Wall tile pasting machine

The technology of a wall brick and a brick machine is applied in the field of wall brick tiling equipment, which can solve the problems of uneven tile bonding, unguaranteed tile quality, affecting the tile bonding effect, etc., so as to improve work efficiency and ensure tile quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

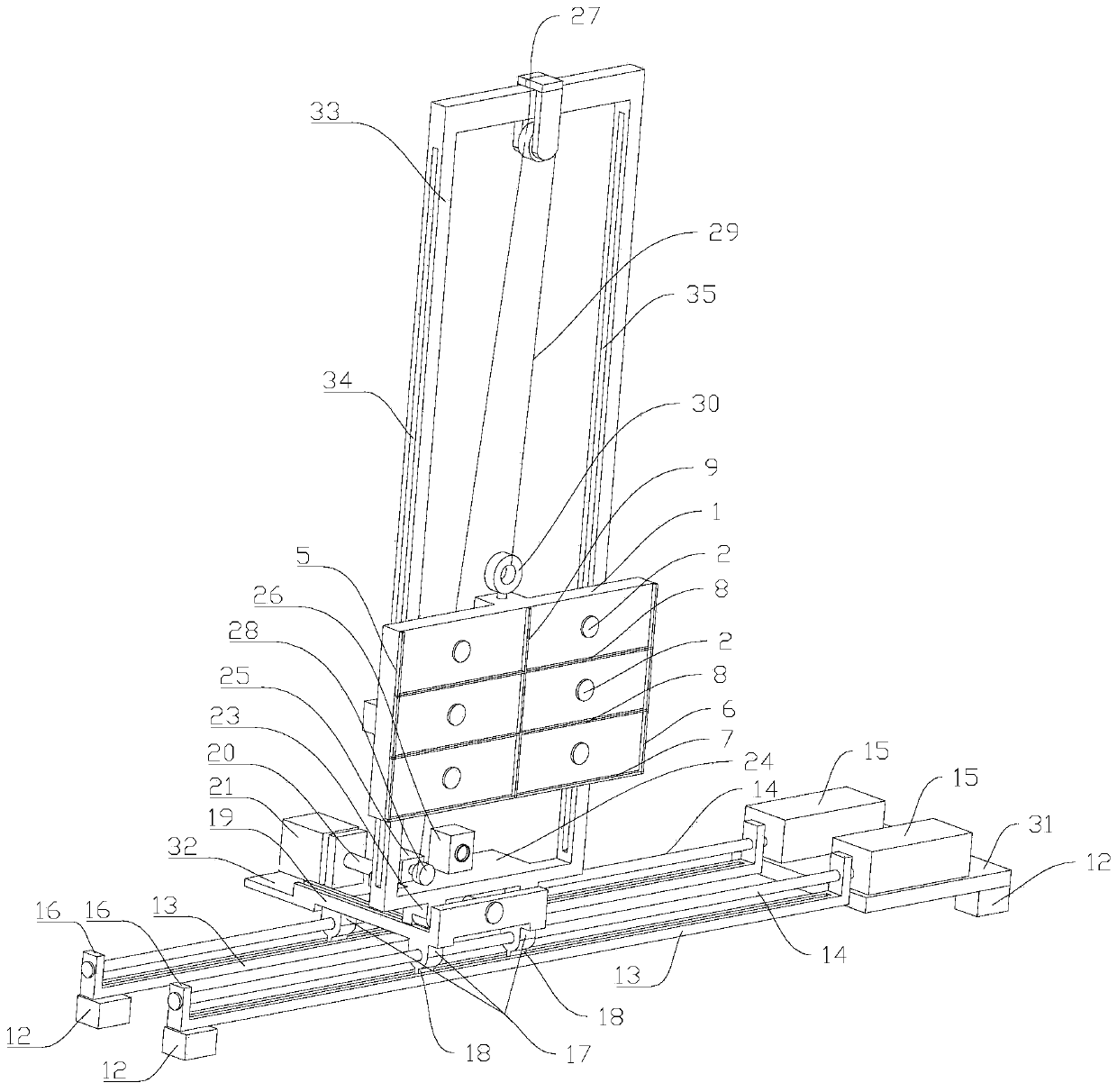

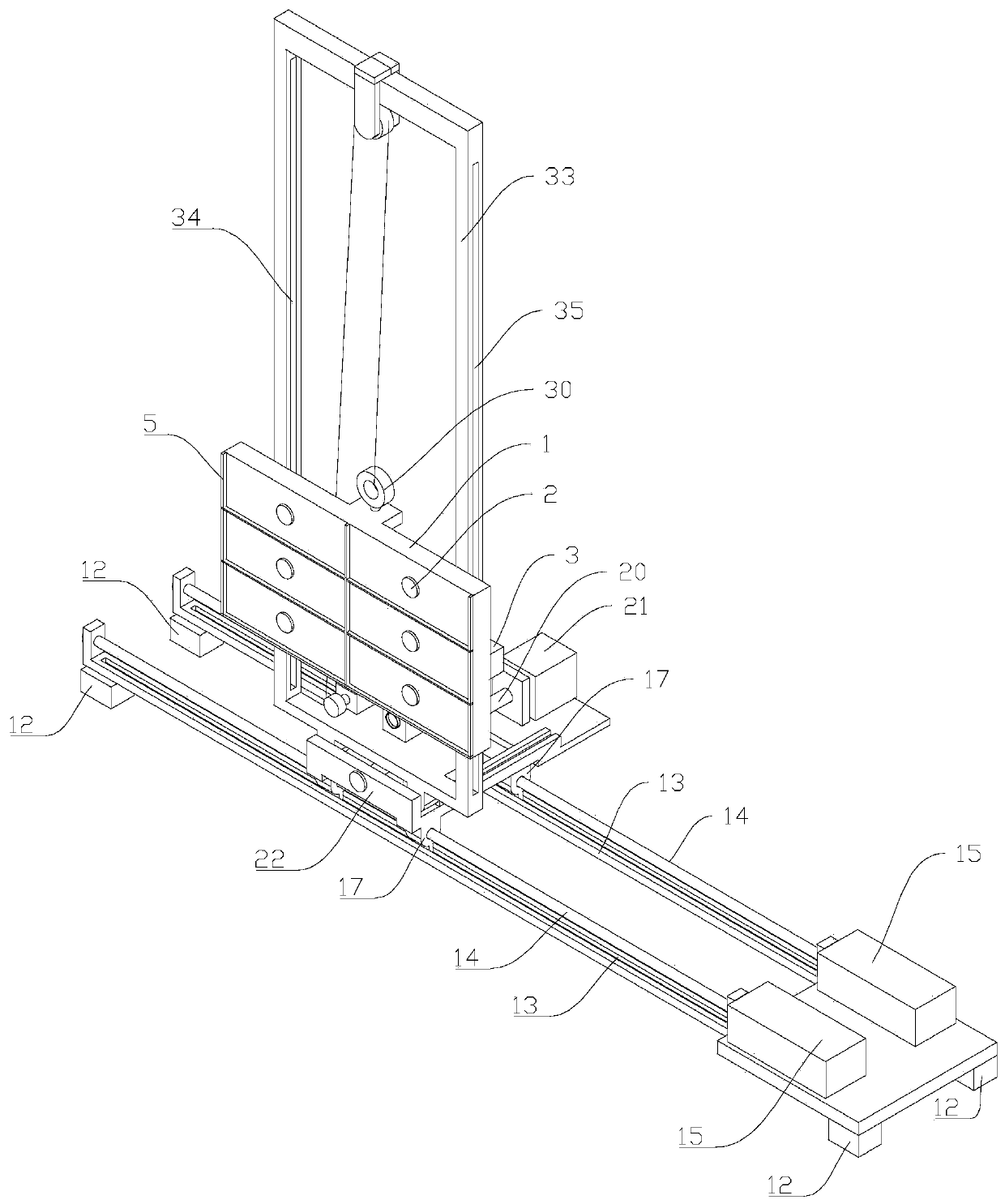

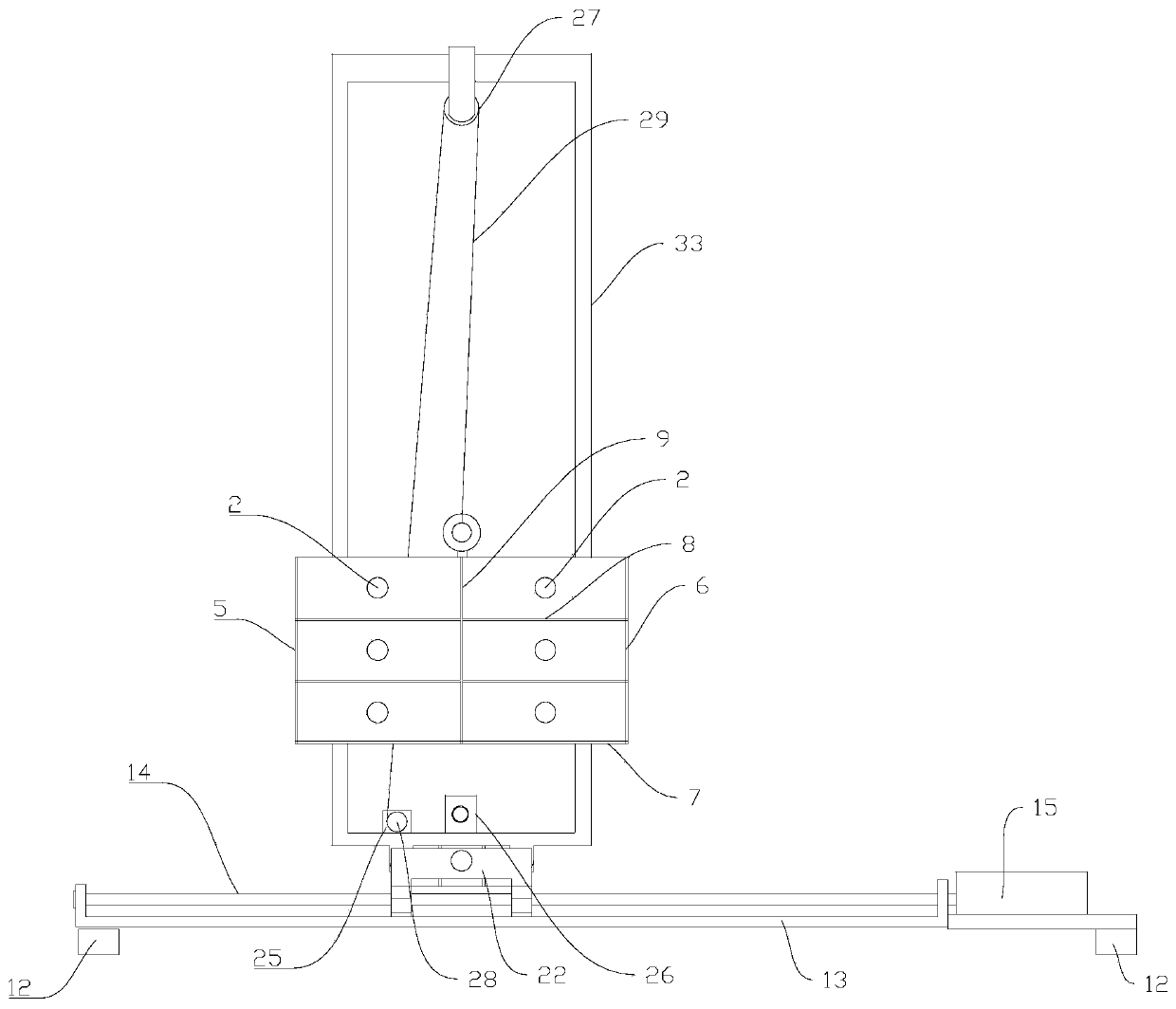

[0041] Such as Figure 1-Figure 8 As shown, the present embodiment provides a kind of wall tile tiling machine, comprises left and right moving frame, the forward and backward moving frame that moves left and right along the left and right moving frame and the elevating frame 33 that moves forward and backward along the front and rear moving frame, and elevating frame 33 is provided with A tile tiling mechanism that lifts and moves along the lifting