Method for calculating alternating-current motor stator winding coil parameters

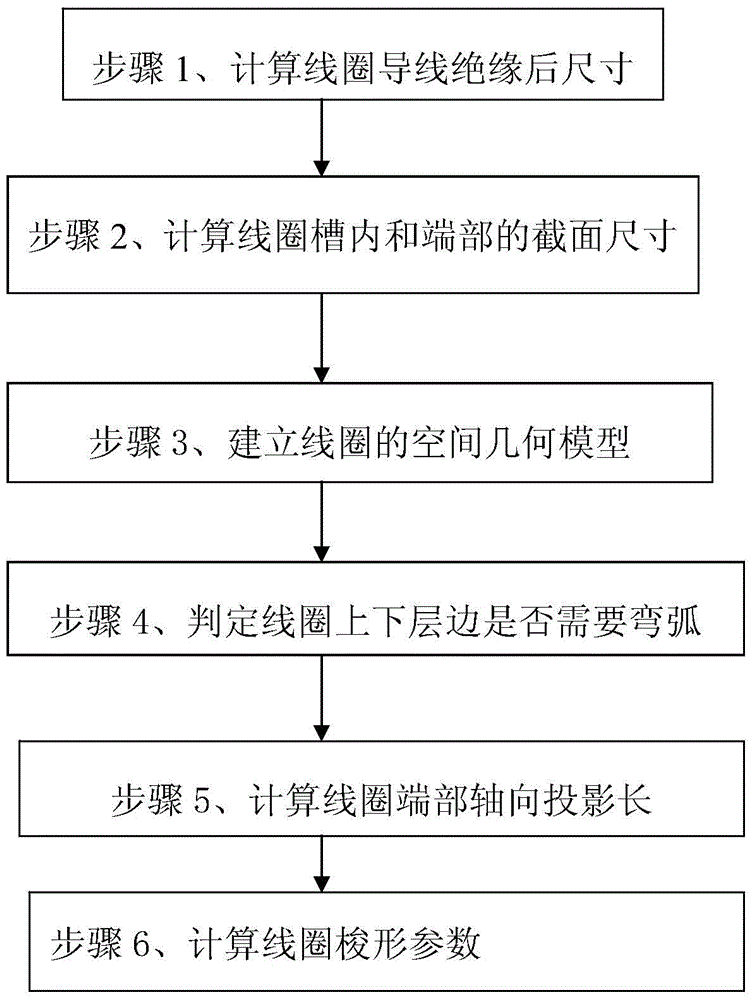

A technology for stator winding coils and AC motors, which is applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of cumbersome process, low calculation accuracy of coil end size, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135] The present invention will be further described below in conjunction with drawings and embodiments.

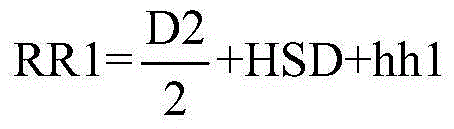

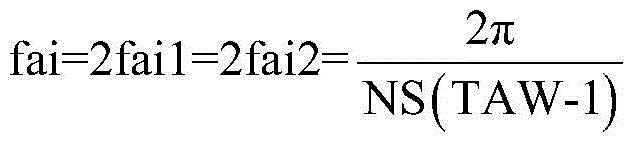

[0136] Referring to the attached drawings, according to the design and insulation process requirements of a certain type of motor, determine the known data: stator inner diameter D2 = 1180mm, iron core axial length LC = 1250mm, number of stator slots NS = 108, number of poles P = 12, coils in the slot The number of columns LIE=1, the number of coil turns N=8, the number of coil layers in the slot CENG=2, the thickness of the first type of bare wire WT1=8.2mm, the width WB1=3.35mm, the thickness of the first type of wire after inter-turn insulation WIT1 = 8.2mm, width WIB1 = 3.35, number of columns of the first type of wire NPD1 = 1, number of layers of the first type of wire in each turn of the coil NCD1 = 1, thickness of the second type of wire bare wire WT2 = 0mm, width WB2 = 0mm , the number of columns NPD2 = 0, the number of layers of the second type of wire in each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com