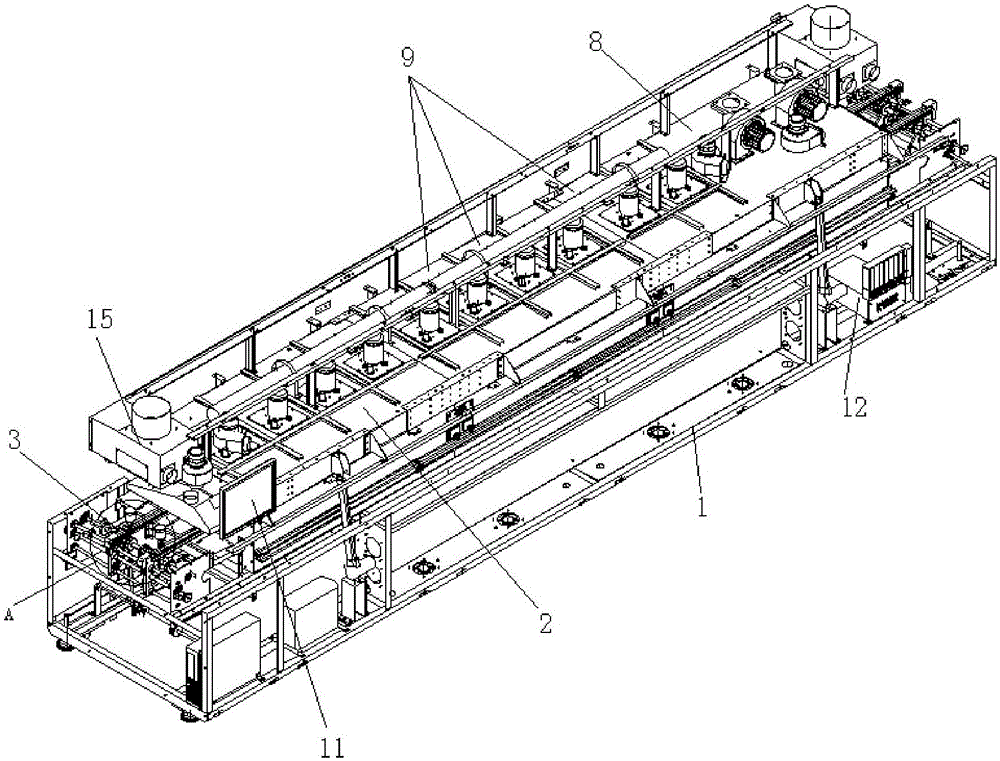

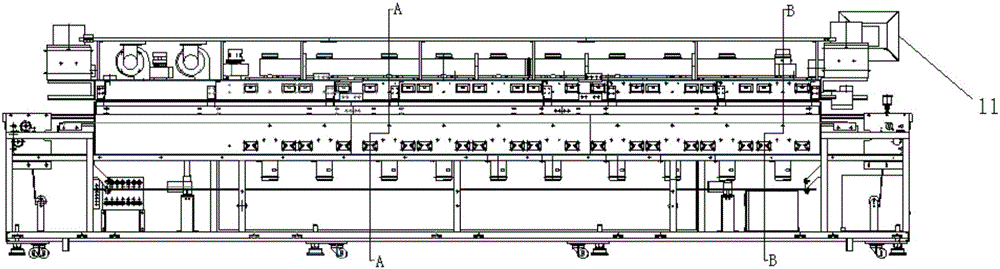

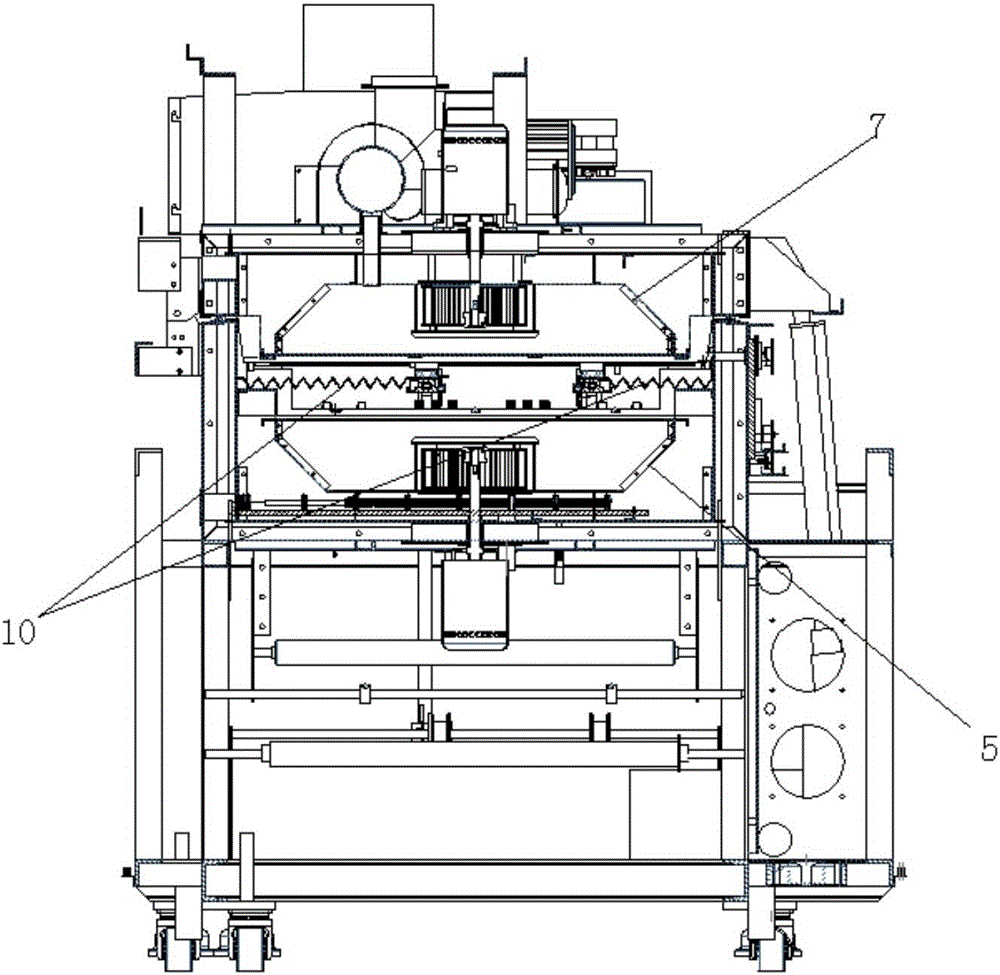

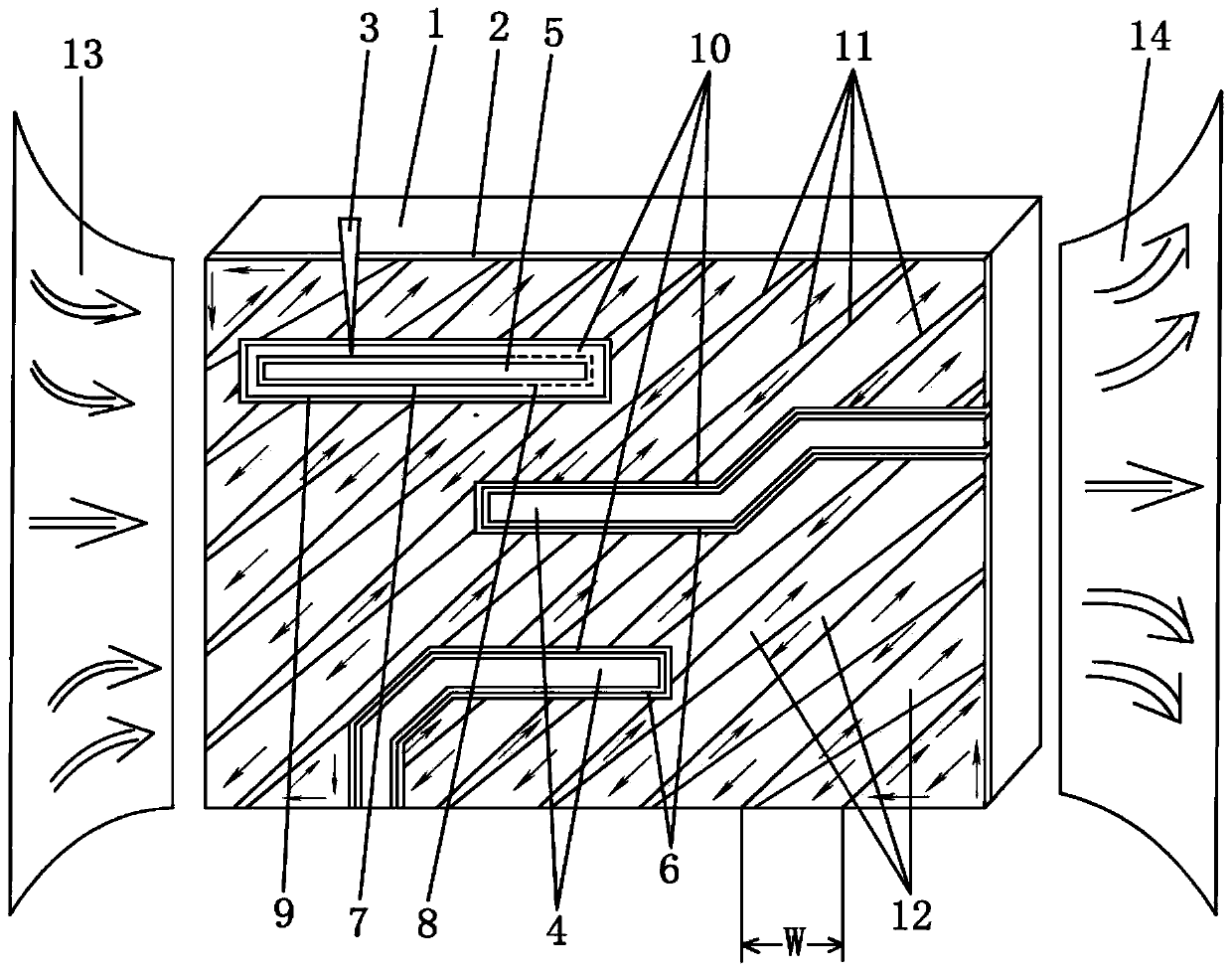

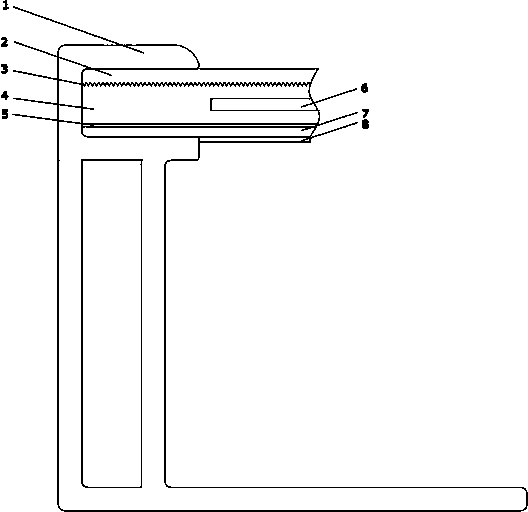

Bidirectional drawing machine for polymide films

The invention provides a bidirectional drawing machine for polymide films; the bidirectional drawing machine comprises a needle plate type chain mechanism, a drawing machine box body, a vertical chain and transmission mechanism, an automatic expanding mechanism, an automatic closed loop heating system and an inner circulating air bellows, wherein the vertical chain and transmission mechanism comprises a main driving motor, a belt pulley, a main shaft, a guide key and a chain wheel; the automatic expanding mechanism comprises a speed reducing motor, a small chain wheel, a breadth adjusting screw rod, a nut and a sliding seat; the electric heating system comprises an embedded type electric heater, a temperature sensor, a temperature controller and an upper computer; by adopting the bidirectional drawing machine, the films are uniformly stressed during stretching and have consistent thickness and high quality, the space of a heating area is reduced, the heating power is minimized, the electric energy is saved, and the exhaust emission is reduced; and therefore, the bidirectional drawing machine is more environmental-friendly.

Owner:万达集团股份有限公司

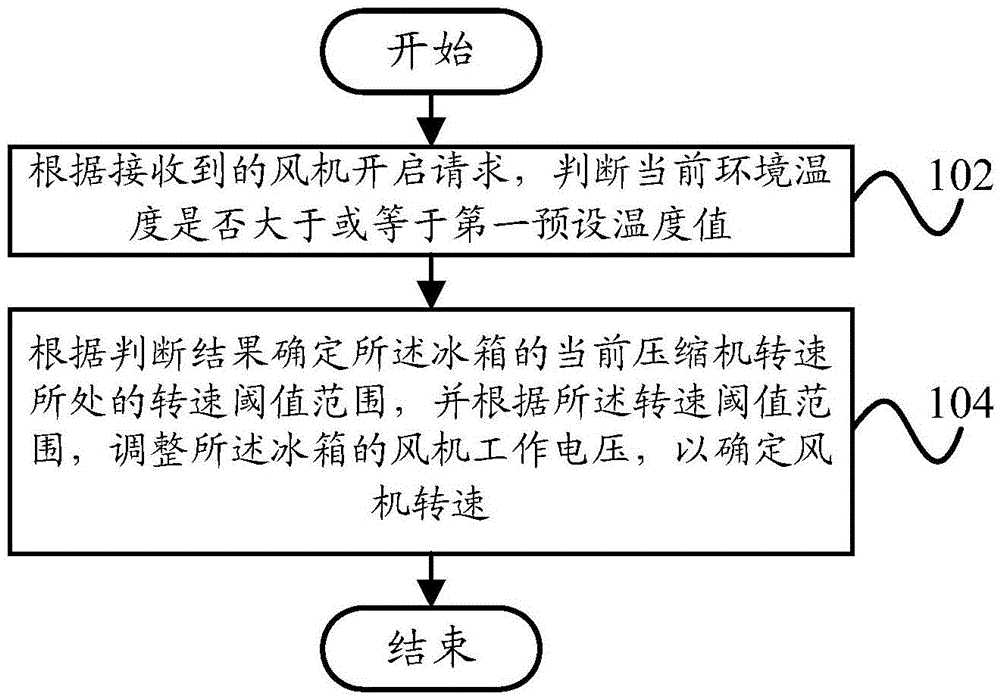

Control method, control system and refrigerator

InactiveCN104833171AControl speedAdjust the temperature in timeLighting and heating apparatusCooling fluid circulationControl systemStop time

The invention provides a control method, a control system and a refrigerator. The control method is used for controlling the rotation speed of a draught fan of the refrigerator, and includes the steps that according to a received draught fan start request, whether current environment temperature is larger than or equal to a first preset temperature value is judged; a rotation speed threshold range of current compressor rotation speed of the refrigerator is determined according to a judgment result, and draught fan work voltage of the refrigerator is adjusted according to the rotation speed threshold range so as to determine the rotation speed of the draught fan. By means of the technical scheme, the rotation speed of the draught fan can be reasonably adjusted through cooperation of the environment temperature, the compressor rotation speed and refrigeration requirements of chambers in the refrigerator, so that start and stop time of a compressor is optimized and overall energy consumption of a refrigerator system is reduced while the cooling speed is guaranteed.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Through hole reflow soldering device and control method thereof

InactiveCN105772886AReduce energy consumptionEnergy savingPrinted circuitsMetal working apparatusReflow solderingEngineering

The invention discloses a through hole reflow soldering device. The through hole reflow soldering device comprises a reflow soldering machine platform. A soldering machine platform cover which can be opened and closed is arranged at the back edge of the upper plane of the reflow soldering machine platform. The upper plane of the reflow soldering machine platform is provided with a product conveying line adjustable in width. The reflow soldering machine platform is internally provided with first lower furnace pipes and second lower furnace pipes from left to right in sequence. A first warm area upper furnace pipe used for air draft is arranged in the position, corresponding to each first lower furnace pipe, of the interior of the soldering machine platform cover. A second warm area upper furnace pipe blowing cold air downwards is arranged in the position, corresponding to each second lower furnace pipe, of the interior of the soldering machine platform cover. Each first warm area upper furnace pipe and the corresponding first lower furnace pipe form a first warm area. Each second warm area upper furnace pipe and the corresponding second lower furnace pipe form a second warm area. Air blocking curtains which are used for separating the cold air from hot air and can be stretched or shortened are arranged in the positions, located between the first warm areas and the second warm areas, of the product conveying line. The reflow soldering machine platform is provided with a man-machine control interface and further provided with a cooling area. The through hole reflow soldering device is suitable for soldering of through holes of PCBs, the soldering temperature is convenient to control, and the soldering effect is better.

