Paraffin phase change heat storage temperature adjusting device for semiconductor technology temperature control equipment

A temperature adjustment device and temperature adjustment technology, which are applied in lighting and heating equipment, machines using electromagnetic/magnetic effects, and machine operation modes, etc., can solve problems such as high operating costs, increased electrical power of attached equipment, and energy waste, etc. Achieve high heat exchange efficiency, stable heat, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A paraffin phase change heat storage temperature adjustment device for semiconductor process temperature control equipment proposed by the present invention is further described as follows in conjunction with the accompanying drawings and specific examples:

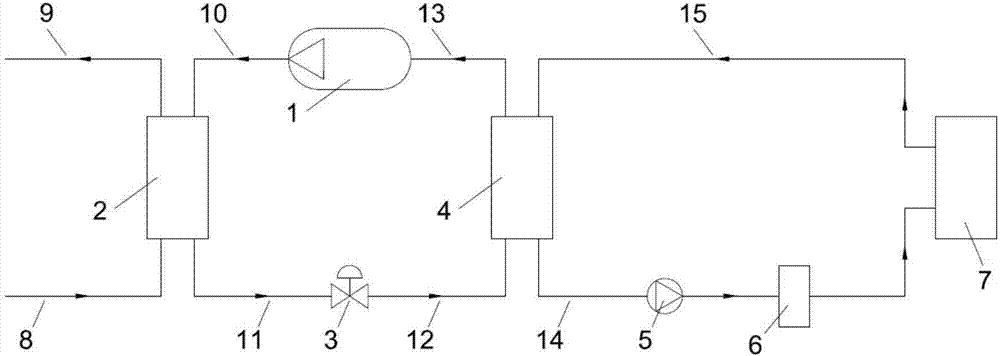

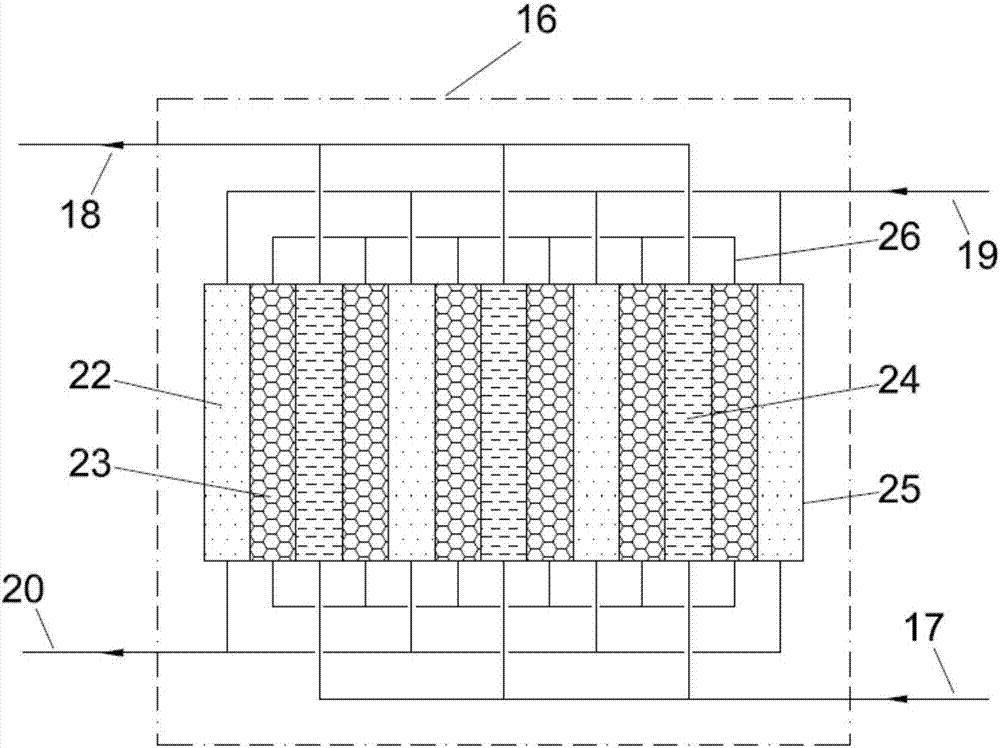

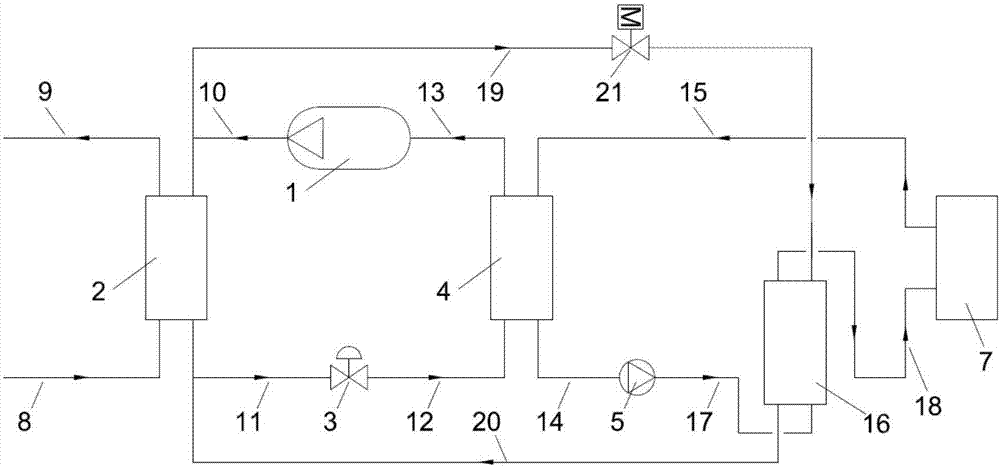

[0020] A paraffin phase change heat storage temperature adjustment device 16 for semiconductor process temperature control equipment proposed by the present invention uses the phase change characteristics of paraffin to absorb heat in liquefaction and release heat in solidification, and use the latent heat of phase change to store heat instead of figure 1 The electric heater in the shown existing temperature control equipment is used, and the structural representation of the present invention is as follows figure 2 As shown, the temperature regulator includes a casing 25 and a plurality of temperature regulation units located in the casing; compressor exhaust heat exchange chambers are provided between two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com