Patents

Literature

90results about How to "Full cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

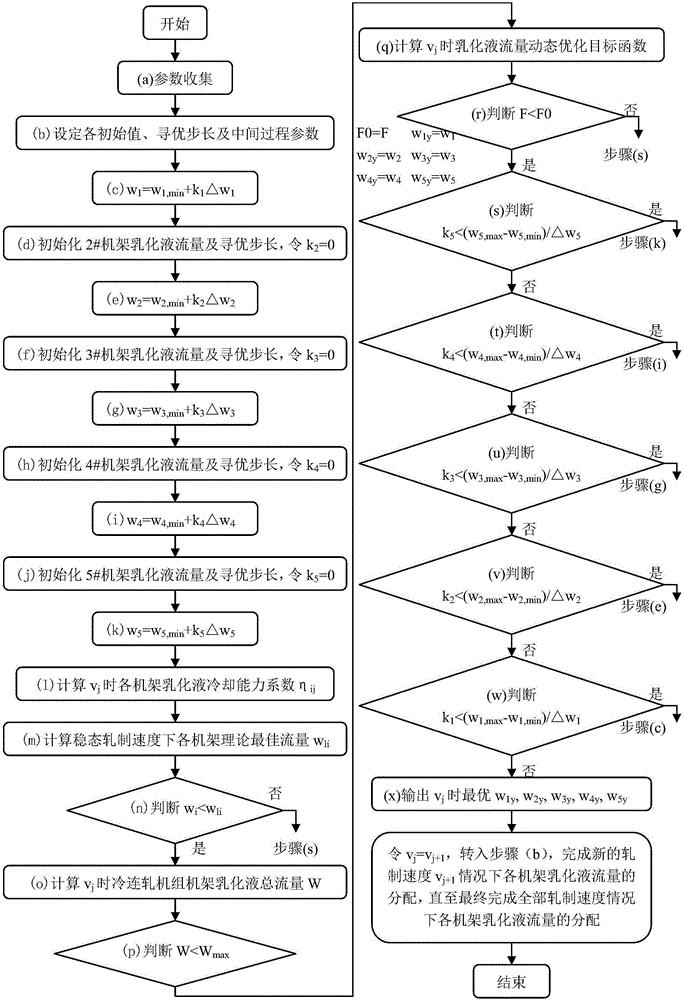

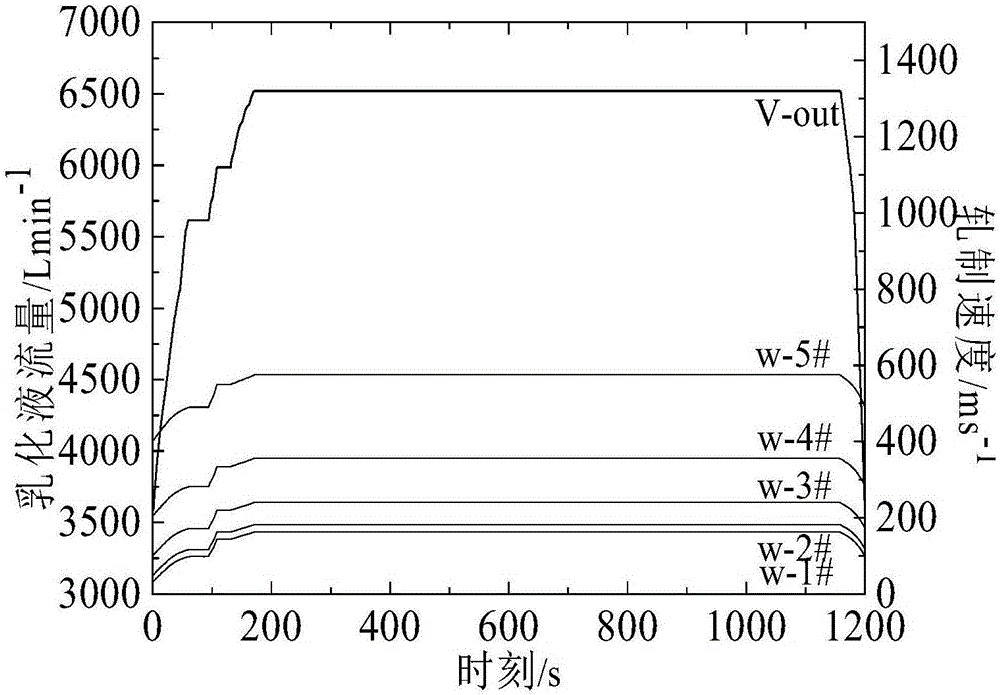

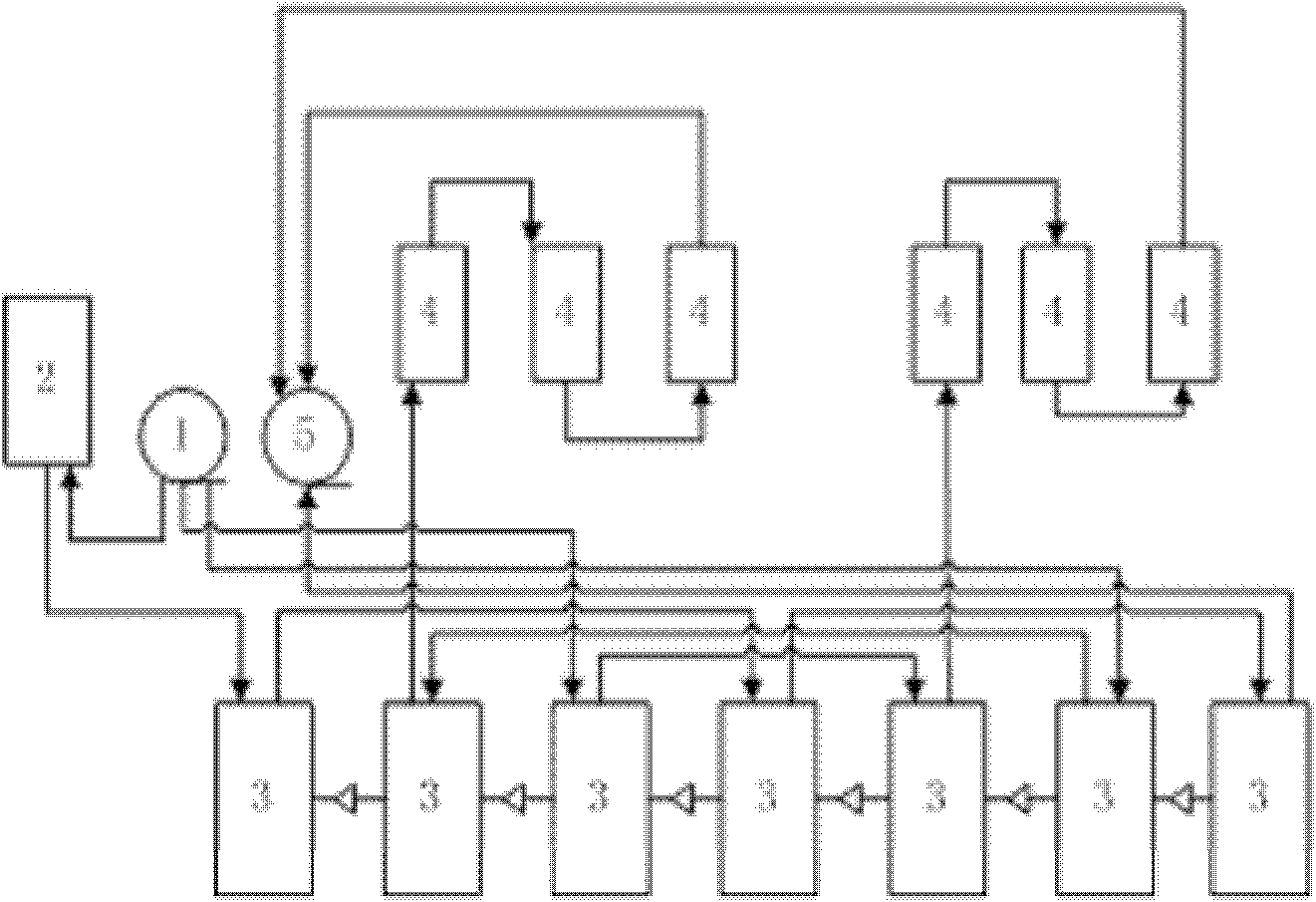

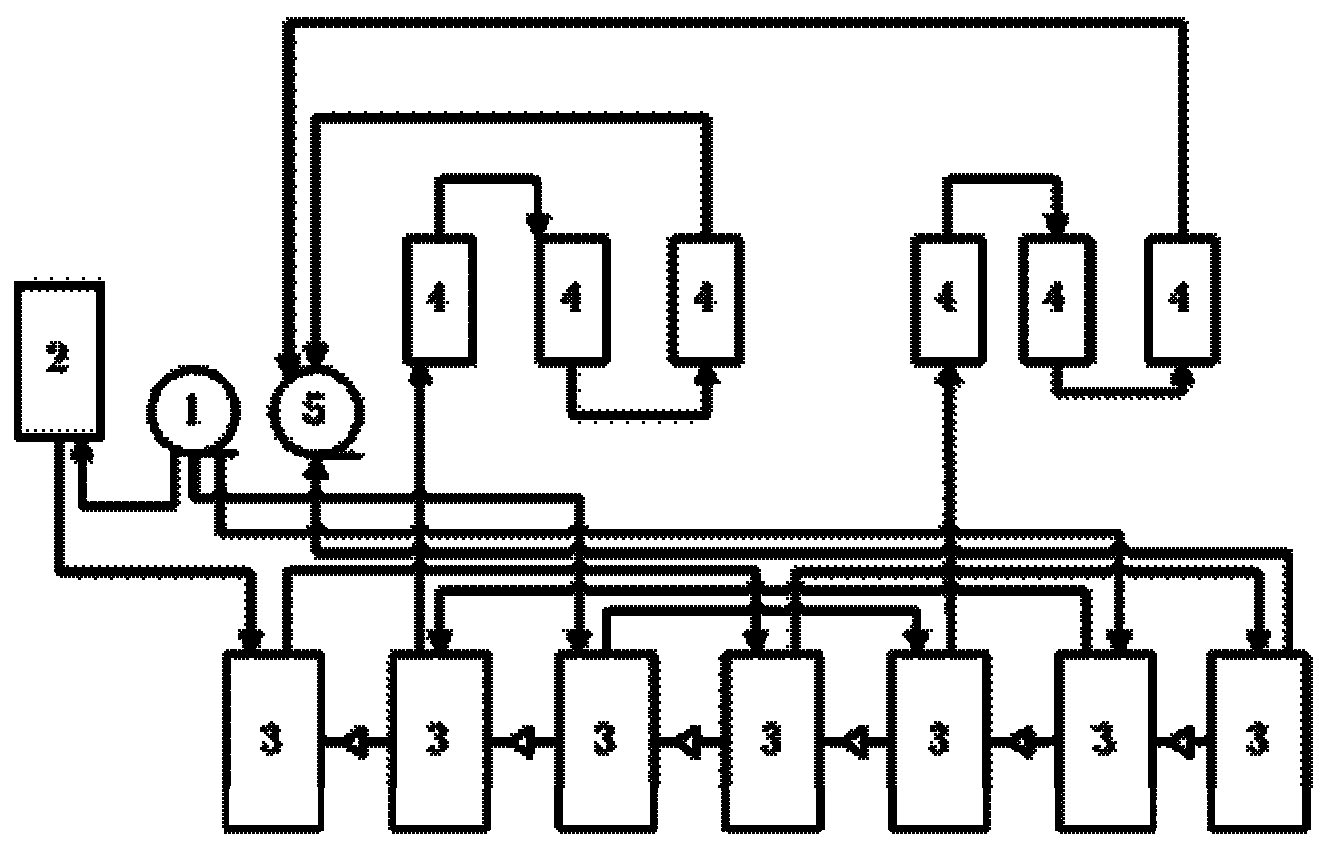

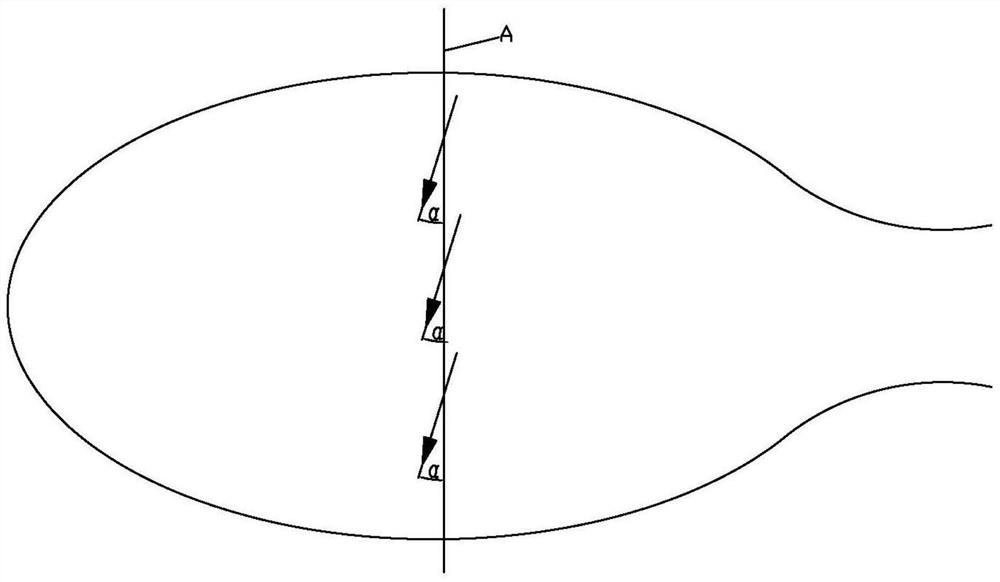

Emulsified liquid flow dynamic and comprehensive optimization setting method suitable for cold continuous rolling unit

ActiveCN106311754AFull cooling effectUniform cooling effectMass flow control deviceMetal rolling arrangementsEngineeringCooling capacity

The invention relates to an emulsified liquid flow dynamic and comprehensive optimization setting method suitable for a cold continuous rolling unit. The method mainly comprises the following steps that (1) parameters are collected; (2) initial values, optimizing step sizes and middle process parameters are set; (3) the flow and the optimizing step sizes of emulsified liquid of a No.2 rack, a No.3 rack, a No.4 rack and a No.5 rack are defined; (4) cooling capacity coefficients of the emulsified liquid of the racks are calculated; (5) the theoretical optimal flow of the racks at the steady rolling speed is calculated; (6) the total flow of the emulsified liquid of the racks is calculated; (7) an emulsified liquid flow dynamic and comprehensive optimization objective function is calculated; (8) the optimal flow of the emulsified liquid of the racks is output; and (9) distribution of the flow of the emulsified liquid of the racks at the new rolling speed is completed till distribution of all the flow is completed. According to the method, the problems that due to fixed distribution of the flow of the emulsified liquid between the racks, the rolling pressure is increased abnormally, and the rolling pressure is inverted are avoided; the cooling capacity of the emulsified liquid is given full play, and the cooling capacity of the emulsified liquid of the racks is more uniform; and the production stability is improved.

Owner:唐山市榕泽钢铁加工有限公司

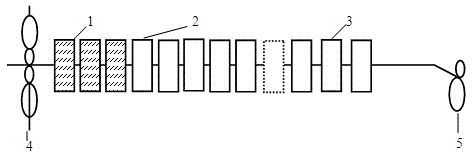

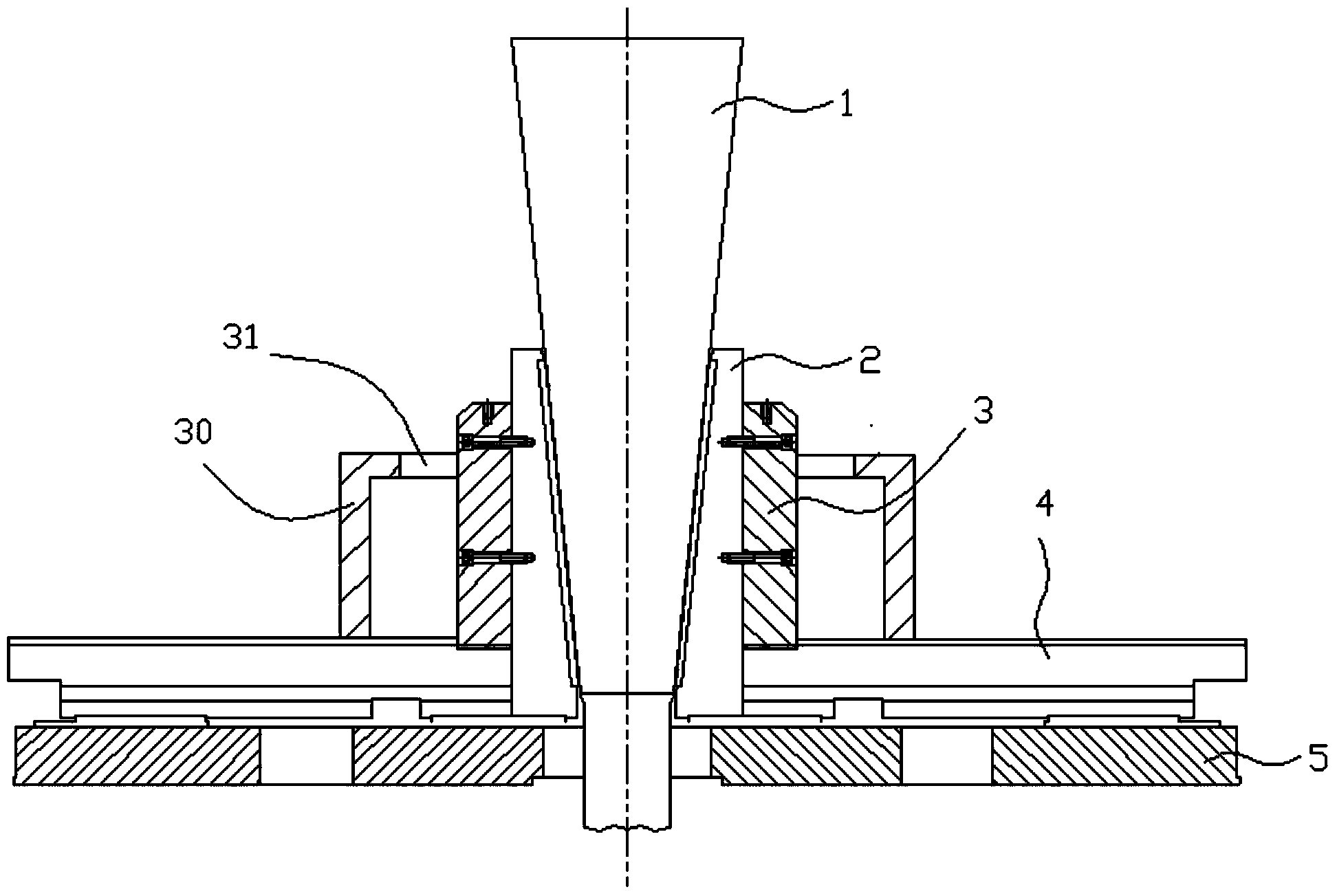

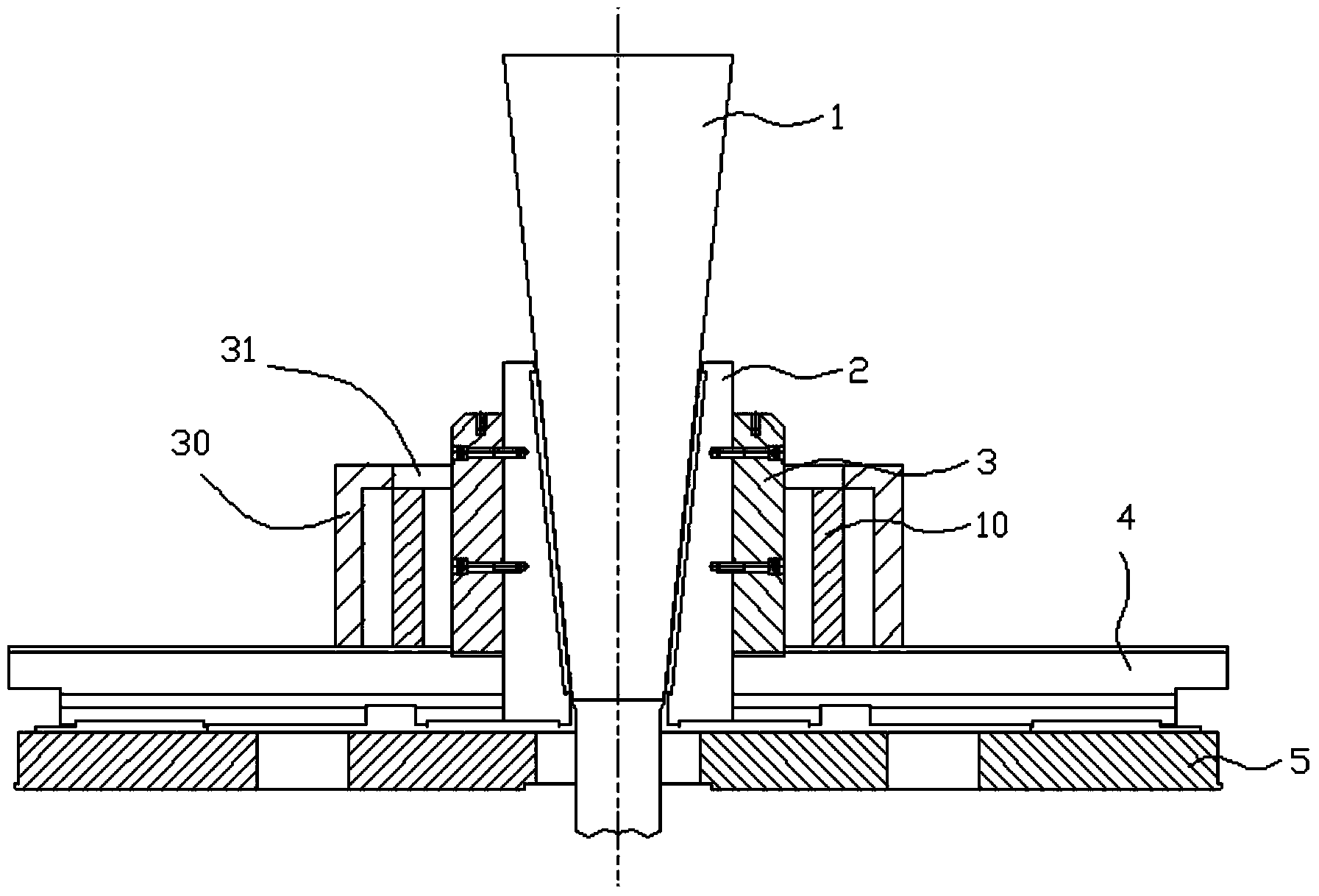

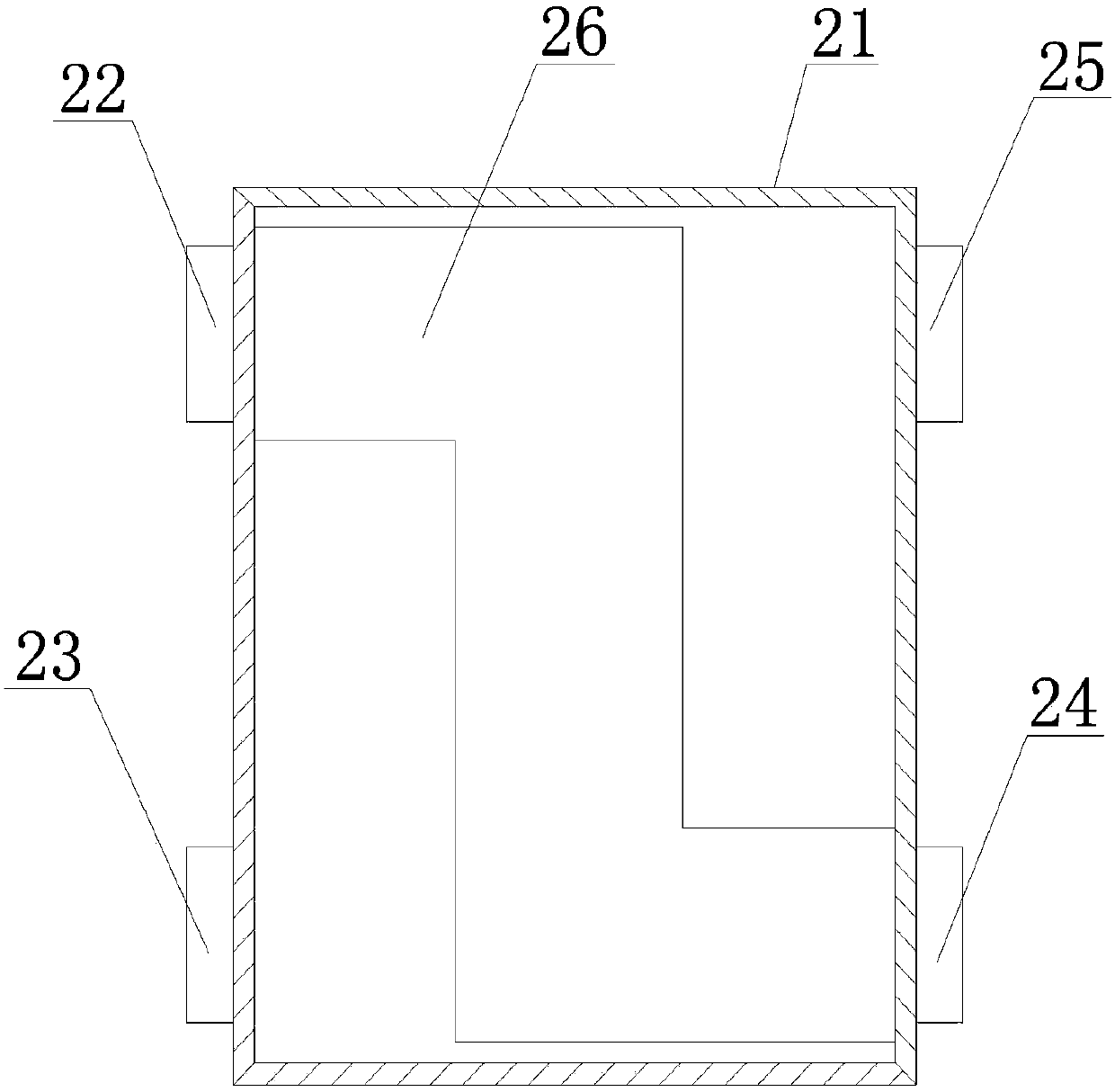

Novel water pipe structure for high voltage direct current converter valve

ActiveCN102163909ACool evenlyFull cooling effectCooling/ventilation/heating modificationsPower conversion systemsElectricityElectrical resistance and conductance

The invention relates to the technical field of a water cooling system in power electronics, in particular to a novel water pipe structure for a high voltage direct current converter valve. The water pipe structure comprises a water inlet, a saturated reactor, a thyristor radiator, a damp resistor and a water outlet; the water pipe structure is formed by connecting three independent cooling branches of a first branch, a second branch and a third branch in parallel; and each of the independent cooling branches is connected with each other in series. In the invention, the direct current converter valve is designed into a mixed distribution way of parallel and series connection; through reasonably matching flow resistance and thermal resistance of thermal elements, under the condition of acquiring excellent heat exchange conditions, the flowing resistance of the a water system is increased a little; simultaneously, the water system has excellent electric insulated property; the number of water joints is reduced; and the leaking probability is reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

