Production method for electric device assembly and electric device assembly

A connection structure and electrical connection technology, applied in the direction of conductive connection, structural parts, battery pack components, etc., can solve the problems of increased weight of connecting components, high manufacturing cost, expensive battery modules or battery packs, etc. Heat dissipation effect, ease of manufacturing process, and simplification of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

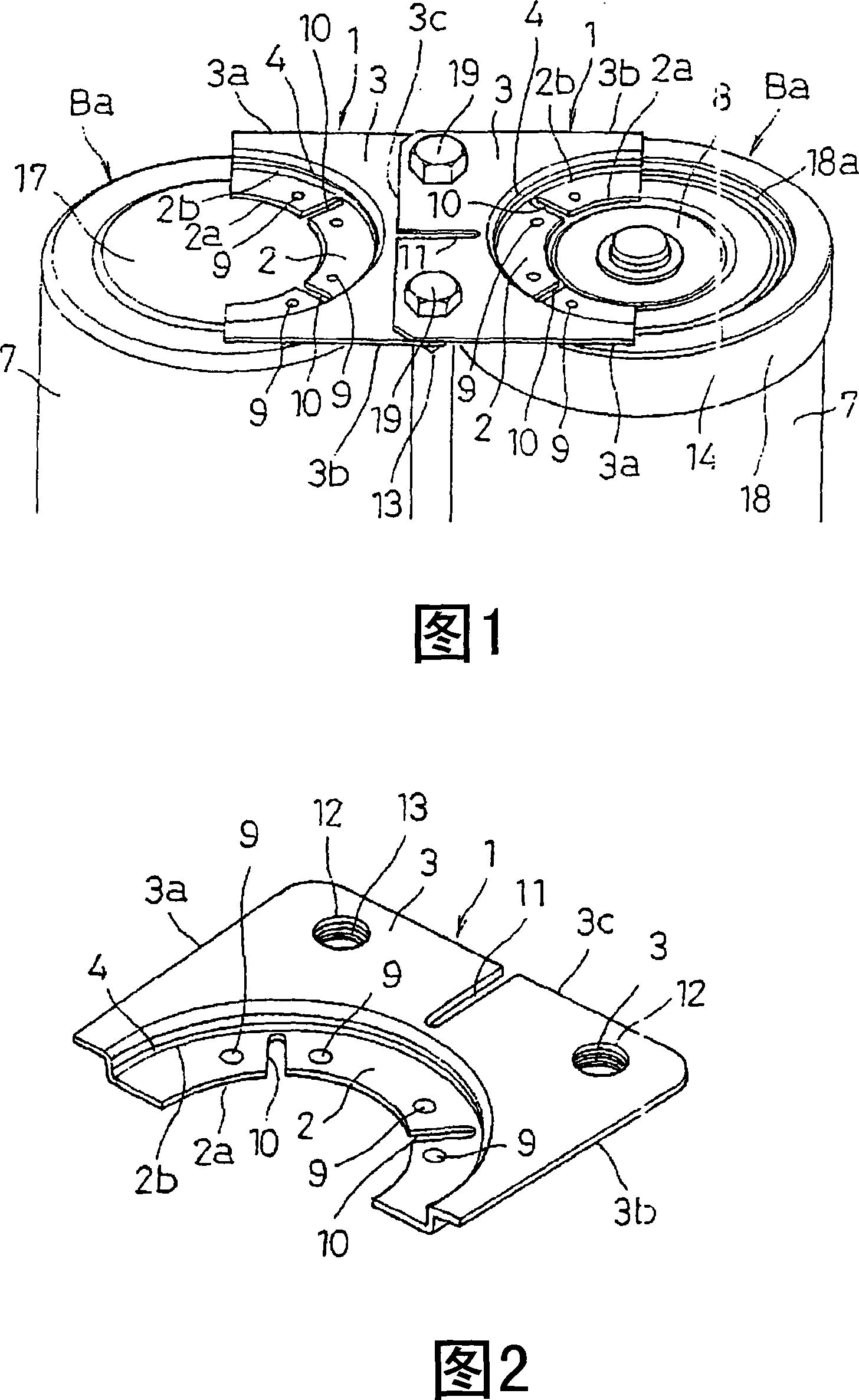