Owner:东莞市创威自动化科技有限公司

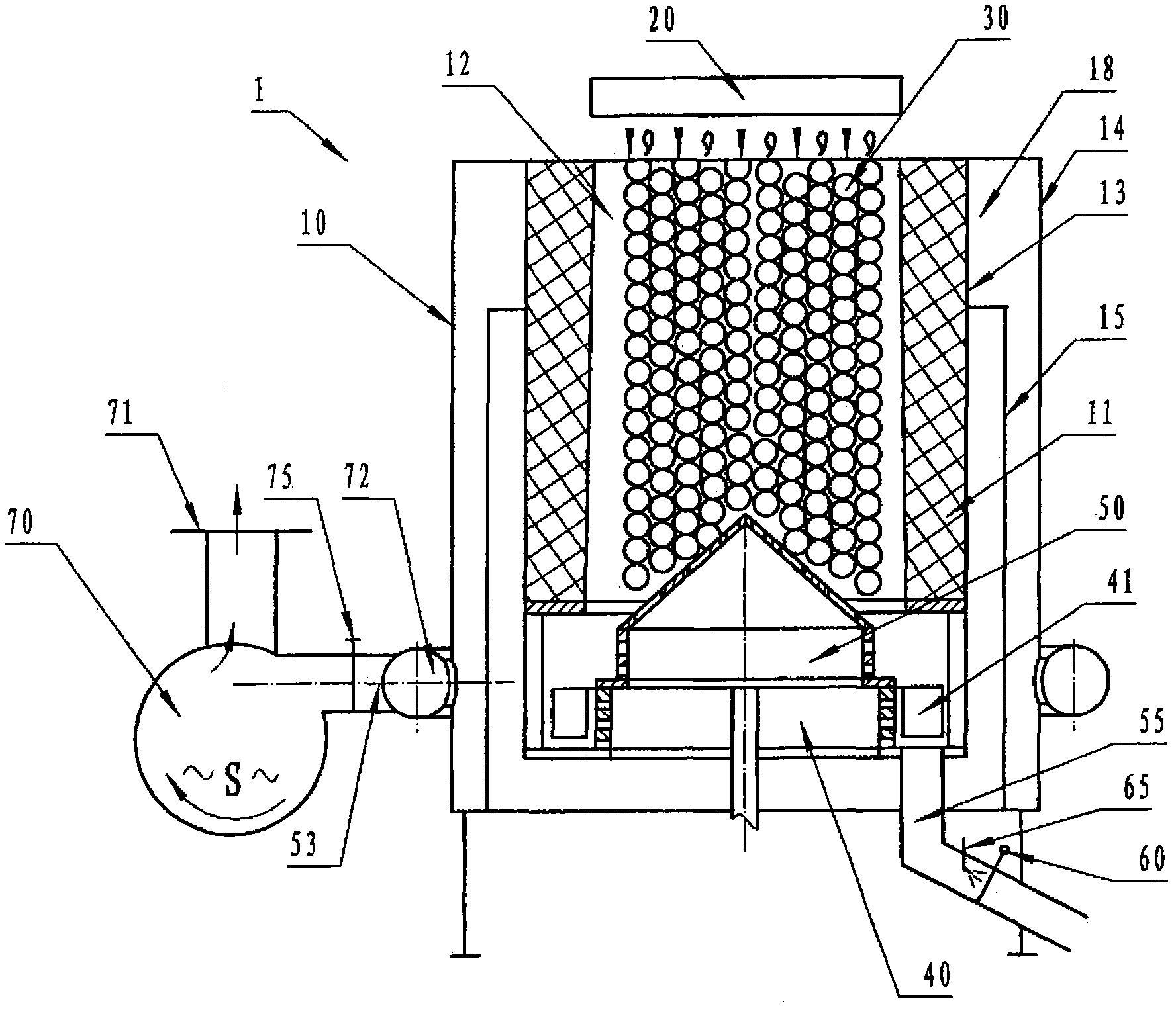

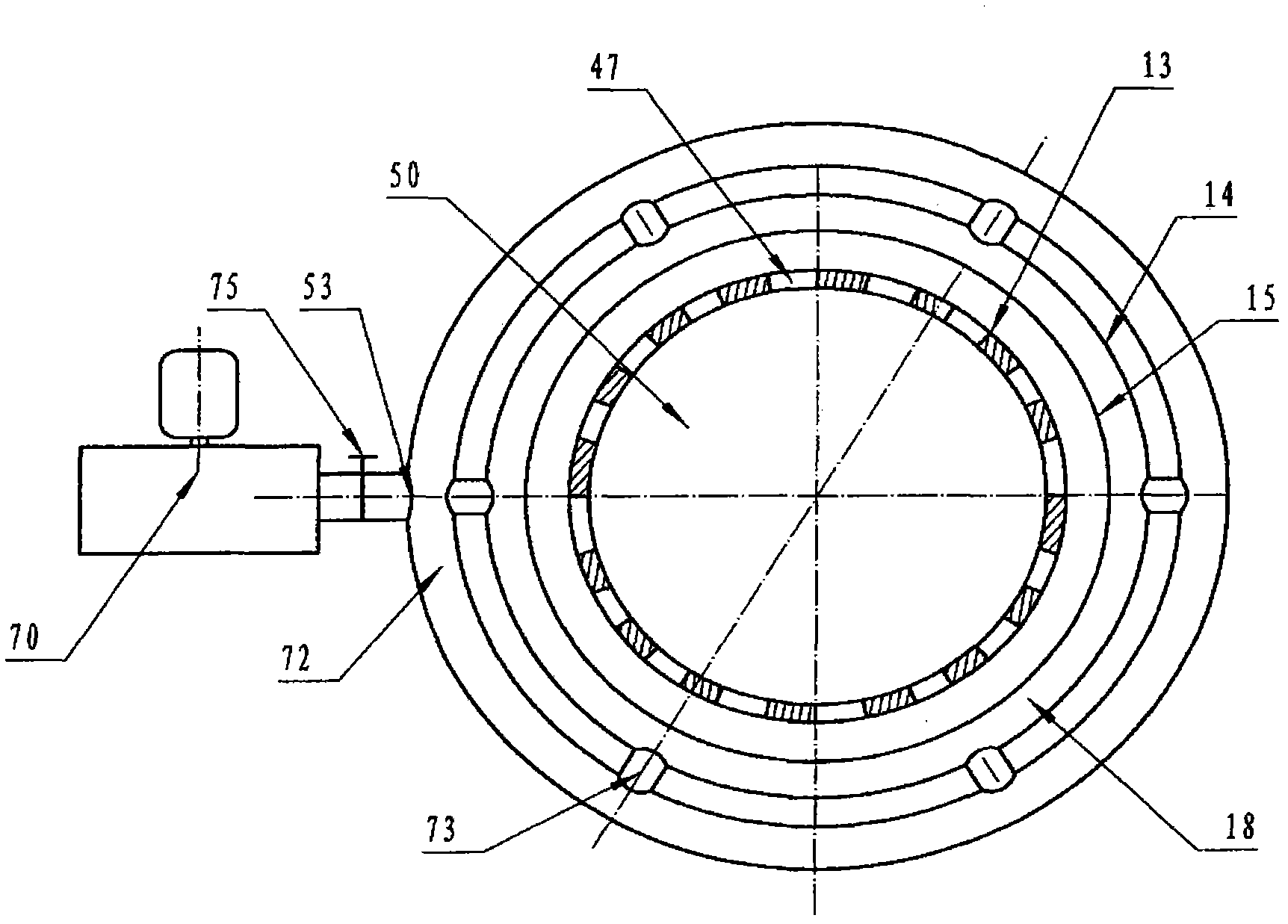

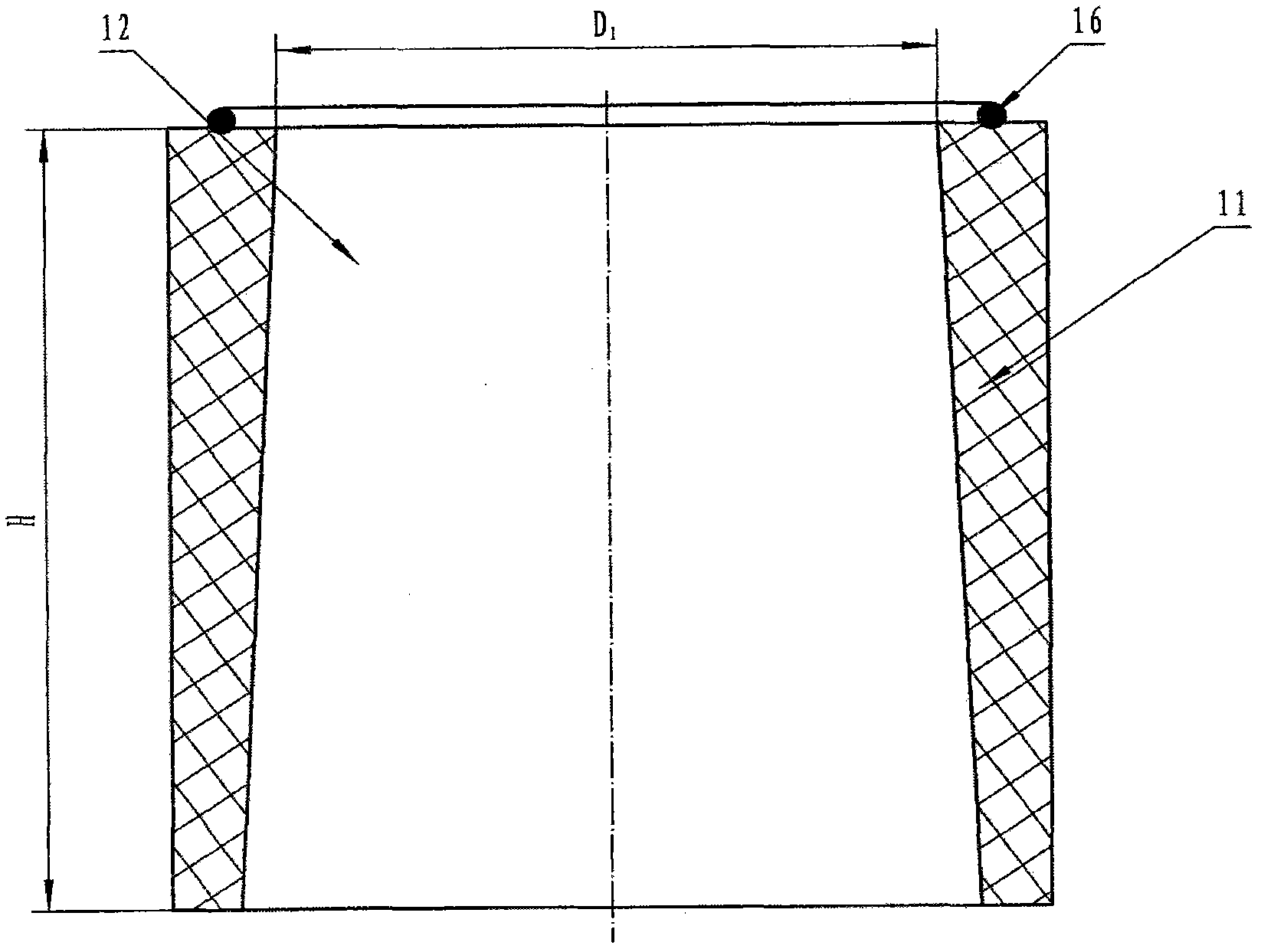

Fly ash product sintering furnace and method and formula thereof

The invention discloses a fly ash product sintering furnace, which comprises a furnace body, a tower grate type discharge ventilation device, a diversion ring, an annular air pipe and an air induction apparatus, wherein the furnace body is provided with a furnace inner shell and a furnace outer shell; a furnace chamber for containing a material is formed in the furnace inner shell; the upper end of the furnace chamber is an ignition end, and the lower end of the furnace chamber is an air induction end; the tower grate type discharge ventilation device is rotatably arranged at the bottom end of the furnace chamber and supports the material in the furnace chamber; the diversion ring is of cylindrical shape and arranged between the furnace inner shell and the furnace outer shell; the annular air pipe is arranged around the outside of the furnace body and provided with an air induction port and multiple ventilation pipelines connected with the furnace outer shell; the air induction apparatus is connected with the air induction port; the diversion ring and the furnace inner shell form a passage; and the high-temperature air in the furnace chamber flows in the passage along the outer side of the furnace inner shell and is used for secondarily heating the furnace chamber. The invention also discloses a sintering method applicable to the sintering furnace. The invention also provides a formula of the fly ash ceramsites applicable to the sintering furnace and the sintering method.

Owner:北京建邦伟业机械制造有限公司

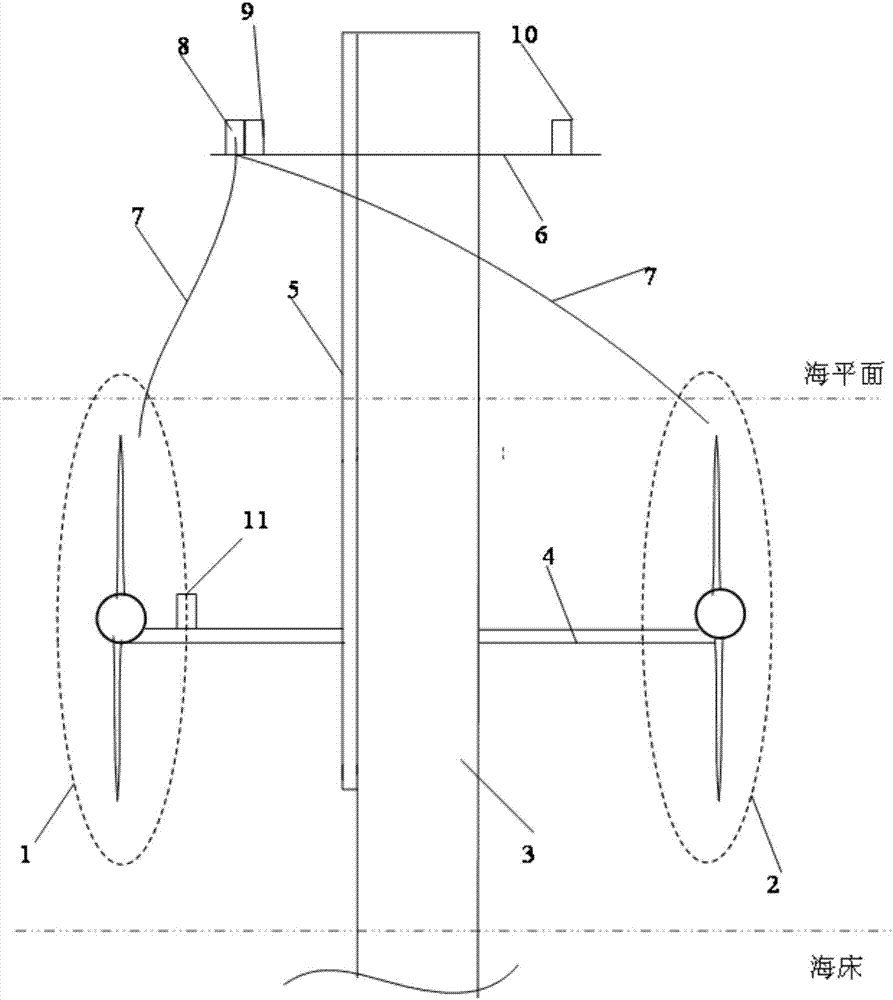

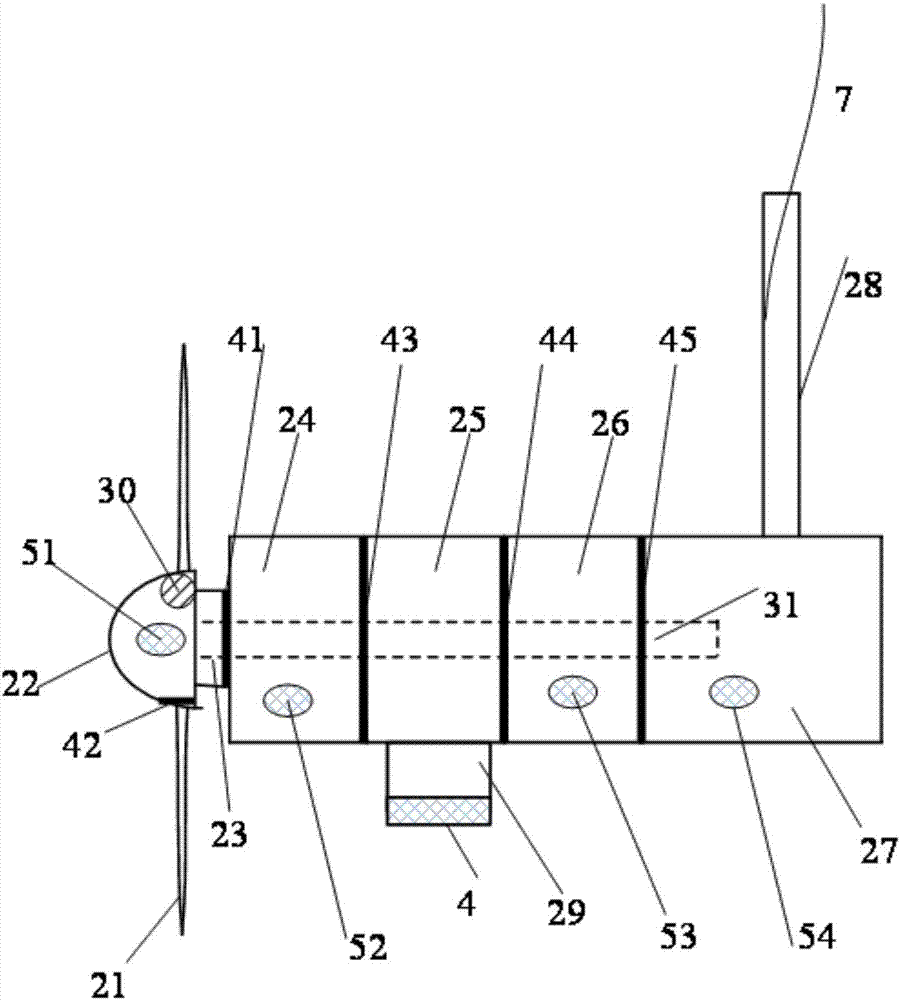

Ocean tidal current power generation system

PendingCN107131093AReduce lossGuaranteed reliabilityHydro energy generationEngine controlPropellerElectric energy

The invention discloses an ocean tidal current power generation system. The system comprises a supporting mechanism, an ocean tidal current power generator set and a signal monitoring mechanism. The supporting mechanism comprises a foundation pile, a horizontal supporting rod and an operating platform. The ocean tidal current power generator set comprises underwater components and an overwater component; each underwater component comprises blades, a hub, a spindle, a gearbox, a coupler, a power generator, a stern compartment and a yawing mechanism, wherein a variable propeller mechanism is arranged in the hub, and the yawing mechanism is arranged between the coupler and the horizontal supporting rod; the overwater component comprises a converter and a control cabinet, and the converter and the control cabinet are both arranged on the operating platform. The signal monitoring mechanism comprises a current meter connected with the control cabinet, and the current meter is arranged on the horizontal supporting rod and used for monitoring the ocean current direction in real time. The ocean tidal current power generation system has advantages that by adoption of the fixed ocean tidal current power generation system and the half-direct-driven wind power generator set, efficient conversion of ocean current energy into electric energy can be realized safely and reliably.