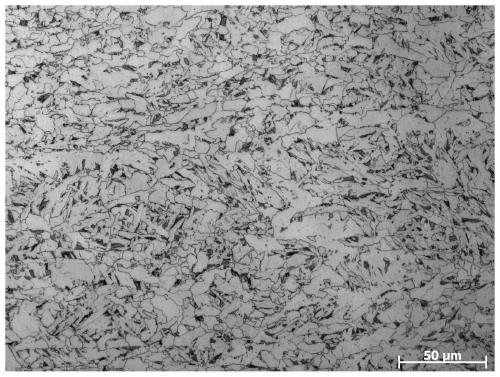

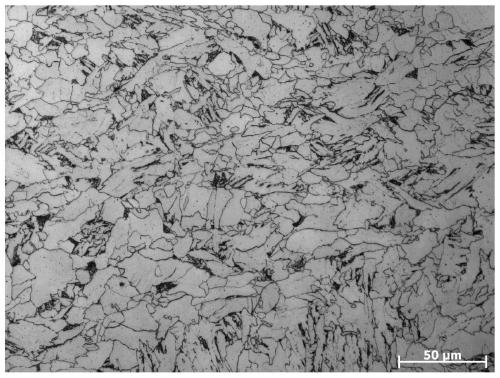

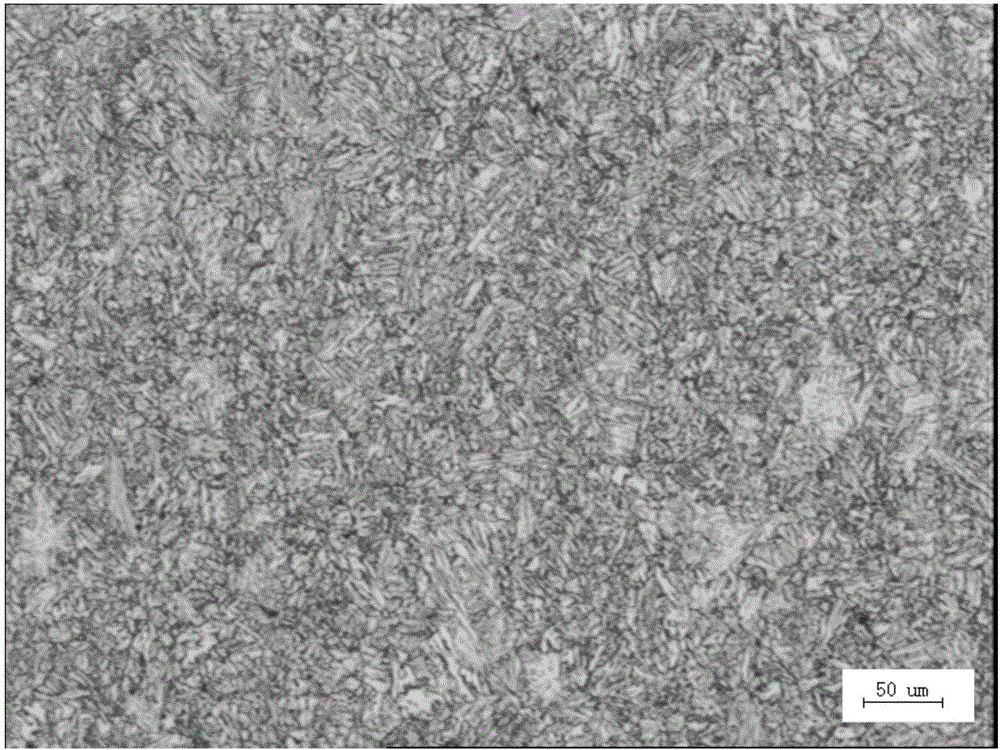

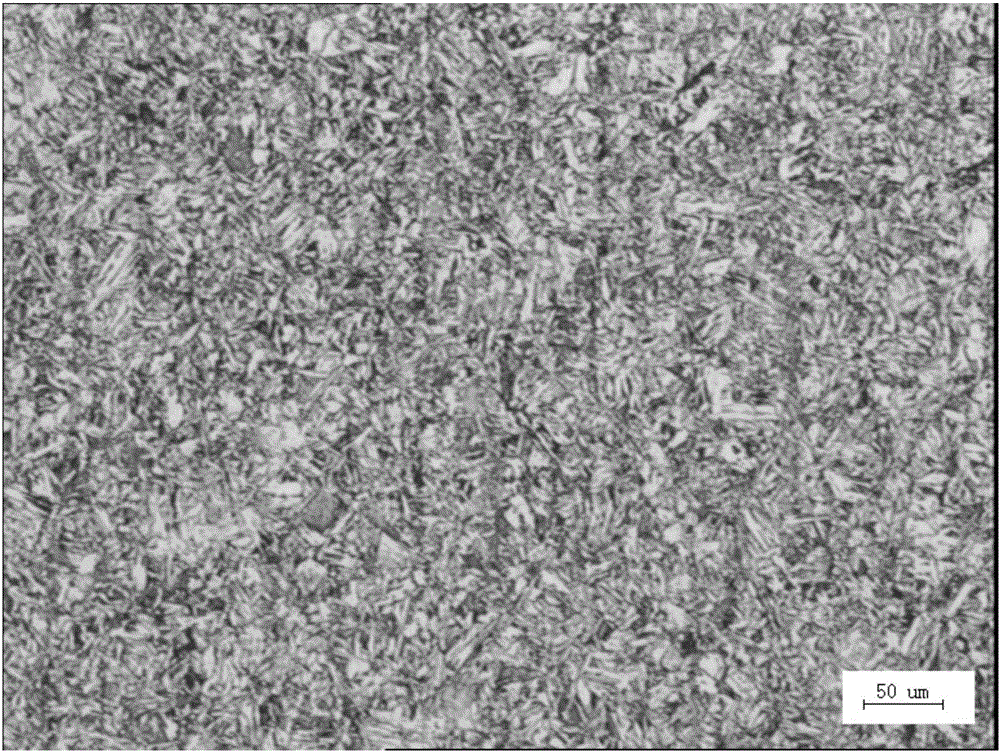

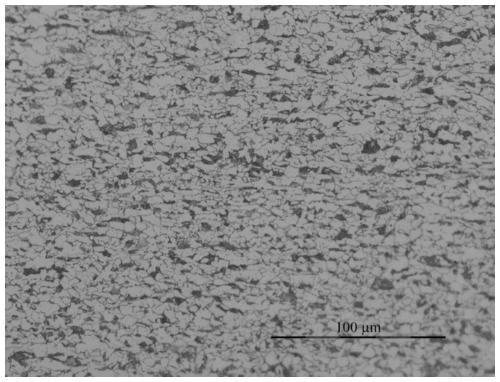

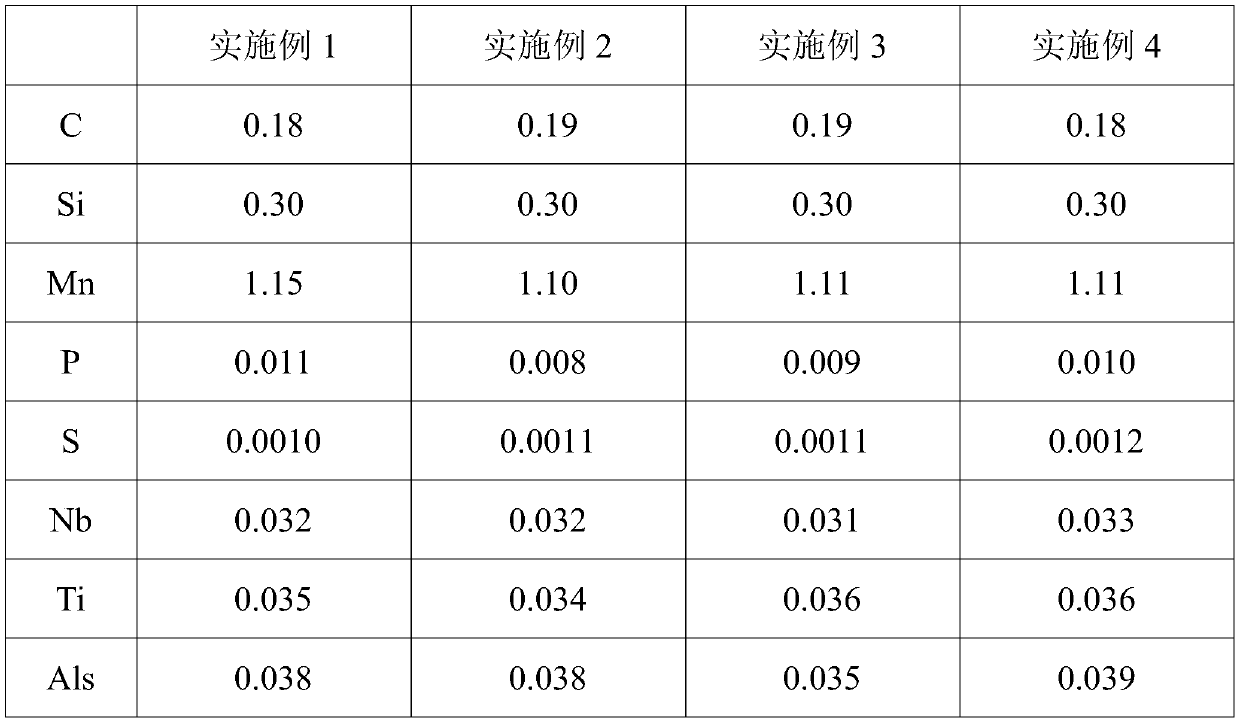

Large-thickness high-toughness steel plate and production method thereof

The invention relates to a large-thickness high-toughness steel plate and a production method thereof. The large-thickness high-toughness steel plate comprises the chemical composition, by mass: C: 0.03-0.07%, Si <= 0.10%, Mn: 1.40-1.60%, P <= 0.015%, S <= 0.010%, Nb: 0.040- 0.050%, Ti: 0.010-0.020%, Cr: 0.20-0.30%, Ni: 0.05-0.15%, Cu: 0.15-0.25%, Alt: 0.020-0.050%, N <= 0.005% and the balance iron and inevitable impurities, and meanwhile the formulas: Cr*7 <= Mn + Cr <= (Mn + Cr + Ni + Cu) * 0.9 and 1.8 <= Cu / Ni <= 2.8 are met. Through reasonable component design and a TMCP controlled rollingand controlled cooling process in a matched mode, the prepared steel plate is good in mechanical property and welding property and wide in application field.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

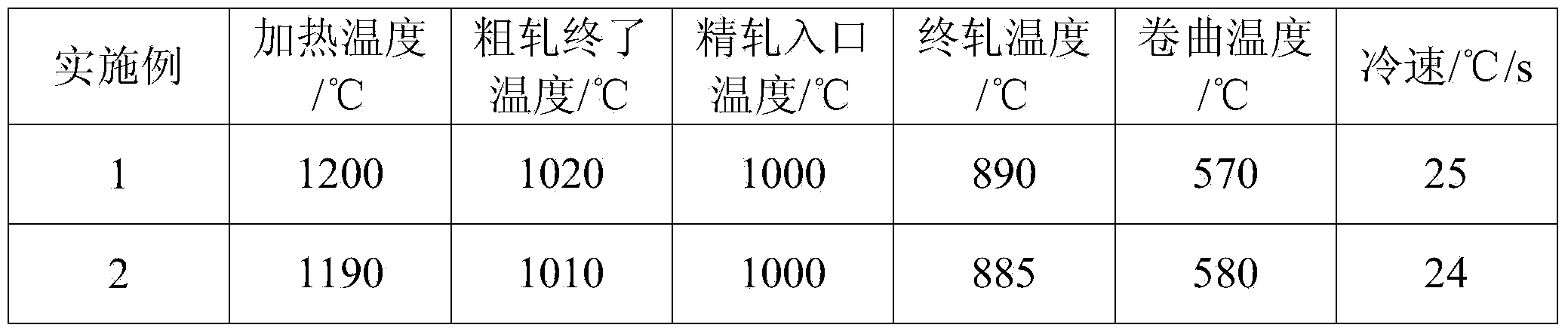

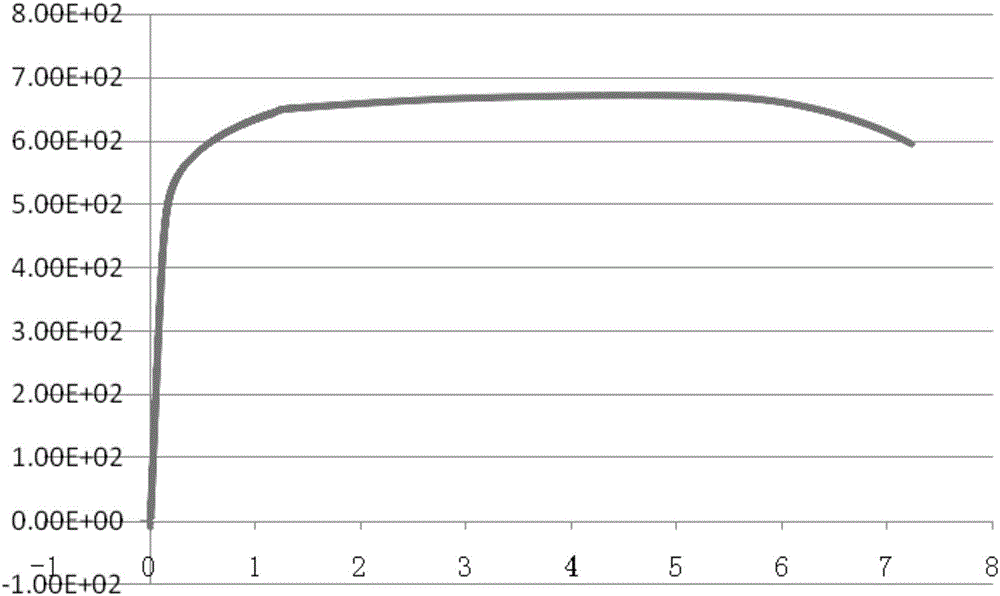

Manufacturing method of high-toughness hot-rolled plate coil for welded gas cylinder

The invention discloses a manufacturing method of a high-toughness hot-rolled plate coil for a welded gas cylinder. The hot-rolled plate coil comprises the following components in percentage by weight: 0.045-0.095% of carbon, 0.20-0.28% of silicon, 1.30-1.50% of manganese, less than or equal to 0.015% of phosphorus, less than or equal to 0.005% of sulfur, 0.020-0.050% of niobium, 0.015-0.030% of titanium, 0.035-0.040% of aluminum and the balance of iron and trace impurities; and the manufacturing technology of the hot-rolled plate coil comprises the steps of smelting, pretreatment of molten iron, refining in an LF furnace, continuous casting, heating, rolling and coiling. In the method disclosed by the invention, the three key links from composition design, rolling to smelting are strictly controlled; and the yield strength of the obtained hot-rolled plate coil is 350-500MPa, the tensile strength is 510-600MPa, the ratio of the yield strength to tensile strength is less than or equal to 0.80, the Charpy impact energy at -20 DEG C is 150J, and the Charpy impact shear area (SA%) at -20 DEG C is 100%.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

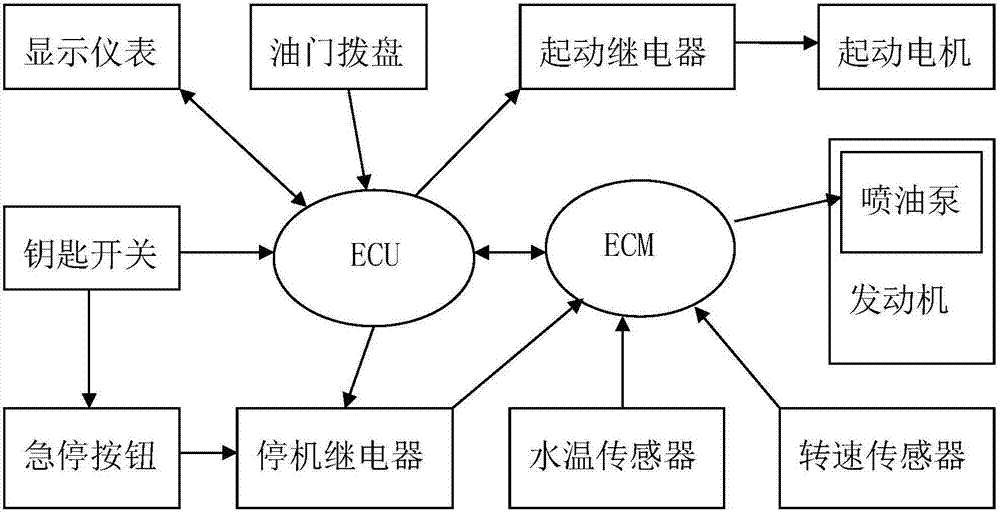

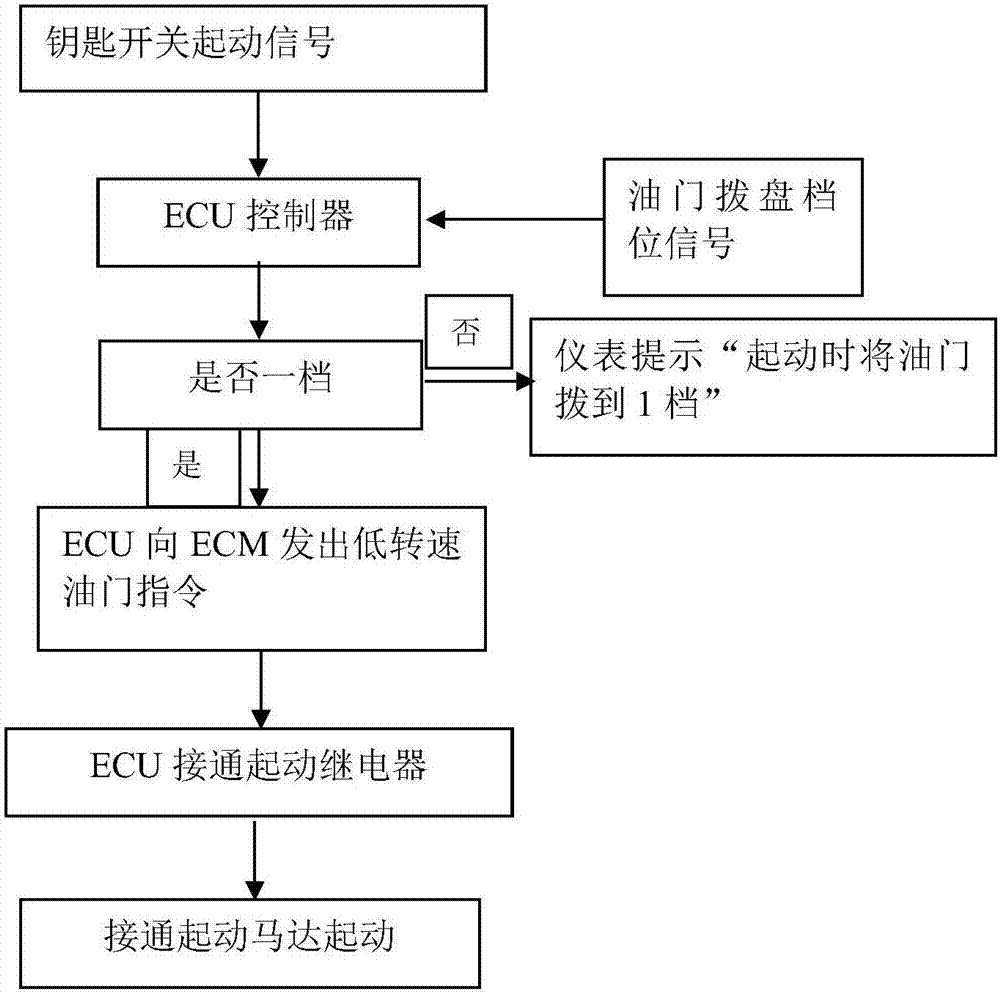

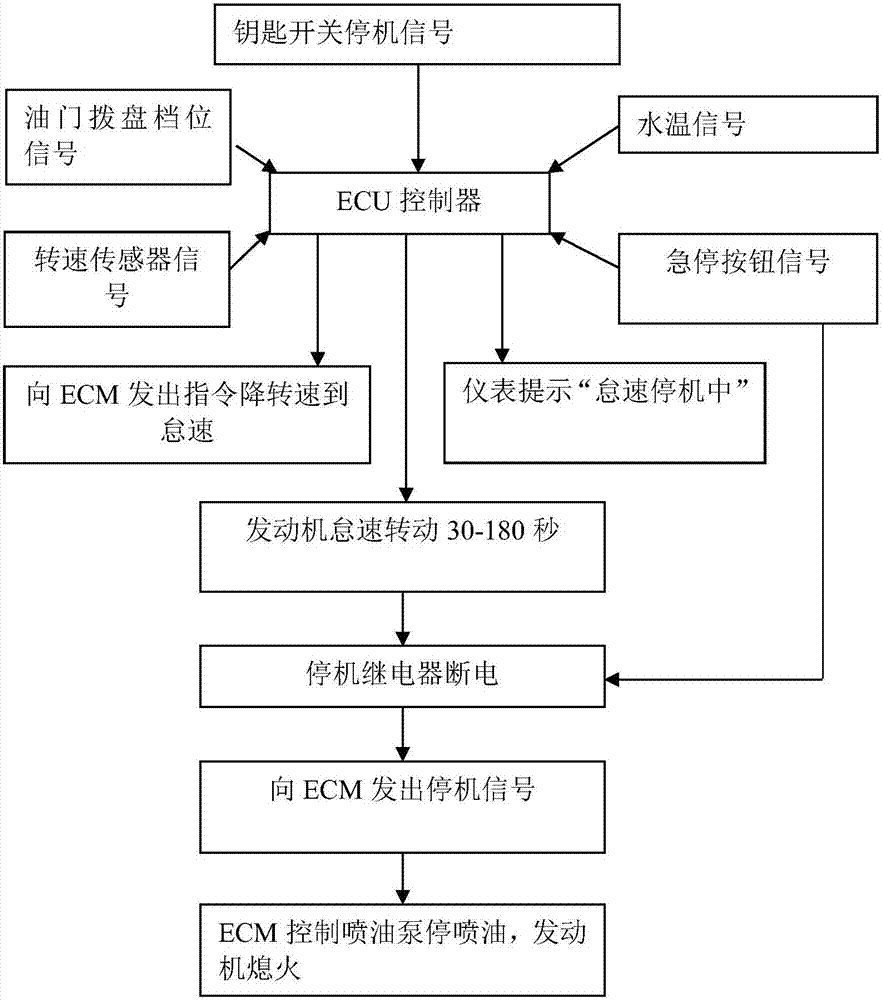

Starting and stopping control system and control method for electronic fuel injection engine of excavator

ActiveCN107461268AReduce the risk of accidentsAvoid damageEngine controllersMachines/enginesControl signalEngineering

Disclosed is a starting and stopping control system for an electronic fuel injection engine of an excavator. The starting and stopping control system comprises an engine, an ECM, an ECU, a display instrument, a key switch, a revolving speed sensor, a water temperature sensor, a throttle dial, a starting relay, a stopping relay and a starting motor. The throttle dial is connected with the ECU. The key switch is connected with the ECU through a wire. The display instrument is connected with the ECU. The ECU is connected with the ECM.A control signal is sent to the ECM. The ECM is connected with the stopping relay, the water temperature sensor and the revolving speed sensor. The engine is connected with the ECM. The starting motor and the starting relay are connected. According to the starting and stopping control system, by controlling starting and stopping of the electronic fuel injection engine of the excavator, accidents such as journal sticking tile burning, piston scraping and piston seizure of the engine caused by poor lubrication and high temperature if the engine is started or stopped at a high throttle position are avoided, and the service life of the engine is prolonged advantageously; in addition, by additionally installing an emergency stopping device, so that stopping can be conducted immediately through an operator in an emergency situation, and accident risks of in the process of operating the excavator are reduced.