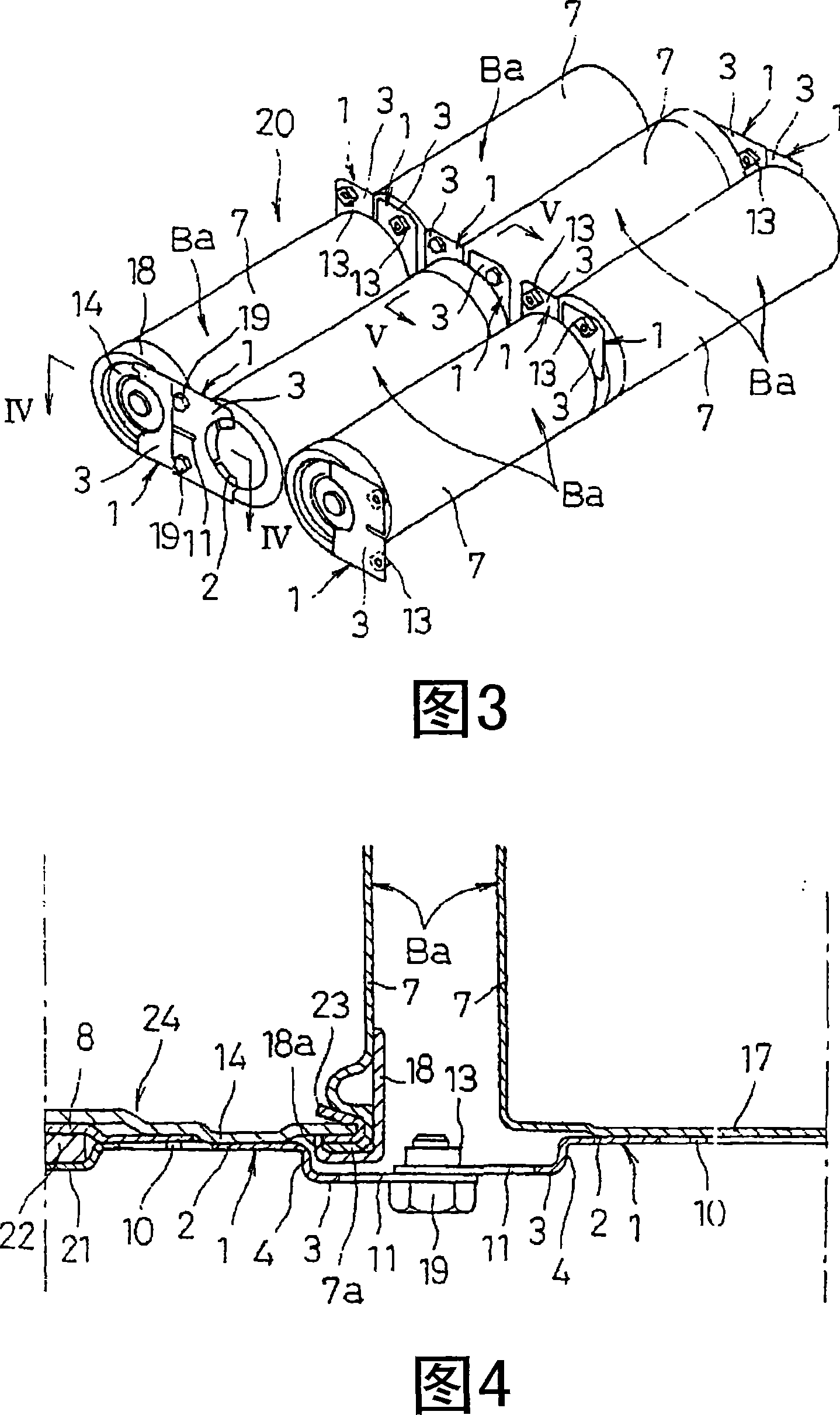

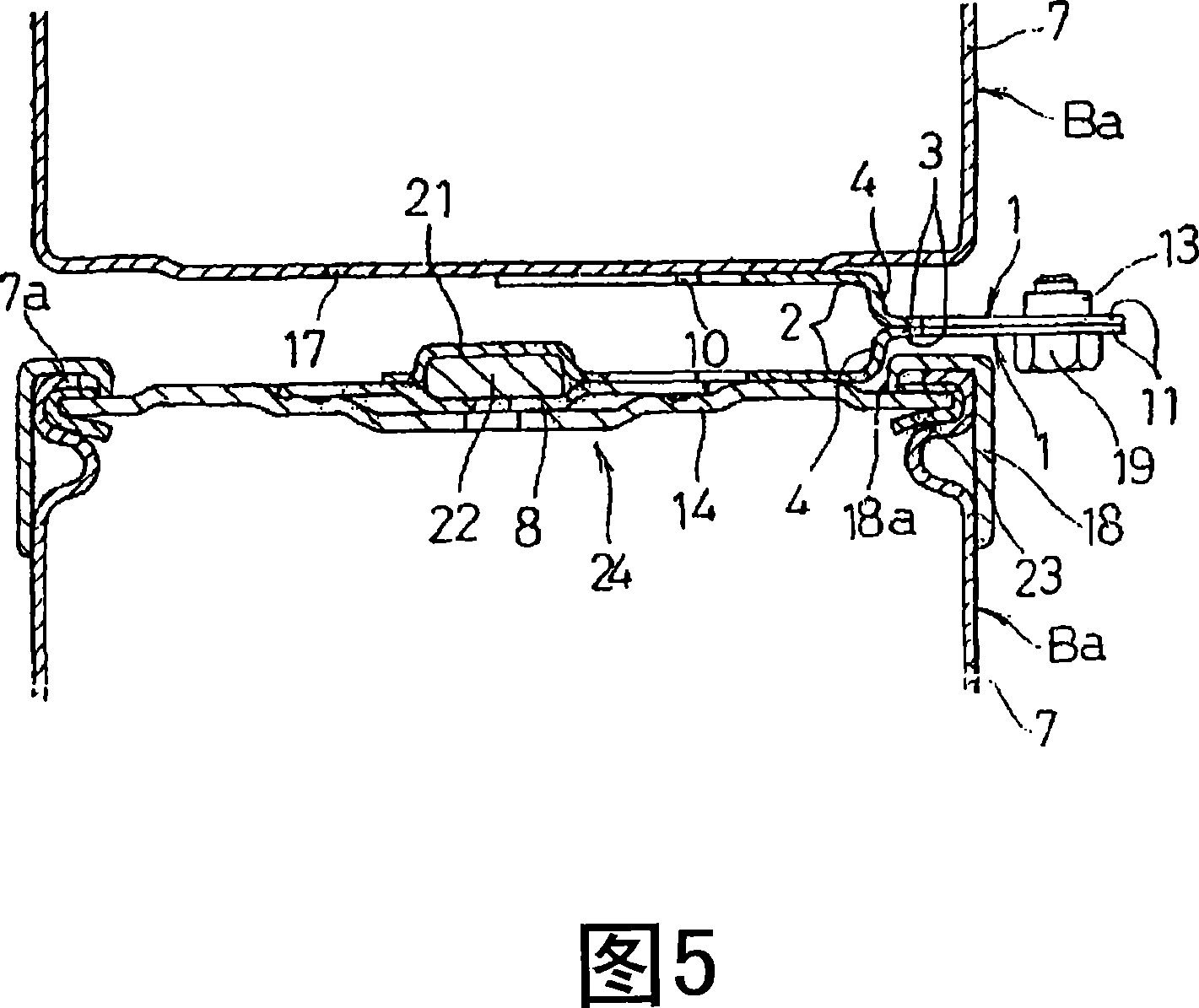

[0039] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a perspective view showing a connection structure of an inter-battery connection structure according to an embodiment of the present invention, and FIG. 2 is a perspective view showing an inter-battery connection plate 1 used for the connection. First, the inter-battery connection plate 1 of FIG. 2 will be described. This inter-battery connection plate 1 has a shape that integrally connects the welding portion 2 fixed to the battery case 7 by welding means and the connecting portion 3 extending from the welding portion 2 via a step portion 4, and the welding portion 2 is relatively connected to the connecting plate 1. Part 3 is a recess.

[0040] The welding portion 2 has a semicircular shape included in the circular end surface of the battery case 7 of the battery Ba shown in FIG. 1 . Specifically, it has a shape as follows: a semicircular inner per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com