Chinese hamburger preparation system

A technology of glutinous rice cakes and pancakes, which is applied in the field of structural improvement of pancake pancake spreading devices, can solve problems such as uneven temperature, complicated installation and maintenance, shaking, etc., and achieve precise control process, high degree of automation, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

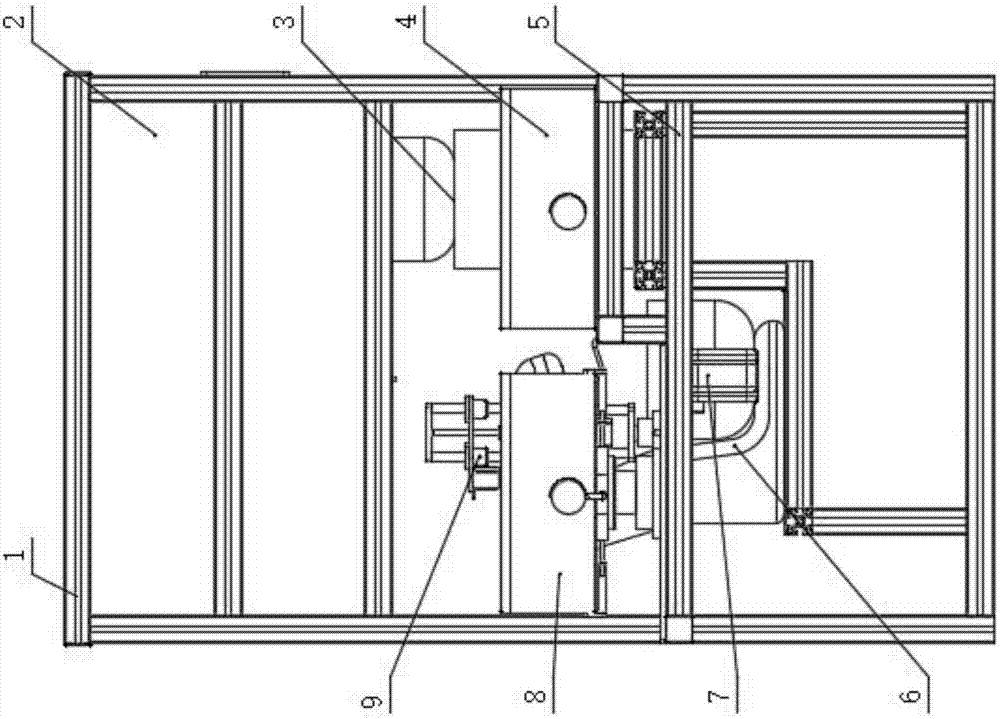

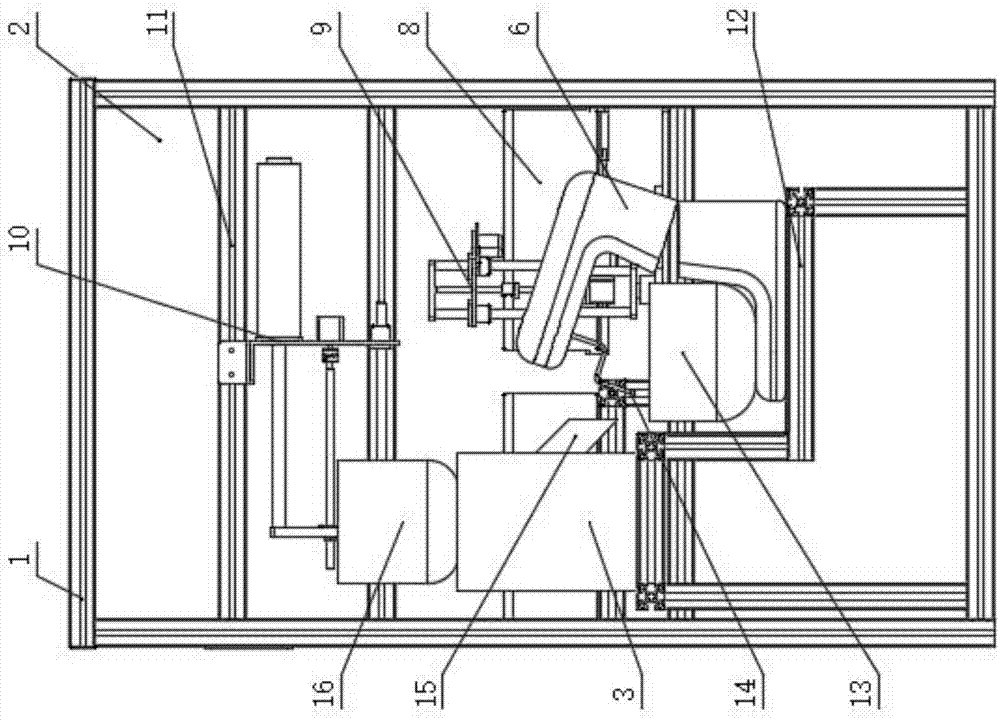

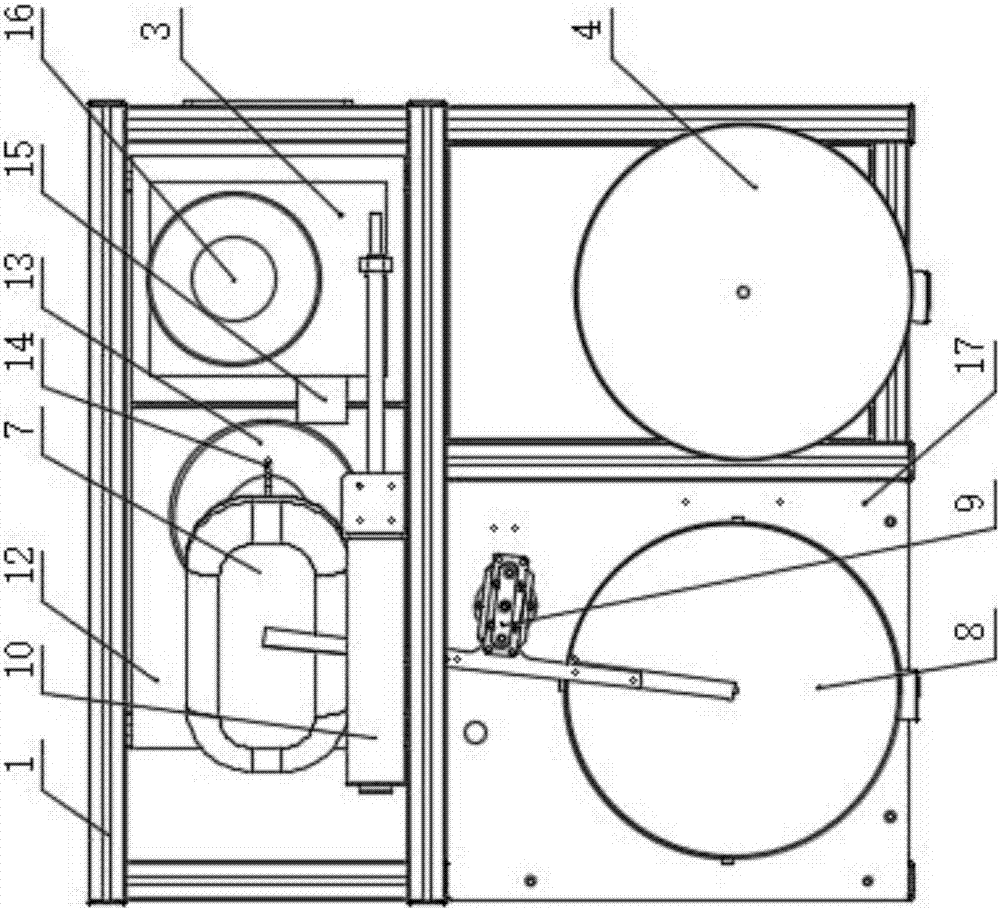

[0047] A pancake glutinous rice spreading system, such as Figure 1~5 As shown, the innovation of the present invention is: comprise support 1, scraper mechanism 9, slurry supply mechanism 10 and surface turning mechanism 8, described surface turning mechanism is set on the workbench 17 of the front bracket 5 of support front end, this The scraping mechanism is arranged on the workbench beside the surface turning mechanism, and the slurry supply mechanism is arranged at any position of the support. The surface 70 in the surface turning mechanism automatically rotates, and the slurry supply mechanism automatically sends The slurry is conveyed on the surface, and the scraper 22 in the scraping mechanism is automatically put in place to scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com