frame 33; the tiling mechanism includes a base plate 1, spacers and suction cups 2, the side of the base plate 1 facing the wall is the tiling surface, and the base plate 1 is provided with multiple spacers, and the multiple spacers The spacer strip forms a plurality of wall tile placement areas on the tile-laying surface of the base plate 1, and the wall tile placement areas are provided with suction cups 2 for absorbing wall tiles.

[0042] The adjustment and positioning of the position of the whole tile tiling mechanism on the h...

Embodiment 2

[0048] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0049] A vibrator 3 is provided on the back surface of the substrate 1 .

[0050] Specifically, the vibrator 3 is a micro-vibrator 3 , and there are two micro-vibrators 3 which are respectively arranged on the left and right sides of the back surface of the substrate 1 .

[0051] The traditional way of vibrating through the vibrator 3 is to vibrate after the plastering is completed and the wall tiles are pasted. In the technical solution, the vibrator 3 is installed on the back of the base plate 1, and after the tile tiling mechanism moves to the set position, the vibrator 3 is started during the process of pouring the mortar, which can ensure the uniformity of the mortar entering. The vibration process, Since the gap between the wall brick and the wall determines the amount of mortar poured, each time the tiling mechanism maintains an equidistant gap with the wall, the amount ...

Embodiment 3

[0053] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0054] In order to ensure that an effective wall brick placement area is formed between the wall brick and the wall surface, the heights of the spacers are all equal, and the heights of the spacer strips are all smaller than the thickness of the wall bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com