Owner:GUODIAN UNITED POWER TECH

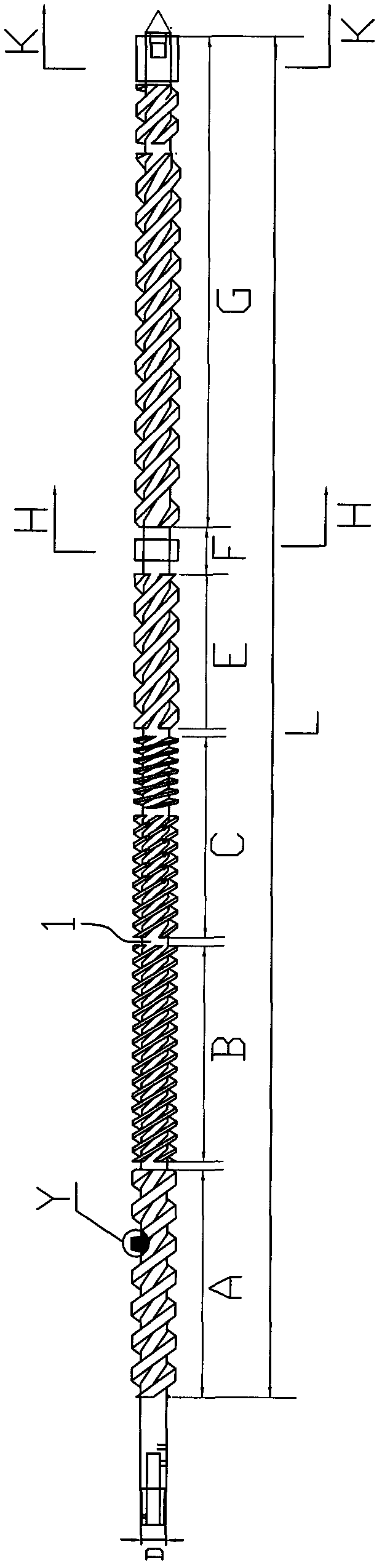

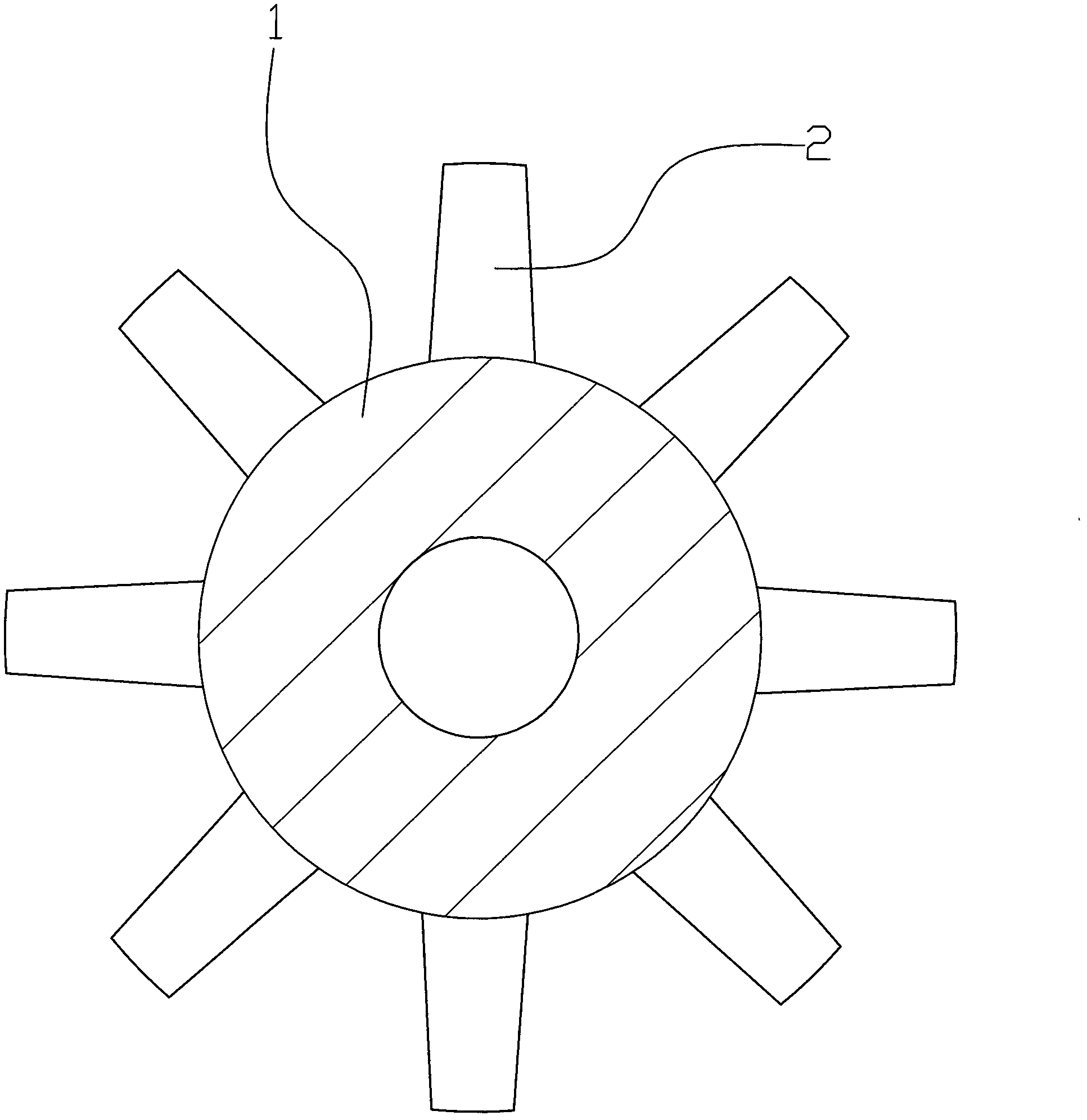

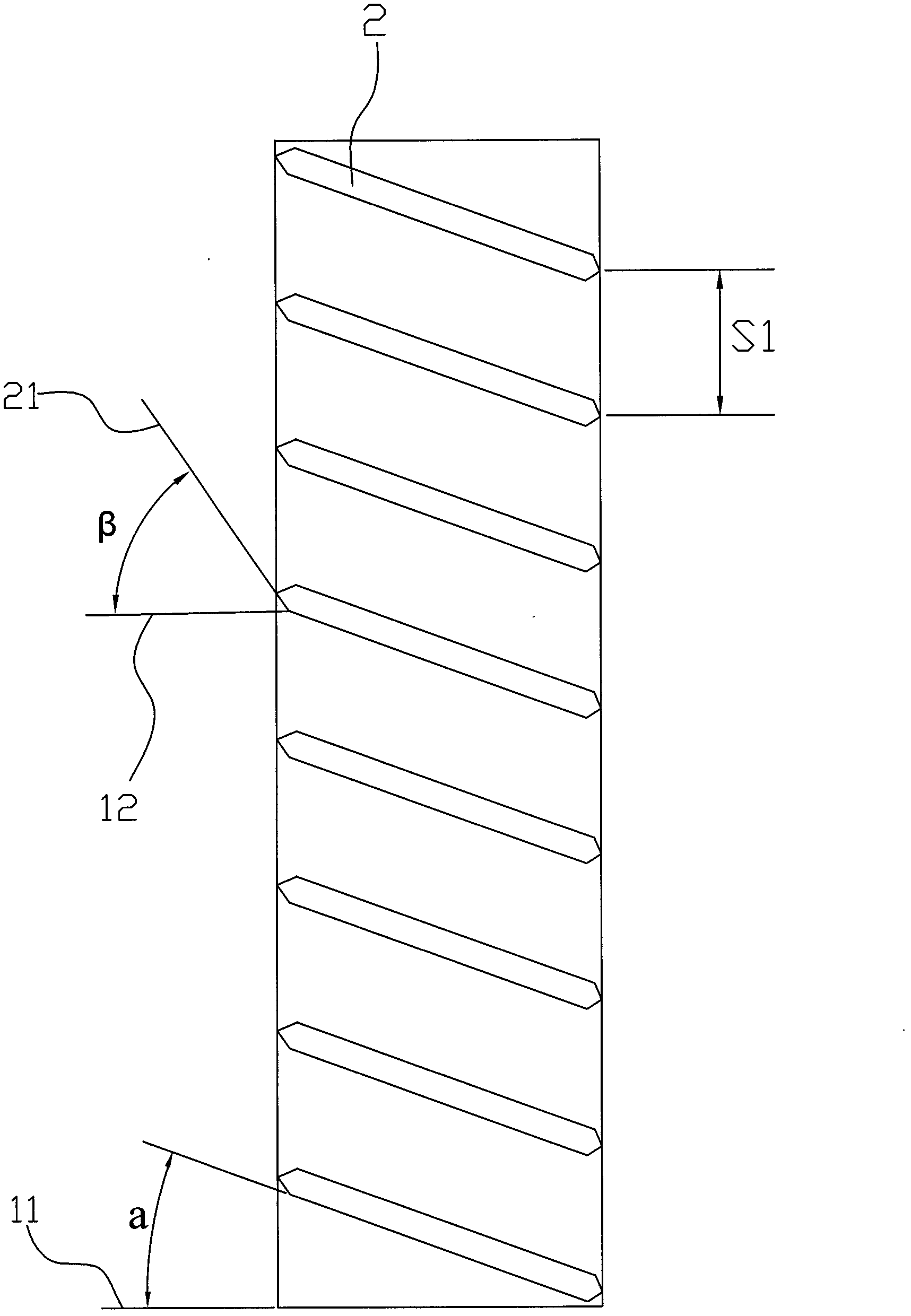

Screws used in twin-screw foaming extruder

The invention discloses screws used in a twin-screw foaming extruder. Each screw comprises a screw body, wherein the screw body is sequentially composed of a feeding segment, a compressing segment, a plasticizing segment, a gas discharging segment, a mixing segment and an extrusion segment; spiral edges are arranged on the feeding segment, the compressing segment, the plasticizing segment, the gas discharging segment and the extrusion segment; and the length-diameter ratio of the screw body is L:D = 29. Each screw is characterized in that multiple inclined spiral edge strips are arranged on the circumference of the mixing segment, the inclined spiral edge strips of two screws are mutually meshed, and the included angle between the extended spiral edge strips and the axial center line of the screw body is 19.5-20.5 degrees. As compared with the prior art, the screws have the advantages that multiple inclined spiral edge strips are arranged on the circumference of the mixing segment of each screw and the inclined spiral edge strips of the two screws are mutually meshed, thus the materials are efficiently and uniformly mixed, the materials can be better mixed with a foaming agent, the produced product is not easy to yellow and uniform in thickness, the production formula cost is reduced and the production efficiency is improved.

Owner:浙江华业塑料机械股份有限公司

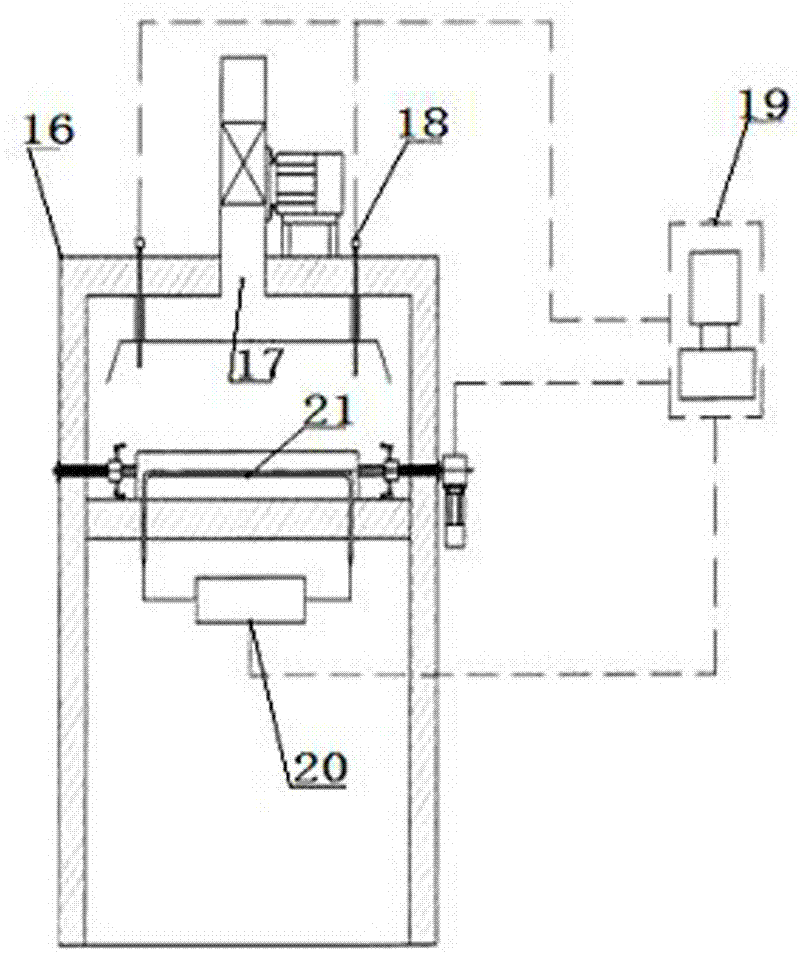

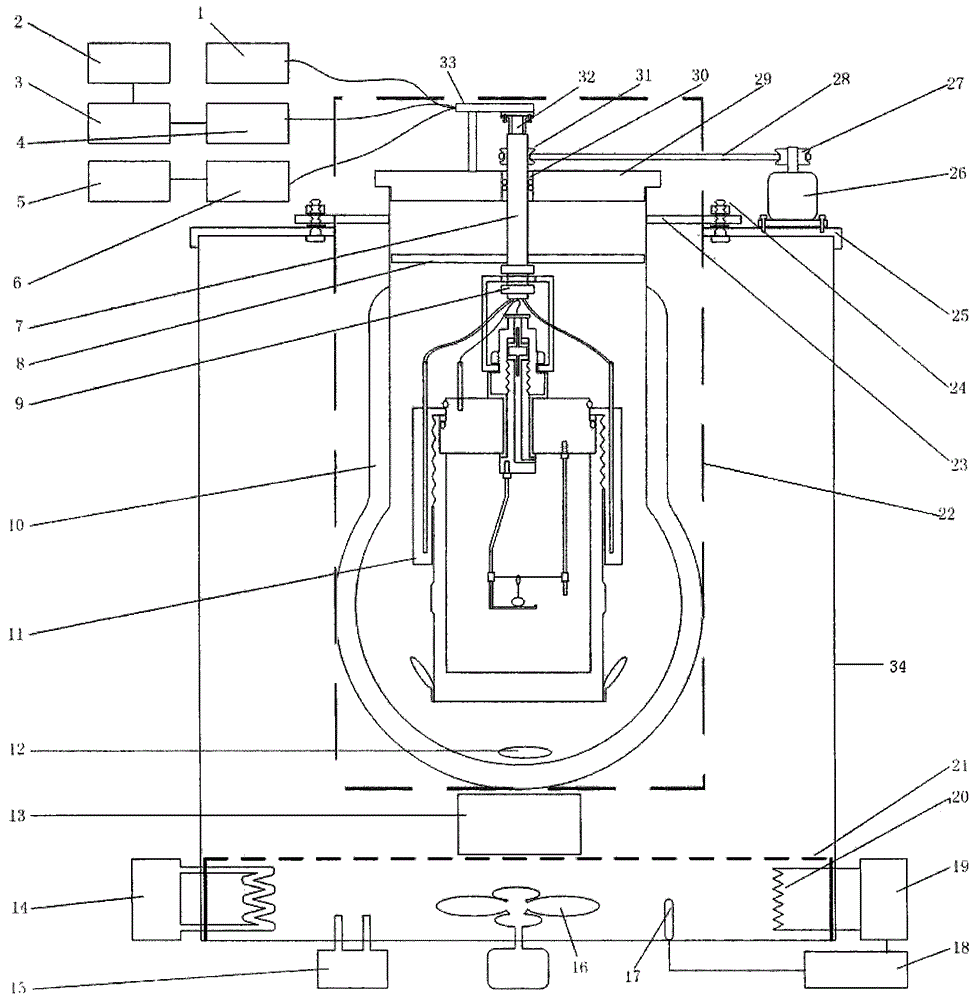

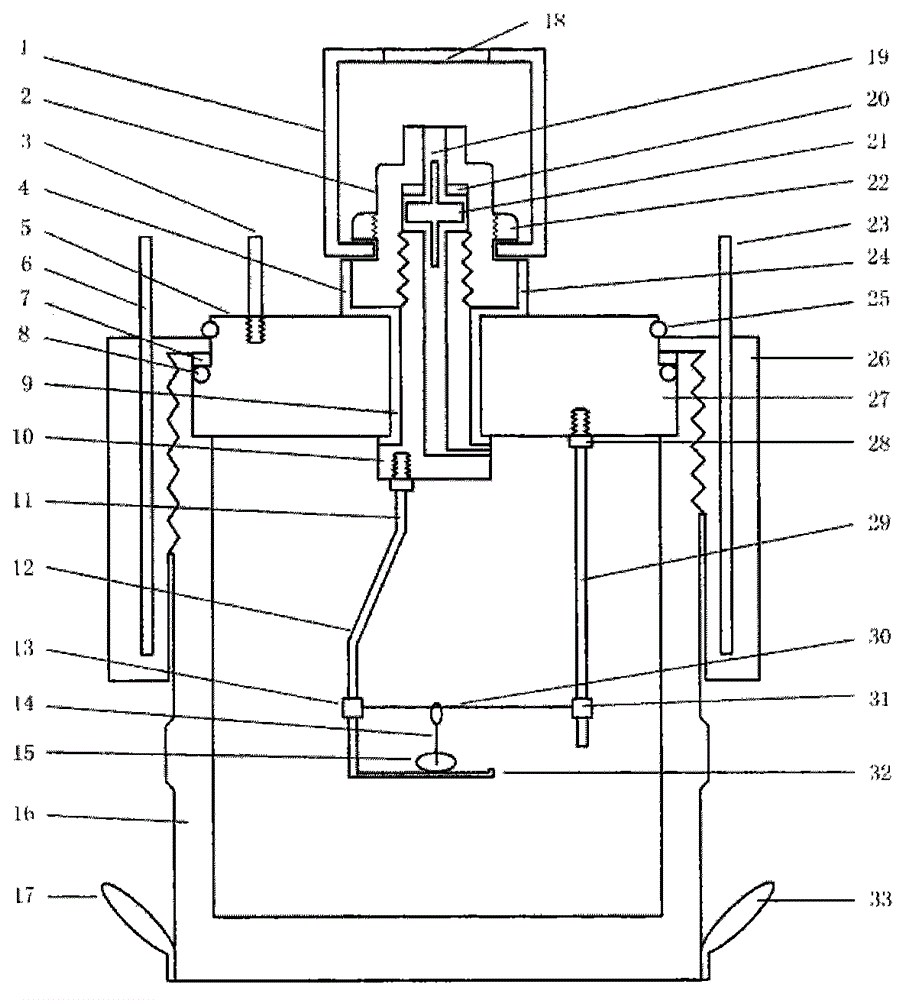

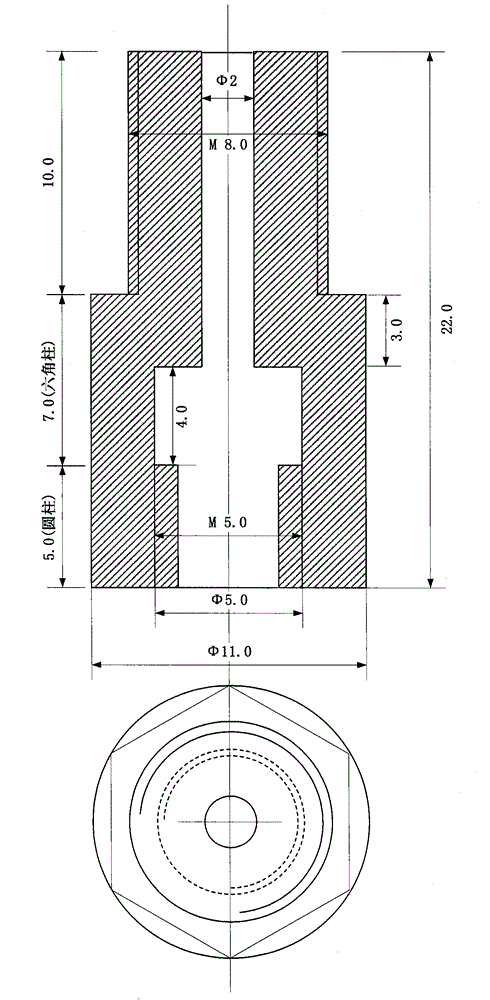

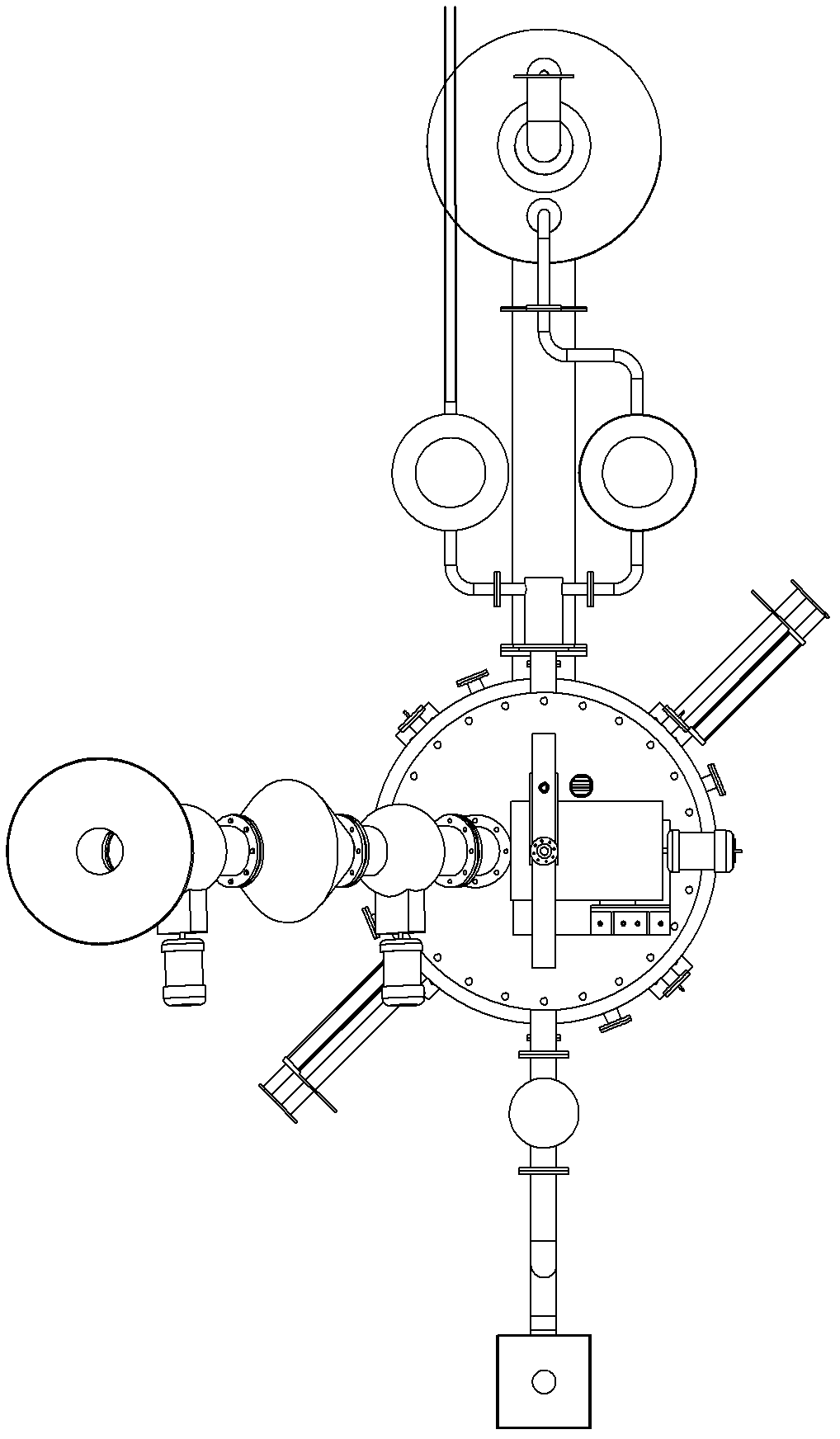

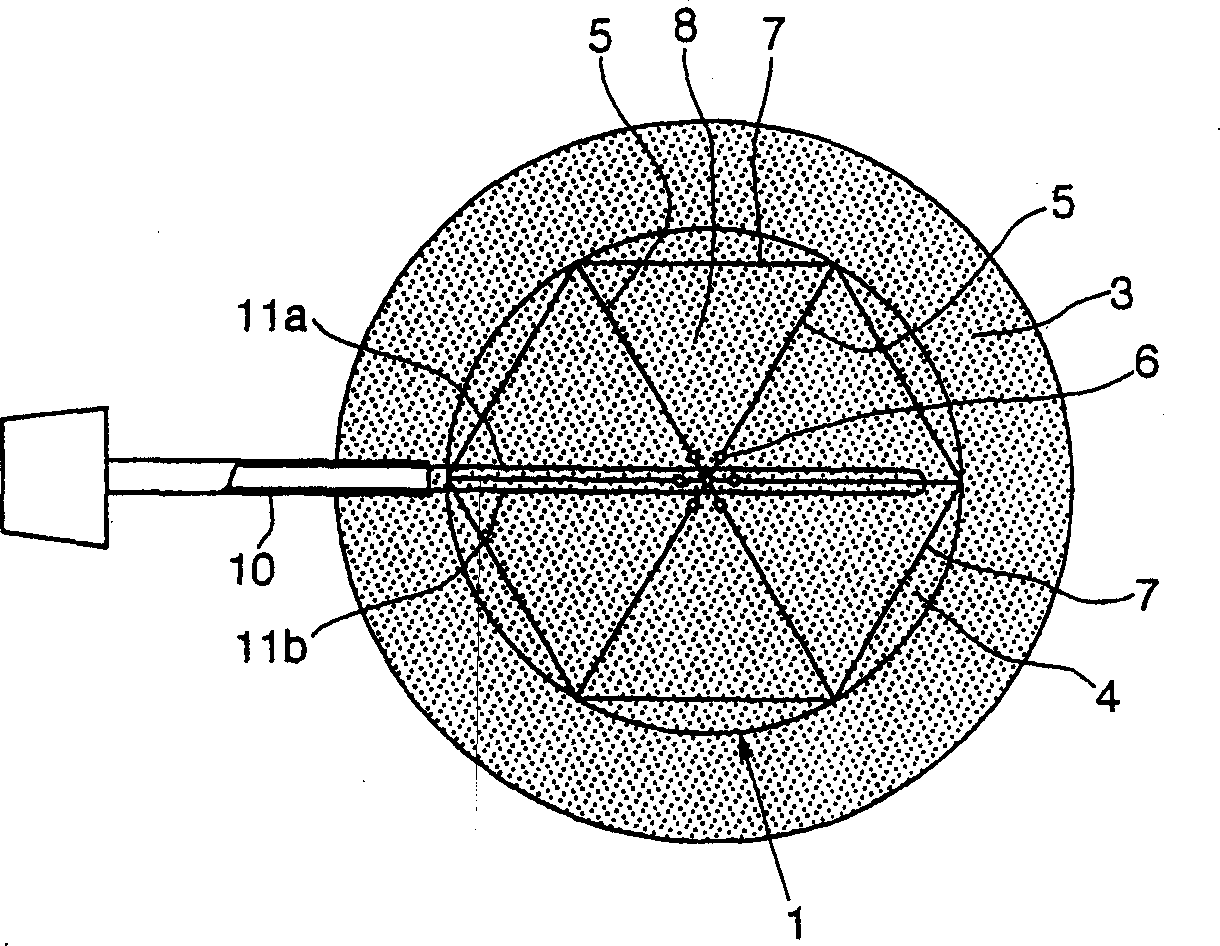

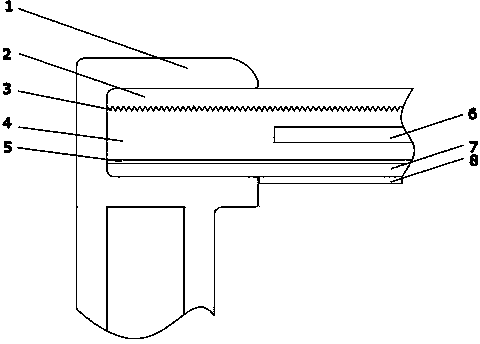

Development of rotating miniature combustion bomb

InactiveCN104155340ASmall volumeOvercoming the need for large sample volumesMaterial heat developmentTwo temperatureEngineering

The invention relates to development and design of a horizontal rotating miniature combustion bomb and a rotation system thereof. The invention consists of two parts, the structure of the combustion bomb and the rotation system. The structure of the combustion bomb has the characteristics of: single head; barrel volume of about 7.30 cm<3>; two temperature measurement thermistors and two thermal resistances on the combustion bomb cover; a mixing blade at the lower part of the bomb body in order to stir a calorimetry agent to flip upwards during rotation and reach quick temperature equilibrium; bomb body made of high temperature high pressure resistant 1Cr18Ni9Ti stainless steel material; platinum or platinum rhodium alloy containing 3-1 / 2% of rhodium on the inner wall of the combustion bomb barrel; and electrode and crucible made of platinum or a platinum rhodium alloy material containing 3-1 / 2 % of rhodium. The rotation system has the characteristics of: rotation of the combustion bomb greater than 360 degrees; three circuits on the combustion bomb (temperature measurement circuit, heating circuit and ignition circuit) connected with the external circuit by using 24 path pure gold contactor collecting ring to ensure smooth circuit; and stepless speed regulation.

