Refrigeration device

A refrigeration device and refrigerant technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of refrigerant pressure drop, inability to gasify refrigerant at intermediate pressure, and refrigerant temperature drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

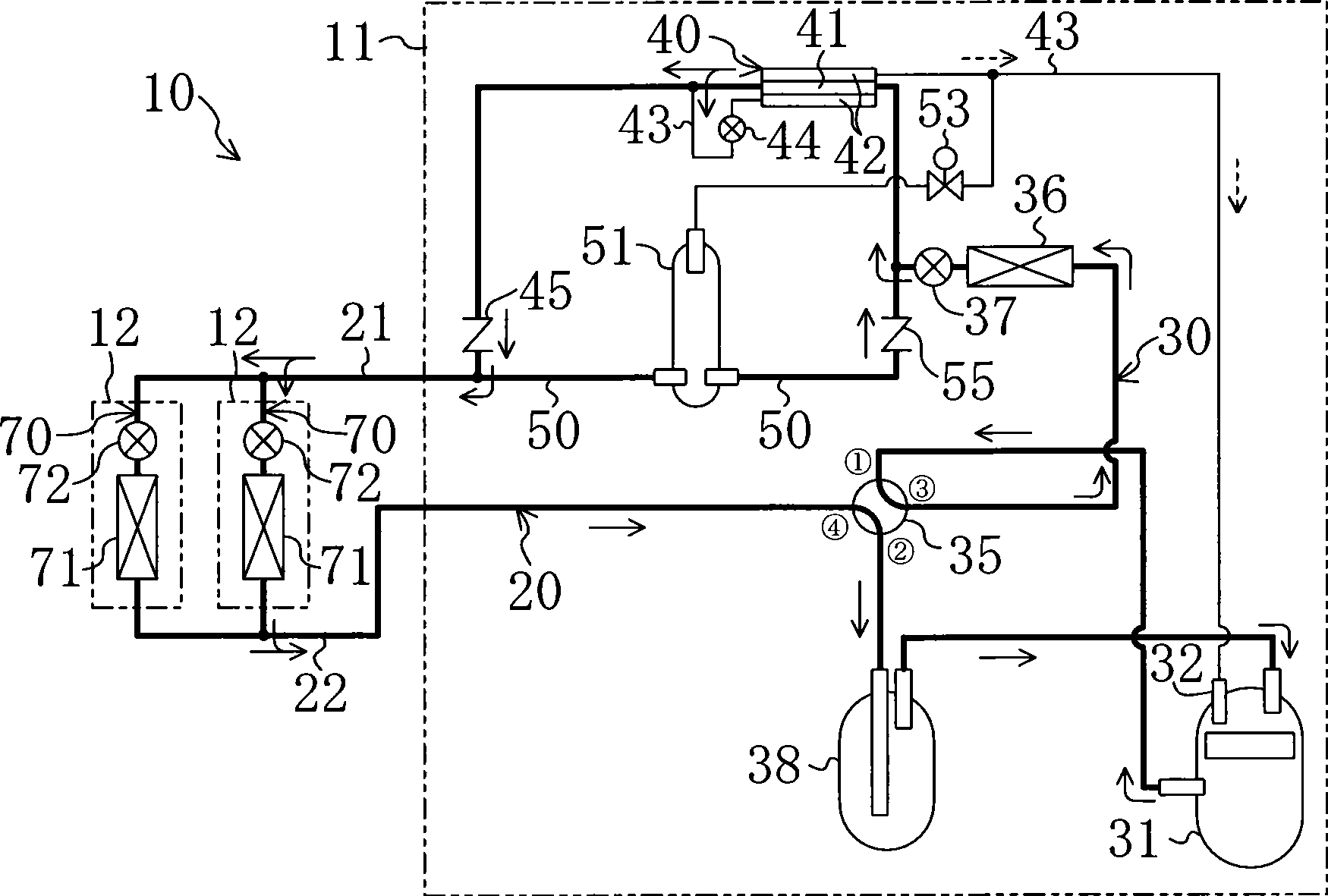

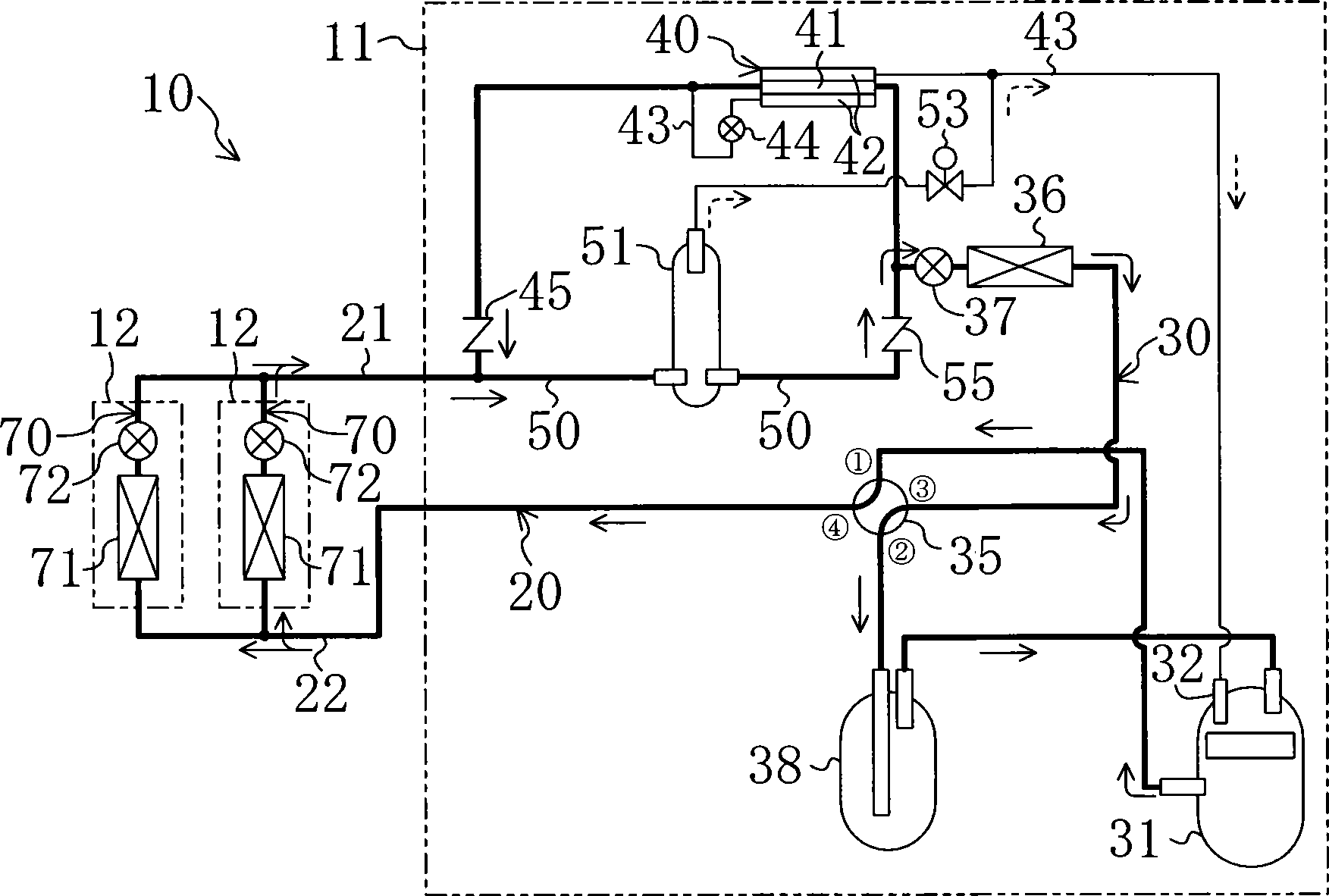

Embodiment 1 of the present invention will be described. The present embodiment relates to an air conditioner 10 constituted by the refrigeration device of the present invention.

[0031] As shown in FIG. 1 , the air conditioner 10 of this embodiment has one outdoor unit 11 and two indoor units 12 . In addition, the number of indoor units 12 is merely an example. An outdoor circuit 30 serving as a heat source side circuit 30 is accommodated in the outdoor unit 11 . Each indoor unit 12 accommodates an indoor circuit 70 as a use-side circuit.

[0032] In the air conditioner 10 , the refrigerant circuit 20 is formed by connecting the outdoor circuit 30 and the indoor circuit 70 with the liquid-side connecting pipe 21 and the gas-side connecting pipe 22 . In this refrigerant circuit 20 , two indoor circuits 70 are connected in parallel to one outdoor circuit 30 .

[0033] Each of the indoor circuits 70 is provided with one indoor heat exchanger 71 as a usage-side heat exchanger...