Owner:GUIZHOU JONYANG KINETICS

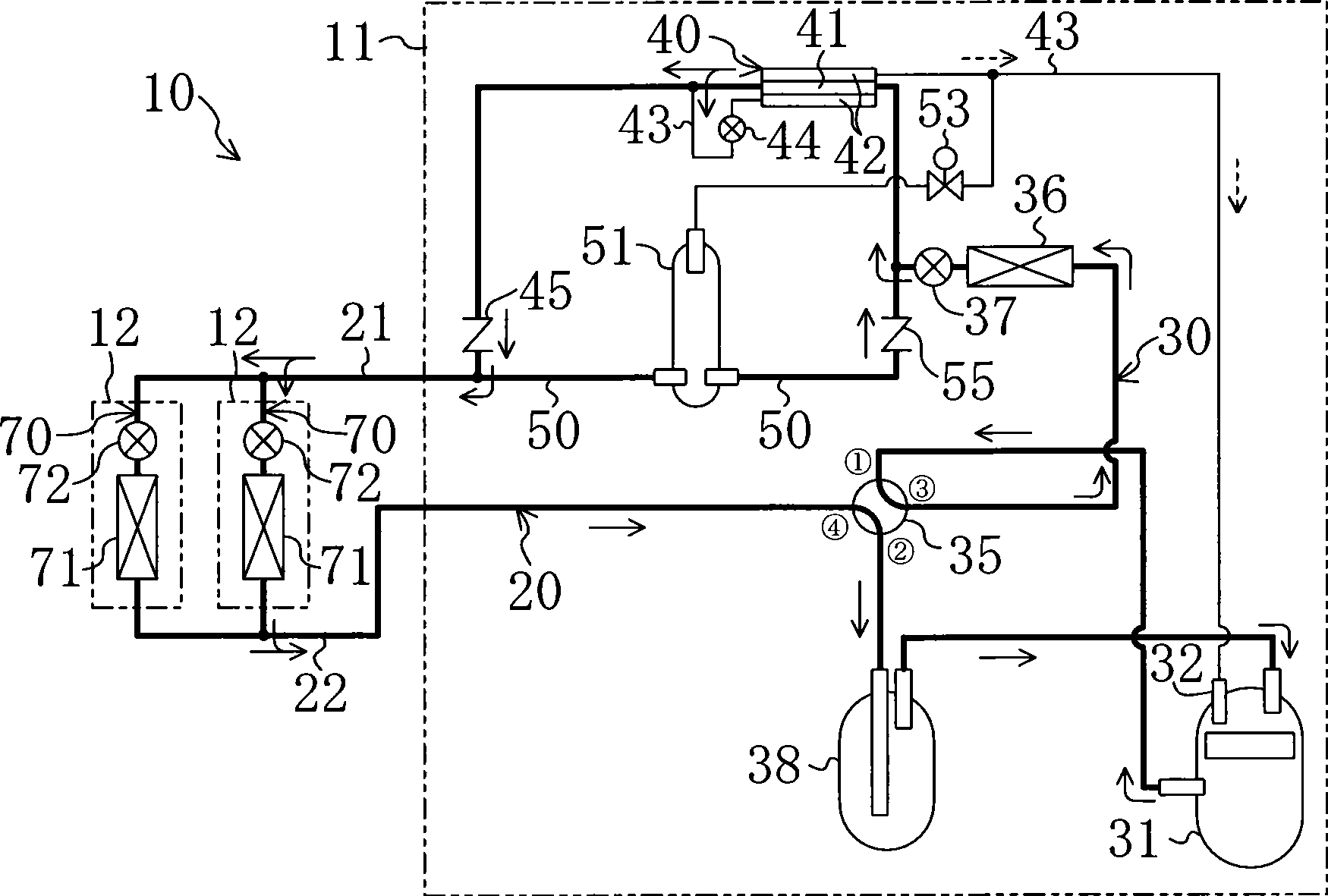

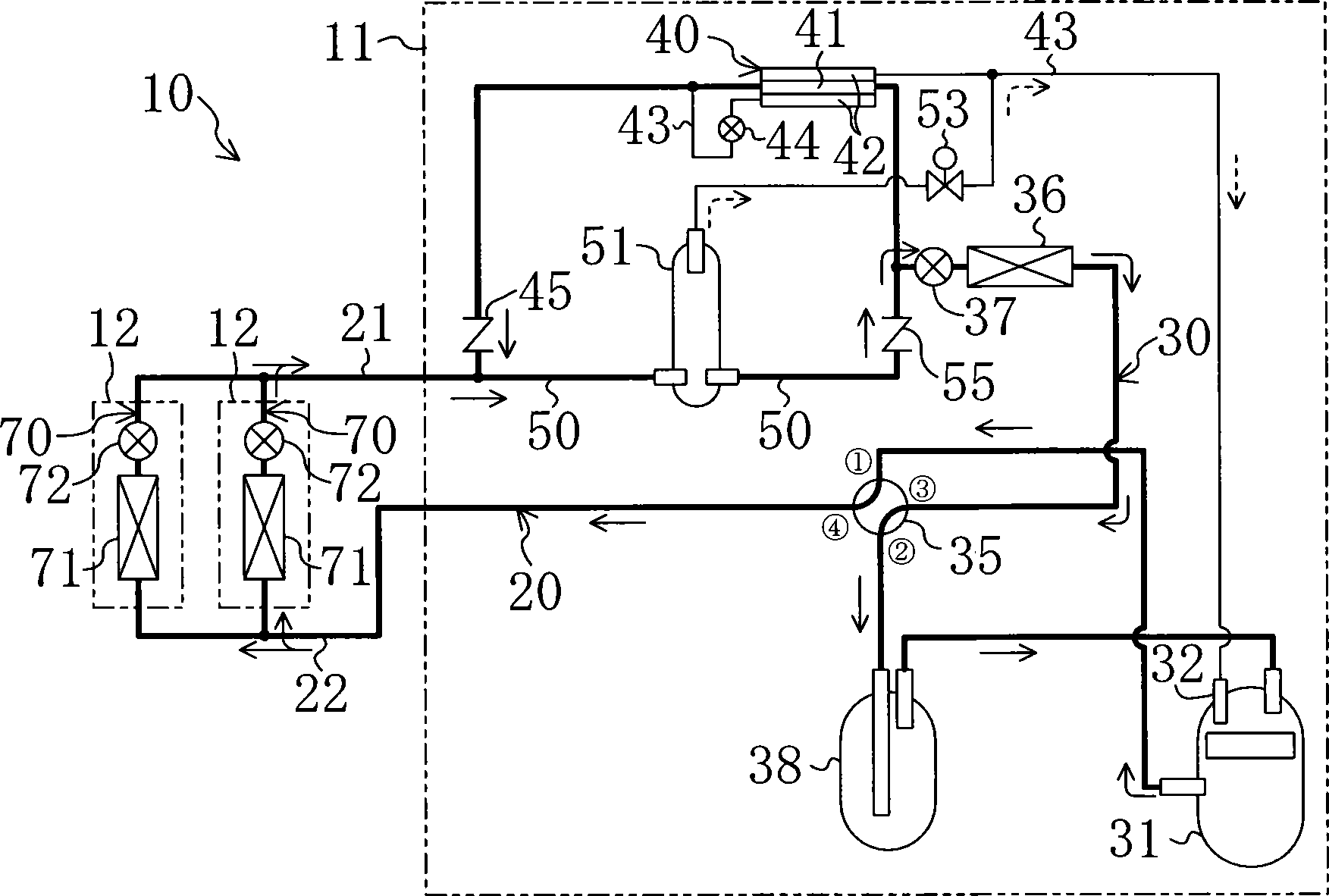

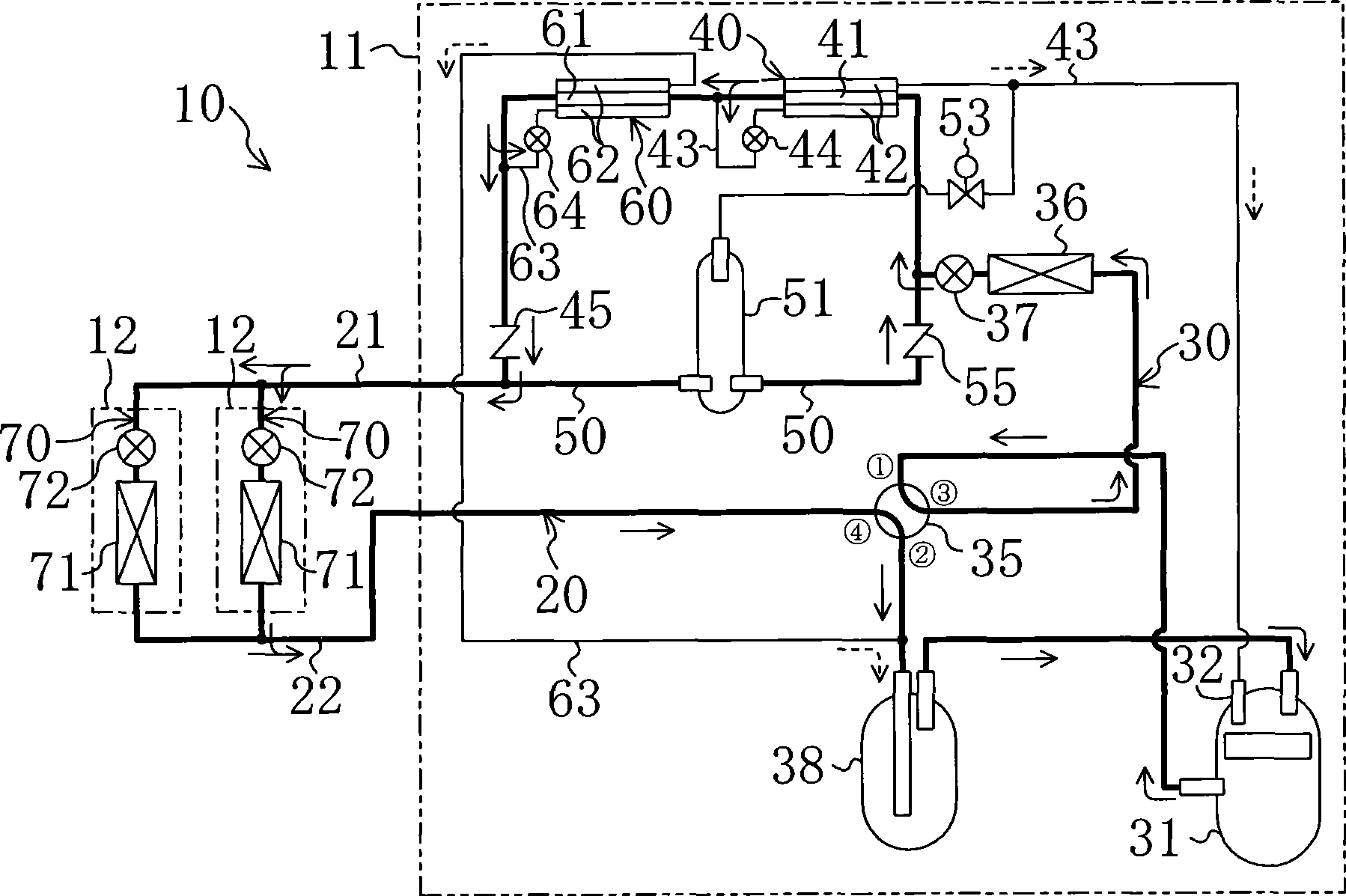

Refrigeration device

InactiveCN101384862AReduce evaporationLess quantityCompression machines with non-reversible cycleCompression machines with reversible cycleVapor–liquid separatorEngineering

Owner:DAIKIN IND LTD

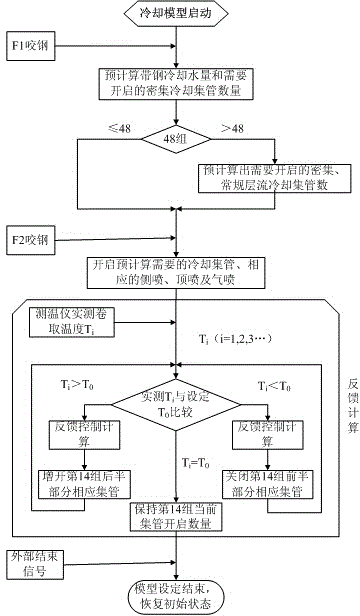

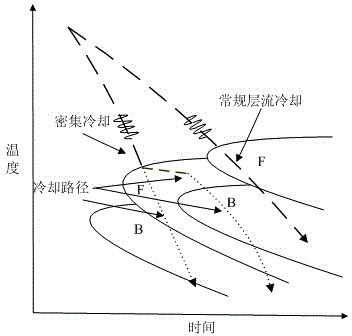

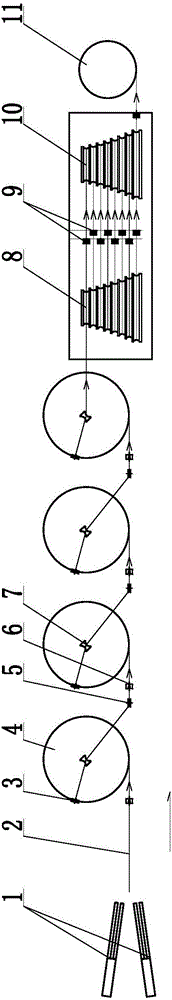

Intensive cooling control method for hot continuous rolling strip steel

ActiveCN105734235AHigh strengthAvoid influenceHeat treatment process controlContinuous rollingControl system

The invention relates to an intensive cooling control method for hot continuous rolling strip steel. According to the intensive cooling control method, in the prior art, hot continuous rolling strip steel laminar flow intensive cooling stable control and usage are mainly achieved. According to the intensive cooling control method for the hot continuous rolling strip steel, on a rolling line, cooling equipment is located on the rear sides of finishing mills and the front side of a recoiling machine and comprises an intensive cooling section, a conventional laminar flow cooling section and an accurate adjustment section which comprise 15 sets of manifolds totally. The intensive cooling control method comprises the following implementation steps that after steel occluding of a rack of the finishing mill F1, the water volume needed by strip steel cooling and the number of the intensive cooling manifolds needing to be opened are pre-calculated through a cooling module; during steel occluding of a rack of the finishing mill F2, a production control system controls to start the cooling module to pre-calculate the intensive cooling manifolds needing to be opened and the eight manifolds of the front half part of the fourteenth set of the accurate adjustment section; and according to a feedback control calculation result of the cooling module, the hot continuous rolling mill production control system conducts feedback control. The intensive cooling control method can be used for hot continuous rolling strip steel production in engineering machinery, general structural steel, automobile structural steel, pipeline steel and other fields.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

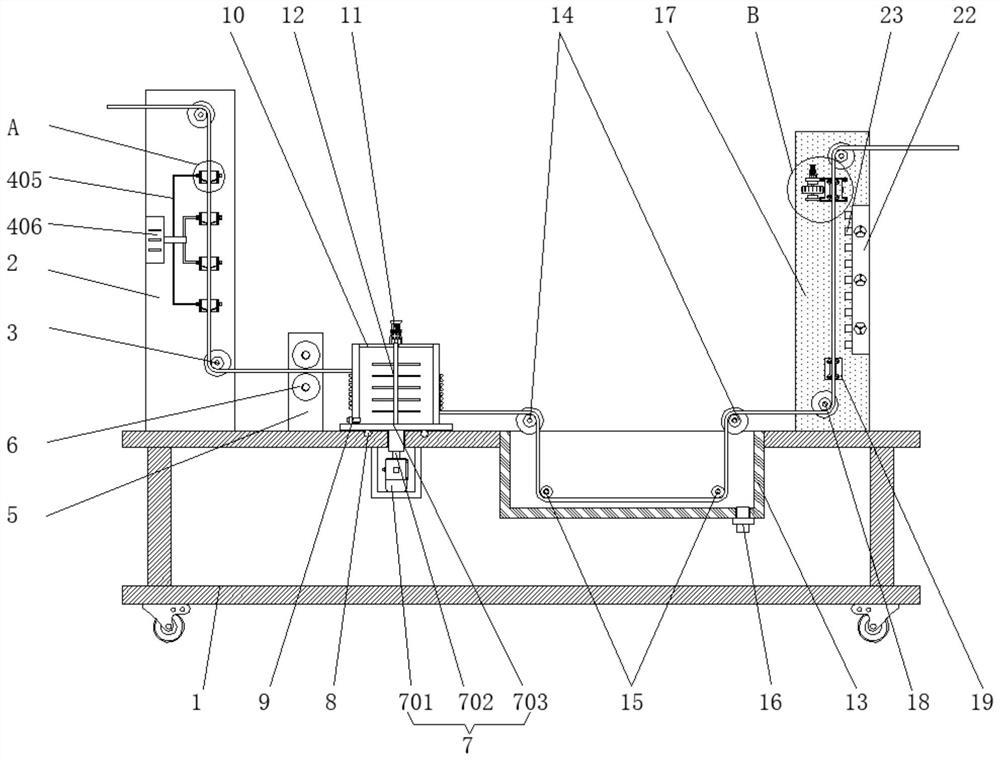

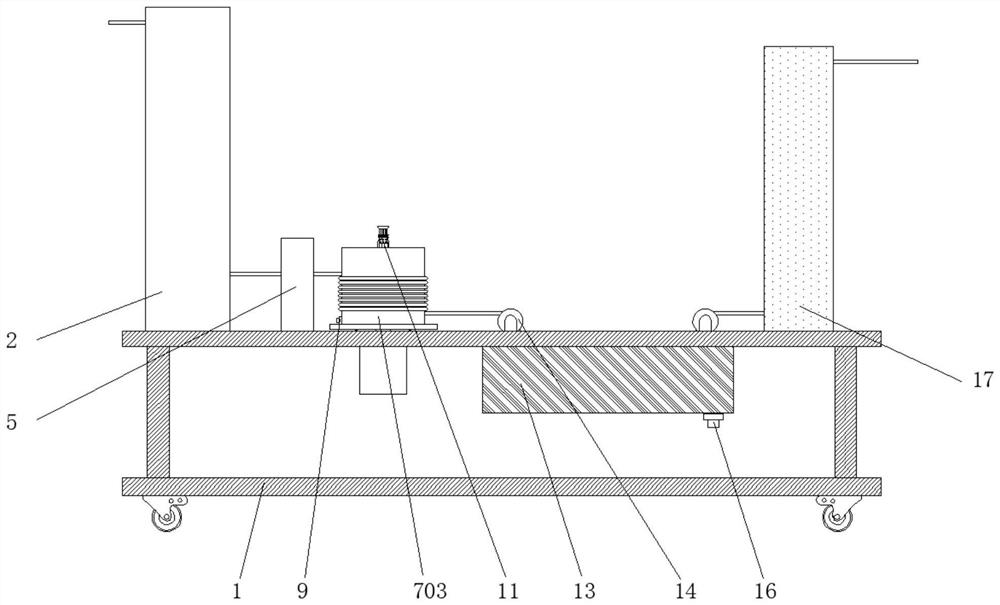

Combined wire drawing machine and wire drawing process

InactiveCN106734277AAvoid the problem of weak cooling capacityCompact structureEngineeringCooling capacity

The invention discloses a combined wire drawing machine. The combined wire drawing machine comprises a duckbilled wire pay-off frame, a wire take-up reel, a plurality of dry wire drawing reels, and a wet-type wire drawing machine table, wherein the duckbilled wire pay-off frame is arranged at the initial end of the combined wire drawing machine and used for guiding steel wires to be drawn out; the wire take-up reel is arranged at the tail end of the combined wire drawing machine and used for collecting the steel wire; the multiple dry wire drawing reels are arranged in sequence, and dry drawing dies are arranged between the dry wire drawing reels; and the wet-type wire drawing machine table is arranged between the wire take-up reel and the dry wire drawing reels and comprises a driving cone pulley and a driven cone pulley, and a plurality of wet drawing dies are arranged between the driving cone pulley and the driven cone pulley. By installing the wet-type wire drawing machine table between the dry wire drawing reels and the wire take-up reel, after dry wire drawing is conducted, wet wire drawing is carried out, and thus, the problem that the cooling capacity is low due to the fact that only dry wire drawing is conducted is solved. The combined wire drawing machine is simple and compact in structure and has the advantages of dry wire drawing and wet wire drawing, the cooling capacity of the combined wire drawing machine is fully achieved, the wire drawing speed is greatly increased, and optimal equipment configuration and good product quality are achieved.

Owner:鹤山恒基钢丝制品有限公司

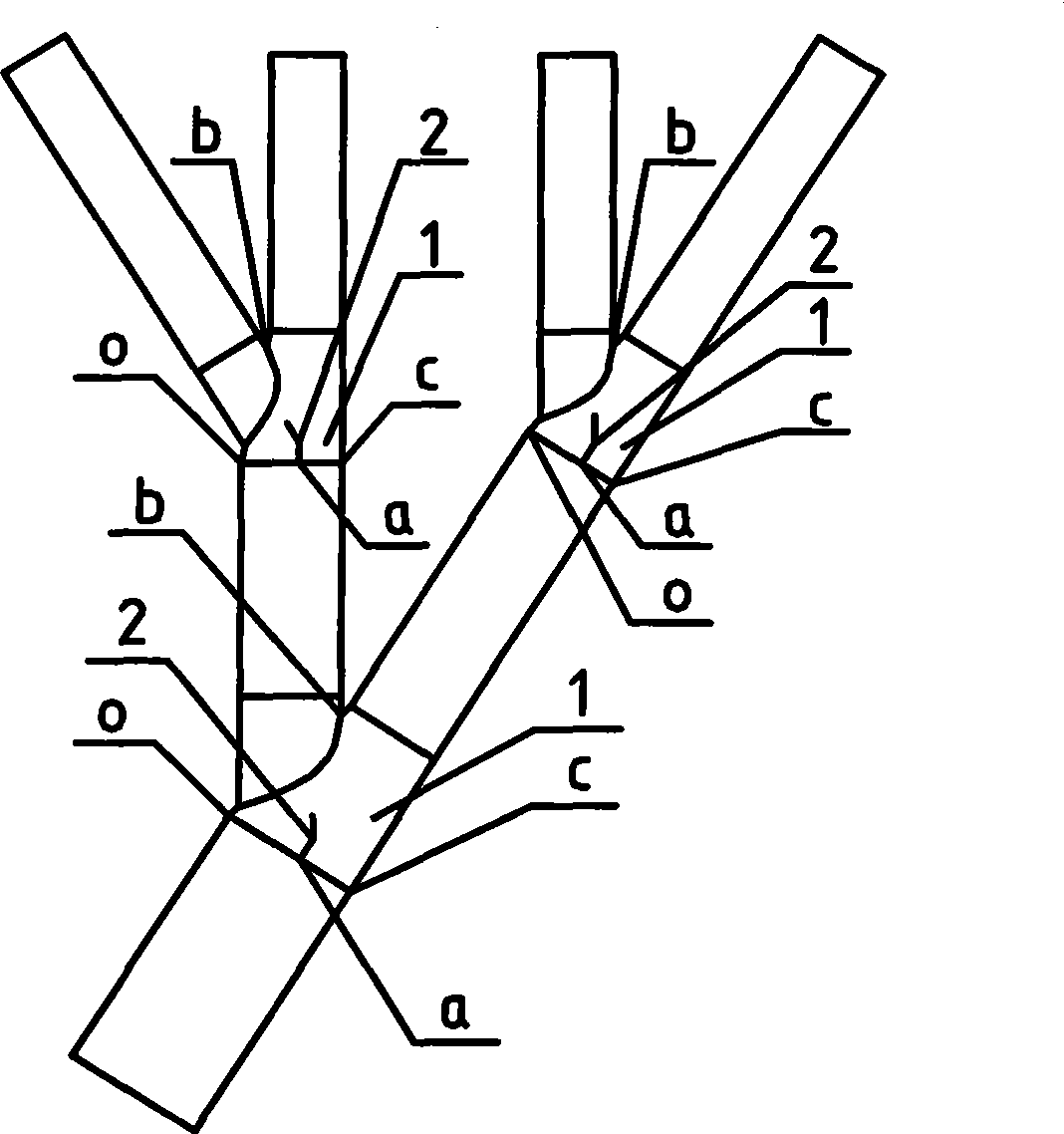

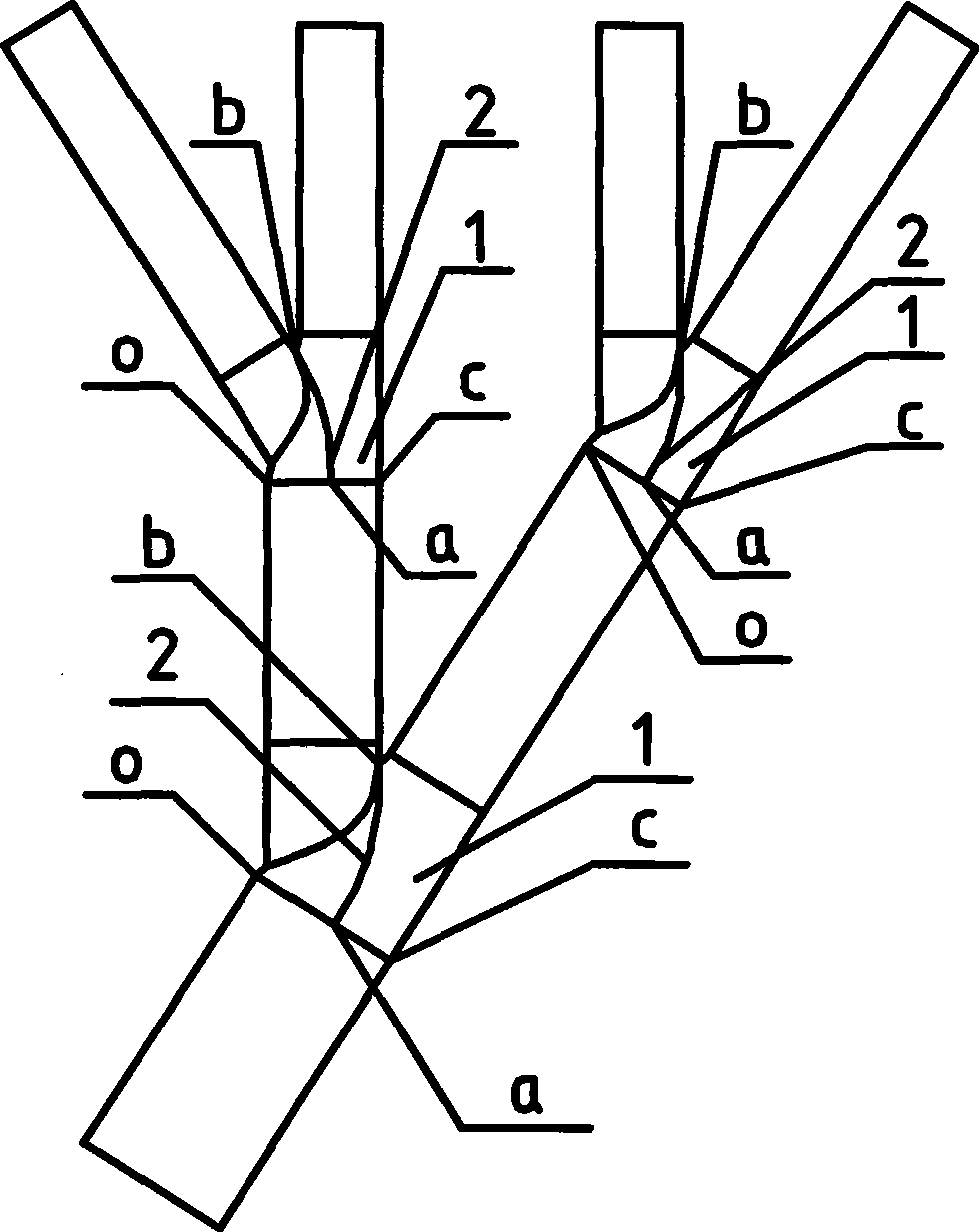

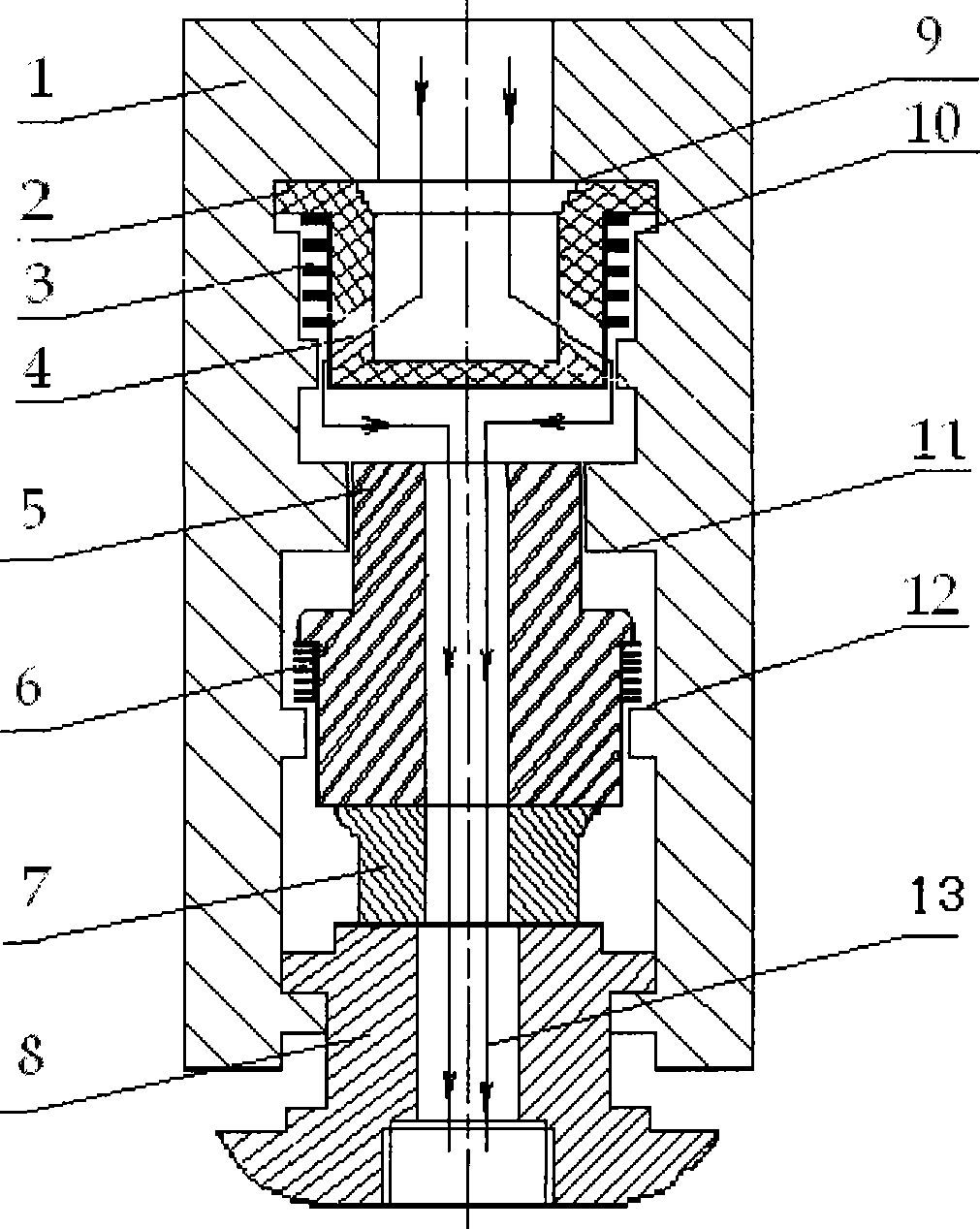

Internal steam conduction apparatus of direct air cooling branch-shaped exhaustion duct system

InactiveCN101476823AGuaranteed safe operationKeep the economy runningEnergy industrySteam/vapor condensersHigh resistanceThermal energy

The invention discloses a flow guide device in a direct air cooling branch-shaped exhaust duct system, which is applied in the field of heat energy power engineering. The device solves the problem of even flow distribution of steam exhaust of a steam turbine among various steam distribution pipes. The device prevents the danger of the freezing of a direct air cooled condenser which is possibly caused by the unreasonable design of the direct air cooling branch-shaped exhaust duct system, and ensures safe operation of the steam turbine in winter. The device ensures that a system prevents the pressure loss of water vapor from being overhigh and the supercooling area from being overlarge, prevents the reduction of heat exchange amount, and reduces the thermal efficiency of power plants when realizing the even distribution of the flow of water vapor. The device fully plays the cooling capacity of various parts of the direct air cooled condenser, and ensures that the steam turbine runs economically in other seasons. For realizing the even distribution of the flow of the water vapor, the distribution of the area of a diversion cross-section depends on the resistances of two branch pipe sections, and a branch pipe with a high resistance should obtain larger diversion area. The device is mainly used for steam diversion and cooling systems of power stations, petrochemical industry, and the like.