Owner:李强国

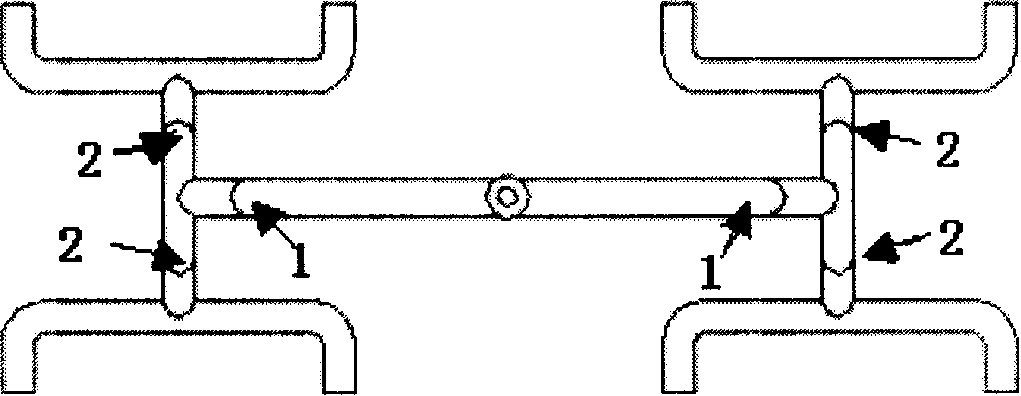

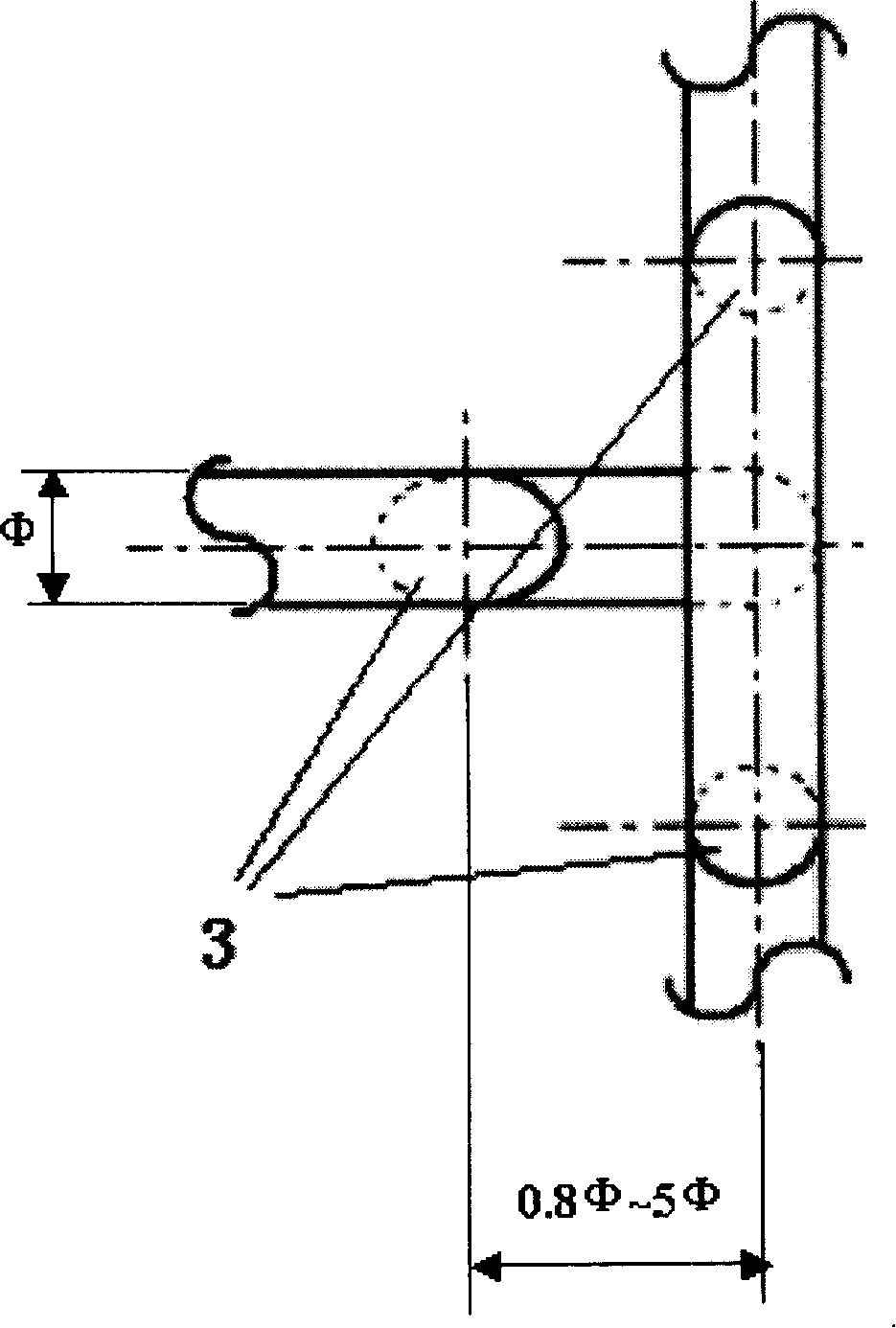

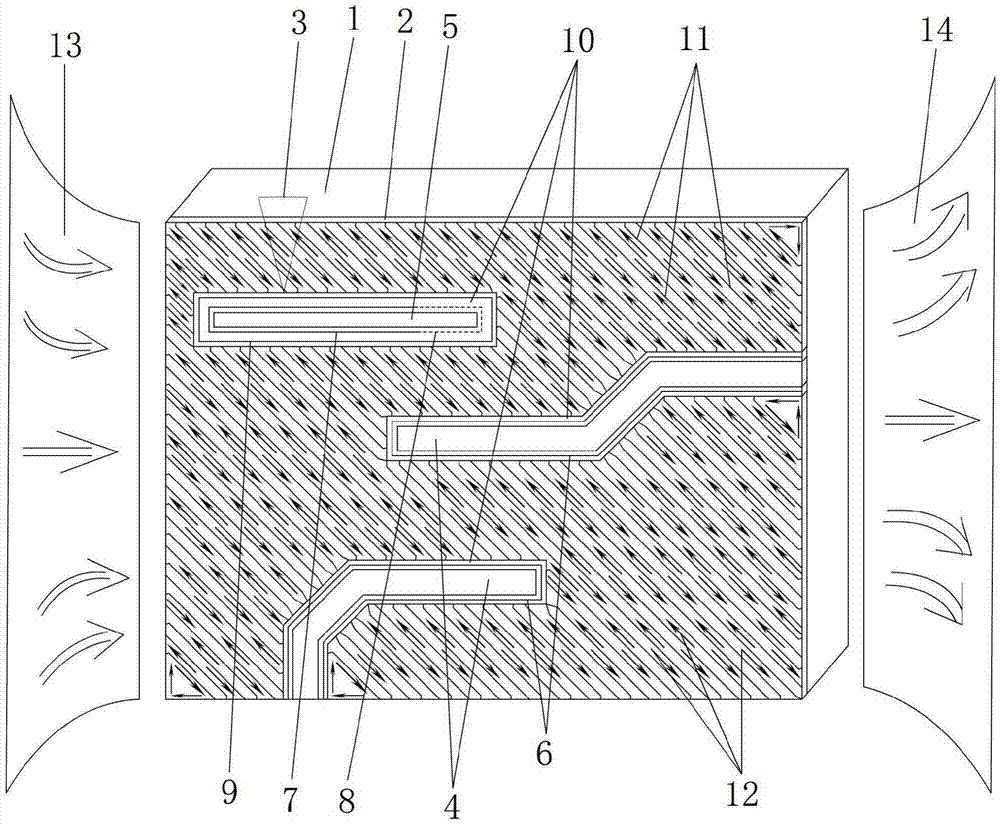

Cold flow passage multi-mould-hole mould flow passage balance structure

The invention provides a die flow passage balance structure with cold flow passage and a plurality of die cavities, comprising a main flow passage, a branch flow passage and a turnover structure. The turnover structure is arranged at the joint between the main flow passage and the branch flow passage. The turnover structure is a round arc structure. Natural arc transition is adopted between the turnover structure and the main flow passage and the branch flow passage. The diameter of the turnover structure is 1-3 times of the diameter of the flow passage where the structure is positioned and the length thereof is 1.5-5 times of the diameter of the flow passage; the translation height of the axis line is 0.5-1.5 times of the diameter of the flow passage. Smelting glue passes through the turnover structure; the layer distribution state of all characteristics of original smelting glue on the flow passage diameter section is disordered and re-mixed; in the turnover structure, the shearing rate, temperature and viscosity of the smelting glue reach uniform state temporality before entering a next flow passage and flow non-balance state can be eliminated after the smelting glue reaches the next flow passage, thus reaching the balanced characteristics such as consistent pressure, temperature and viscosity of all die cavities, etc. and leading the quality of all die cavity products to tend to consistency.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

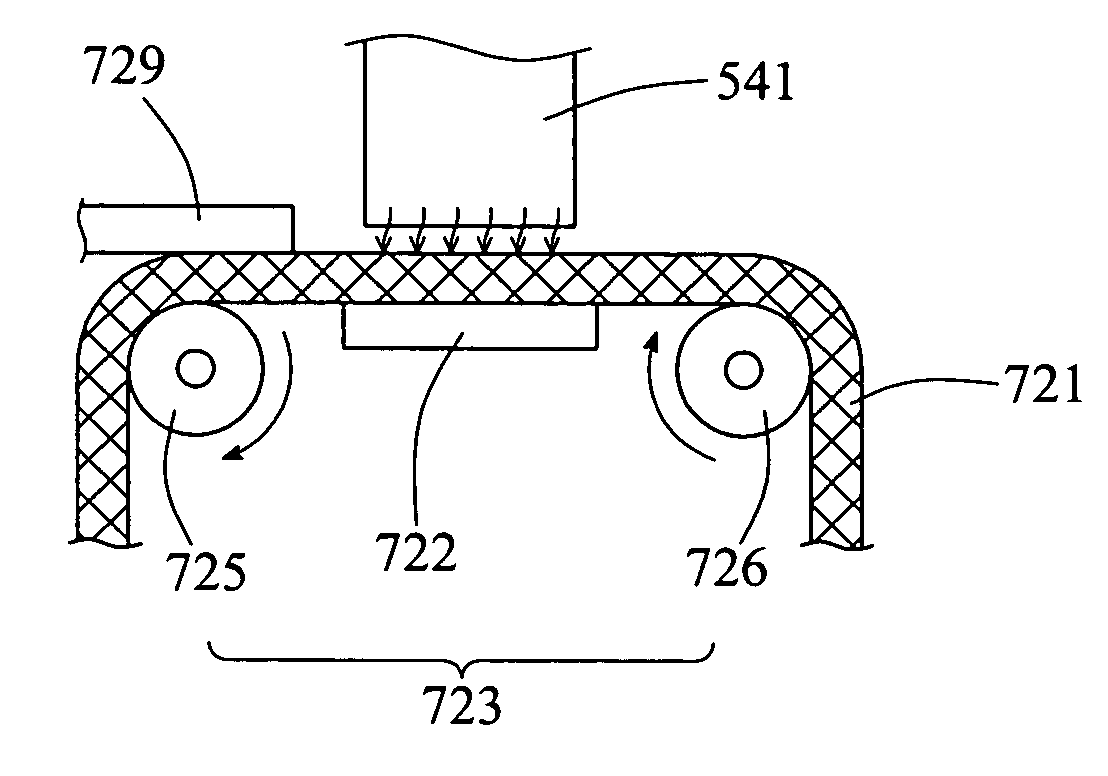

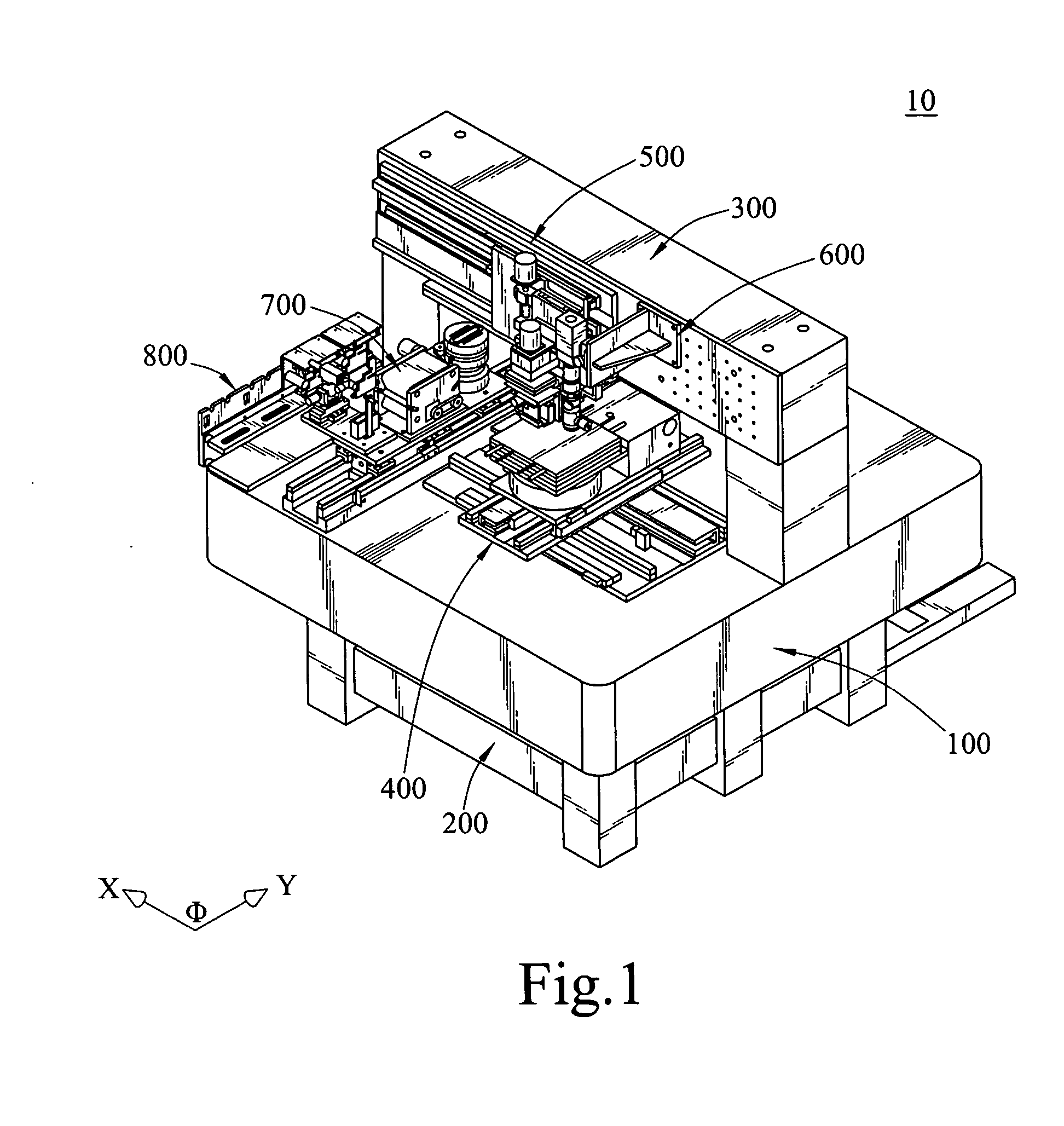

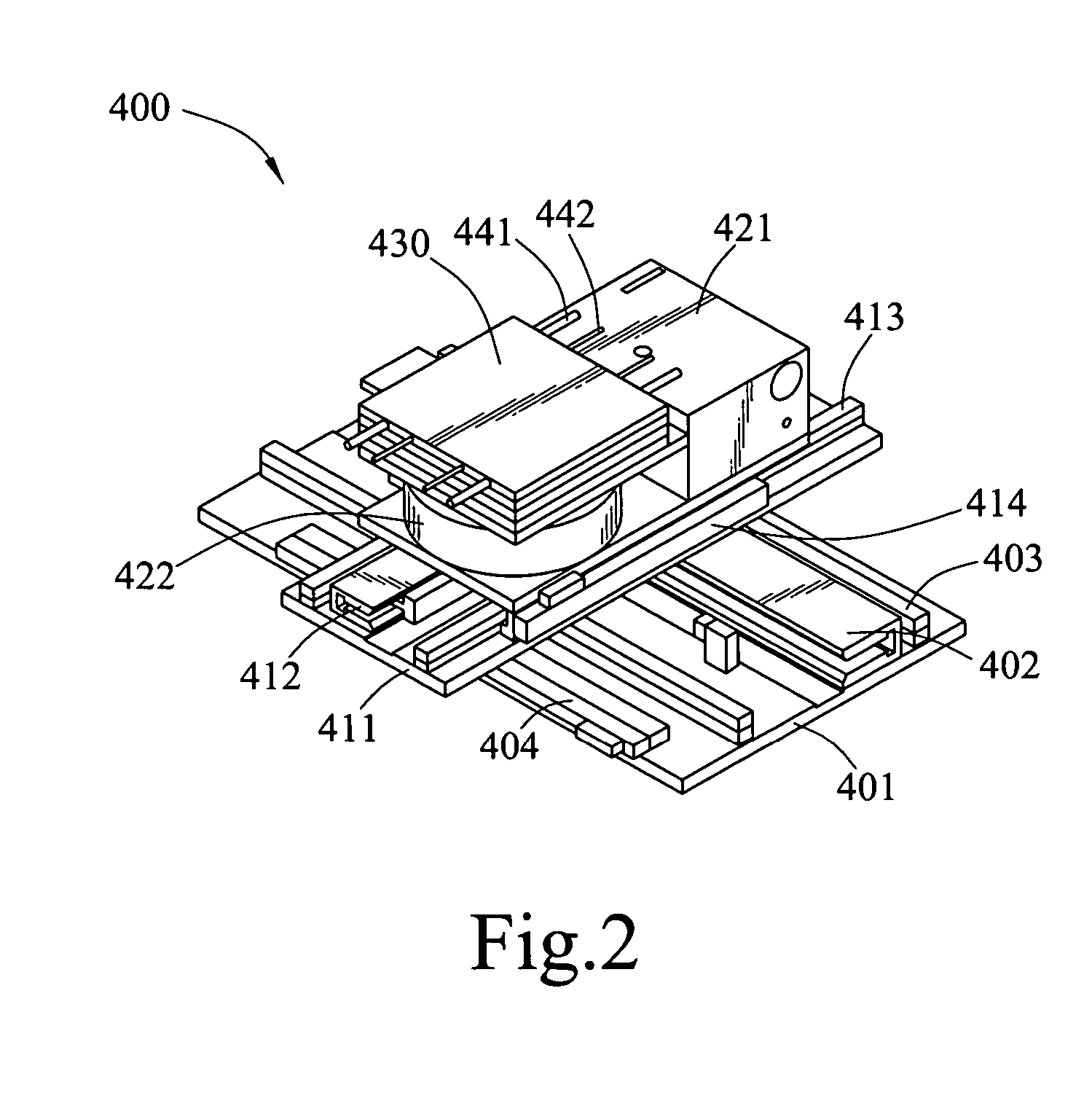

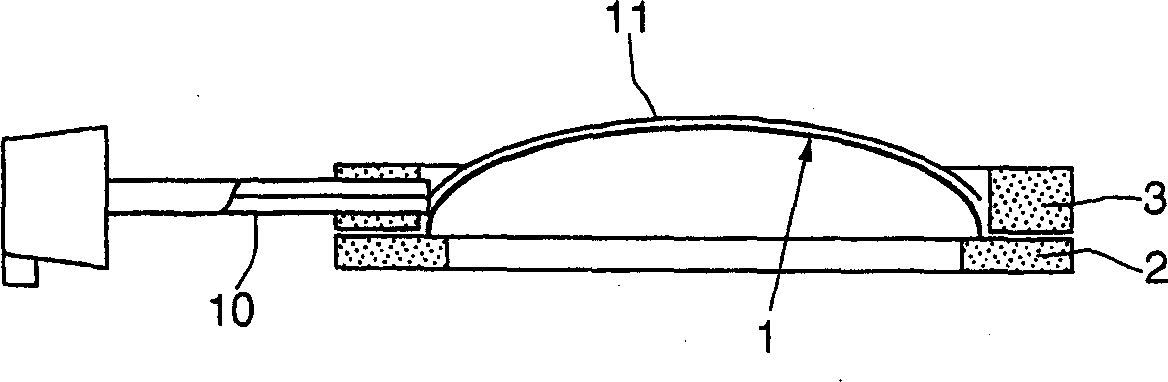

Micro-droplet injection apparatus and injecting process using the same

ActiveUS20070153033A1Shortening micro-element process timeOperation efficiency can be improvedSolid-state devicesPower drive mechanismsTemperature controlImage detection

A micro-droplet injection apparatus and the injecting process using the same are provided for fabricating a micro-element. The apparatus includes an injection module, a moving stage module, an image detection module, and a temperature controlling module. The injection module is provided for injecting a micro-droplet on a substrate carried on the moving stage module, and the substrate is detected by the image detection module for detecting the relative position and inclined angle between the substrate and a injection head of the injection module. The temperature controlling module is provided for controlling the surface temperature of the substrate, such that the temperature of the substrate and the micro-droplets is balanced, and then the surface flatness of the film plated by micro-droplets is improved. The apparatus operates according to processing requirements of different substrates, achieving a stage multiplex function, and raising operation efficiency.