Embodiment approach 2

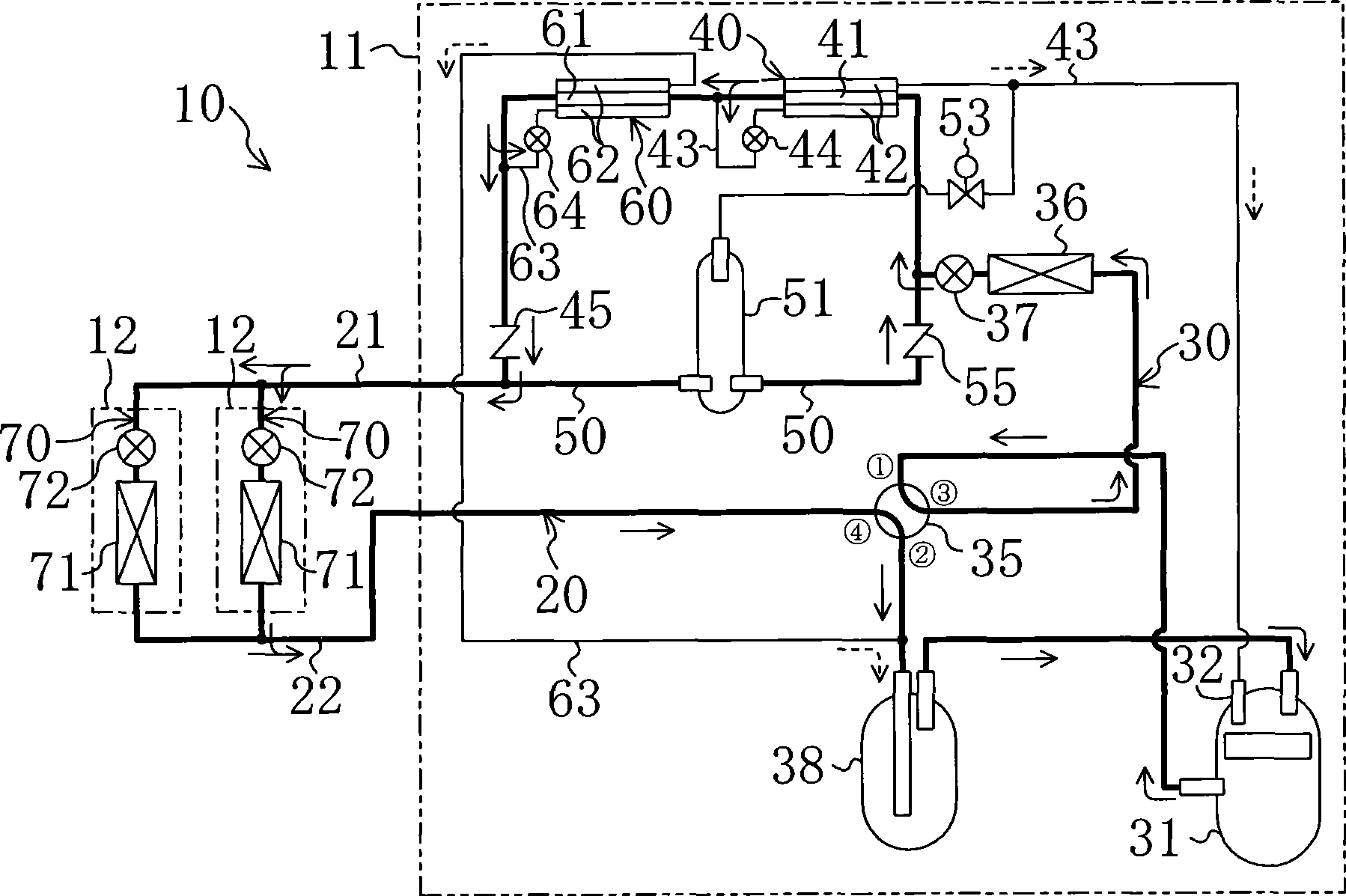

Embodiment 2 of the present invention will be described. This embodiment is an example in which a subcooling heat exchanger 60 and a supercooling duct 63 are added to the air conditioner 10 of the first embodiment. Here, differences between the air conditioner 10 of the present embodiment and the first embodiment described above will be described.

[0060] As shown in FIG. 2 , a subcooling heat exchanger 60 is provided in the outdoor circuit 30 . The subcooling heat exchanger 60 is a heat exchanger for exchanging heat between refrigerants in a jacket heat exchanger, a plate heat exchanger, and the like. A first flow path 61 and a second flow path 62 are formed in the subcooling heat exchanger 60 . The first flow path 61 of the subcooling heat exchanger 60 is provided between the intermediate pressure heat exchanger 40 and the first check valve 45 in the outdoor circuit 30 .

[0061] The start end of the supercooling pipe 63 is connected between the subcooling heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com