Owner:BEIJING JIAOTONG UNIV

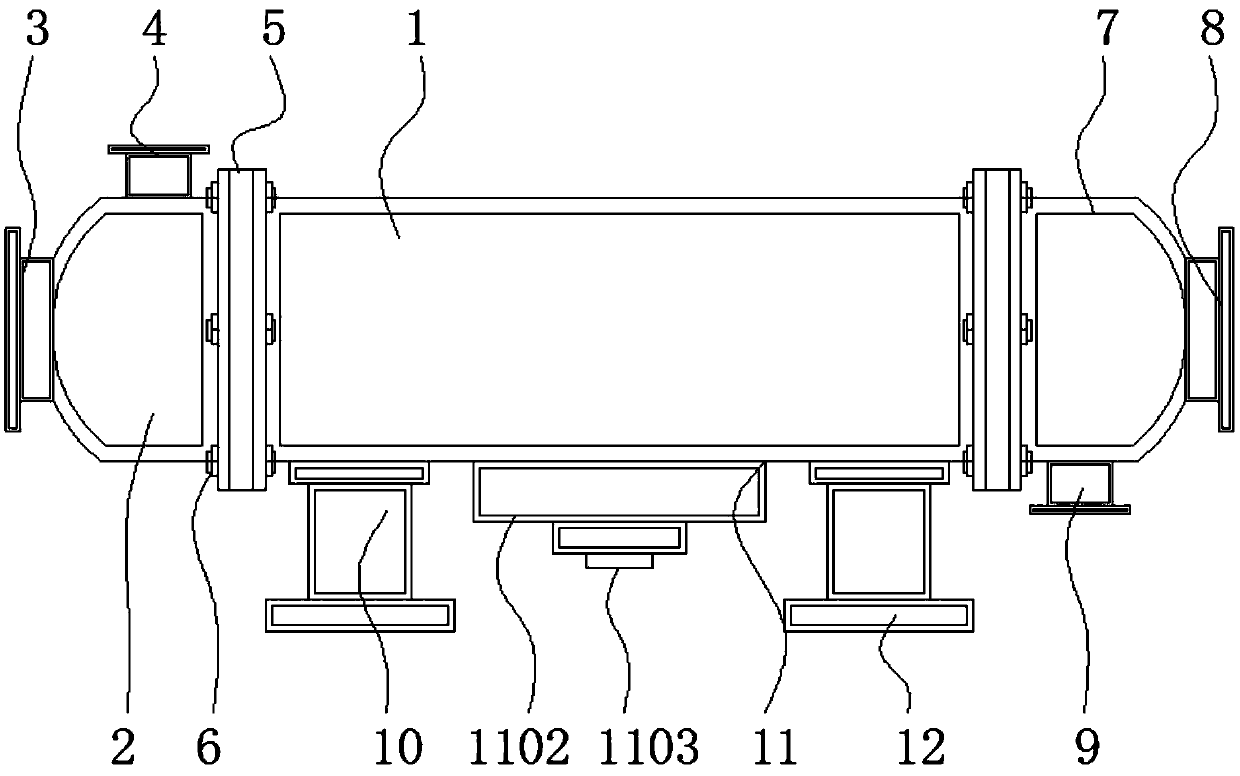

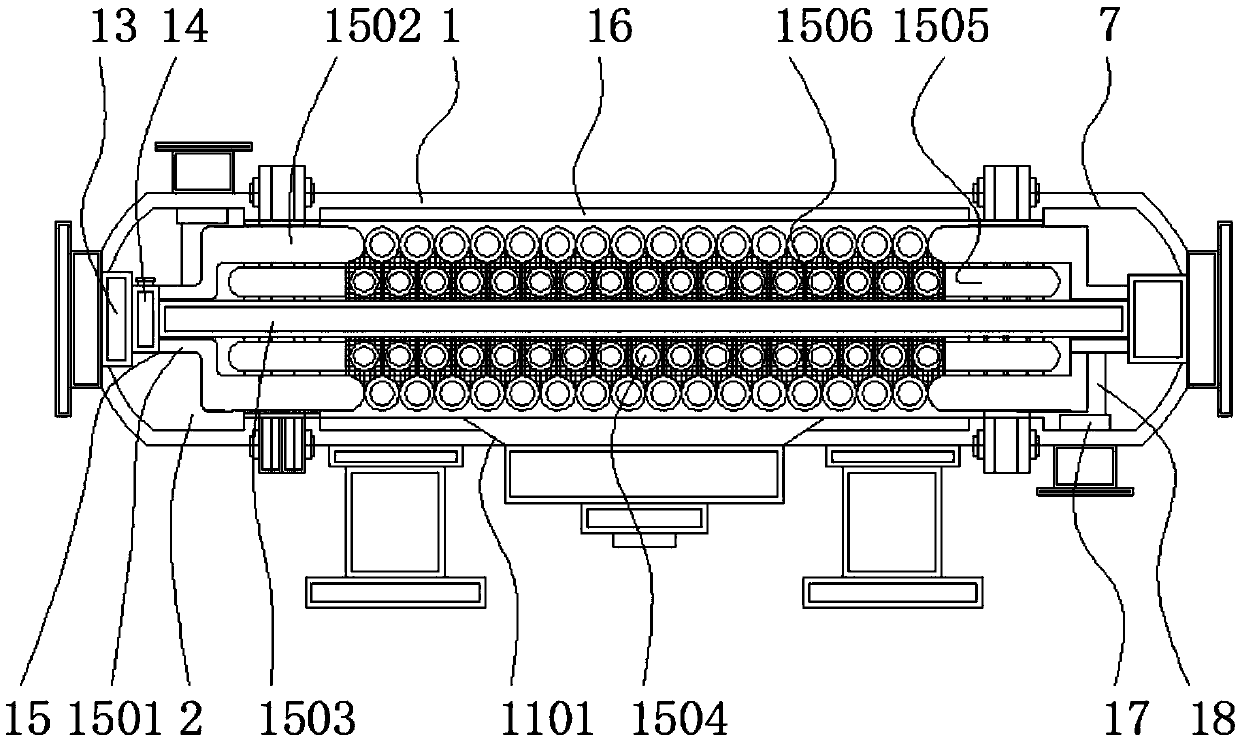

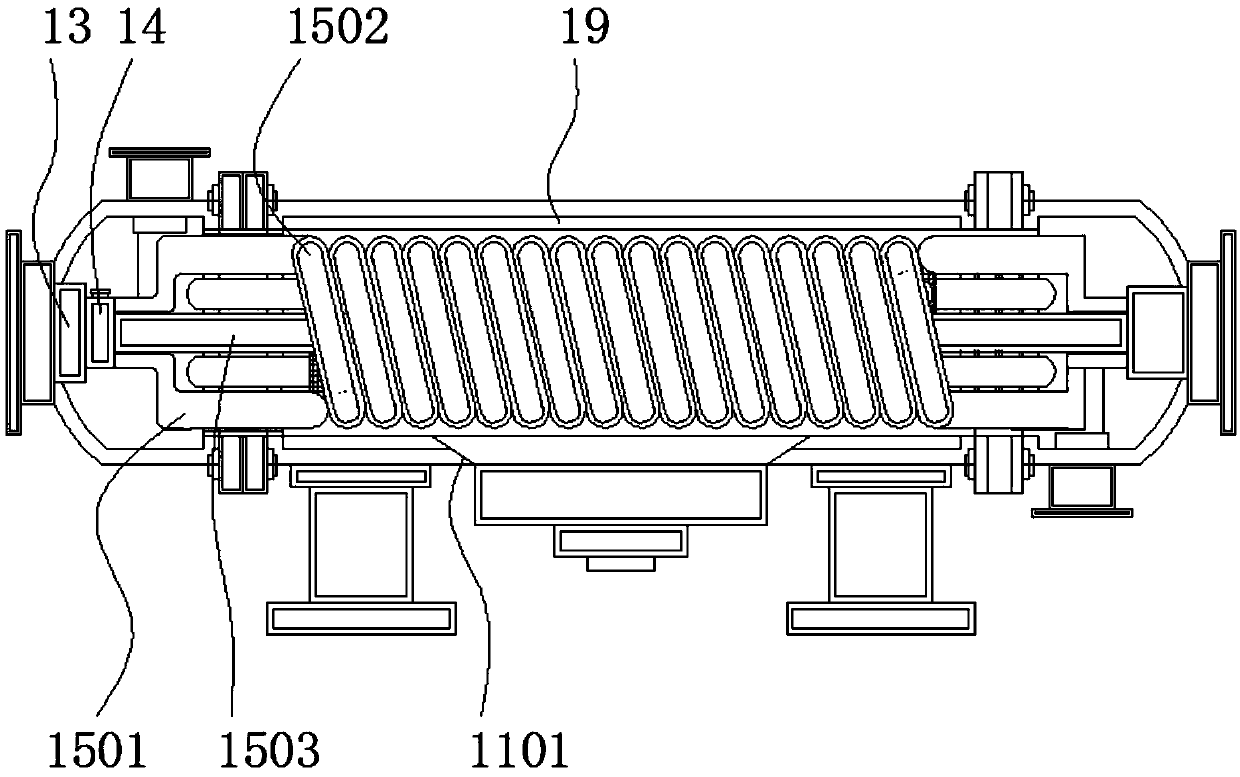

Casing heat exchanger with irregular-shaped inner tube

InactiveCN109539829AFast heat transferReduce the degree of oxidationStationary tubular conduit assembliesHeat transfer modificationHeat flowEngineering

The invention discloses a casing heat exchanger with an irregular-shaped inner tube, and relates to the technical field of heat exchangers. The exchanger comprises a heat exchanger body, a flange anda collecting mechanism, one end of the heat exchanger body is provided with a first interface, a second interface is screwed to the heat exchanger body, a cold fluid outlet is formed in one side of ahot fluid inlet, and a hot fluid inlet baffle plate is internally embedded with a hot fluid tube. According to the casing type heat exchanger, through the arrangement of spiral winding between a firstcooling tube and a second cooling tube, a hollow cooling outer tube is enclosed therebetween, the mutual cooperation between the outer tube and a third cooling tube, multi-directional heat exchangingis conducted on a heat flow fluid passing therethrough, the arrangement of the spiral winding manner can prolong the time for the cooling fluid to flow inside the heat exchanger, possibility is provided for the sufficient exchange between the cooling fluid and the heat flow fluid, and the use performance of the heat exchanger is improved.

Owner:陶锋

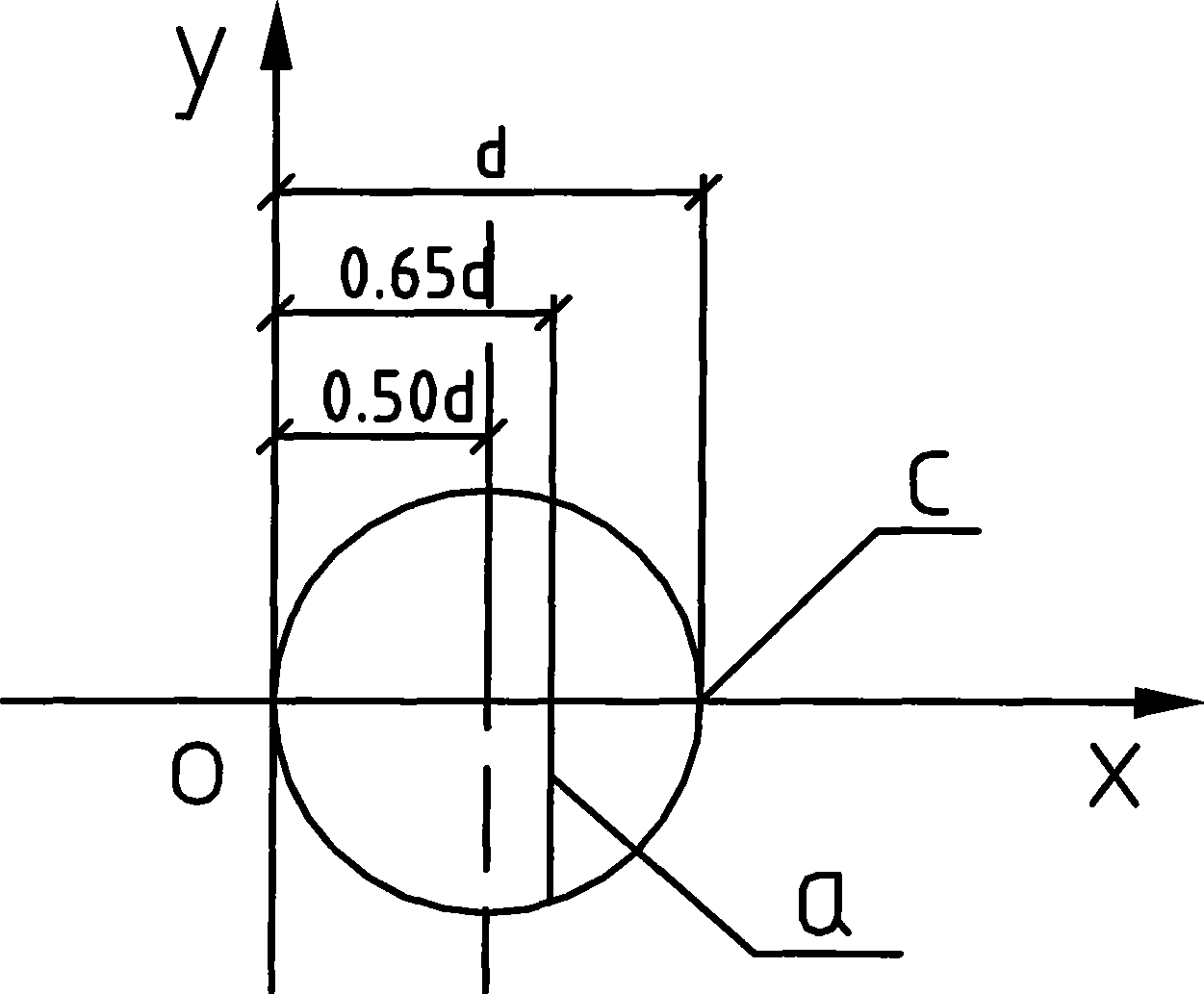

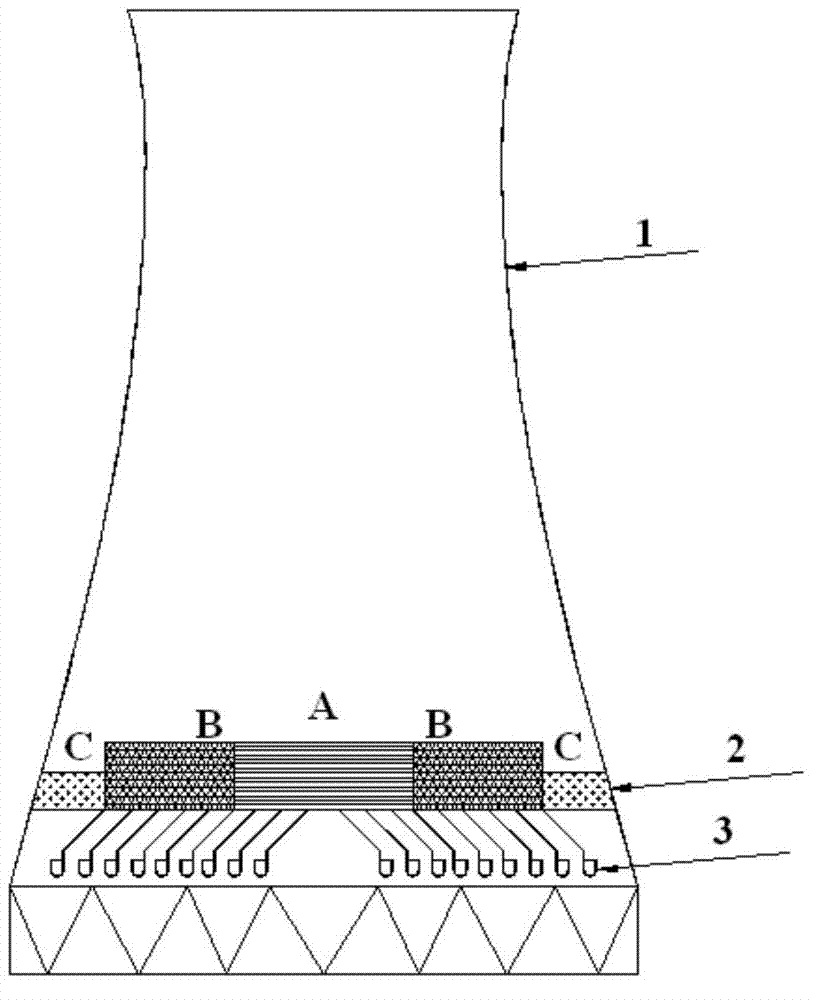

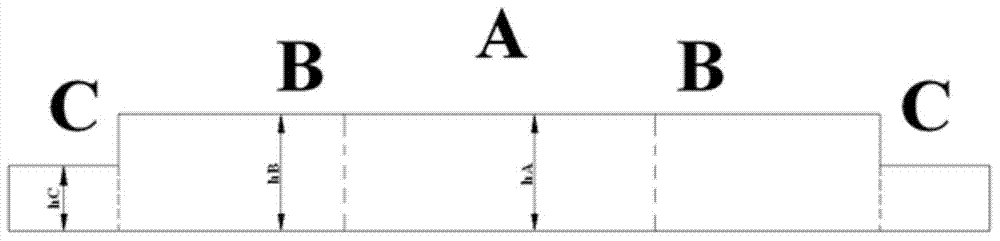

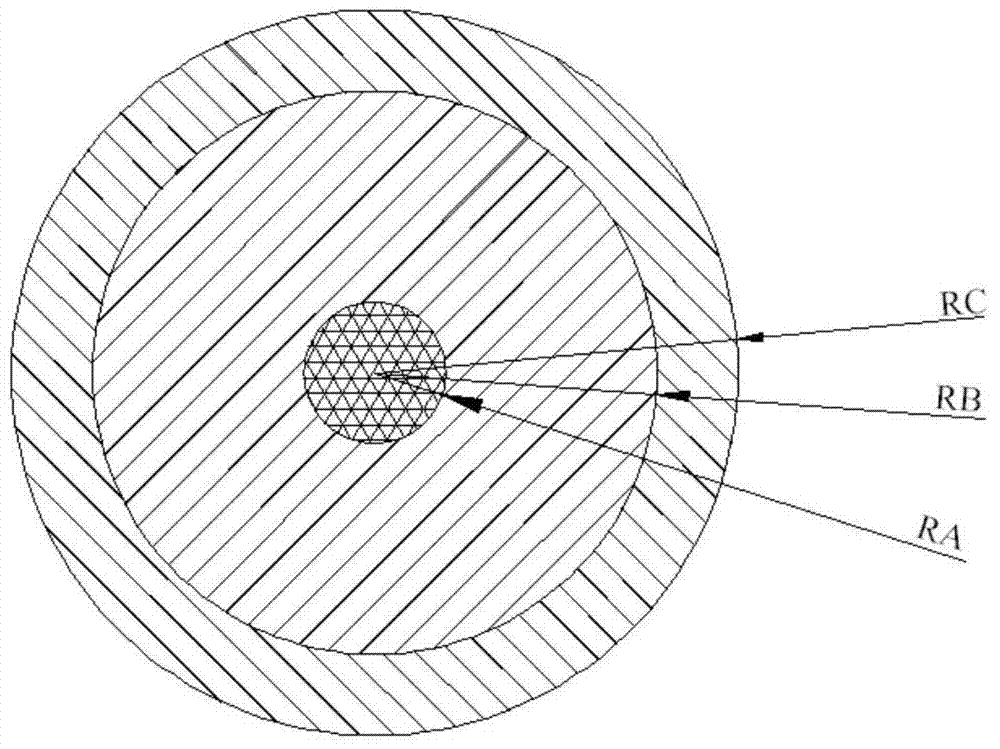

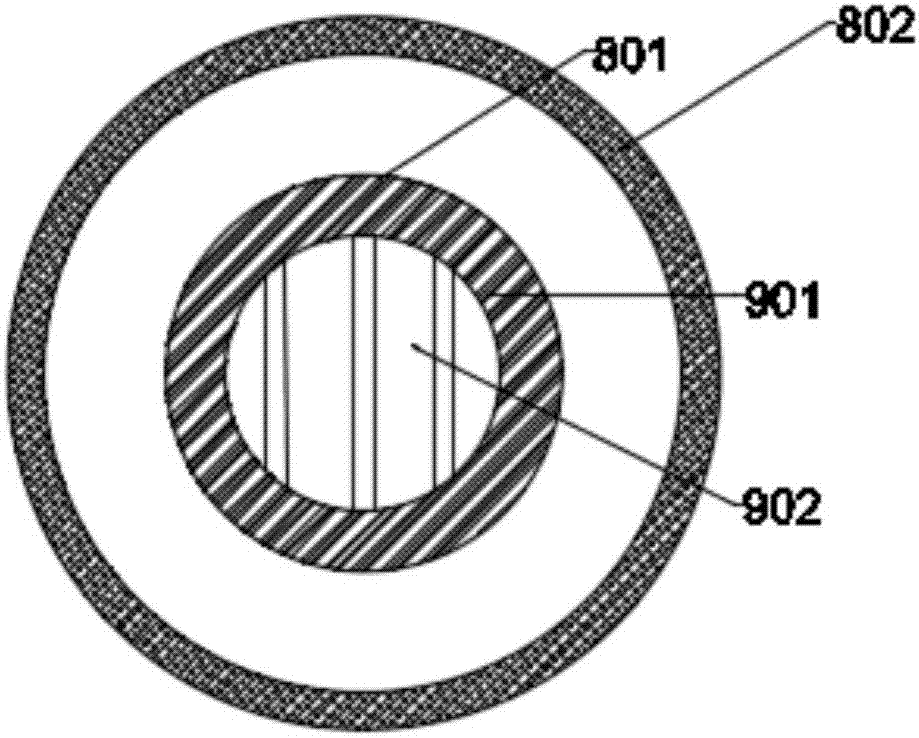

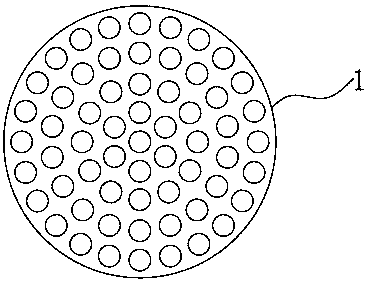

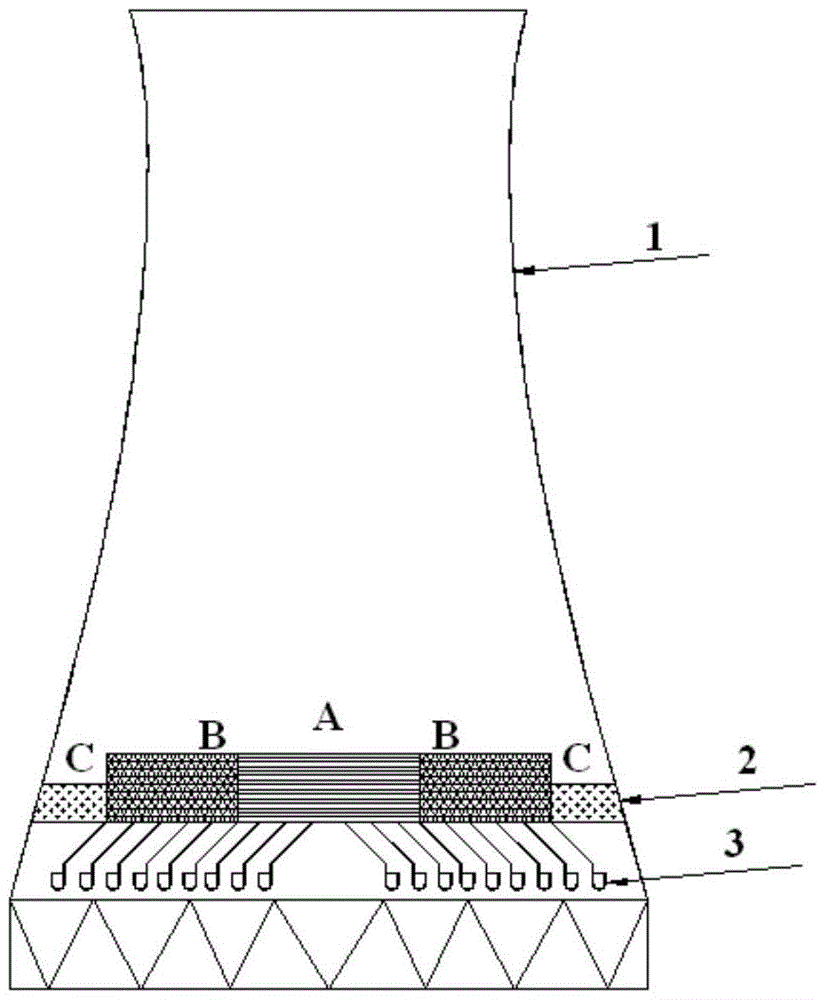

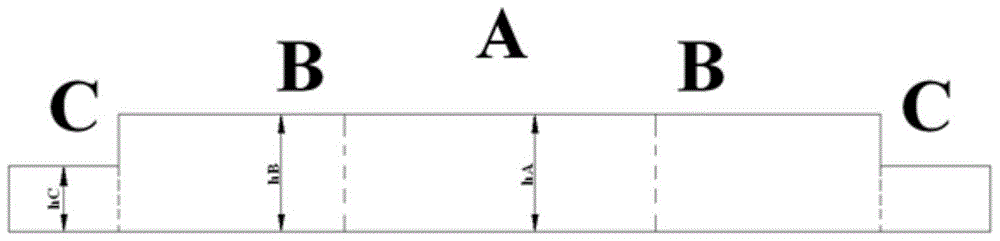

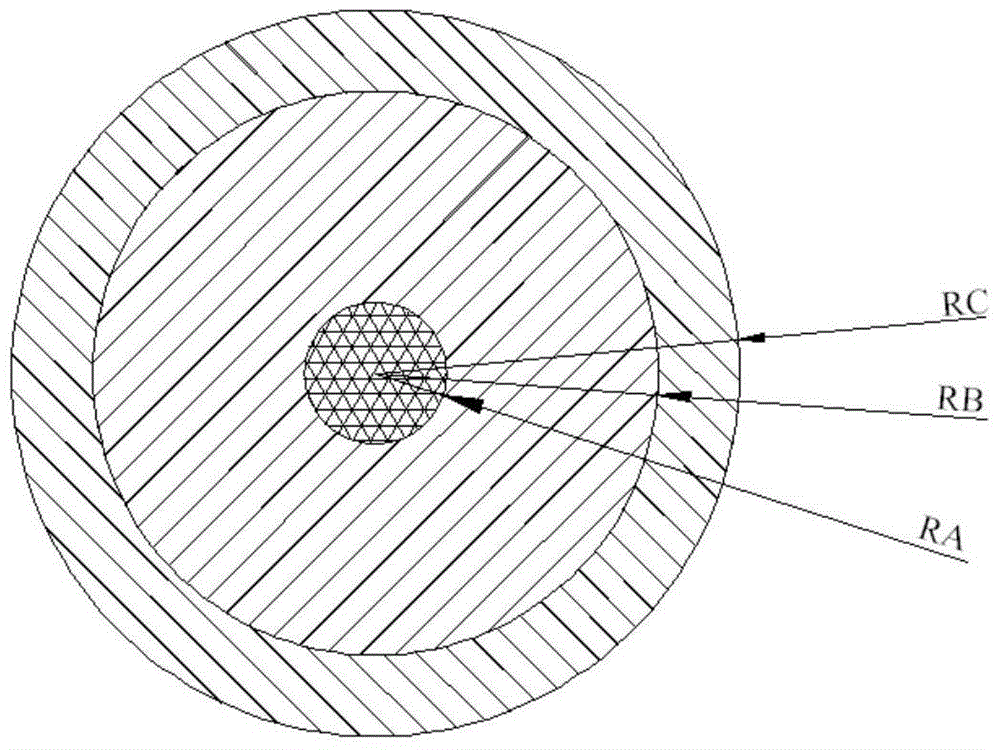

Non-uniform packing system for high-level water recovery cooling tower

ActiveCN104848728AImprove cooling efficiencyIncrease air-to-water ratioTrickle coolersCENBOLCooling tower

The invention discloses a non-uniform packing system for a high-level water recovery cooling tower. The non-uniform packing system for the high-level water recovery cooling tower comprises a packing area, wherein the packing area is located in the cooling tower. Non-uniform arrangement and partition arrangement are adopted by packing in the packing area. According to the partition mode of the packing area, the vertical axis of the cooling tower serves as the center, three annular regions including the region A, the region B and the region C are formed outwards in sequence, wherein the radii of the three annular regions are different. According to the relation of the radii of the packing in the three packing regions, the radius of the packing in the region A is smaller than or equal to that of the packing in the region B and that of the packing in the region C, and the radius of the packing in the region B is smaller than or equal to that of the packing in the region C. According to the relation of the thicknesses of the packing in the three packing regions, the thickness of the packing in the region A is larger than or equal to that of the packing in the region B and that of the packing in the region C, and the thickness of the packing in the region B is larger than that of the packing in the region C. According to the non-uniform packing system for the high-level water recovery cooling tower, non-uniform arrangement of the packing in the regions of the high-level water recovery cooling tower is adopted, the gas-water ratio in the tower can be increased to the maximum extent, the cooling performance of the packing in the tower is fully utilized, and the cooling efficiency of the cooling tower is improved.