Owner:IND TECH RES INST

Method for selectively removing conductive layer on baseplate material

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

Closed permeating waterproof fruit film bag

InactiveCN101019494ALarge air flowEliminate fruit rustCoatingsPlant protective coveringsPolyolefinCalcium carbonate

The present invention discloses one kind of closed permeating waterproof fruit film bag. The polyolefin film bag is prepared with LDPE polyolefin resin, LLDPE polyolefin resin or PP-polyolefin copolymer resin, calcium carbonate or talcum powder, coupler, modifier and dispersant as materials in a special plastic film bag making machine. It is provided with one tying rope in the mouth.

Owner:徐世慧

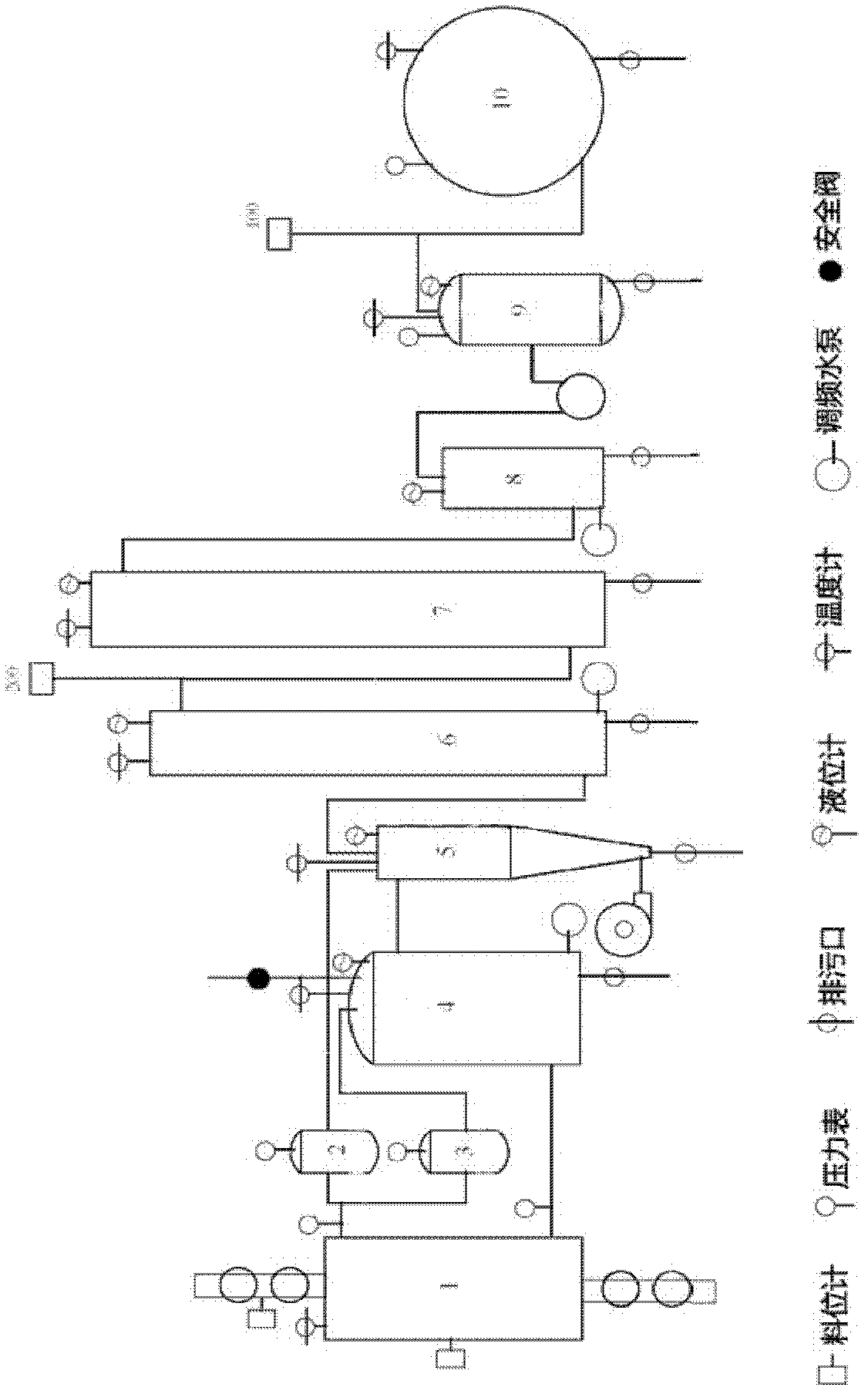

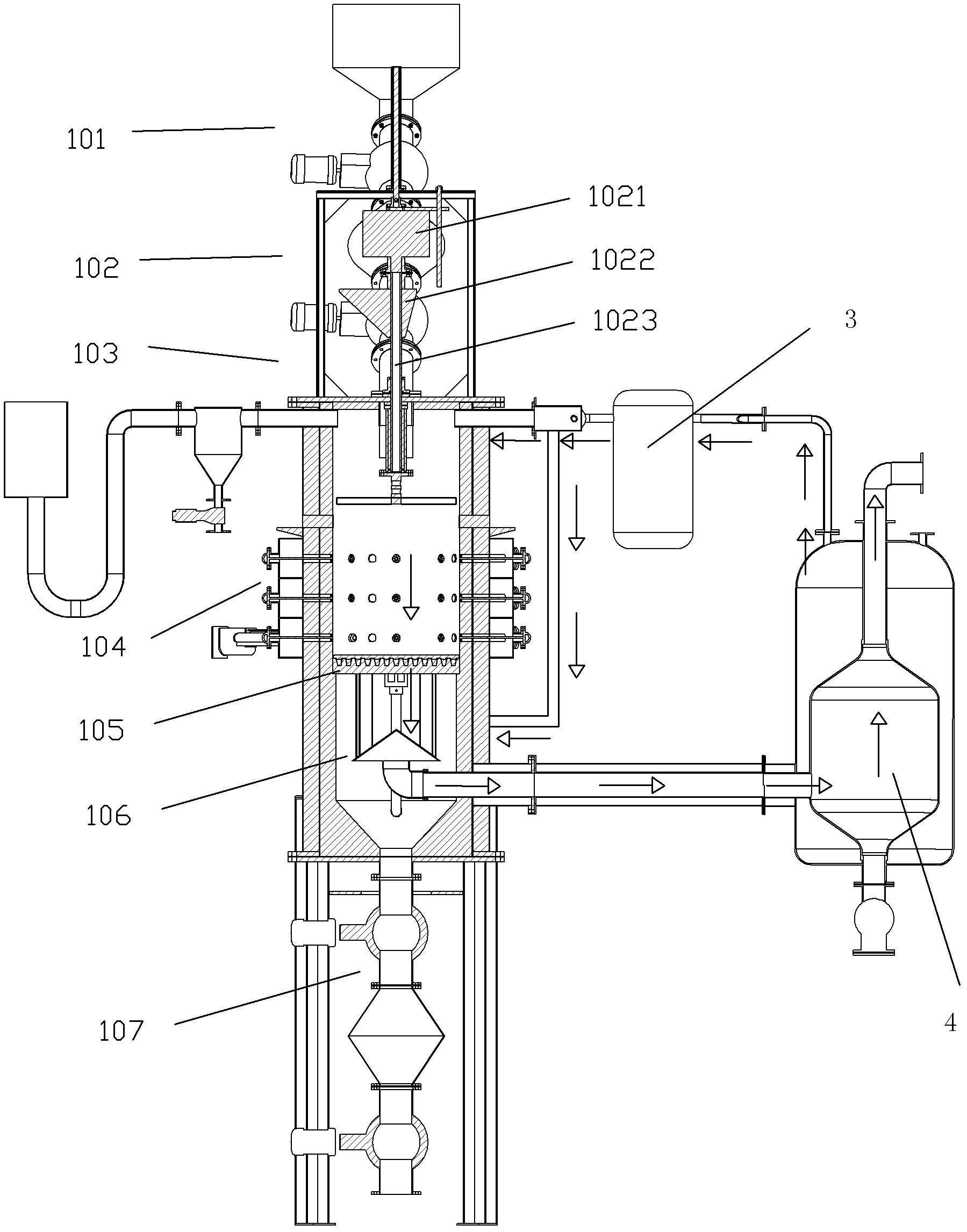

Biomass gasification device and process

InactiveCN102329654AImprove gasification efficiencySafe and controllable operationCombustible gas productionCooling towerSprayer

The invention relates to a biomass gasification device and process. The device comprises a gasification reaction chamber, a steam heat exchanger, a steam buffer tank, an air buffer tank, an inner and outer double-cyclone heat exchanging dust collector, a cooling tower, an electro tar precipitator, a hydrogen sulfide removal sprayer, a water ring compressor, a gas-water separator, a gas storage tank and a control system of the device, which are connected through a gas pipeline; the gasification reaction chamber comprises an automatic feeding device, a two-stage gasification zone, a vibrating grate, an automatic ignition device, an automatic slagging device and an automatic leveling device. The gasification process comprises the following steps of: gas generation; gasification medium preheating; gas purifying and filtering; and gas compression and storage. The biomass gasification device and process are scientific and environment friendly, have the remarkable characteristics of simple structural design, high degree of automation as well as stable, controllable and continuous gasification reaction, have high gasification efficiency and entire caloricity, are suitable for popularization and application on a large scale, and are particularly applicable to continuous and stable generation of the traditional gas generating set.

Owner:张建超

Gas-shielded flux-cored wire for welding of SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device

ActiveCN107971657AAdjust the melting pointAdjustable viscosityArc welding apparatusWelding/cutting media/materialsManganeseSodium titanate

The invention discloses a gas-shielded flux-cored wire for welding of a SUS316L austenitic stainless steel deep-cooling low-temperature storage and transportation container and device and the preparation method thereof. The as-shielded flux-cored wire comprises a steel strip and a flux core wrapped in the steel strip, and the flux core comprises the following components of, by weight, 4.25-5.85 parts of natural rutile, 0.8-1.9 parts of quartz sand, 0.7-1.8 parts of sodium titanate, 0.25-0.3 part of sodium fluoride, 0.125-0.275 part of calcined alpha alumina, 0. 27wt% of calcined alpha aluminaand 0.025-0.15 part of nitrogen-containing ferrochromium, 0.085-0.05 part of spray silicon iron, 1.05-1.45 parts of electrolytic manganese, 3.6-4.85 parts of metal chromium, 6.42-6.85 parts of atomized iron powder, 1. 9-2.5 parts of nickel powder, and 1.0-1.35 parts of molybdenum. The gas-shielded flux-cored wire has the advantages that efficient semi-automatic and automatic welding technologies are achieved, the welding efficiency is high, splashing is low, the appearance is attractive, the welding current is wide, and the voltage adaptability strong.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Device for preventing explosions in electrical transformers

InactiveCN1346499AReduce releaseTemperature balanceTransformers/inductances coolingTransformers/inductances casingsTransformerEngineering

The invention concerns a device for preventing explosions in an electrical transformer comprising a vessel filled with a fuel cooling fluid, and means for decompressing the transformer vessel. The decompressing means comprise a rupture element (1) with an incorporated explosion detector provided with a retaining part (4) including first zones with reduced thickness relative to the rest of the retaining element (4) and capable of being torn off without being fragmented when said element (1) is ruptured, and second zones with reduced thickness relative to the rest of the retaining element (4) and capable of bending without getting torn off when said element (1) is ruptured. Said rupture element (1) is capable of being ruptured when the pressure inside the vessel exceeds a predetermined ceiling. The signal of the explosion detector integrated in the rupture disc triggering a cooling system and preventing oxygen from coming in contact with the explosive gases generated by the electric arc by contact with oil.

Owner:菲利普·马尼耶

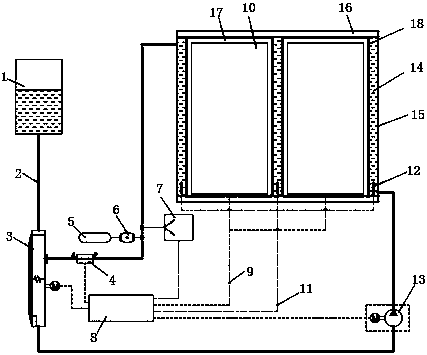

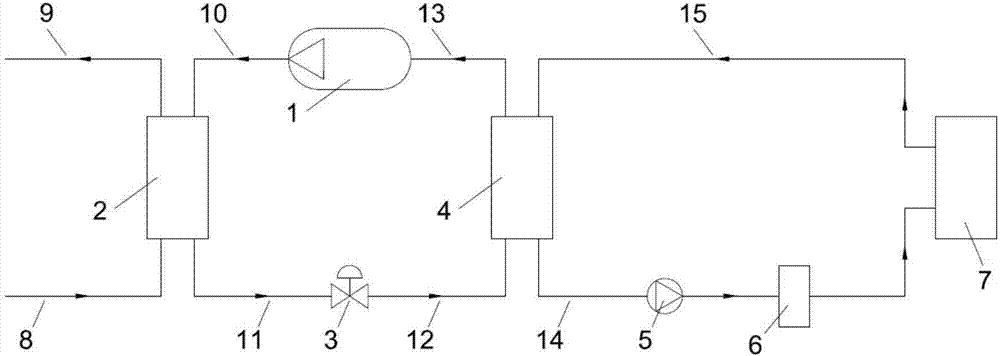

Vacuum liquid-cooled coupling heat management system of power battery and operating method

InactiveCN107706484AInsulate temperature conductionTo achieve heat insulation effectSecondary cellsCell component detailsElectrical batteryHydraulic pump

The invention discloses a vacuum liquid-cooled coupling heat management system of a power battery and an operating method. The vacuum liquid-cooled coupling heat management system comprises a batterypack, hollow cooling plates arranged on two sides of the battery pack, a liquid cooling circuit, with a hydraulic pump, communicating with the cooling plates, and a battery control unit, wherein the liquid cooling circuit is connected with a temperature controller, an electromagnetic valve, an air interchanger and a vacuum pump; the temperature controller is connected with a cooling liquid standbytank; and the air interchanger comprises an air storage tank with a filter screen and an air inlet valve connected with the liquid cooling circuit. The temperature conduction between battery packs isisolated by vacuum plates formed by the cooling plates through the air interchanger and a vacuum pump system, the effects of heat insulation and heat preservation are reached, the hidden danger thatthe temperature of the dense region of the battery pack is increased locally is solved, and the waste of energy sources is reduced, so that the cruising power of a finished automobile power battery system is improved, and the service life of the finished automobile power battery system is prolonged; and when the local temperature is abnormal, liquid can be quickly filled for cooling, so that the temperature of the battery pack and the temperature of the finished automobile system are balanced again.

Owner:DONGGUAN DRN NEW ENERGY

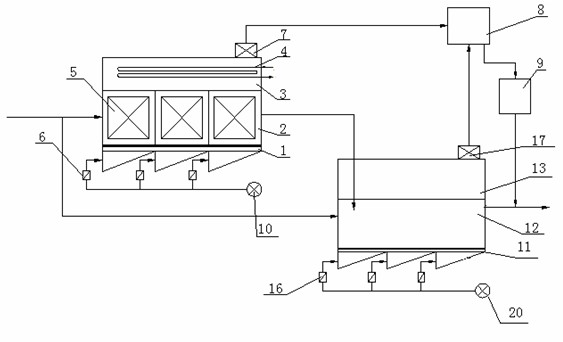

System for conditioning through coking charge coal humidity difference

ActiveCN102585867AExpand the adjustment rangeImprove controllabilityCoke ovensProcess engineeringCoal

The invention discloses a system for conditioning through the coking charge coal humidity difference. The system comprises an internal fluidized bed type drying and conditioning machine, a fluidized bed type dry-wet coal mixing conditioning machine, a deduster (8) and a granulator (9), the coking charge coal humidity difference conditioning machine is formed by the internal fluidized bed type drying and conditioning machine and the fluidized bed type dry-wet coal mixing conditioning machine, the internal fluidized bed type drying and conditioning machine deeply dehumdifies partial wet coal needing conditioning, and sends the dried partial coal to the fluidized bed type dry-wet coal mixing conditioning machine, and the dried partial coal and the other welt coal needing conditioning are subjected to hybrid conditioning in a fluidization state. The system has the advantages of simplified flow, reduced heat transfer and heating surfaces, simple structure, good interchangeability, convenient examination and maintenance, reliable operation, reliable and flexible conditioning control and adjustment, full and reasonable energy utilization, and reduction of the size of standby equipment of present conditioning systems.

Owner:WUXI YIEN TECH

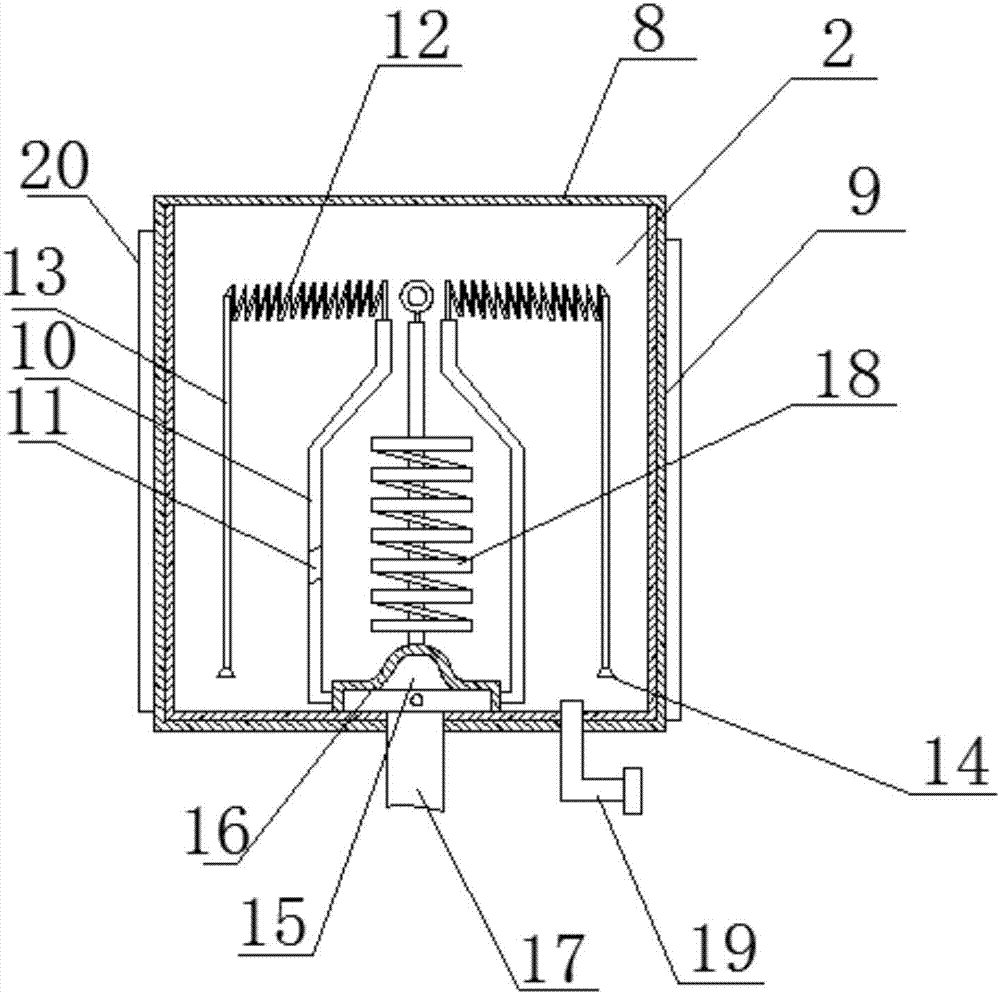

Vibration soaking pit furnace

ActiveCN104677107AAchieve flowAchieve temperatureFurnace typesProcess efficiency improvementEngineeringMechanical engineering

The invention relates to a vibration soaking pit furnace, which comprises a furnace body, a heat insulation shell, a nozzle, a smoke vent and a liquid outlet; the inner wall of the top part of the furnace body is fixedly provided with a fan coil revolving shaft; a fan coil of which the interior is hollow rotatably sheathes the fan coil revolving shaft; the lower bottom face of the fan coil is provided with needle rods; all the needle rods are parallel with each other and are vertical to the lower bottom face of the fan coil; the upper ends of all the needle rods penetrate through the lower bottom face of the fan coil and are fixedly arranged on the inner wall of the top face of the fan coil; all the needle rods extend downwards to molten aluminum; collision beads capable of freely moving fill in the fan coil; a ratchet-shaped texture is formed on the side circumferential wall of the fan coil; ventilation openings are also formed in the side circumferential wall of the fan coil. The temperature of the molten aluminum in the furnace body can be effectively balanced by the vibration soaking pit furnace, so that the quality of the molten aluminum is increased, and meanwhile, smoke pollution is reduced.

