Cooling air channel structure of dry type transformer

A technology of dry-type transformer and cooling air duct, which is applied in transformer/inductor cooling, transformer/inductor parts, transformer/reactor installation/support/suspension, etc. Hot air cannot be discharged in time, energy is not fully utilized, etc., to improve the cooling effect, prevent pipe blockage, and improve cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

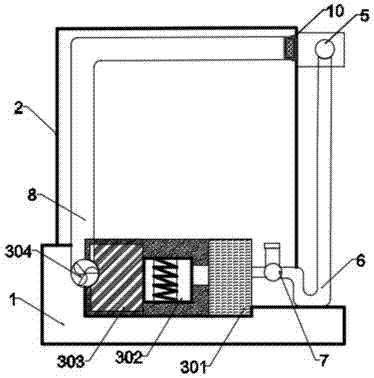

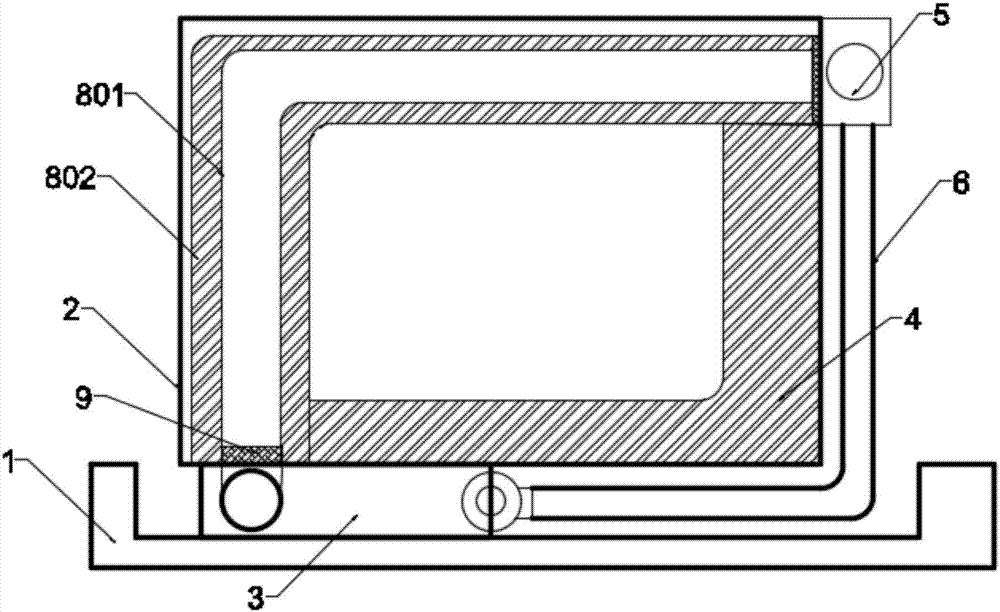

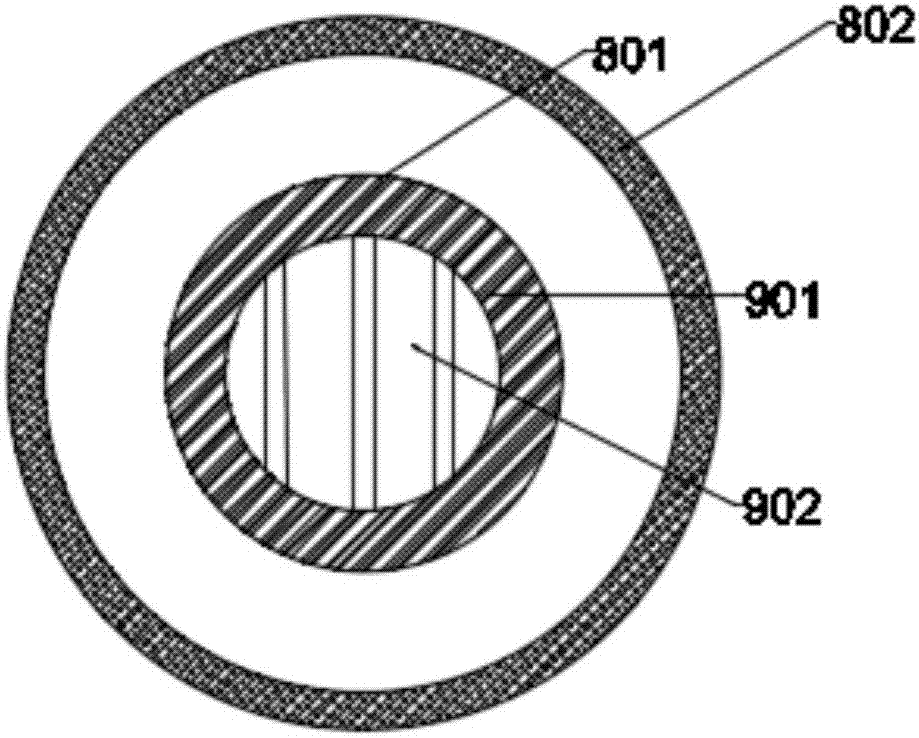

[0029] Such as figure 1 and figure 2 As shown, the present invention provides a dry-type transformer cooling duct structure, including a fixed base 1, a fixed groove is dug in the center of the upper surface of the fixed base 1, and a transformer box 2 is embedded in the groove. There are circular through holes dug on the bottom of both sides of the box body 2, and there is a cooling fan 3 temporarily under the circular through holes; the fixed base 1 and the transformer box body 2 are both made of insulating materials, have good insulation performance, and are fixed There are threaded mounting holes drilled on the base 1, which can be easily installed and disassembled;

[0030] The base of the cooling fan 3 is installed on both sides of the fixed base 1 through fixing screws, and the air outlet of the cooling fan 3 is sleeved with a cooling air duct 4, and the cooling air duct 4 is connected inside the transformer box 2, and the two sides The air outlets of the side coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com