Owner:SHANDONG UNIV

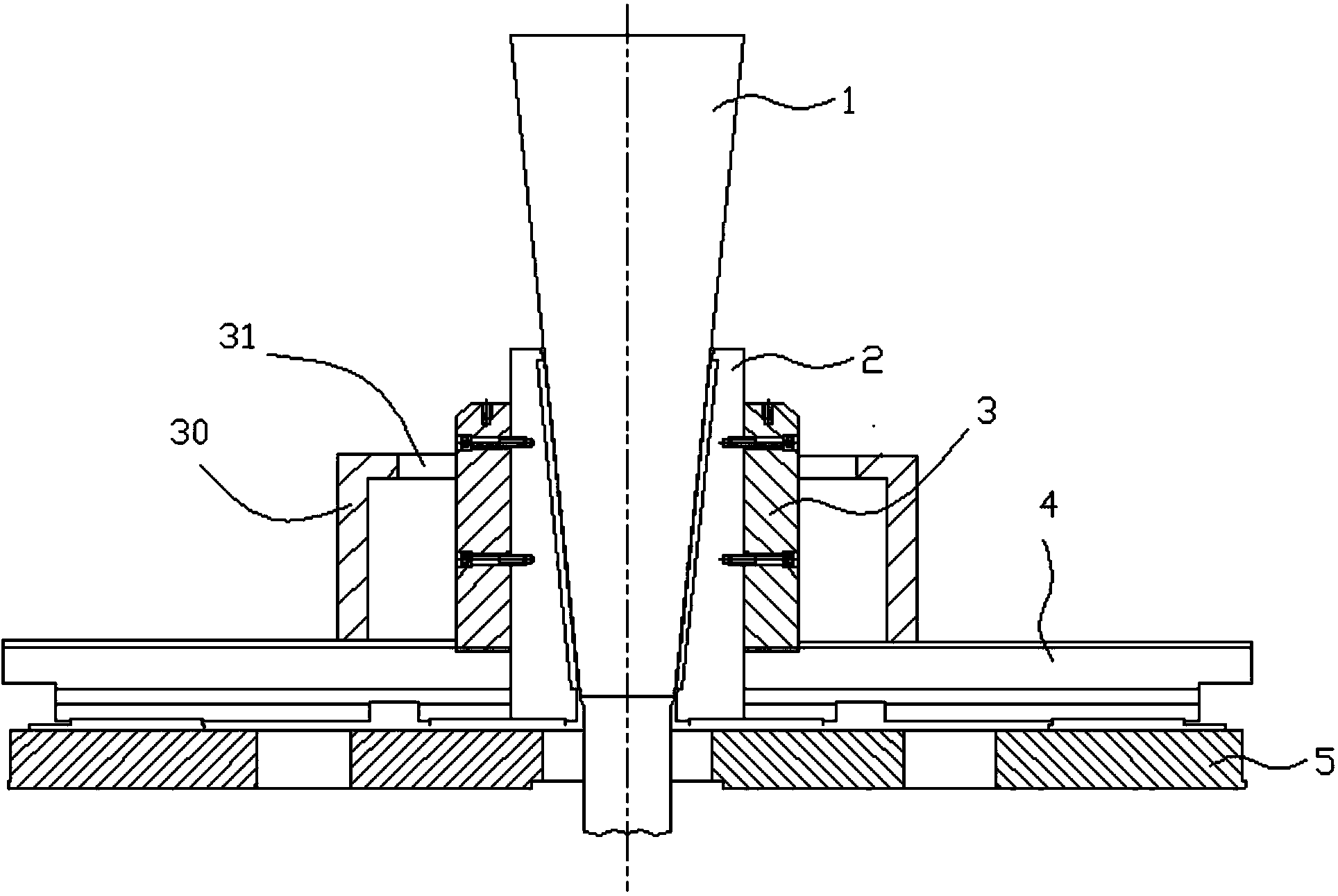

Heat bulging forming method for stainless steel rectangular cross section annular elements

ActiveCN103447377AHigh dimensional accuracyAchieve precision bulge formingShaping toolsProduction rateLarge deformation

The invention discloses a heat bulging forming method for stainless steel rectangular cross section annular elements. The method comprises the following steps that a preheated mold sleeve is fixed on a work table of a bulging machine, then, a heated stainless steel rectangular cross section annular element is sheathed on the periphery of a preheated bulging block in the bulging machine so that the heated stainless steel rectangular cross section annular element is positioned in an annular space surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve, the bulging machine is started so that the bulging block extrudes the annular element from the inner circumference surface of the annular element in the radial direction, deforms 10 percent to 13 percent, and is then extruded into the inner annular surface of the mold sleeve, a sealed die cavity surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve is fully filled, and the bulged rectangular cross section annular element is formed after the pressure preservation. The method adopts one-step large-deformation-quantity bulging forming, the operation is simplified, and the bulged rectangular cross section annular element with high dimension precision, high product quality and high productivity is obtained. The bulged rectangular cross section annular element is mainly used for rotating body parts of tubular casings and the like used in the fields of aeronautics and astronautics and the like.

Owner:GUIZHOU AVIATION TECHN DEV

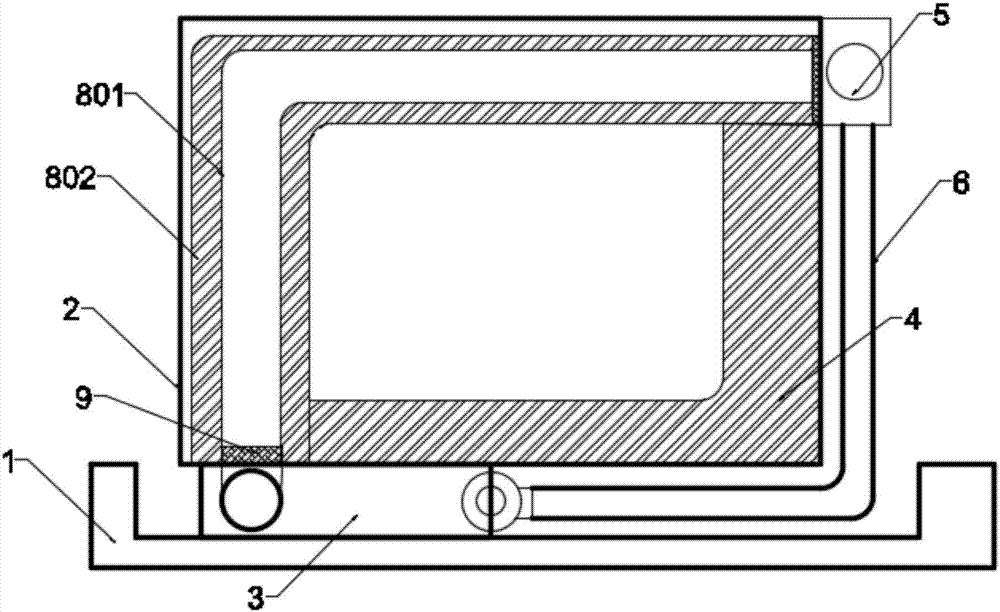

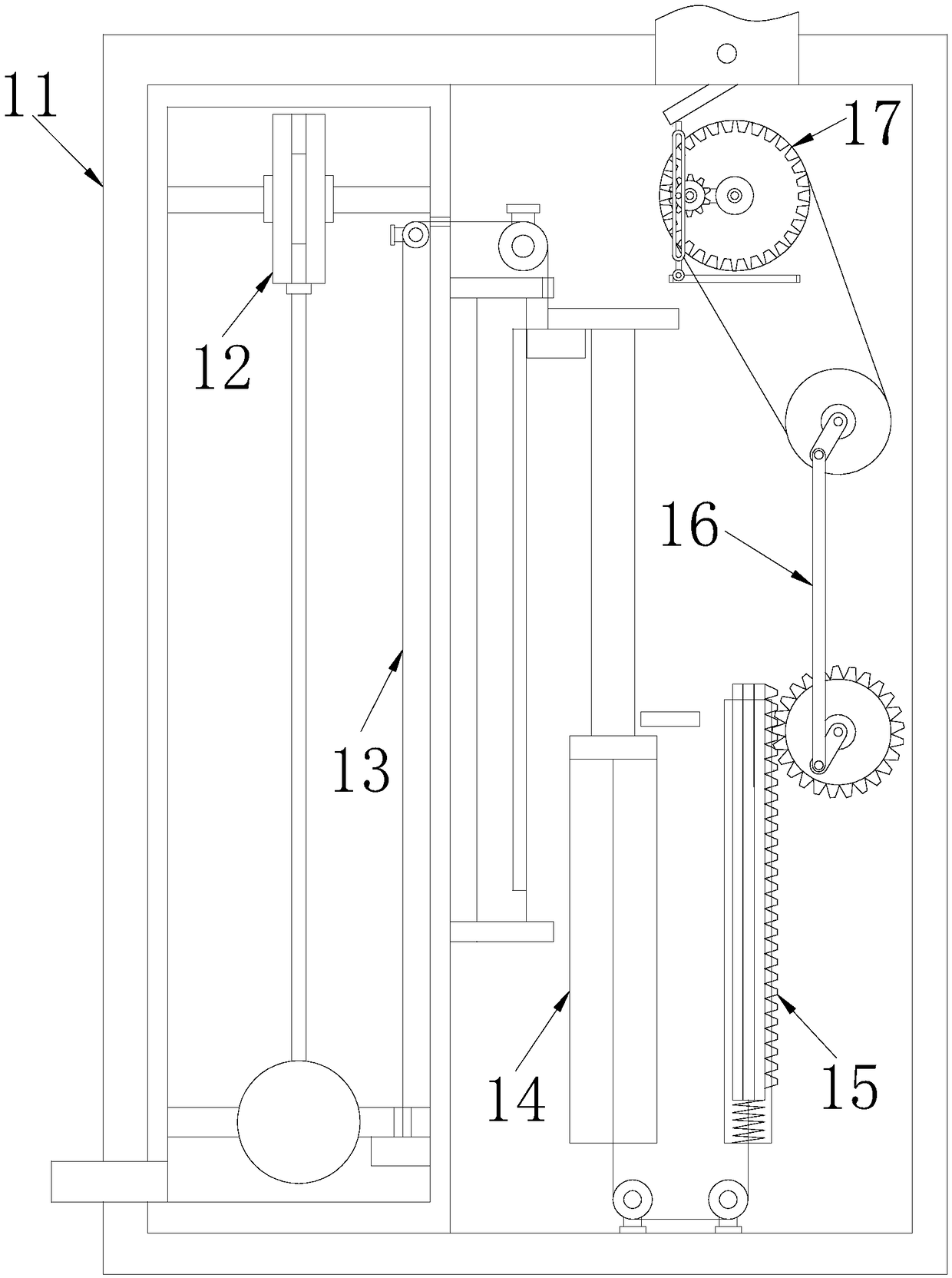

Cooling air channel structure of dry type transformer

ActiveCN107424738ARealize deliverySpeed up circulationTransformers/reacts mounting/support/suspensionTransformers/inductances coolingCold airTransformer

The invention discloses a cooling air channel structure of a dry type transformer. The cooling air channel structure comprises a fixed base; a transformer box is embedded on the upper surface of the fixed base; circular through holes are formed in the bottoms on the two sides of the transformer box; a cooling fan is embedded below the circular through holes; the air outlet of the cooling fan is sleeved with a cooling air channel; the cooling air channel passes through the interior of the transformer box, and the air outlets of the cooling air channel on the two sides are both provided with air pumps; the air pumps are fixed on the top surface of the shell of the transformer box; the air outlets of the air pumps are connected with backflow cooling pipes; the tail ends of the backflow cooling pipes are connected to the coolant inlet of the cooling fan through a three-way valve; the cooling air channel comprises an air channel pipe; an air division plate is mounted in the air inlet of the air channel pipe; and a filtering net is embedded in the outlet of the air channel pipe. By adoption of the cooling air channel structure, shunting of cold air and hot air is realized, the cooling effect can be improved, and recycling can be realized to save energy and reduce pollution.

Owner:山东新碧园生态园林有限公司

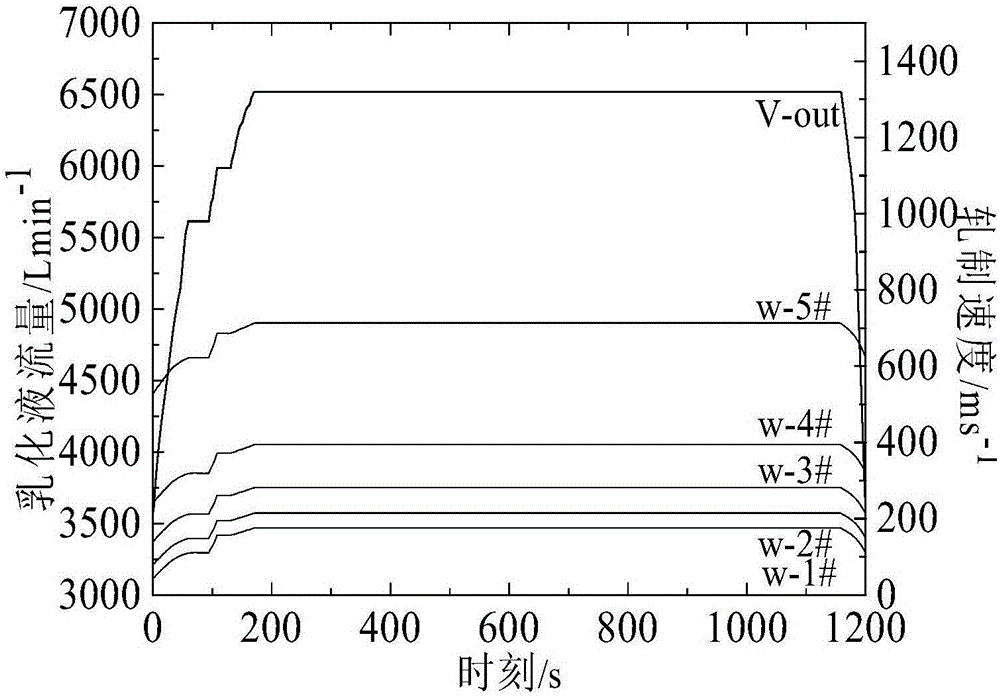

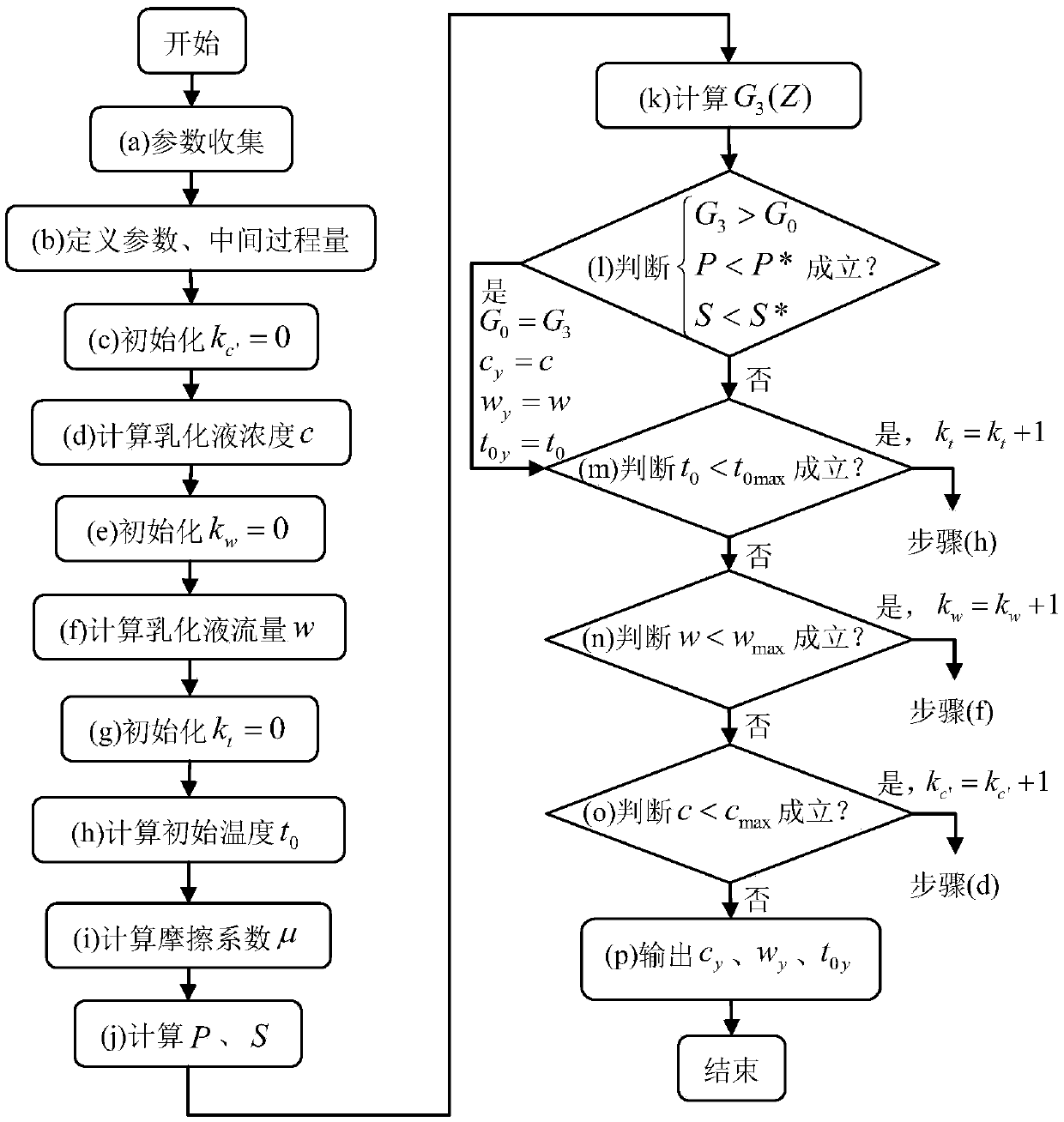

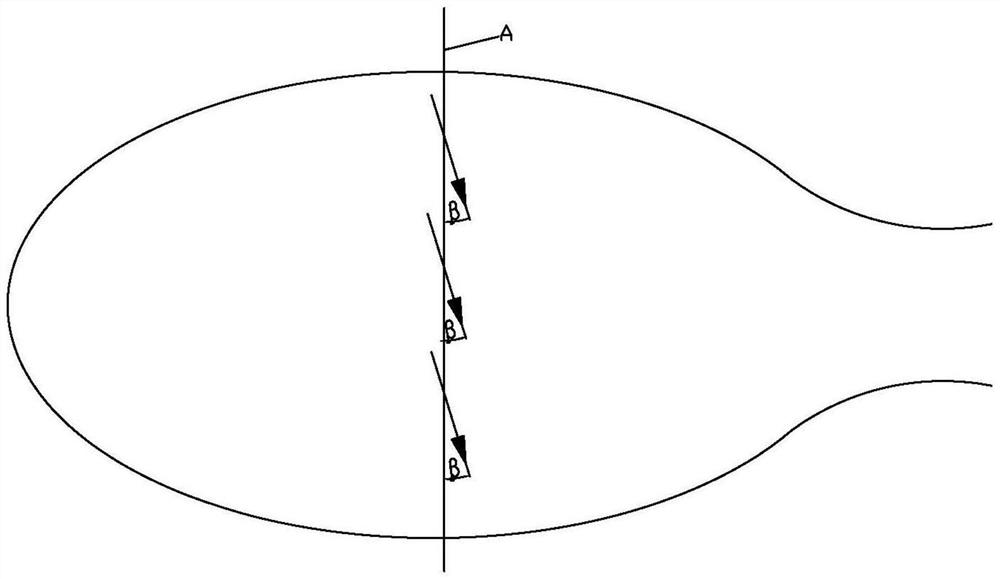

Process lubrication optimization method aiming at stable rolling under large deformation of DCR unit

ActiveCN108714627AFull cooling effectUniform cooling effectRollsDesign optimisation/simulationFully developedEmulsion

Disclosed is a process lubrication optimization method aiming at stable rolling under large deformation of a DCR unit. The method mainly includes the following steps executed by a computer: (1) collecting main equipment and process parameters of a secondary cold rolling mill unit; (2) defining the parameters and intermediate process parameters; (3) initializing k<c>' to 0; (4) calculating emulsionconcentration c; (5) initializing k<w> to 0; (6) calculating an emulsion flow rate w; (7) initializing k<t> to 0; (8) calculating an initial temperature t<0>; (9) calculating a friction coefficient mu; (10) calculating rolling pressure P and a forward slip value S; (11) calculating a function G<3>(Z); (12) determining whether inequalities are true; and (13) outputting optimum emulsion concentration c<y>, an optimum flow rate w<y> and an optimum temperature t<0y>. On the premise of stable rolling, the secondary cold rolling mill unit outputs the optimum emulsion concentration c<y>, the optimumflow rate w<y> and the optimum temperature t<0y>. Therefore, the cooling capability of an emulsion is fully developed, and the cooling capacity of the emulsion in each rack is more uniform, which improves the stability of production.

