Double-protection spray gun for Maerz kiln

A double-layer protection and spray gun technology, applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of short life, fast wear, etc., and achieve the effect of preventing excessive temperature rise, increasing efficiency, and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

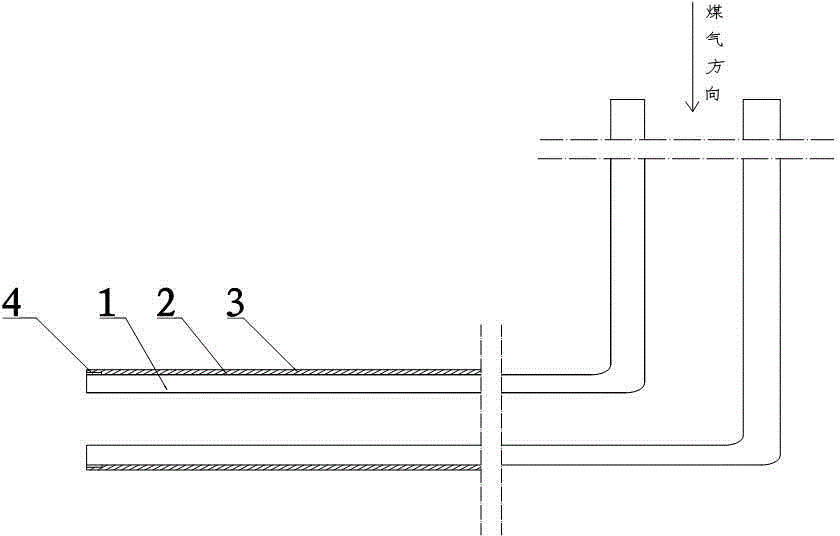

[0012] When the spray gun is working, the stainless steel spray gun outer tube 1 wraps the stainless steel spray gun inner tube 2, and the two are hollow structural design to prevent the temperature of the spray gun from rising too high. The high-temperature material first comes into contact with the ceramic protective layer 3 of the spray gun. The high temperature resistance and wear resistance of the ceramic protective layer are higher than those of the heat-resistant stainless steel tube, which prolongs the service time of the Maerz kiln spray gun, reduces damage, saves equipment costs, and increases efficiency.

Embodiment 2

[0014] When the spray gun is working, the stainless steel spray gun outer tube 1 wraps the stainless steel spray gun inner tube 2, and both are hollow structural design to prevent the temperature of the spray gun from rising too high. The front end of the protective cover is provided with a backstop part 4 that prevents the ceramic protective cover from falling off, to prevent the ceramic protective cover of the spray gun from contacting and rubbing against the high-temperature material and falling off. The backstop part 4 is a backstop ring or a backstop snap ring. The ceramic protective cover that comes into contact with the spray gun, the high temperature resistance and wear resistance of the ceramic protective cover are higher than those of the heat-resistant stainless steel tube, which prolongs the service time of the spray gun in Maerz kiln, reduces damage, saves equipment costs and increases benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com