Owner:SUZHOU SHENGPULA NEW MATERIAL SCI & TECH

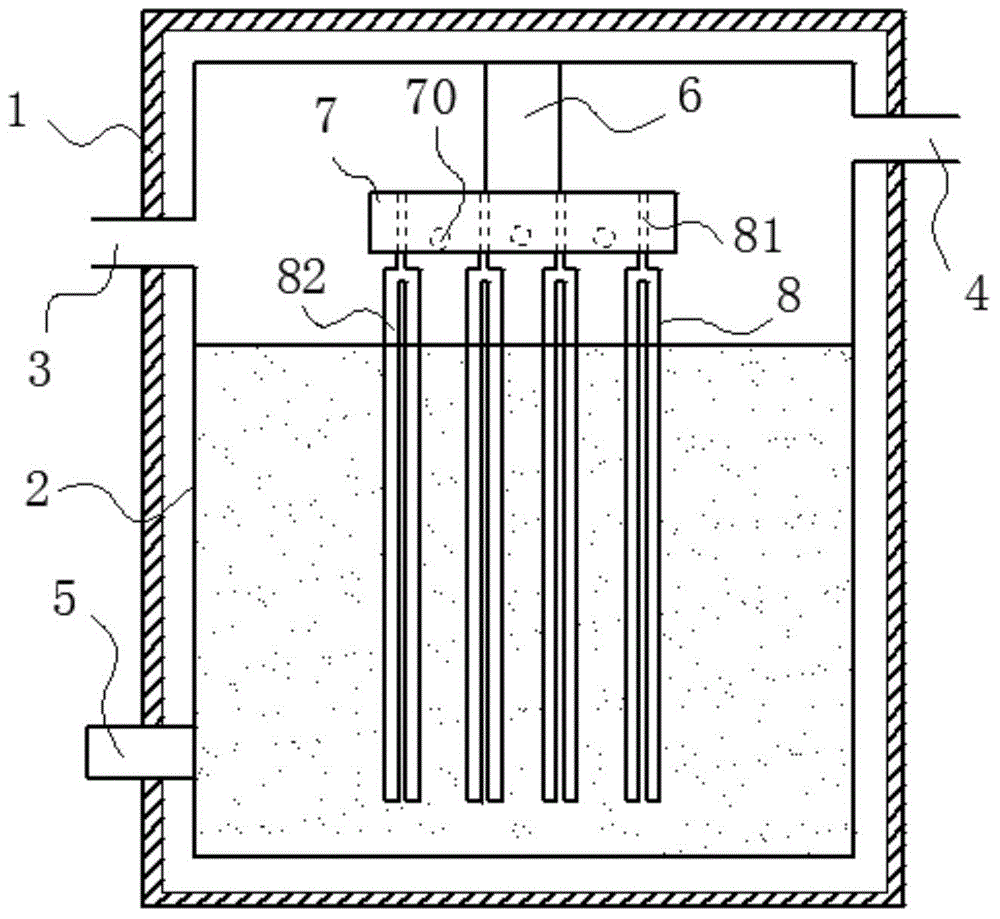

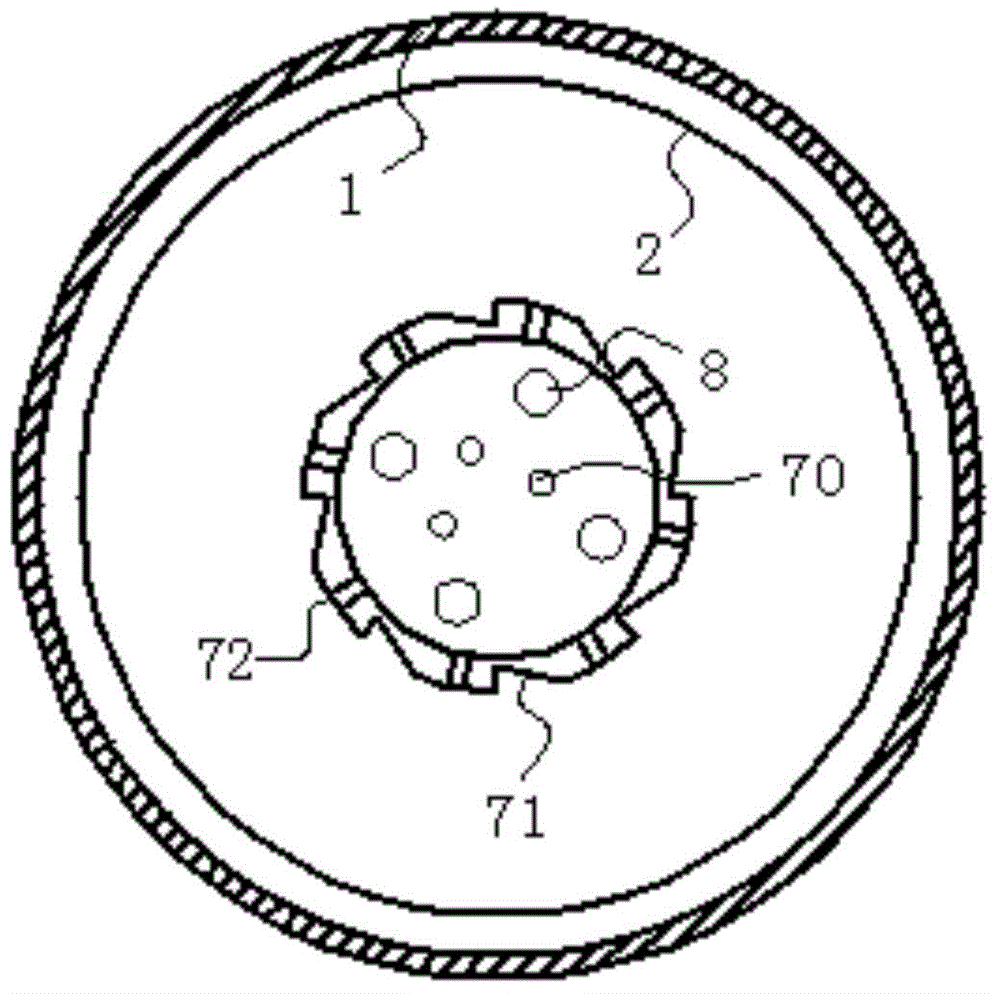

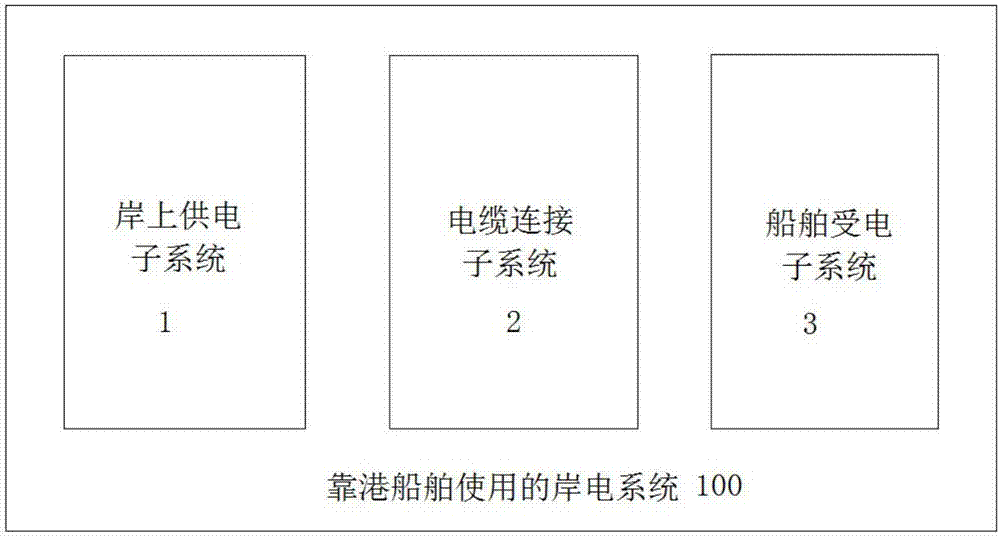

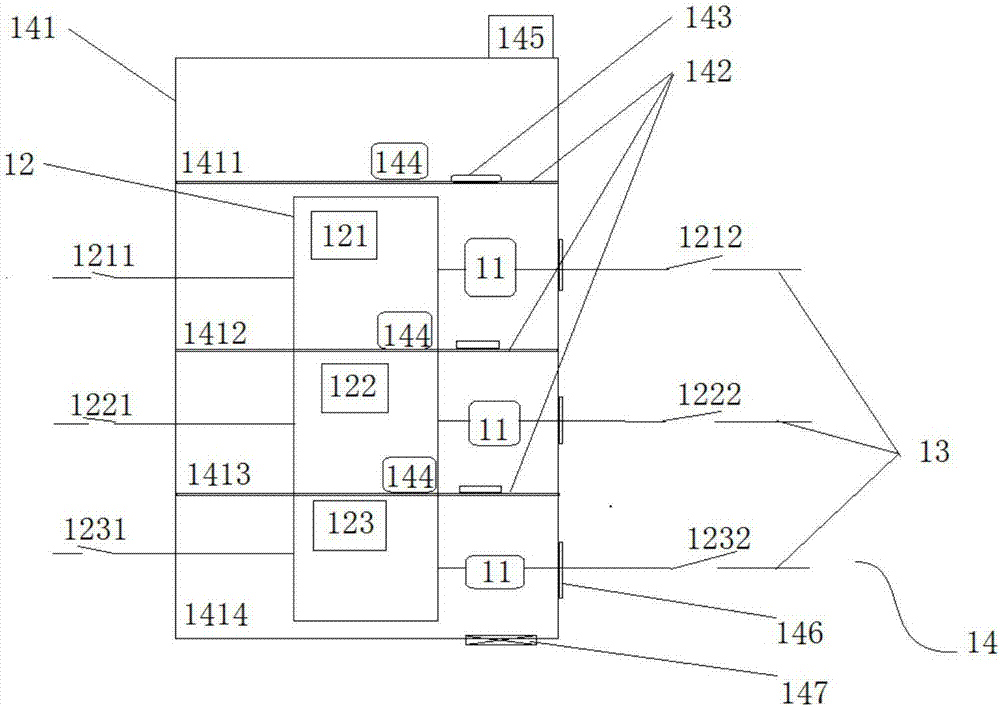

Shore power system for anchored ships

PendingCN107086571ASimple shore power systemNovel ideaCouplings bases/casesSubstation/switching arrangement casingsLightning arresterDeck

The invention relates to a shore power system for anchored ships. The shore power system comprises an onshore power supply subsystem, a cable connection subsystem and a ship power-receiving subsystem. All the three subsystem are provided with protective layers and lightning arresters. The onshore power supply subsystem comprises a power supply device in a shore power distribution container, a shore cable laying and collecting device, a cable. The shore power distribution container is equipped therein with air conditioner indoor unit and is provided with three cable outlet doors at the container body and a waterproof ventilation window. The cable connection subsystem comprises a shore power electrical box, a plug-in device, a charging device and a movable base. The ship power-receiving subsystem comprises a ship power cable and a ship power cable laying and collecting device. The ship power cable extends out of from a hull deck surface and passes through a cylinder which is disposed on the top wall surface of the hull and through which a plurality of cables can pass.

Owner:STATE GRID JIBEI ENERGY SAVING SERVICE +1

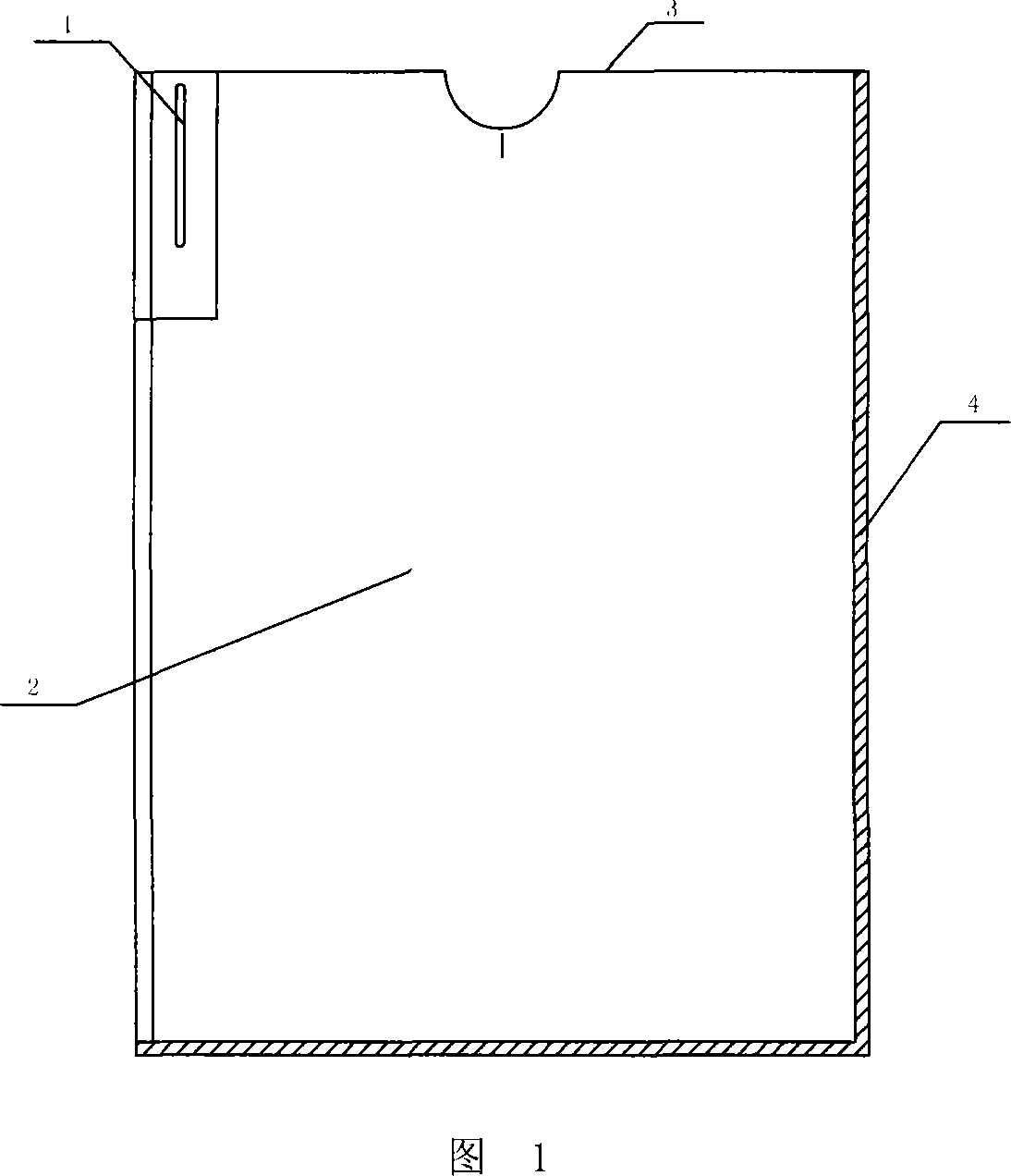

Entirely-foamed aviation cold-chain transport box comprising vacuum insulation boards