Owner:YANSHAN UNIV

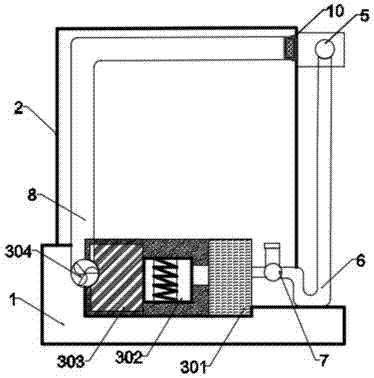

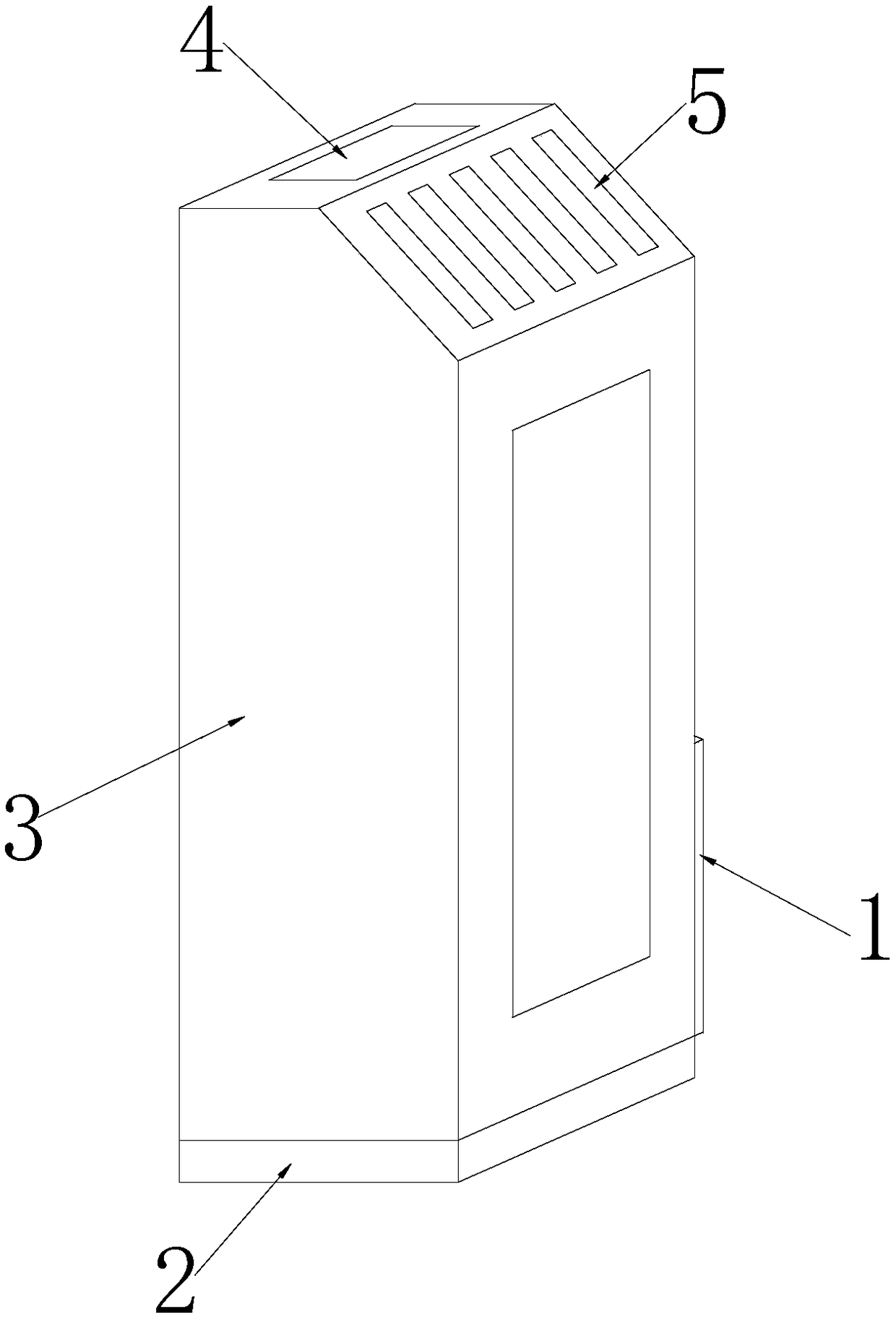

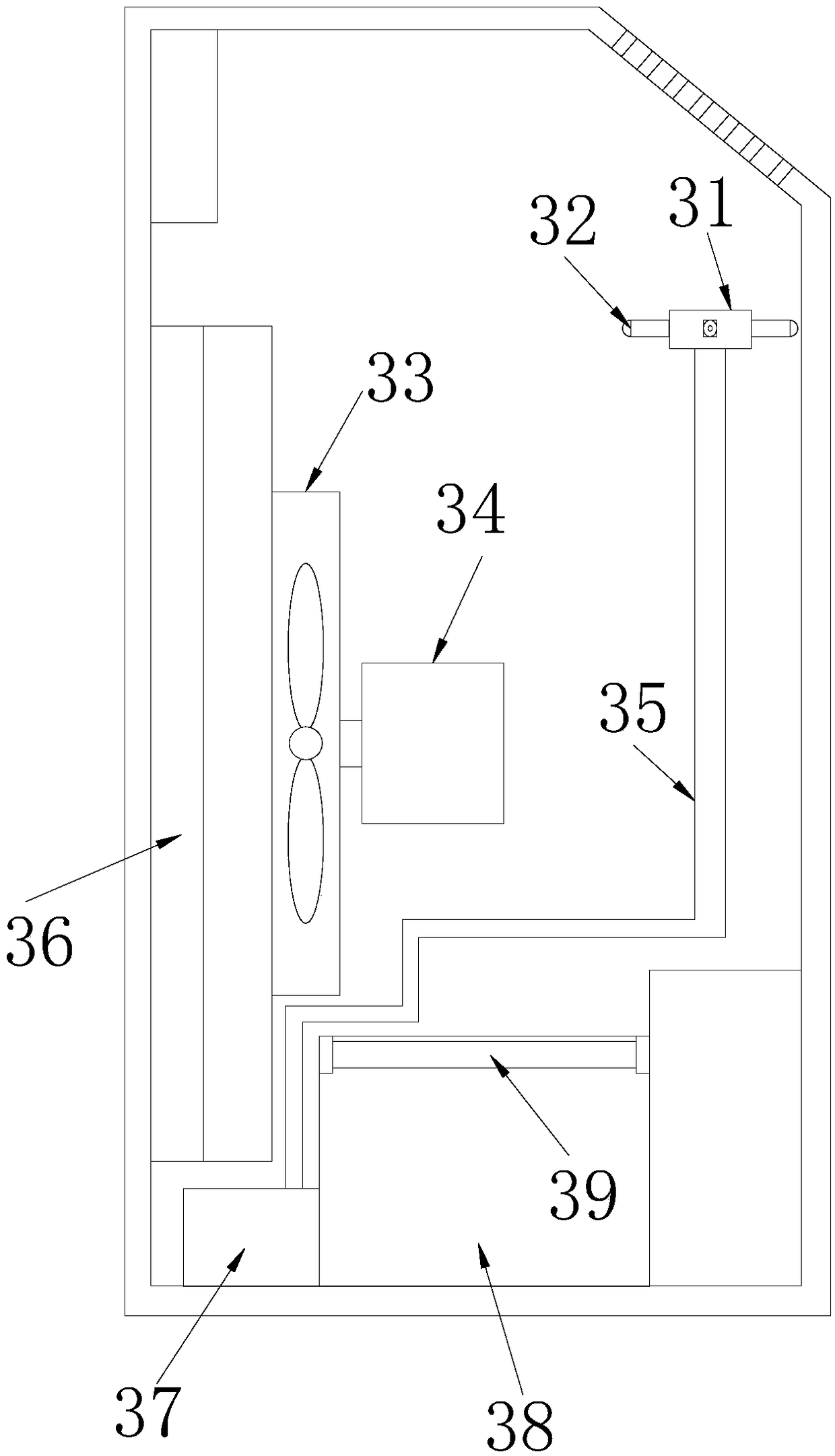

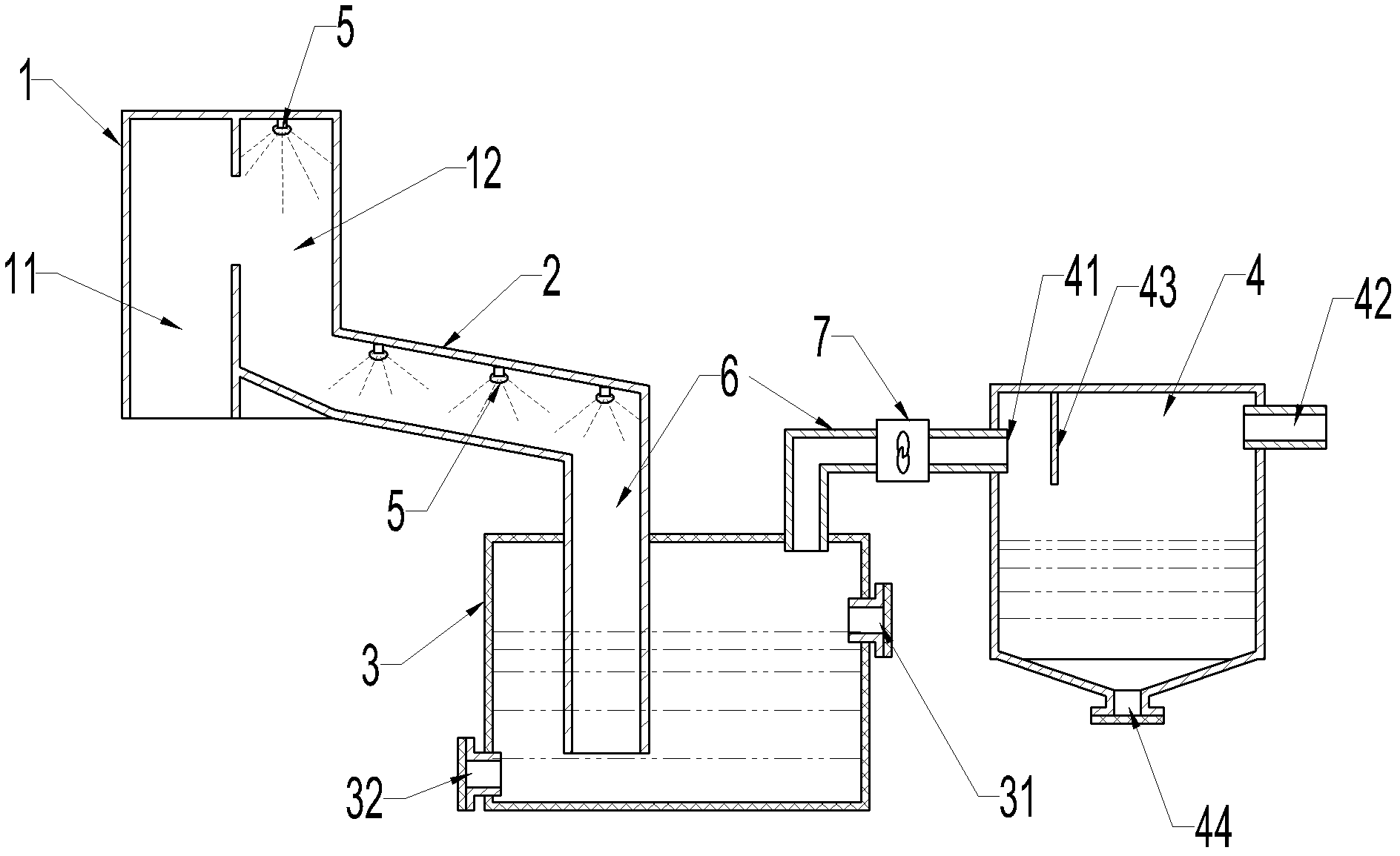

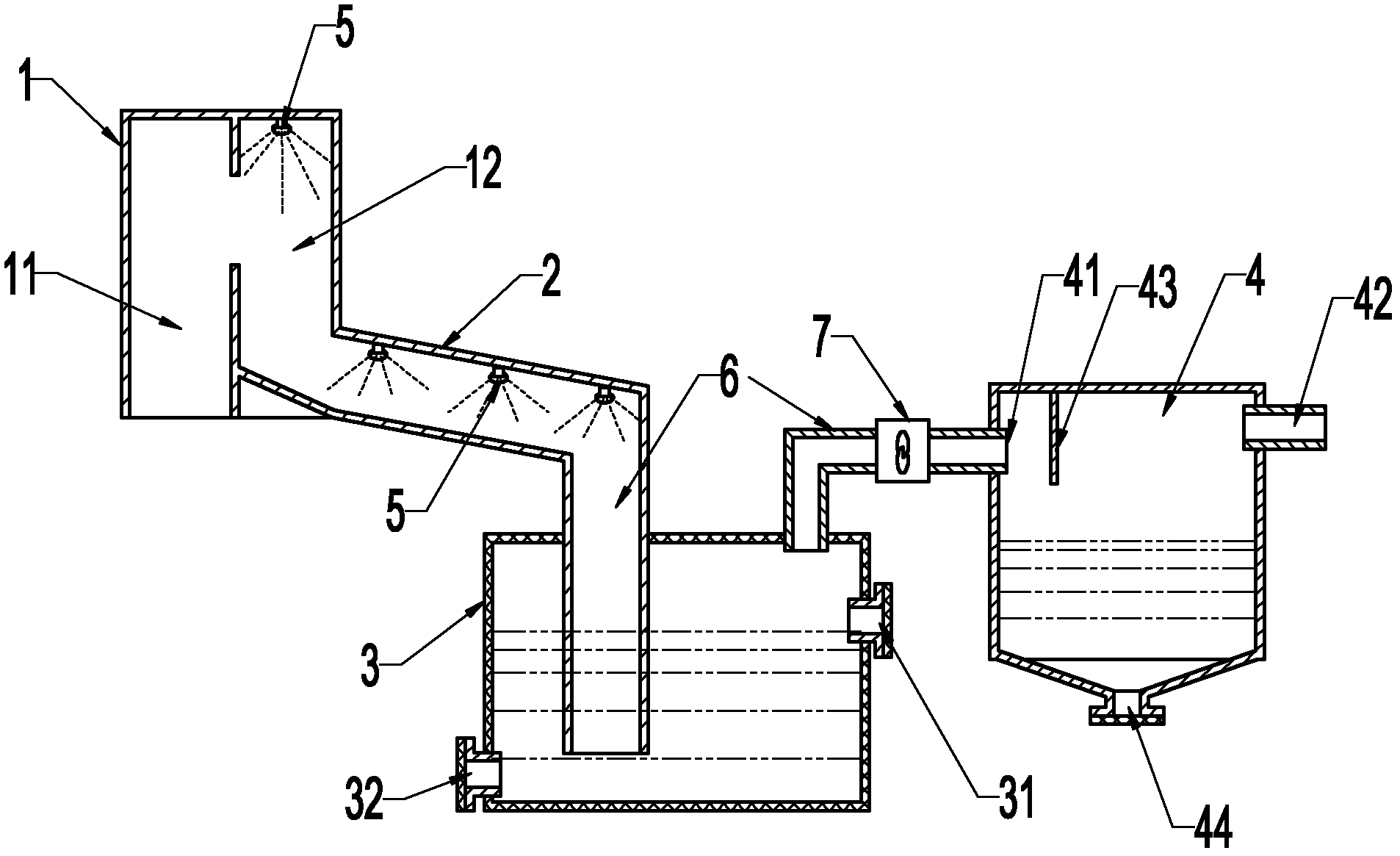

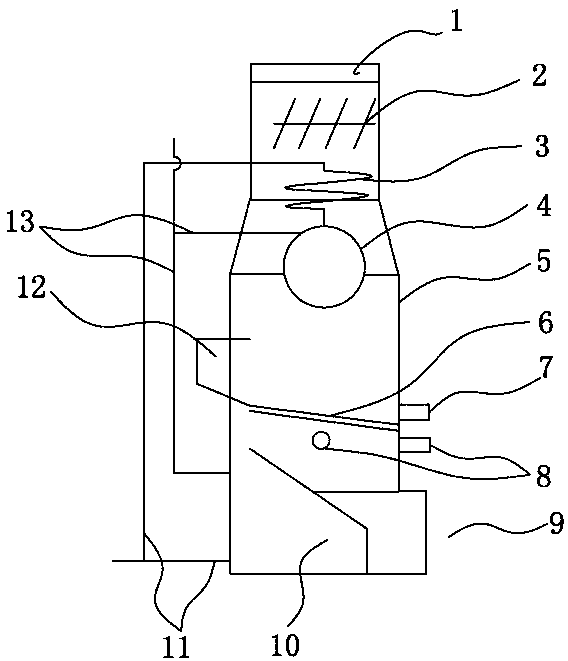

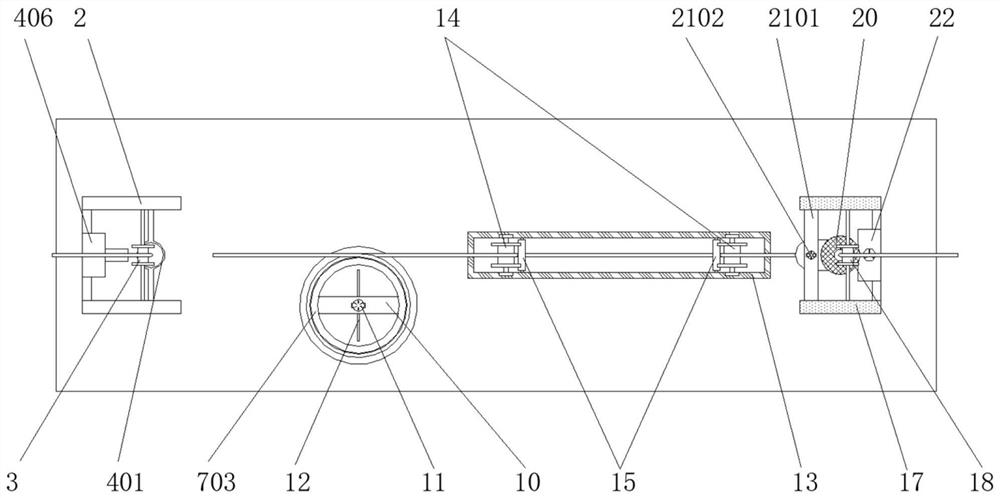

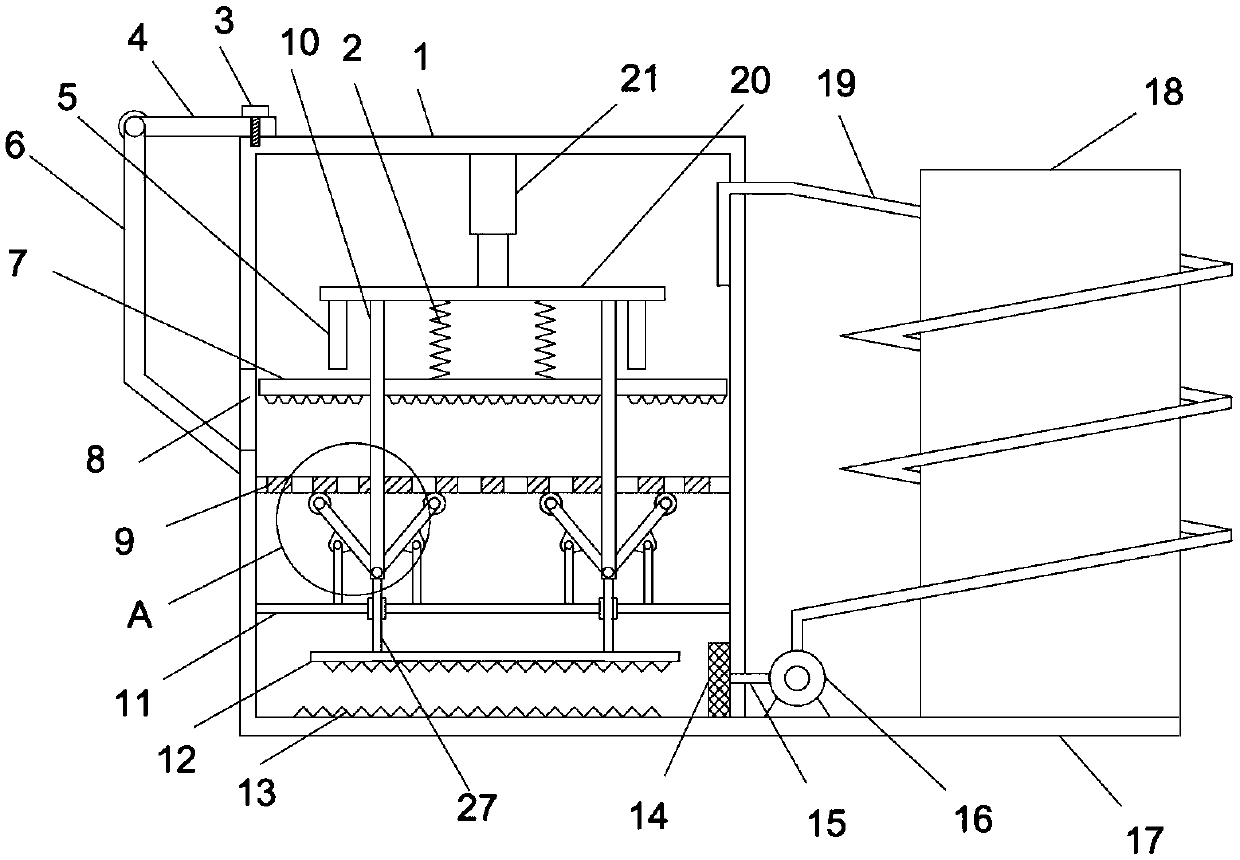

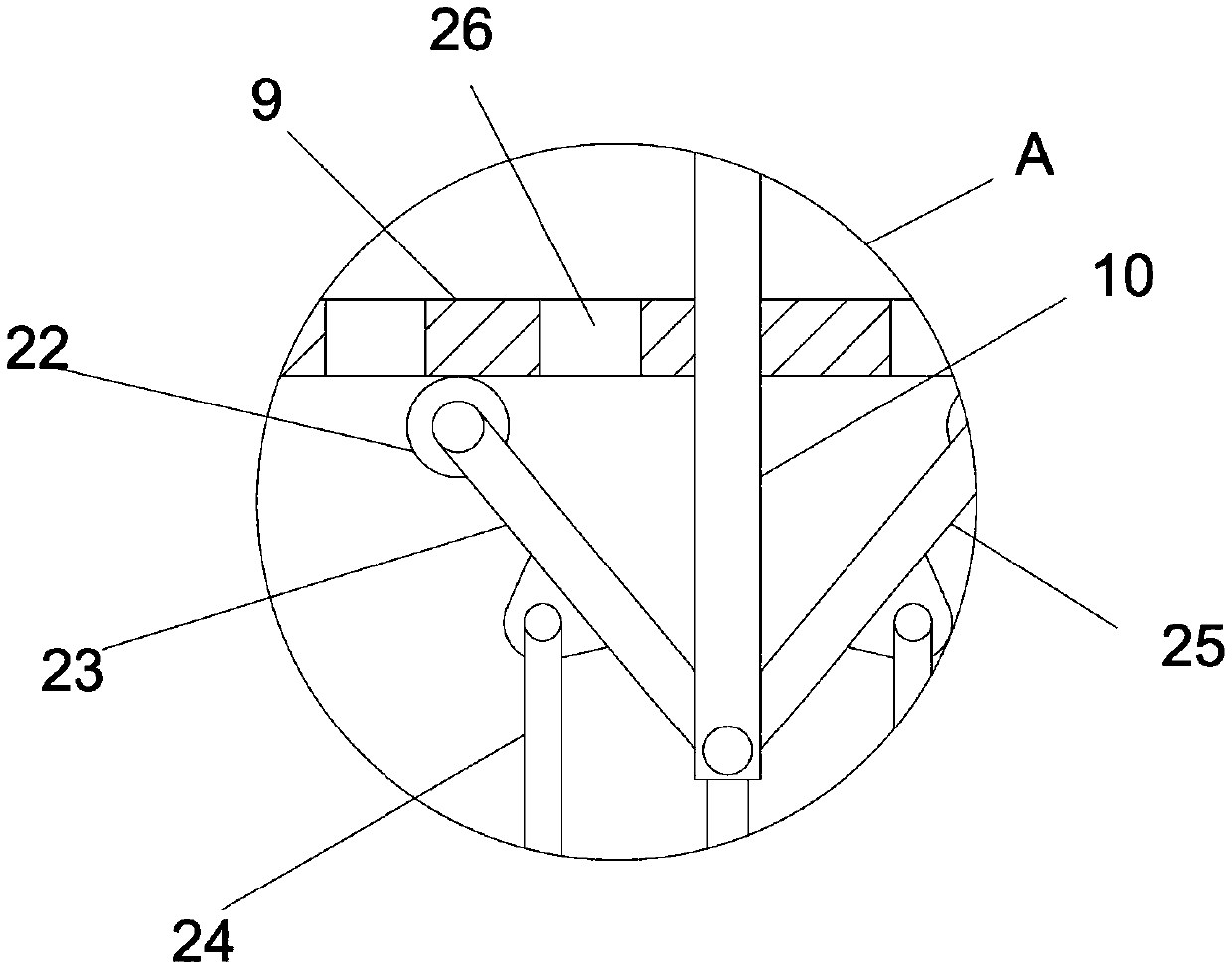

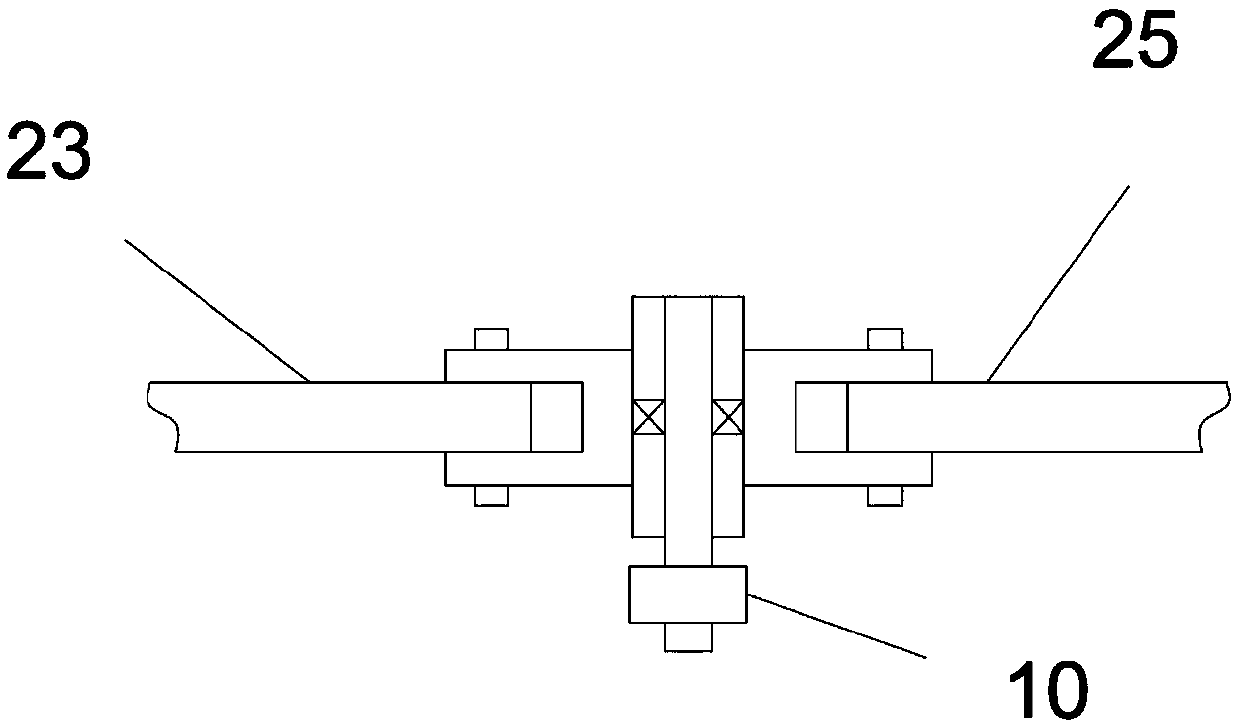

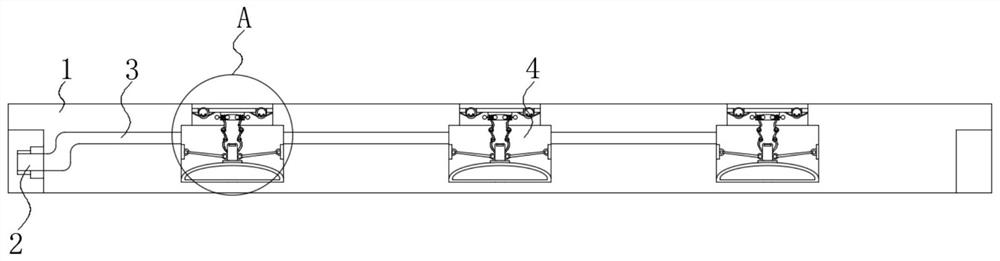

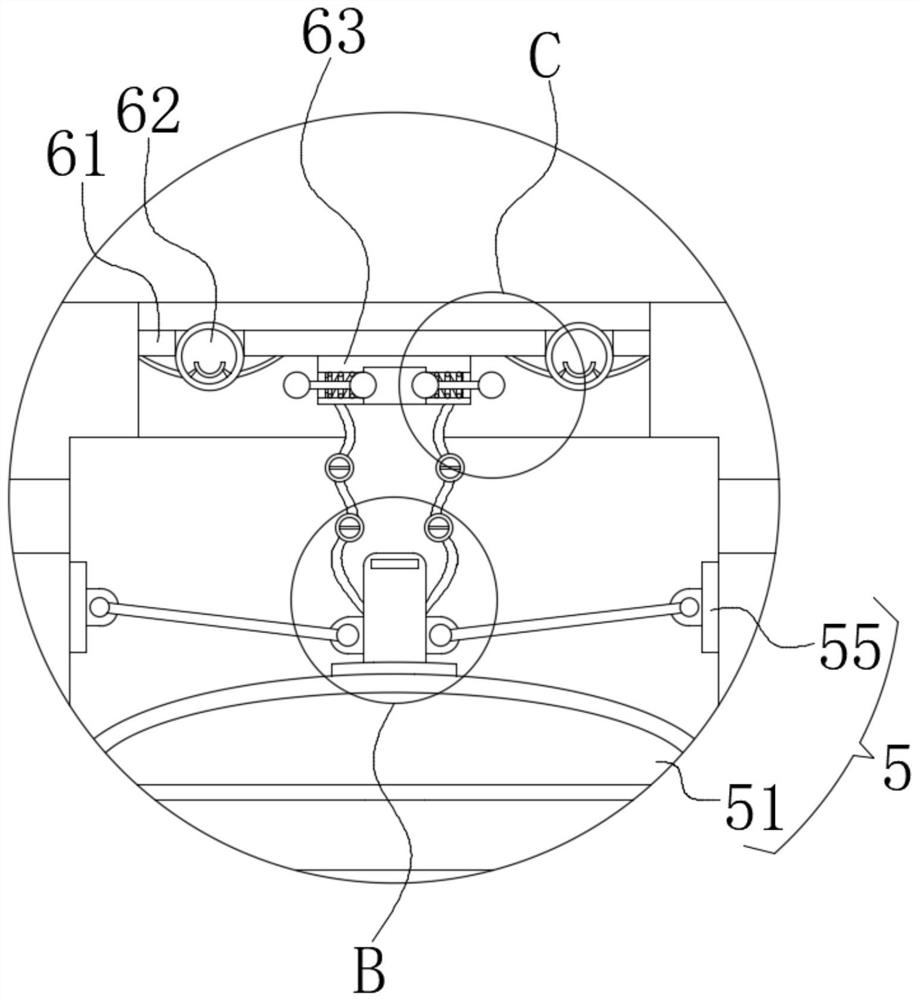

Automatic humidifying and atomizing device for air purifier

ActiveCN108662692AFully humidifiedFull cooling effectMechanical apparatusWater/sewage treatment by irradiationEngineeringWater tanks

The invention discloses an automatic humidifying and atomizing device for an air purifier. The automatic humidifying and atomizing device structurally comprises a low-water-level prompt device, a base, an air purifier body, an intelligent controller and an air outlet, wherein the bottom of the air purifier body is connected with the top of the base; the low-water-level prompt device which communicates with the air purifier body is mounted on one side of the air purifier body; and the intelligent controller is embedded into the top surface of the air purifier body. Compared with the prior art,the automatic humidifying and atomizing device has the following beneficial effects: since the automatic humidifying and atomizing device is provided with the low-water-level prompt device that is connected to a water tank, a low-water-level prompt role can be played to conveniently prompt a user to add water in time, enough water exists in the water tank to humidify and atomize air, and accordingly, the purpose of fully humidifying and cooling air is achieved. Thus, skin can be effectively prevented from dryness. Meanwhile, water always exists in the water tank, and a water pump may not be inidling operation. The service life of the water pump is favorably prolonged while the water pump is protected.

