Distributed winding flexible transformer by mixed winding of magnetic conductive wire and electrical wire

A distributed winding and flexible transformer technology, applied in the field of transformers, can solve the problems of occupying the space of printed circuit boards, and achieve the effects of flexible overall structure design, good heat dissipation, and reduced copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

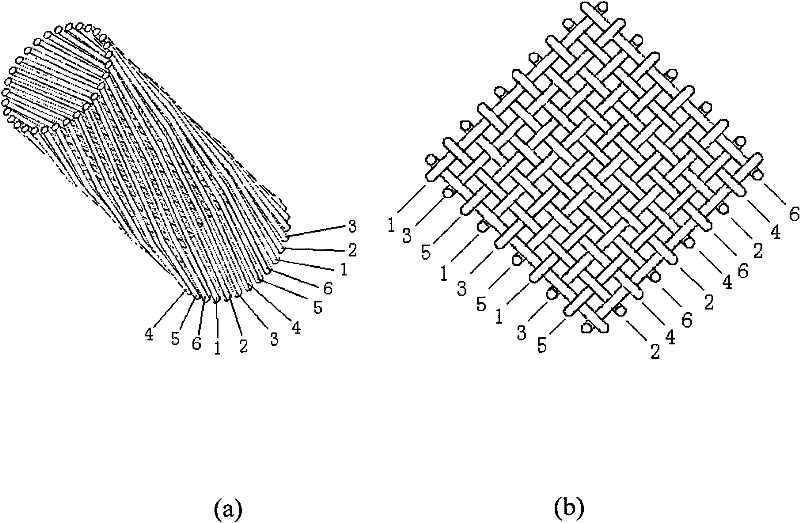

[0032] refer to figure 1 As shown, the coil winding method of the transformer adopts figure 1 (a) Structure shown. The primary winding copper wires of the coil and the secondary winding copper wires are arranged adjacently, that is, copper wires 1, 3, and 5 are primary winding wires, copper wires 2, 4, and 6 are secondary winding wires, and the two adjacent copper wires The wires belong to the primary winding and the secondary winding respectively, and the two separated copper wires belong to the winding of the same phase. The primary winding and the secondary winding are arranged circularly on the surface of the magnetic core in turn. In order to ensure that the coil is fixed on the surface of the magnetic core, the above-mentioned conductive copper wire is helically wound along the surface layer of the magnetic core, that is, the copper w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com