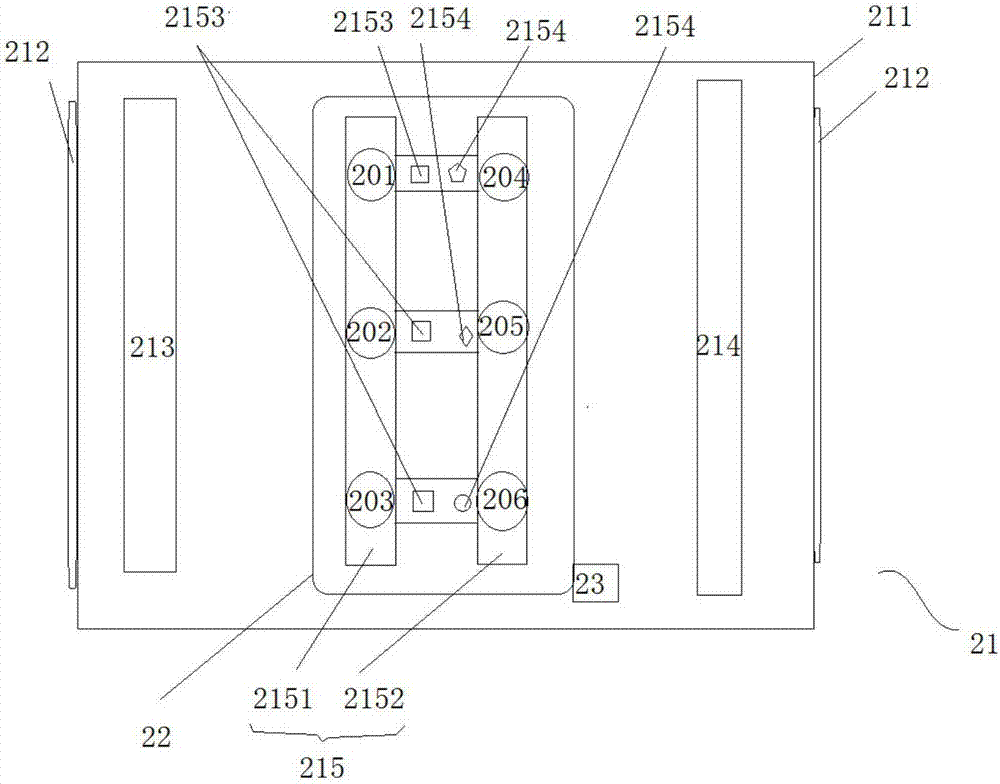

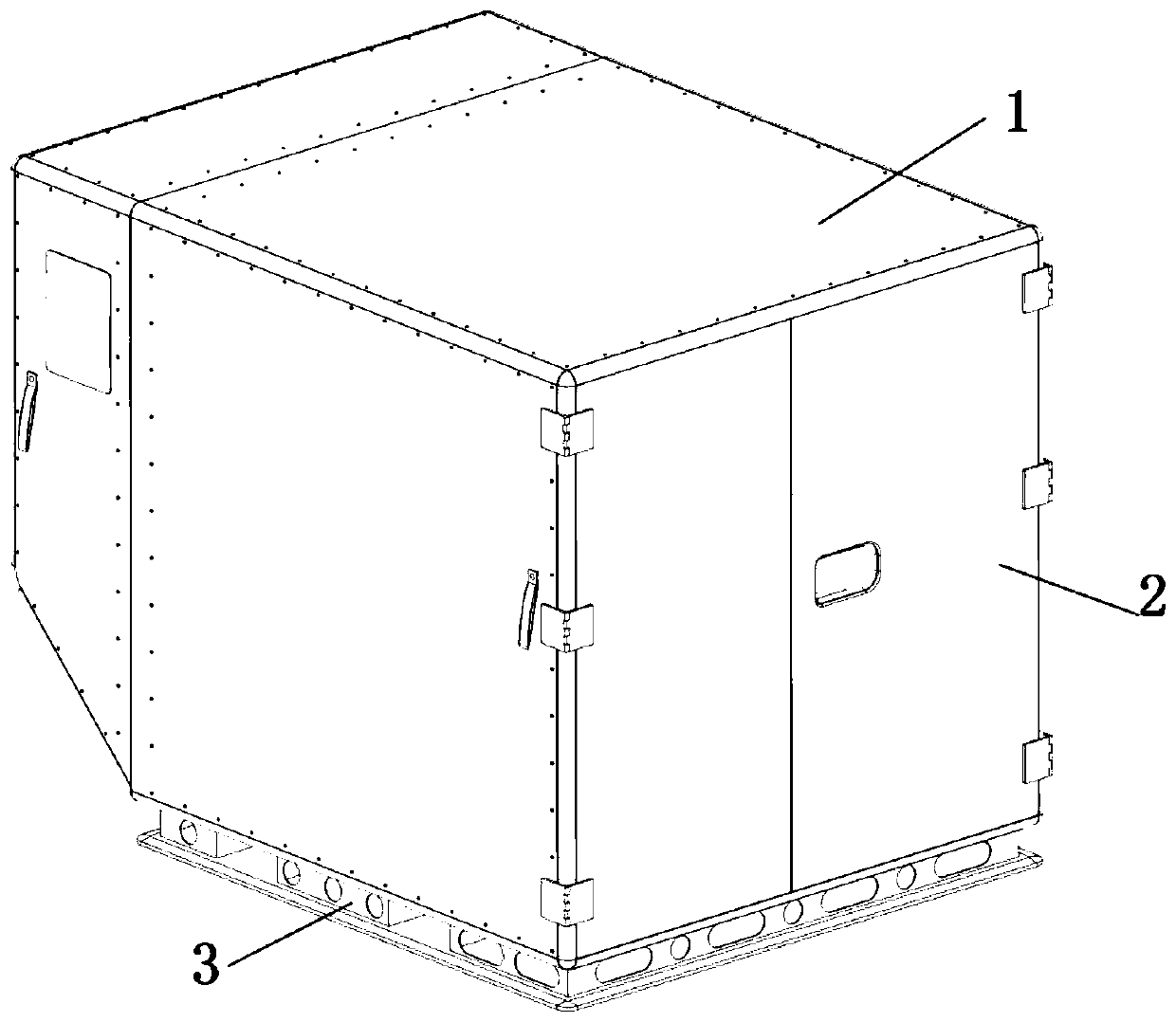

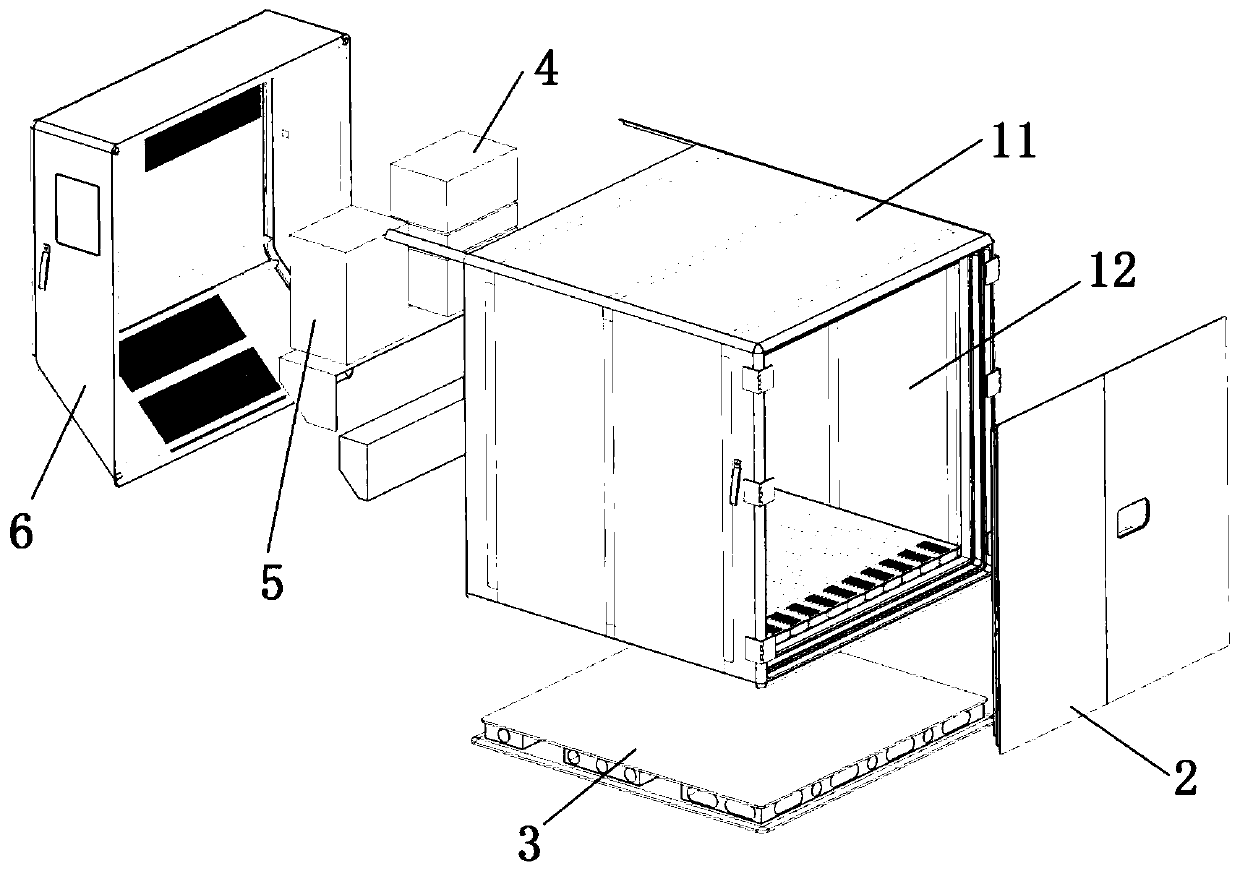

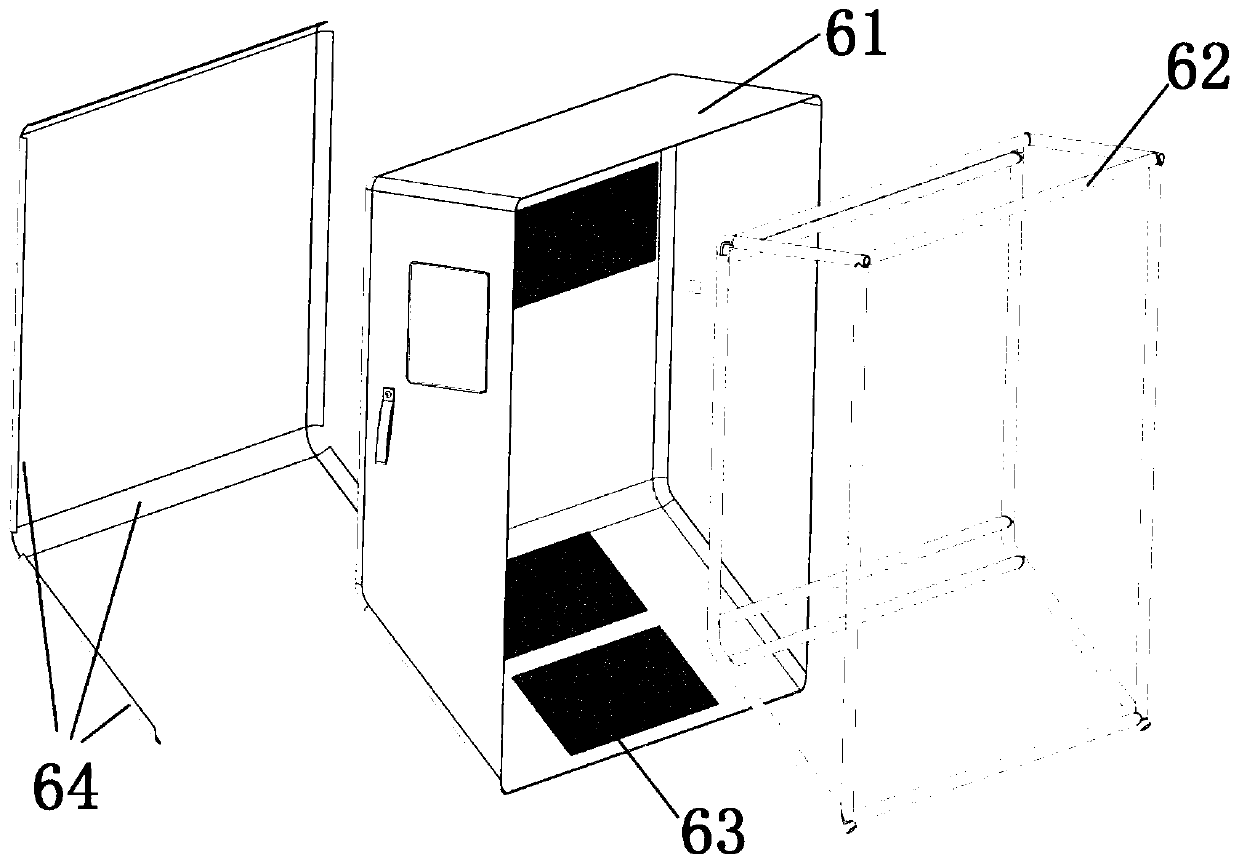

InactiveCN110779255AHigh strengthExcellent waterproof and impermeabilityLighting and heating apparatusDomestic refrigeratorsAviationCold chain

The invention belongs to the field of heat insulation, and relates to an entirely-foamed aviation cold-chain transport box comprising vacuum insulation boards. The entirely-foamed aviation cold-chaintransport box comprises a box body, a door body hinged to the front side of the box body, a protective cover fixedly installed on the rear side of the box body, and a base fixedly installed at the bottom of the box body. A refrigeration system and a storage battery used for supplying power to the refrigeration system are arranged in the box body. A plurality of I-shaped reinforcing rods used for enhancing the compressive strength of the box body are fixedly installed in the middle of the box body. Heat insulation layers made of the vacuum insulation boards are installed on the inner side of the box body and the inner side of the door body. The heat-insulation property, the temperature uniformity, the bearing capacity and the like of the aviation cold-chain transport box can be improved.

Owner:重庆复升冷鲜香科技有限公司

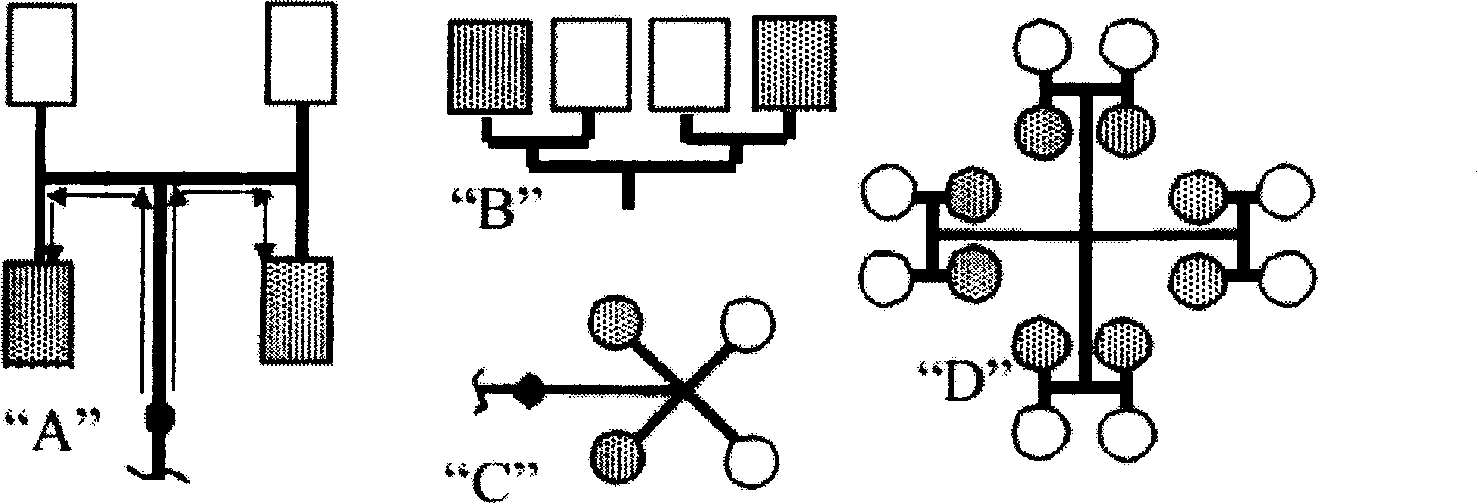

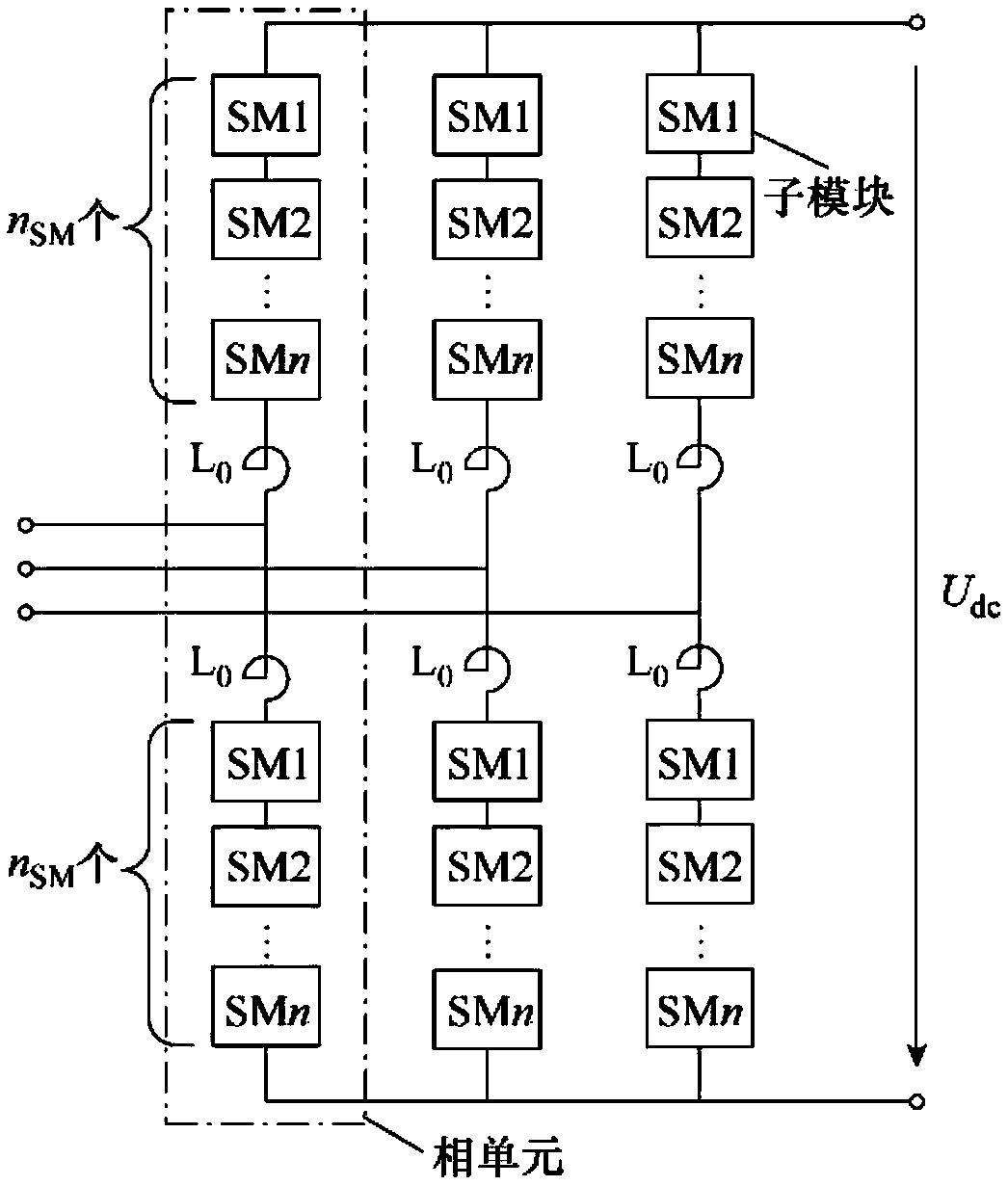

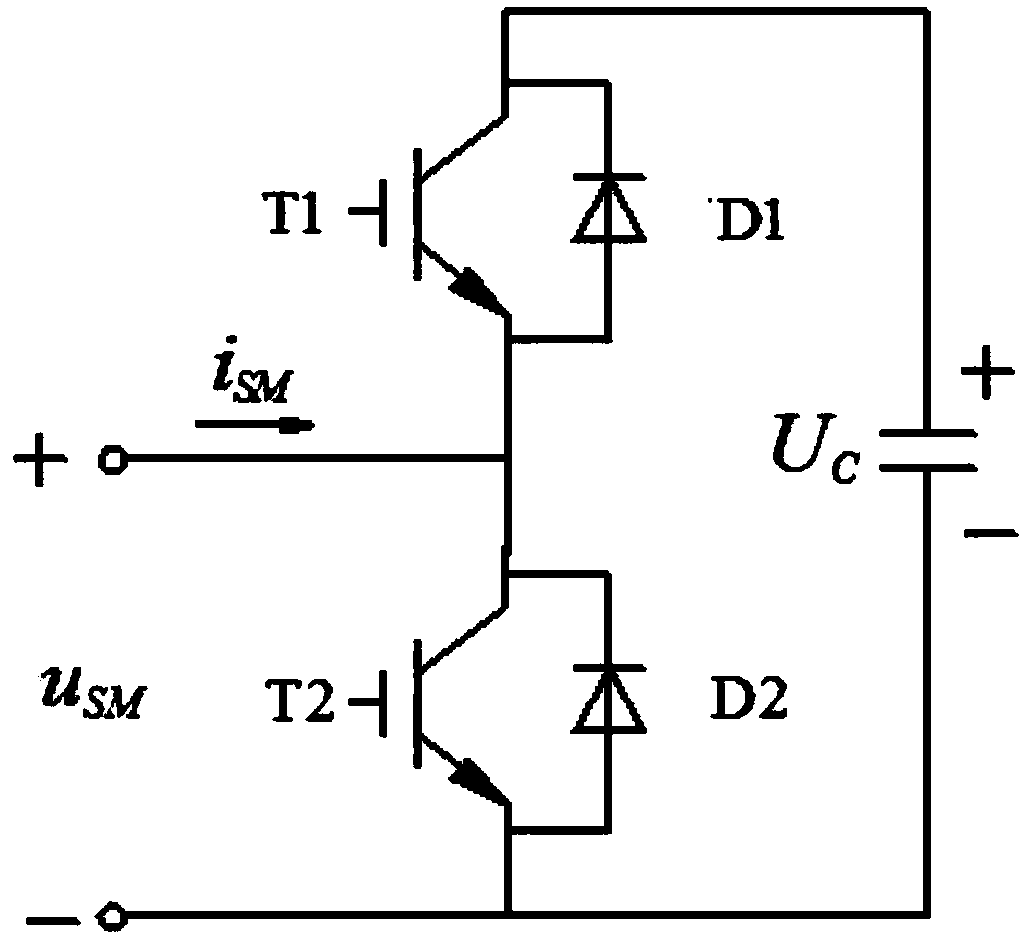

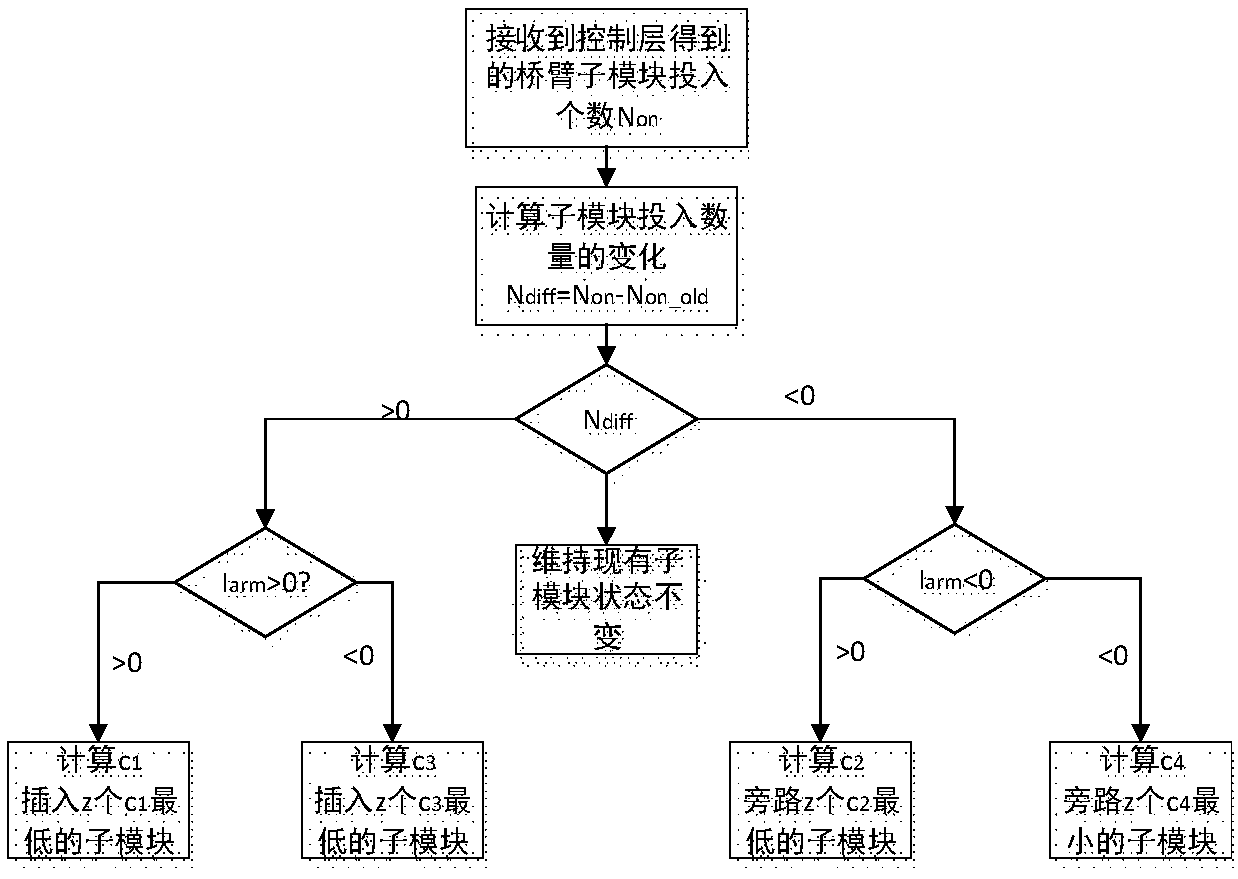

Thermal balance control method for modular multilevel converter

Provided in the invention is a thermal balance control method for a modular multilevel converter. The method comprises: step one, an invested sub module number instruction Non that is needed by one bridge arm and is obtained by a converter control layer according to an NLC method is received and a change Ndiff of the sub module investment number is calculated; step two, a capacitance voltage of each sub module is measured and a minimum capacitance voltage vcmin and a maximum capacitance voltage vcmax are found out, temperatures of an IGBT and an anti-parallel diode in each sub module are measured and T1min, T2min, D1min, and D2min are found out; and step three, positive and negative properties and an arm current direction are the Ndiff are determined. According to the invention, the temperature is added into the balance algorithm based on the capacitance voltage balance algorithm, so that the modular multilevel capacitance voltages are balanced and the temperature is balanced; and on the basis of the opened sub module number during the last cycle, ranking of all sub modules is not needed during ranking, so that the algorithm becomes simple.