Owner:嘉兴市万荣电器股份有限公司

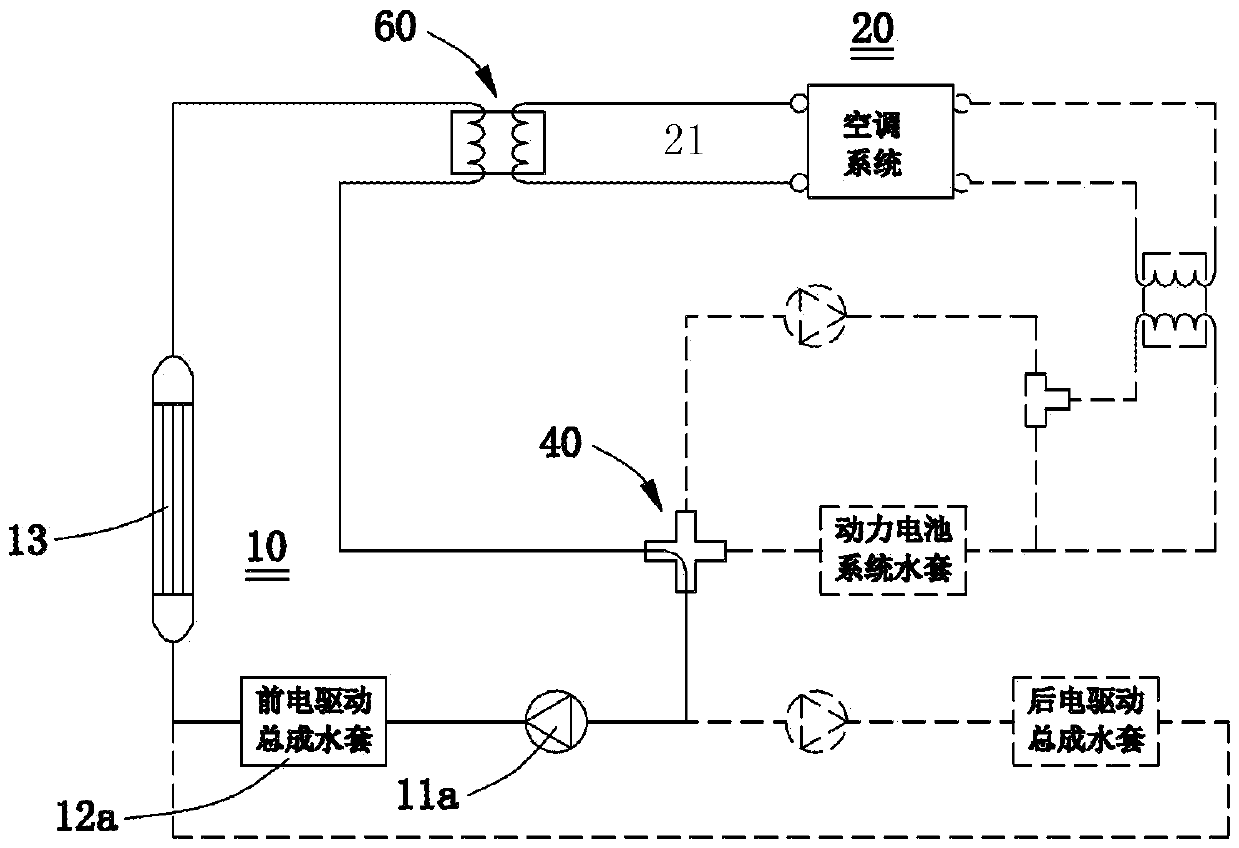

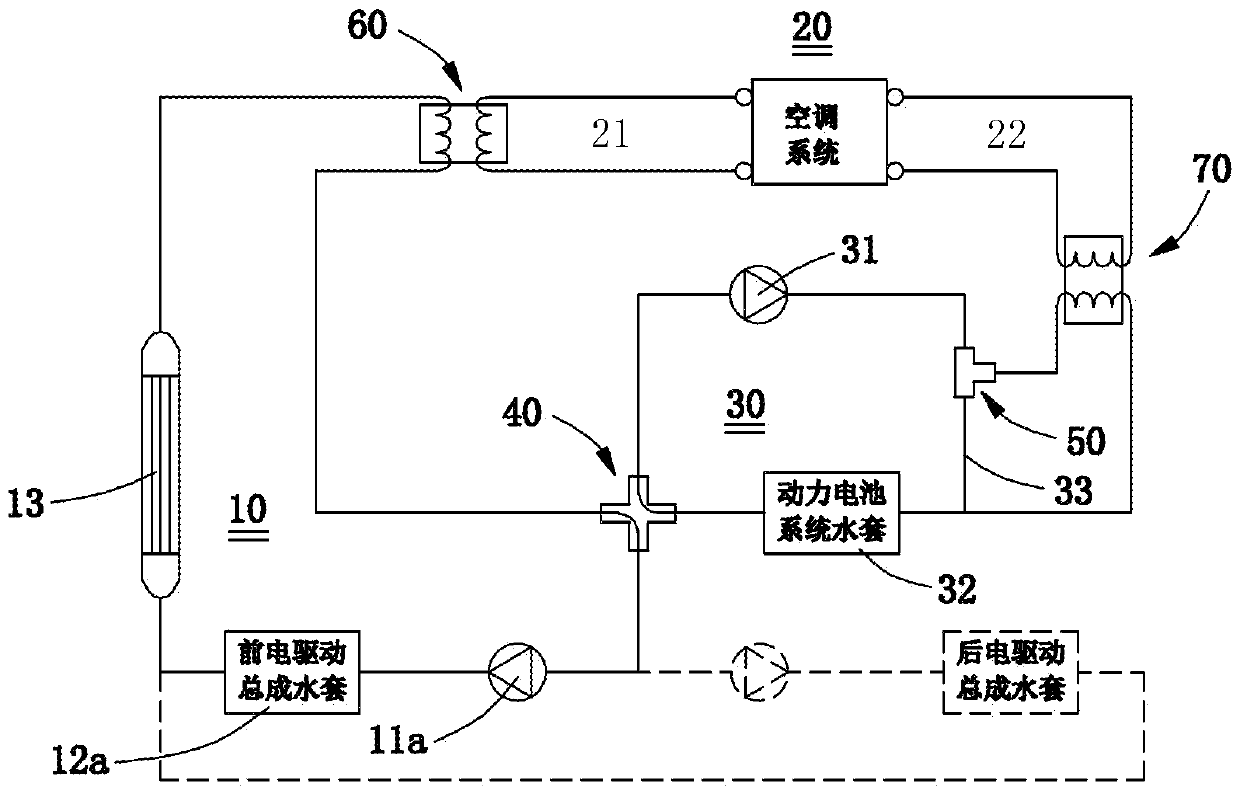

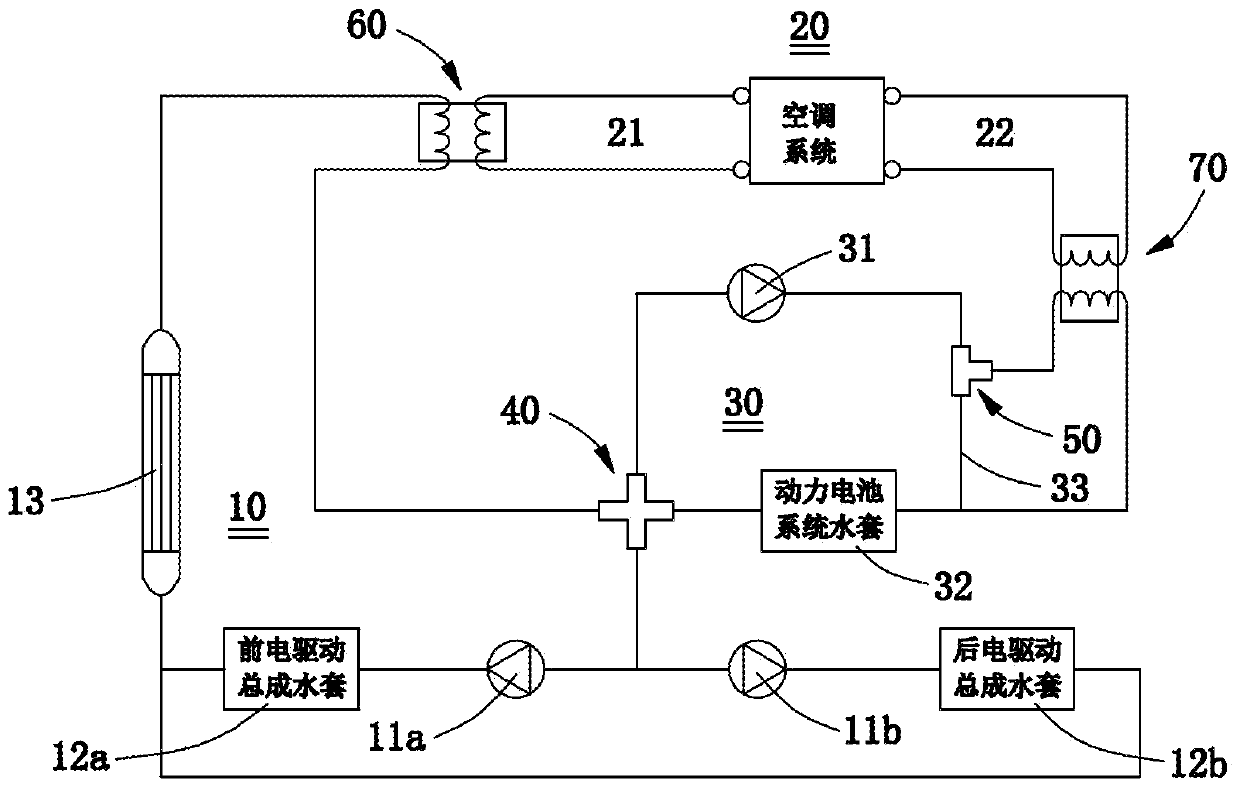

Battery electric vehicle cooling system and vehicle

InactiveCN107719136ASimple module structureLittle correlationAir-treating devicesVehicle heating/cooling devicesElectricityPower battery

The invention relates to a pure electric vehicle cooling system and a battery electric vehicle including same. The cooling system comprises an electric drive system cooling circuit, an air-conditioning system loop and a power battery system cooling circuit. The cooling system also comprises a four-way control valve connected between the electric drive system cooling circuit and the power battery system cooling circuit and used to switch over on-off of the electric drive system cooling circuit and the power battery system cooling circuit, and a three-way control valve used to control heat exchange between the power battery system cooling circuit and the air-conditioning system loop in the power battery system cooling circuit. A heat exchange device between the electric drive system coolingcircuit and the air-conditioning system loop forms a water-cooled condenser of the air-conditioning system loop. A heat exchange device between the power battery system cooling circuit and the air-conditioning system loop forms a low-temperature cooler used for the power battery system cooling circuit. A heat exchanger module in the system is simple in structure and low in correlative influence, and fully develops cooling performance and preferably improves environment adaptability of a whole vehicle.

Owner:NIO ANHUI HLDG CO LTD

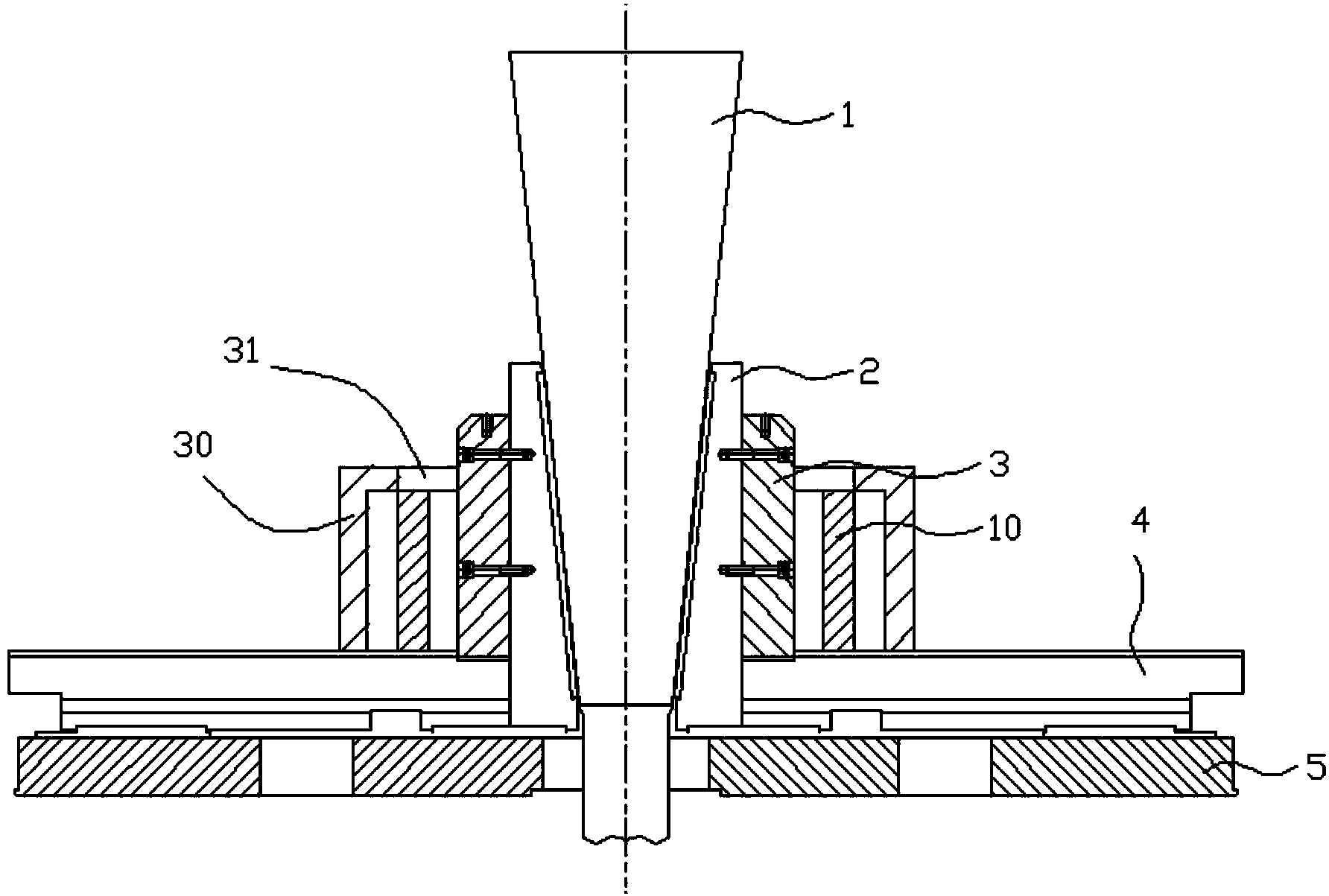

Hot bulging forming method for bearing steel rectangular cross-section ring unit

ActiveCN103447378AHigh dimensional accuracySimplified bulging processShaping toolsProduction rateLarge deformation

The invention discloses a hot bulging forming method for a bearing steel rectangular cross-section ring unit. The hot bulging forming method comprises the following steps of fixing a preheated die sleeve on a worktable of a bulging machine, then, sleeving the periphery of a preheated bulging block in the bulging machine with the preheated bearing steel rectangular cross-section ring unit, and enabling the bearing steel rectangular cross-section ring unit to locate in an annular space formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve; starting the bulging machine to enable the bulging block to extrude the ring unit along a radial direction from the inner circumferential surface of the ring unit and extruding into the inner ring surface of the die sleeve after the ring unit is deformed by 9-11 percent to fill a closed mold cavity formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve, and retaining the pressure of the ring unit to enable the ring unit to become the bulged rectangular cross-section ring unit. According to the method, by adopting one-time large-deformation bulging forming, the operation is simplified, and the bulged rectangular cross-section ring unit which is high in dimensional accuracy, good in product quality and high in production rate is obtained. The bulged rectangular cross-section ring unit is mainly used for revolved body parts used in the fields of wind power generation and the like.

Owner:GUIZHOU AVIATION TECHN DEV

a scrubber

The invention relates to a scrubber tower. The scrubber tower is characterized by comprising a vertical tower, a transverse tower, a scrubbing chamber and an oil-gas separation chamber, wherein the vertical tower is longitudinally separated into a gas inlet chamber and a spray chamber, the gas inlet chamber is communicated with the middle part of the spray chamber, and a spray head is arranged onthe top of the spray chamber; the transverse tower is communicated with the bottom of the spray chamber, and spray heads are distributed on the top of the transverse tower; a pipeline communicated with the end part of the transverse tower is inserted to a position below the liquid level of the scrubbing chamber, the top of the scrubbing chamber is connected with a draught fan through a pipeline, and output of the draught fan is communicated with an air inlet on the upper part of the oil-gas separation chamber through a pipeline; an air outlet is also formed on the upper part of the oil gas separation chamber; and an oil separation baffle is arranged between the air inlet and the air outlet, and close to the side of the air inlet. According to the scrubber tower, a structure of the vertical and the transverse towers is adopted and is matched with the scrubbing chamber and the oil-gas separation chamber, so that the aim of purifying a gas source is achieved.

Owner:FUJIAN BOYI ENVIRONMENTAL PROTECTION TECH

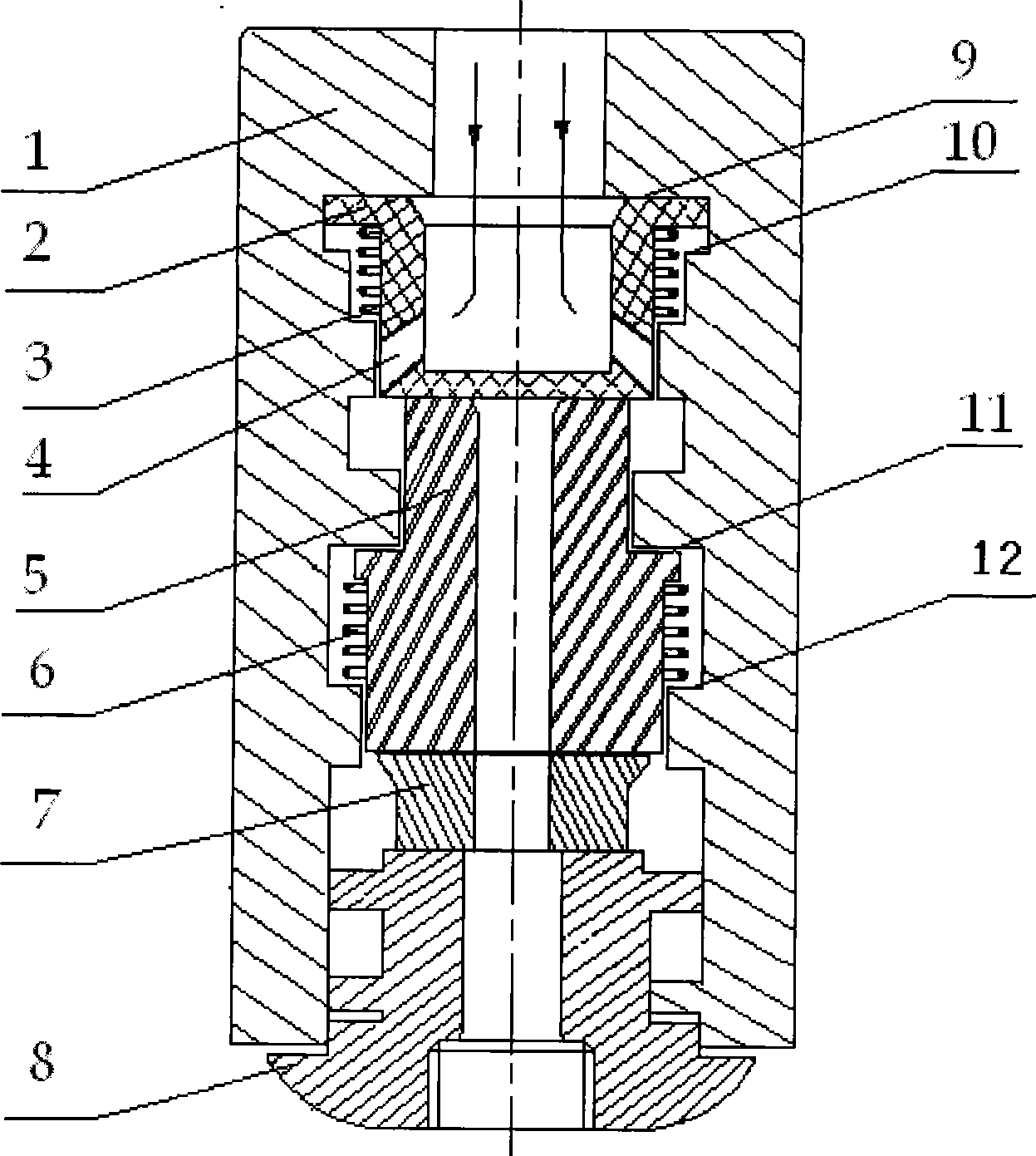

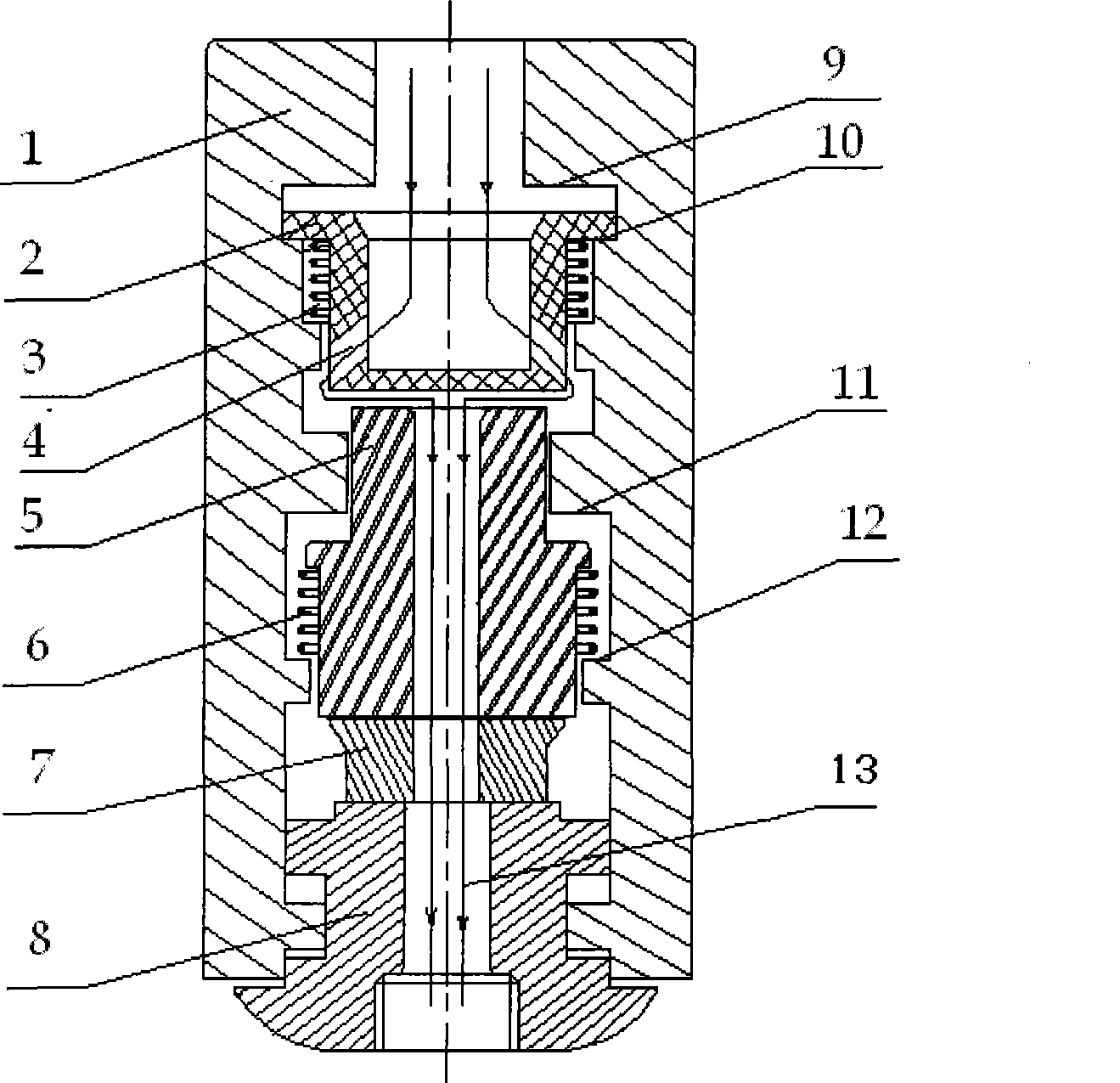

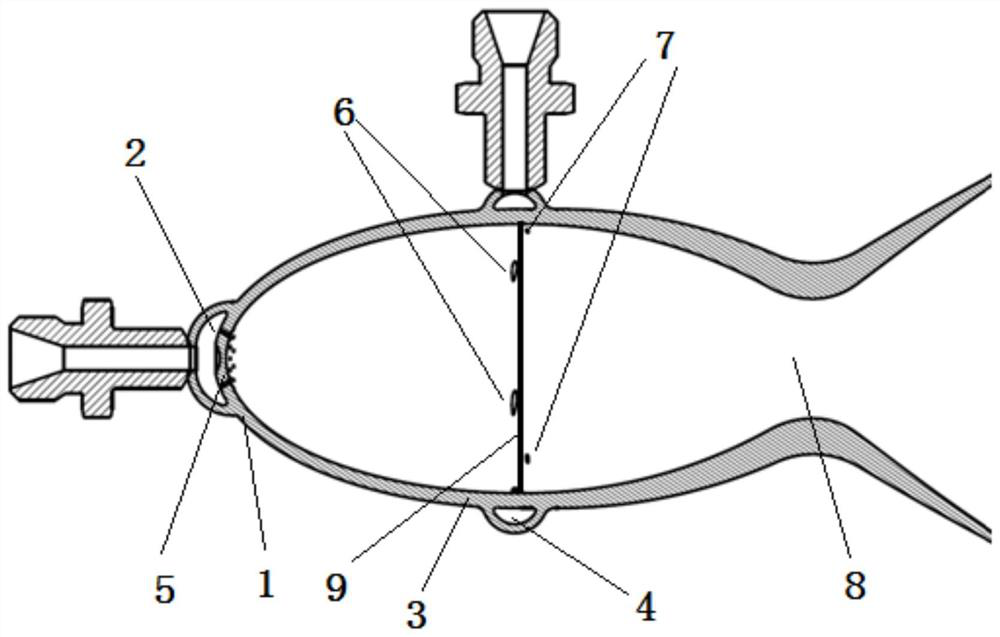

Liquid impact excitation method and device applied to vibration cutting

InactiveCN101362347AImprove cooling effectGood chip removalMechanical vibrations separationMetal working apparatusVibration amplitudeHydraulic pump

The invention relates to a liquid impact vibration excitation method and a device which are applied to vibration cutting. In the invention, liquid impact energy is taken as the vibration excitation source of a vibration excitation device, a liquid channel is cut off instantaneously, and the hydraulic pressure increases sharply. The vibration excitation device comprises a casing, a live valve, a live valve spring, a piston, a piston spring, an amplitude changing mechanism and a shank fixture. The vibration excitation device and a cutting cooling system are combined into a whole, and the cutting fluid for generating the liquid impact energy is taken as the cooling fluid of the cutting cooling system at the same time, therefore, the structure of the cutting cooling system is simplified; compared with the common cutting fluid, the high pressure cutting fluid has better cooling effect and chip removal effect; a hydraulic system for generating the high pressure cutting fluid is required to be configured when the device works, especially for a hydraulic pump; the liquid impact energy has the advantages of small energy transmission loss and high efficiency, the vibration amplitude and the frequency can be adjusted by adjusting the pressure and flow quantity of the cutting fluid, and the requirements of more cutting processes and different processing materials are met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

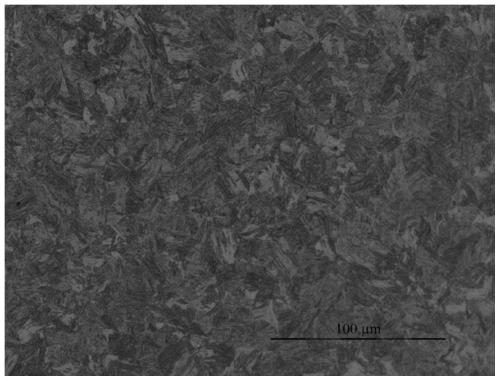

Anti-seismic structural steel with yield strength being 550MPa grade, and production method thereof

The invention relates to an anti-seismic structural steel with the yield strength being 550MPa grade, and a production method thereof. The anti-seismic structural steel contains the following components in percentage by weight: 0.12 to 0.22 percent of carbon, 0.20 to 0.60 percent of silicon, 1.00 to 1.60 percent of manganese, 0.05 to 0.15 percent of aluminum, 0.20 to 0.60 percent of chromium, and the balance ferrum and impurities. According to the anti-seismic structural steel with the yield strength being 550MPa grade, and the production method thereof provided by the invention, thermal mechanical control processing (TMCP) is carried out based on metallurgy processes such as recrystallization and phase change, and hardening treatments such as solution strengthening, precipitation strengthening, dislocation strengthening and grain refining are completed under the specified deformation and temperature conditions, so that the performance of a steel plate at a rolling state can be optimized.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Garbage incinerator with heat recovery device

InactiveCN108224428ABurn completelyFully activeIncinerator apparatusSteam generation using hot heat carriersActivated carbonThermal energy

The invention discloses a garbage incinerator with a heat recovery device. The garbage incinerator with the heat recovery device comprises an activated carbon plate, a water inlet coil pipe, an incinerator body, a grid plate, a through hole, an air inlet hole, a slag discharging port, the heat recovery device, a water inlet pipeline, a garbage feeding port and a steam output pipeline, the grid plate is arranged in the incinerator body and used for supporting garbage to be burnt, ash after burnt can fall down from through holes in the grid plate and is conveniently discharged from the lower portion of the incinerator body, the garbage feeding port and the through hole are formed in the incinerator wall above the grid plate, and a flamethrower connected with a fuel tank is mounted at the through hole. By the aid of the activated carbon plate, the grid plate and the water inlet coil pipe, high-temperature flue gas outputted by the incinerator body is cooled, and dust and harmful gas outputted by the incinerator body are absorbed, so that clean and environment-friendly garbage incineration is achieved.

