Single stator framework, chain type motor stator and motor

A technology of stator frame and single body, which is applied in the fields of stator frame body, chain motor stator, and motor. It can solve the problems of large temperature rise of the motor stator, generation safety, and unreliable insulation performance, so as to increase the heat dissipation area and effectively The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

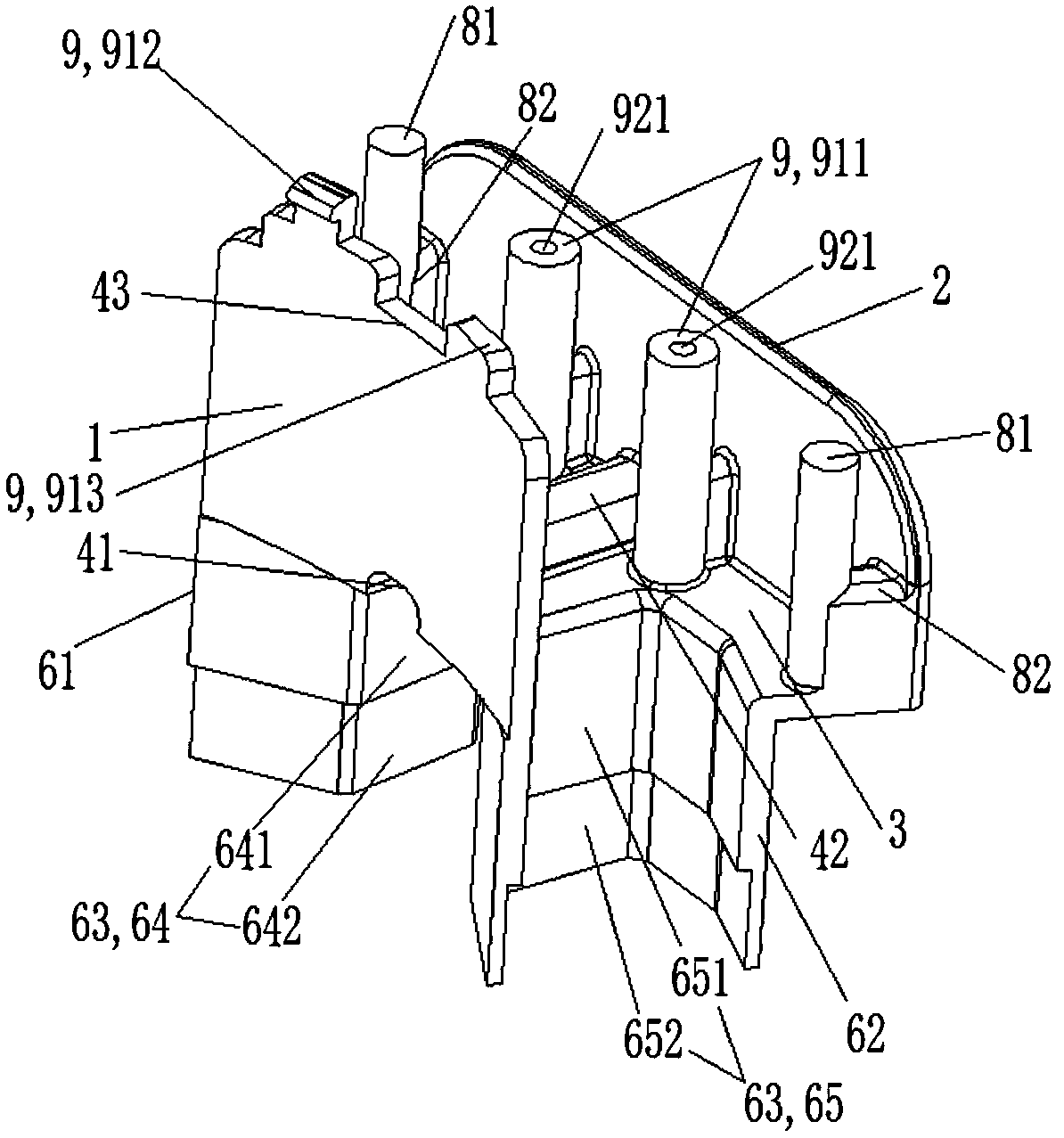

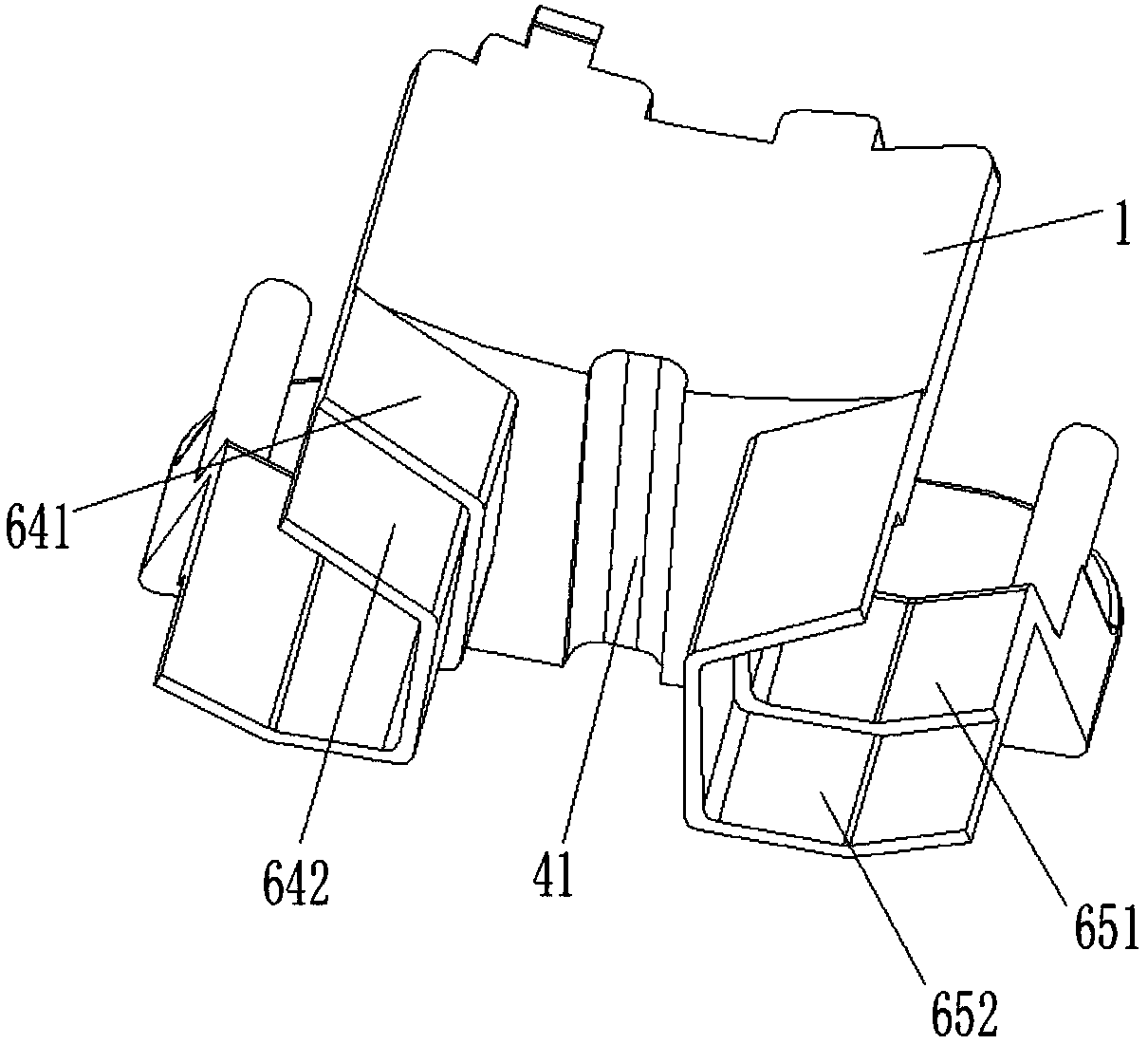