Owner:SHENYANG POLYTECHNIC UNIV

Domestic coffee machine

The invention discloses a domestic coffee machine. The domestic coffee machine includes a machine body and a base, a water tank is arranged in the machine body, the lower end of the water tank is provided with a communication pipeline, a heat-insulation storage tank is further arranged on the machine body, a heating device and a temperature sensor are arranged in the heat-insulation storage tank, the upper end of the water tank is provided with a cover, electric heating wires are arranged in the water tank, the bottom of the water tank is provided with a water inlet pipe and a water outlet pipe, the portion, close to the water inlet end of the water inlet pipe, of the bottom of the water tank is provided with a water retaining hood, the side face of the water retaining hood is provided with a plurality of vertical diversion pipes, the upper ends of the diversion pipes are connected with spiral pipes, the outer ends of the spiral pipes are provided with vertical reflux pipes, the lower ends of the reflux pipes are provided with water distribution spray nozzles, the electric heating wires are located over the water retaining hood, the outer side of the water tank is provided with capacitor electrode probes, the upper ends of the capacitor electrode probes are close to the opposite top locations of the water tank, and the lower ends of the capacitor electrode probes are close to the opposite bottom locations of the water tank. The domestic coffee machine is simple in structure, convenient to use, good in heating effect and environmentally friendly, the energy is saved, and water-level monitoring is convenient.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

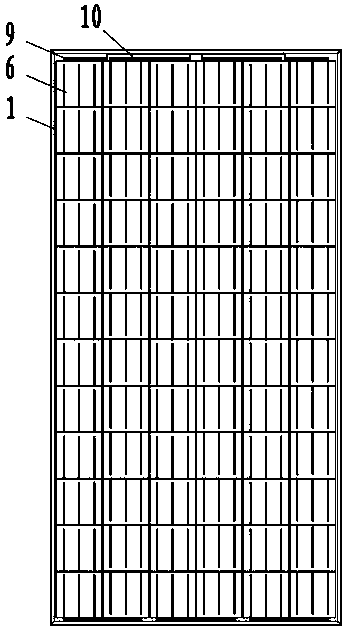

Photovoltaic module

InactiveCN103367507ASolve functionReduce output powerSolar heating energyGlass/slag layered productsUltraviolet lightsEngineering physics

The invention discloses a photovoltaic module applied to new technologies. The photovoltaic module comprises a junction box and a lamination layer, wherein the lamination layer sequentially comprises the following components from top to bottom: a front plate tempered glass matrix capable of absorbing or reflecting infrared light and ultraviolet light or light with other wavebands, a front plate tempered glass textured suede, a packaging layer with an UV (ultraviolet) absorption or transmission function, a back plate tempered glass matrix, and a heat dissipation film layer; a crystalline silicon battery is arranged in the packaging layer, and a reflective function film layer is plated on the inner surface of the back plate tempered glass; an aluminium alloy border is installed at the periphery of the lamination layer composed of the layers above. The photovoltaic module disclosed by the invention is reasonable in structure; the internal temperature of the module can be effectively reduced, the output power of the module can be increased, and the service life of the module can be prolonged.

Owner:HANWHA SOLARONE QIDONG

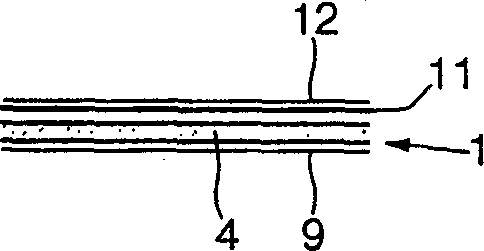

Method for making electric conduction patterns on metal-foil-clad insulating substrate

ActiveCN103769749AInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilLaser beams

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

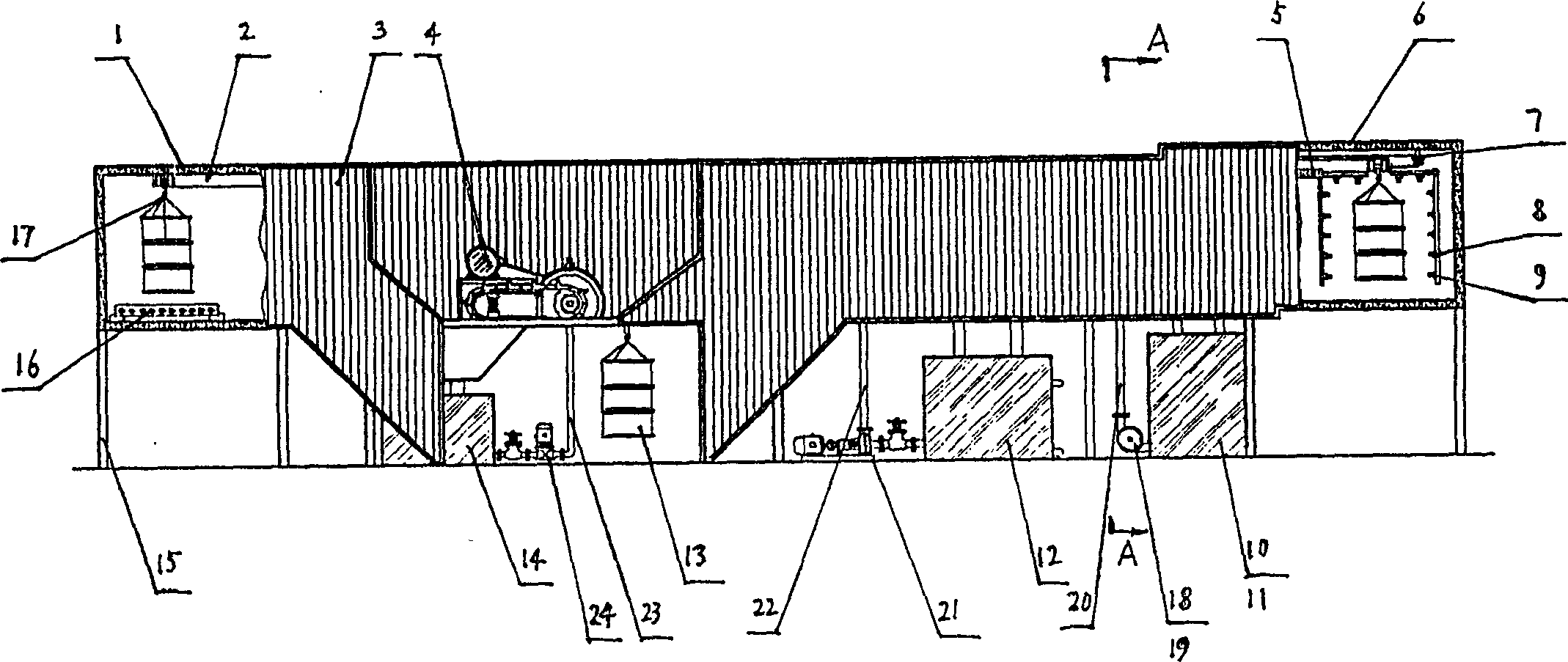

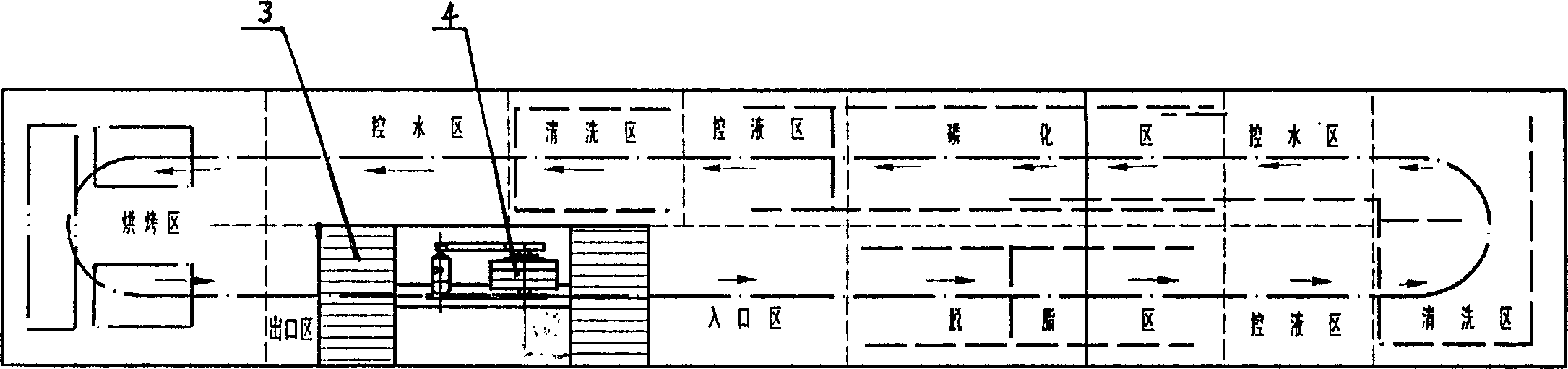

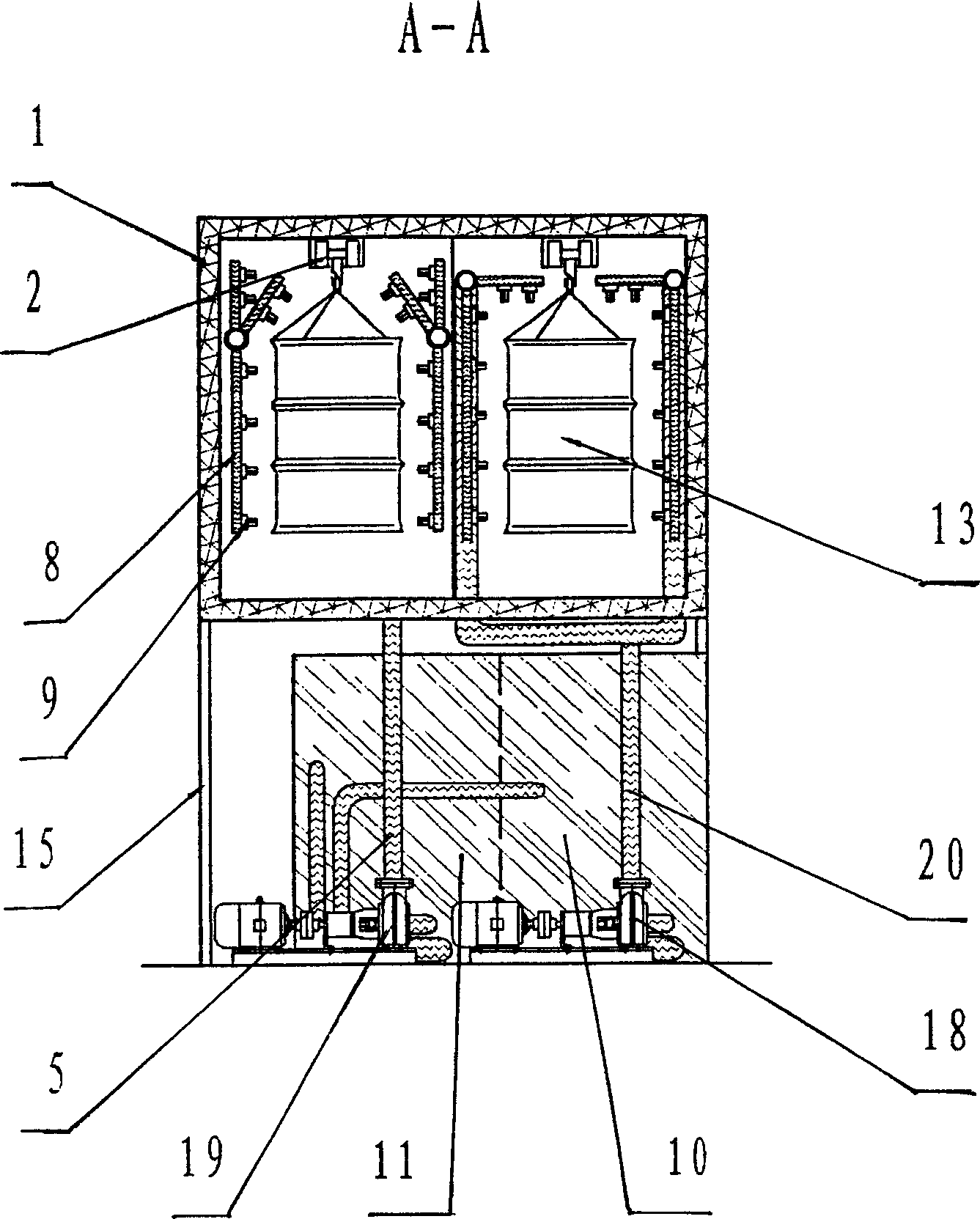

Automatic sprinkling type phosphatization treatment system for surface of steel barrel

InactiveCN1840734ADoes not take up work spaceSmall footprintMetallic material coating processesEngineeringEnergy consumption

The disclosed auto-spray phosphating system on steel barrel surface comprises an overhead ring tunnel with ports and ring gear chain device inside. Wherein, the said chain device comprises for work piece in turn an entrance area, a degrease area, a liquid regulating area, a cleaning area, a water regulating area, a phosphating area, a liquid regulating area, a cleaning area, a water regulating area (hole-form), a roasting area, and an exit area. The advantages of this invention include: saving space and energy consumption, convenient to clean precipitate, and cutting length.

Owner:SANMENXIA CITY JINHUI PACKAGING

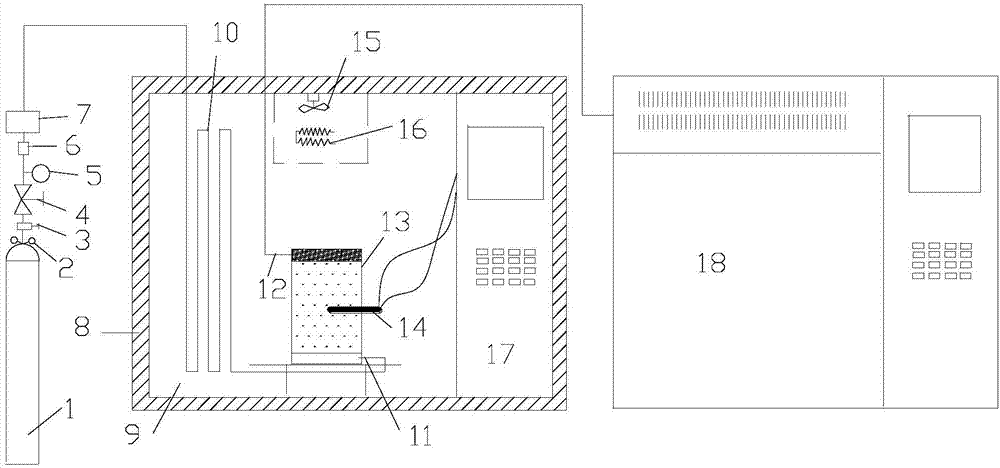

Chromatographic analysis and index optimization determinator for coal bed spontaneous combustion mark gas

PendingCN107449847AFast injection timeRealize the requirement of recycling the gas samples generated in the coal sample tankComponent separationSpontaneous combustionTemperature control

The invention discloses a chromatographic analysis and index optimization determinator for a coal bed spontaneous combustion mark gas. The chromatographic analysis and index optimization determinator comprises a temperature control box, wherein a coal sample tank is arranged in the temperature control box; a gas inlet pipe is arranged at the bottom of the coal sample tank; the gas inlet pipe is connected with a gas intake system arranged outside the temperature control box; a gas delivery pipe of the gas intake system is connected with a preheating tube after entering the temperature control box; the preheating tube is connected with the gas inlet pipe; a gas outlet pipe is arranged at the upper part of the coal sample tank and connected with a gas chromatographic instrument; a temperature sensor I for detecting the temperature in the coal sample tank is mounted on the coal sample tank in an inserting manner; a temperature sensor II is arranged in the temperature control box; and the temperature sensor I and the temperature sensor II are connected with a controller; and the controller is used for controlling the temperature in the temperature control box according to the detected temperature, and simultaneously monitors and records temperature changes of the temperature control box and the coal sample tank.

Owner:SHANDONG DINGAN TESTING CO LTD

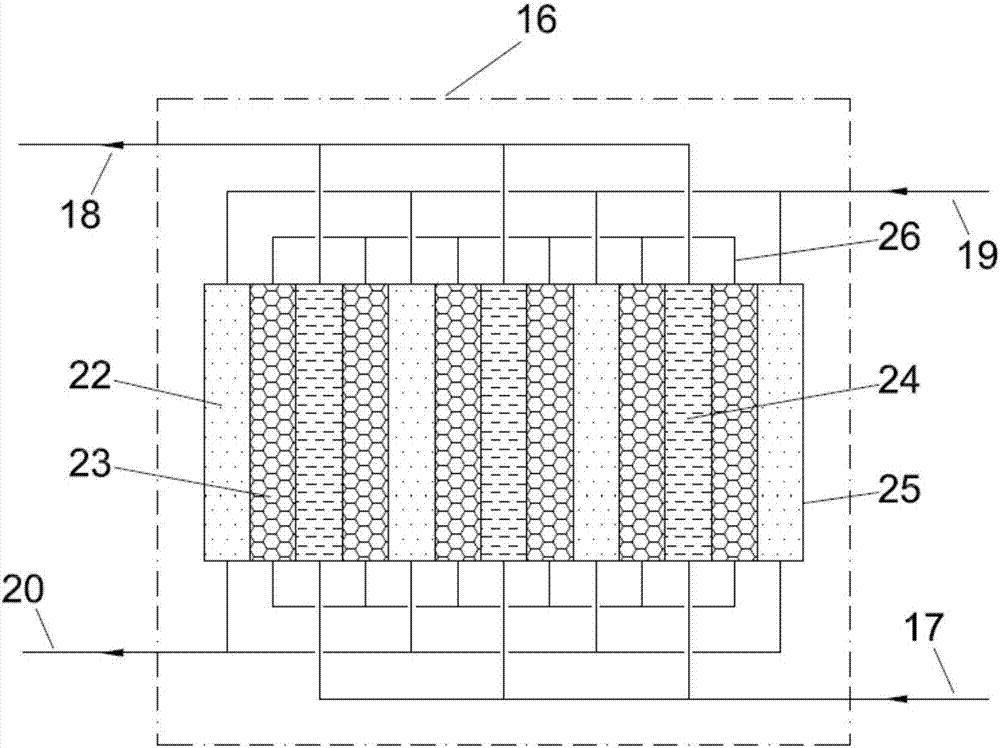

Paraffin phase change heat storage temperature adjusting device for semiconductor technology temperature control equipment

InactiveCN106969532AAvoid excessive temperature riseAvoid the disadvantages of difficult temperature controlMachines using electric/magnetic effectsRefrigeration safety arrangementTemperature controlTwo temperature

The invention provides a paraffin phase change heat storage temperature adjusting device for semiconductor technology temperature control equipment, and belongs to the technical field of temperature control equipment. The paraffin phase change heat storage temperature adjusting device comprises a shell and multiple temperature adjusting units located in the shell. A compressor exhaust heat exchange cavity is formed between every two adjacent temperature adjusting units, and a compressor exhaust heat exchange cavity is formed between each temperature adjusting unit and the shell. Each temperature adjusting unit comprises a refrigerating medium heat exchange cavity in the middle and paraffin heat storage cavities located in the two sides of the refrigerating medium heat exchange cavity. The upper end and the lower end of each paraffin heat storage cavity communicate through a paraffin communicating pipe. The two ends of each refrigerating medium heat exchange cavity are provided with a refrigerating medium liquid outlet pipe connector and a refrigerating medium liquid inlet pipe connector correspondingly. The two ends of each compressor exhaust heat exchange cavity are provided with a compressor exhaust gas inlet pipe connector and a compressor exhaust gas outlet pipe connector correspondingly. According to the device, heat in compressor exhaust waste heat is stored in paraffin, the paraffin achieves heating and temperature adjusting on a refrigerating medium in the phase change process, and the temperature control equipment is more economical and environment-friendly and saves more energy; and loads of a cooling-water machine attached to a semiconductor enterprise can be reduced, and energy consumption is further reduced.

Owner:BEIJING JINGYI AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com