Owner:JIANGSU MARITIME INST

Efficient dedusting, cooling and air-drying integrated equipment for cable processing

ActiveCN112216442APlay the role of limit supportAchieve dust removal effectCleaning using gasesCable/conductor manufactureWater storageWater storage tank

The invention discloses an efficient dedusting, cooling and air-drying integrated equipment for cable processing. The equipment comprises a dedusting mechanism, a primary cooling mechanism, a water storage tank and a limiting frame, a second bearing plate is arranged on the right side of a first bearing plate, the primary cooling mechanism penetrates through the top of a bearing table, and the water storage tank is fixed to the top of the bearing table in a penetrating mode. A second fixed pulley is arranged on the upper side of the water storage tank, a third fixed pulley is rotatably connected into the water storage tank, a third bearing plate is arranged on the right side of the water storage tank, a fourth fixed pulley is rotatably connected between the third bearing plate, and a fan is arranged on the right side between the fixing sleeve and the limiting frame. And the torsion mechanism is arranged on the limiting frame. According to the efficient dedusting, cooling and air-dryingintegrated equipment for cable processing, water needs to be introduced into the water storage tank before the equipment is used, in the process that a cable is wound around the third fixed pulley, water in the water storage tank can conduct secondary cooling treatment on the cable, and the cooling effect is conveniently enhanced.

Owner:镇江市沃通机械有限公司

A non-uniform filling system for high-level water collection cooling tower

ActiveCN104848728BImprove cooling efficiencyIncrease air-to-water ratioTrickle coolersCooling towerTower

The invention discloses a non-uniform packing system for a high-level water recovery cooling tower. The non-uniform packing system for the high-level water recovery cooling tower comprises a packing area, wherein the packing area is located in the cooling tower. Non-uniform arrangement and partition arrangement are adopted by packing in the packing area. According to the partition mode of the packing area, the vertical axis of the cooling tower serves as the center, three annular regions including the region A, the region B and the region C are formed outwards in sequence, wherein the radii of the three annular regions are different. According to the relation of the radii of the packing in the three packing regions, the radius of the packing in the region A is smaller than or equal to that of the packing in the region B and that of the packing in the region C, and the radius of the packing in the region B is smaller than or equal to that of the packing in the region C. According to the relation of the thicknesses of the packing in the three packing regions, the thickness of the packing in the region A is larger than or equal to that of the packing in the region B and that of the packing in the region C, and the thickness of the packing in the region B is larger than that of the packing in the region C. According to the non-uniform packing system for the high-level water recovery cooling tower, non-uniform arrangement of the packing in the regions of the high-level water recovery cooling tower is adopted, the gas-water ratio in the tower can be increased to the maximum extent, the cooling performance of the packing in the tower is fully utilized, and the cooling efficiency of the cooling tower is improved.

Owner:SHANDONG UNIV

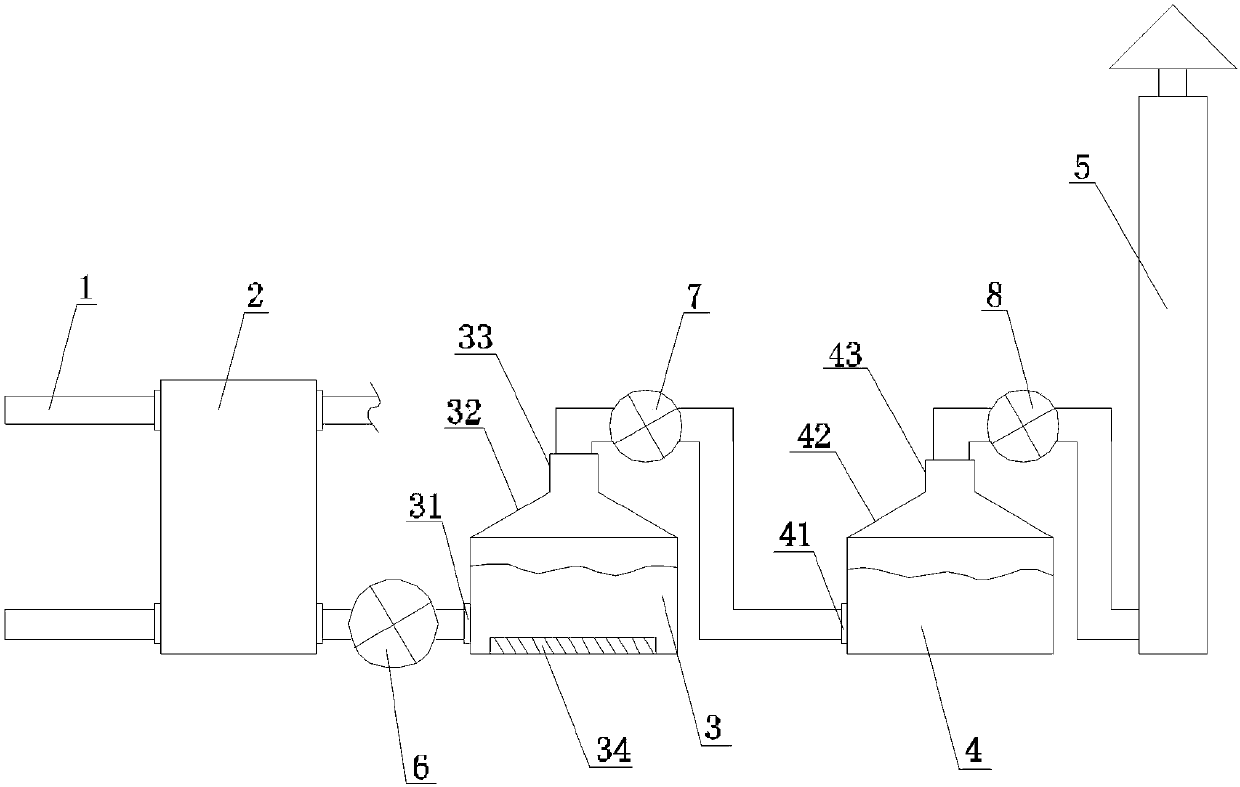

Efficient purification and exhaust system for flue gas

InactiveCN107837624AImprove purification efficiencyCreate pollutionHuman health protectionUsing liquid separation agentAtmospheric airPollution

The invention discloses an efficient purification and exhaust system for flue gas. According to efficient purification and exhaust system, the problems of energy waste and low purification efficiencyof the flue gas in the prior art are solved. The efficient purification and exhaust system comprises high-temperature flue gas conveying pipelines, a heat exchanger, a cooling and dedusting pool, an alkaline water pond and a high-altitude exhaust smoke bin, wherein the heat exchanger comprises a heat exchanger casing, a flue gas inlet pipe, an air outlet pipe, a flue gas outlet pipe, an air inletpipe and a heat exchange pipeline; the heat exchanger casing is of a dual-layer structure; the cooling and dedusting pool is provided with a dust removing pipe, a conical dust removing top cover, a waste gas outlet pipe and an ultrasonic generator; the ultrasonic generator generates ultrasonic waves for vibrating and scattering flue gas bubbles, so that the flue gas can make contact with dust removing water more sufficiently and further full cooling and purification are realized. The efficient purification and exhaust system disclosed by the invention has the advantages of simple structure, scientific and reasonable design, convenience in use and high purification efficiency of the flue gas; high-temperature flue gas and combustion supply gas at the combustion stage are subjected to heat exchange, so that energy can be effectively saved; meanwhile, the flue gas is subjected to cooling and dust removal as well as removal of harmful substances, so that pollution to atmosphere during exhaust is avoided.

Owner:CHENGDU UNIV OF INFORMATION TECH

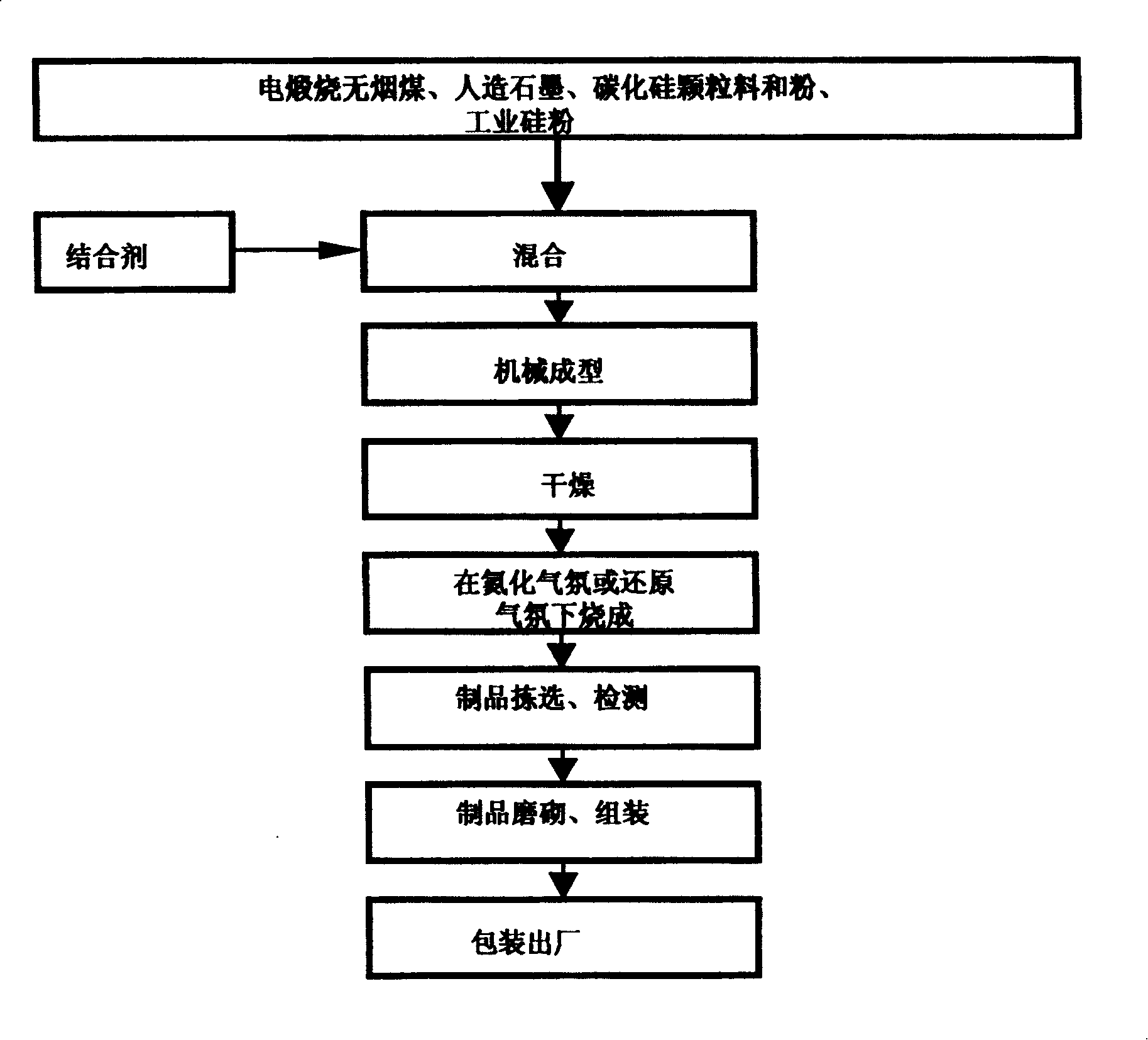

Novel semi-graphitization silicon nitride carbide brick and its production method

The invention relates the fire resistive material and the preparing method, especially the new pattern graphitization silicon carbide nitride brick and its preparing method. The material comprises 20-50wt% anthracite coal, 20-40wt% graphite, 15-30wt% industrial silicon, 10-30wt% silicon carbide, and 7-20wt% binding agent. The method comprises the following steps: mixing the raw material and binding agent, press forming, drying, and baking them at 1200-1800Deg.C for 8-24 hours at the atmosphere of nitrogen, and charging 0.1MPa nitrogen into calcining kiln. The invention has the advantages of good opposing iron and alkali metal corrosion capability, good heat conductivity, high thermal conductivity factor which above 30 w / m.k, and good earthquake resistance and high machinery strength. The invention can be used in furnace bottom, furnace hearth and inside lining from breast to shaft, extending the durability, and improving economic benefit.

Owner:郑州华宇高炉工程技术有限公司

Liquid-film cooled thrust chamber for rail posture control engine

ActiveCN111963339APerfect for whole body coolingAchieve whole body coolingRocket engine plantsThrust chamberWhole body

The invention discloses a liquid-film cooled thrust chamber for a rail posture control engine. A first propellant chamber is arranged on the outer side of the head of the thrust chamber, and a secondpropellant chamber is arranged on the outer side of the middle position of the body of the thrust chamber. A plurality of first spray holes communicating with the first propellant chamber are formed in the shell wall of the head of the thrust chamber. A plurality of combustion jet holes and a plurality of liquid film jet holes are evenly formed in the shell wall of the body of the thrust chamber in the circumferential direction. A second propellant is sprayed to the head and the throat of the thrust chamber through the combustion jet holes and the multiple liquid film jet holes respectively, aliquid film is sprayed towards the throat of the thrust chamber, and a tangential liquid feeding mode is adopted, so that loss of the liquid film can be reduced. The cooling performance of the liquidfilm is given full play to. In addition, the combustion jet holes face the head of the thrust chamber, a tangential liquid feeding mode is adopted, the cooling performance of the liquid film can be achieved, meanwhile, the liquid film can react with the first propellant, therefore the proportion of the liquid film in the propellant can be reduced, and whole-body cooling of the thrust chamber is achieved.

Owner:XIAN AEROSPACE PROPULSION INST

A niobium-titanium-chromium-boron alloy wear-resistant steel and preparation method thereof

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Big data service equipment

InactiveCN110580091ARealize repeated crushingReduce the temperatureDigital data processing detailsIce waterCooling effect

The invention discloses big data service equipment which comprises a big data processing box body and a cooling box, a storage box is fixedly installed on the upper left side wall of the cooling box,a rotating cover plate is rotatably arranged at the upper end of the storage box, a locking screw is vertically arranged on the rotating cover plate in a penetrating mode, and a liquid inlet pipe is communicated with a net cage; the outlet end of the lifting pump is provided with an annular pipe in a communicating mode, then cooling treatment is conducted on the big data processing box body through the annular pipe, ice water can circulate in the annular pipe and the cooling box, water in the annular pipe is kept at a low temperature, and the sufficient cooling effect is achieved; repeated crushing of ice blocks is realized through the opposite extrusion effect of the pressing plate and the bearing plate; further crushing of ice blocks is achieved through mutual extrusion of the crushing pressing plate and the sawtooth nails, the fully crushed ice blocks are mixed with water, the water temperature is rapidly reduced, rapid exchange with heat in the big data processing box body is further achieved, and the cooling effect is remarkable and rapid.

Owner:佛山市易于嘉农业科技有限公司

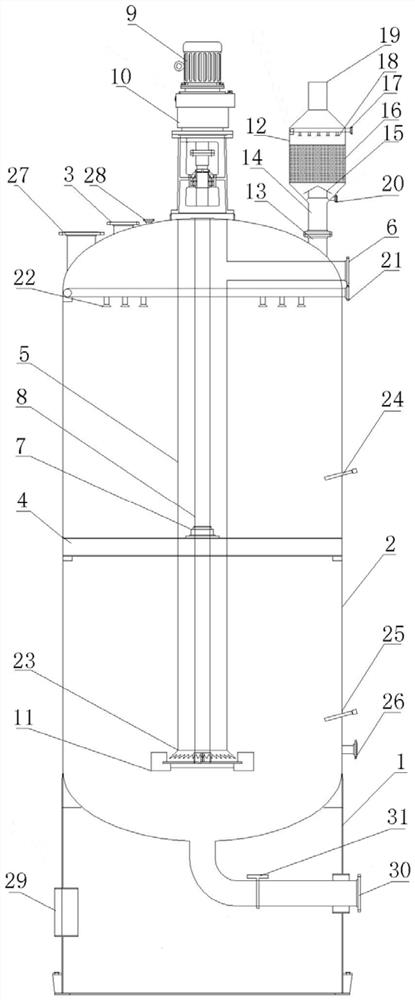

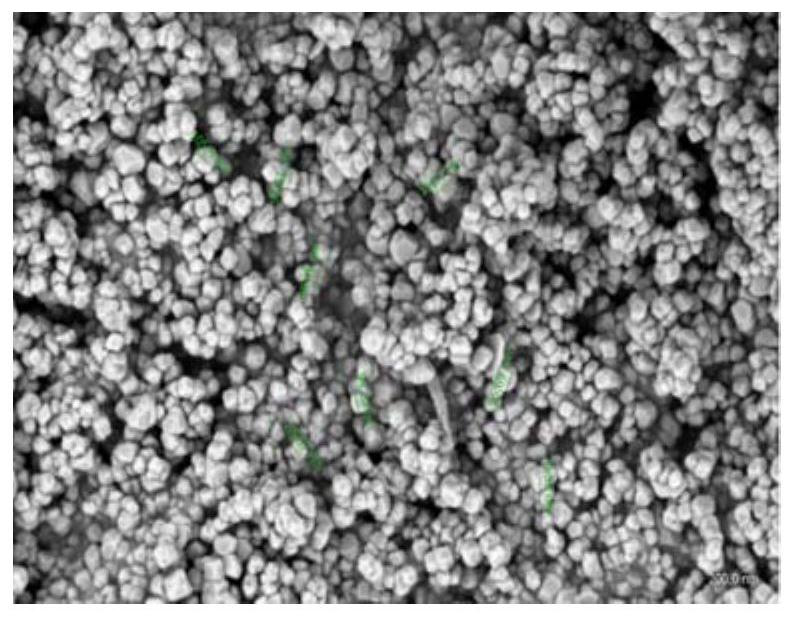

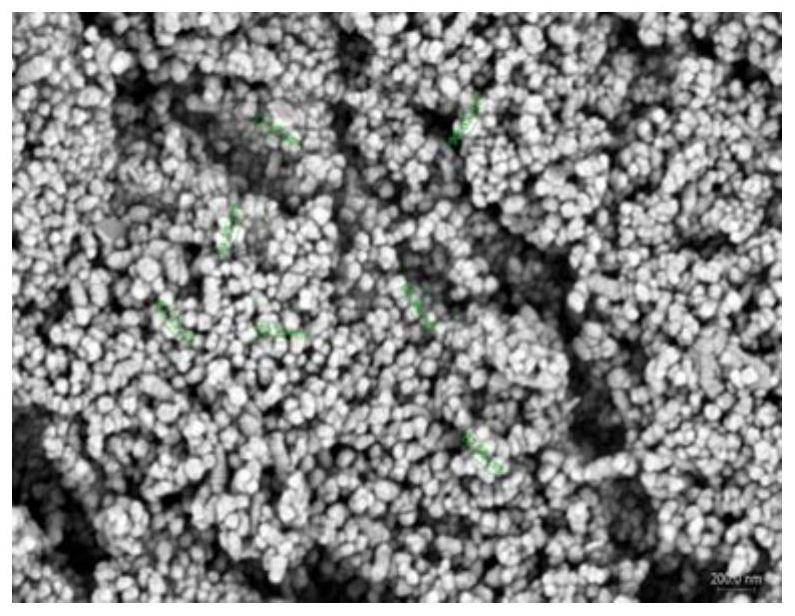

Environment-friendly nano calcium carbonate carbonation method

ActiveCN112678858AAccelerate and promote the rate of nucleationAvoid problems with uneven particle size distributionCalcium/strontium/barium carbonatesMaterial nanotechnologySlurryNanostructured carbon

The invention discloses an environment-friendly nano calcium carbonate carbonation method which comprises the following steps: S1, injecting lime slurry into a reaction kettle, stopping feeding when the feeding amount is 1 / 5-2 / 5 of the volume of the reaction kettle, and adjusting the rotating speed at the same time; introducing kiln gas into the reaction kettle, and discharging reaction tail gas after treatment; when the pH value of the slurry in the reaction kettle is 7.5-8.0, stopping air intake, and adjusting the rotating speed; and s2, injecting lime slurry into the reaction kettle containing the seed crystal, stopping feeding when the feeding amount reaches 4 / 5 of the volume of the reaction kettle, adjusting the rotating speed, stirring and aging; and introducing the kiln gas again, and when the pH value of the slurry in the reaction kettle is 7 and the slurry at the upper part and the lower part in the reaction kettle has no relative temperature difference, enabling the carbonation reaction to reach the end point. According to the method, the nano calcium carbonate with the average particle size of 40-100 nm is stably produced, and meanwhile, in the production process, the generated tail gas is treated and then discharged, so that the atmosphere is hardly influenced, and the environmental protection requirement is met.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

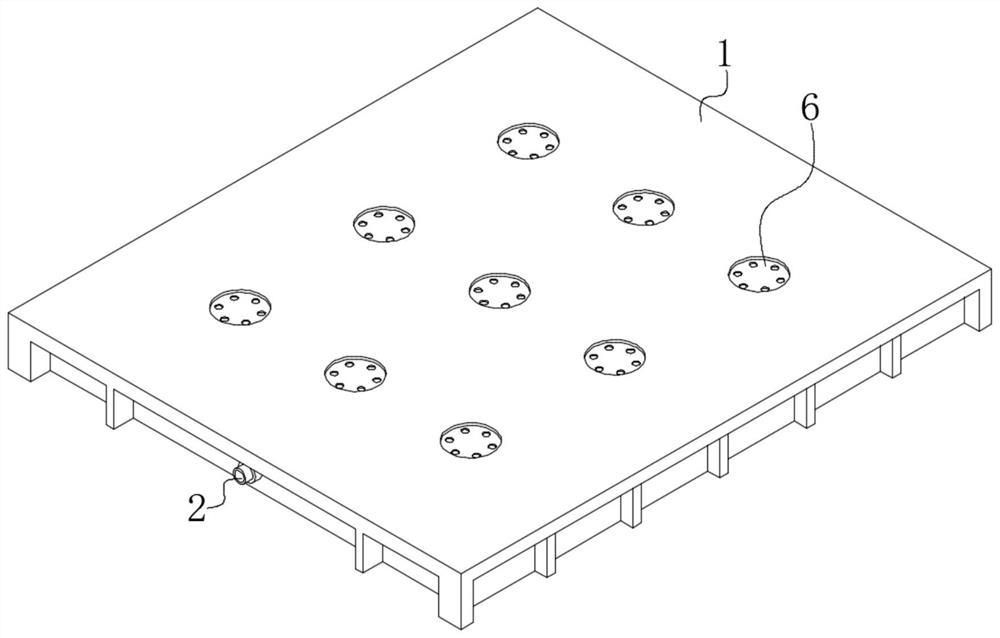

Rapidly-formed multi-layer hot-pressed building formwork

InactiveCN112814368ATemperature monitoringRealize the temperature detection effectForming/stuttering elementsTemperature controlArchitectural engineering

The invention discloses a rapidly-formed multi-layer hot-pressed building formwork, and relates to the technical field of building formworks. The rapidly-formed multi-layer hot-pressed building formwork comprises a formwork face, a one-way water inlet valve is fixedly connected to the middle of the front face of the formwork face, water guiding grooves distributed in a latticed mode are formed in the formwork face, water collecting cavities distributed in an equidistant array mode are formed in the formwork face, the water collecting cavities are all located at the intersections of the water guiding grooves and communicate with inner cavities of the water guiding grooves, temperature control opening and closing mechanisms are arranged in the water collecting cavities, a mounting opening communicating with the water collecting cavities is formed in the top of the formwork face, and a multidirectional drainage mechanism is arranged in the mounting opening. According to the rapidly-formed multi-layer hot-pressed building formwork, whether the temperature of all positions of the formwork face is too high or not can be detected in time through the temperature control opening and closing mechanisms, automatic operation is conducted when the temperature of the formwork face is too high, water is drained to the surface of the formwork face in time for cooling treatment, and compared with a traditional manual watering cooling mode, the workload of field staff in a high-temperature environment is reduced.

Owner:武汉黄陂鸿泰路桥钢模有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com