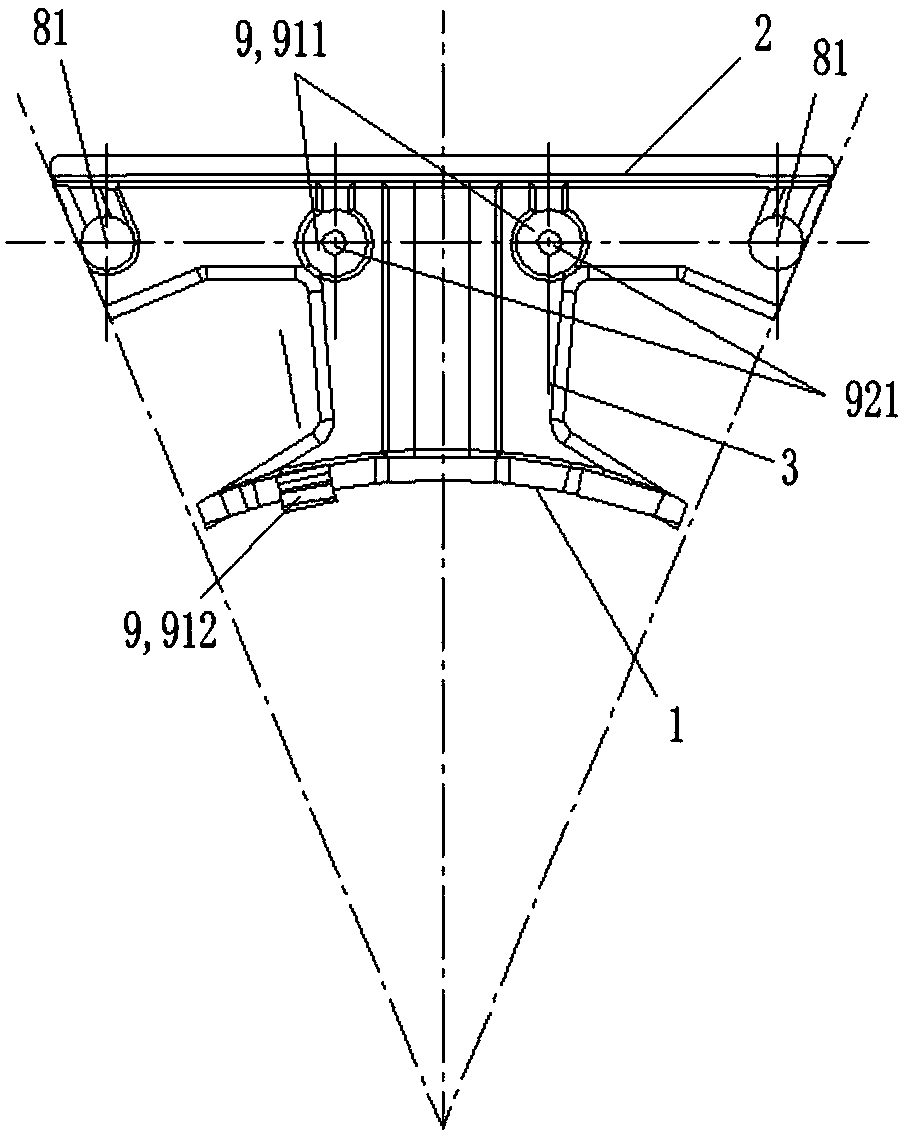

[0035] see Figure 1 to Figure 6 As shown, according to the embodiment of the present invention, a single stator skeleton is provided, including an inner ring wall 1, an outer ring wall 2, and a connecting wall 3 between the inner ring wall 1 and the outer ring wall 2. The ring wall 2 is disposed on the end surface of the stator core 104 , and the end surface of the stator core 104 is partially exposed on the outer peripheral side of the outer ring wall 2 . In this technical solution, since the outer ring wall 2 exposes the end face of the stator core 104 on the outer peripheral side of the outer ring wall 2, when the stator skeleton is assembled with the stator core 104 The exposed heat dissipation surface 105 is formed on the upper and lower end surfaces of the outer wall of the stator core 104. This method avoids that the stator core 104 in the prior art is embedded in the outer ring wall with a curved surface. , the problem of excessive temperature rise caused by the smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com