Patents

Literature

65results about How to "Guaranteed Low Temperature Toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

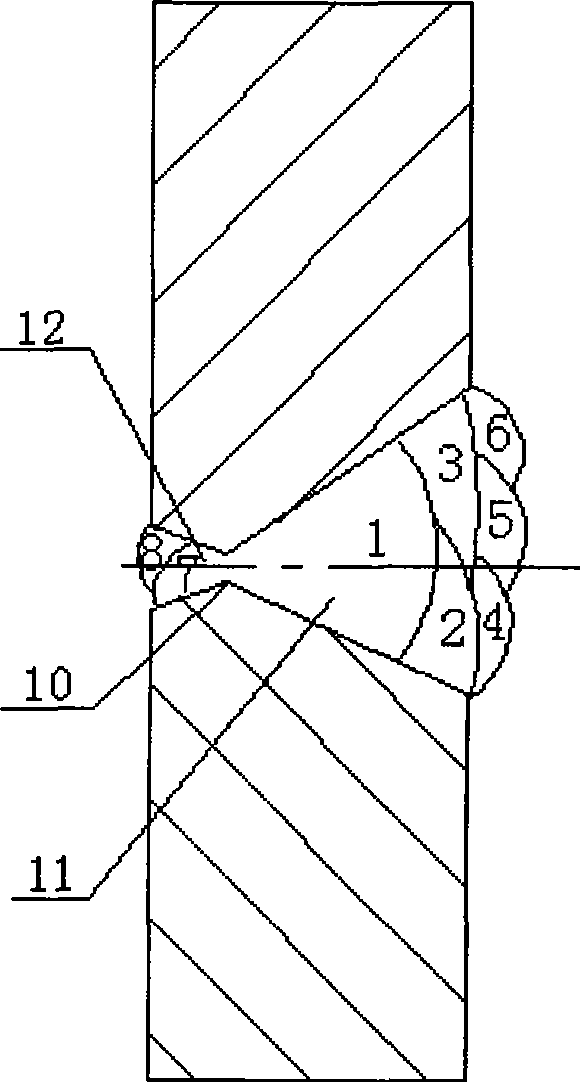

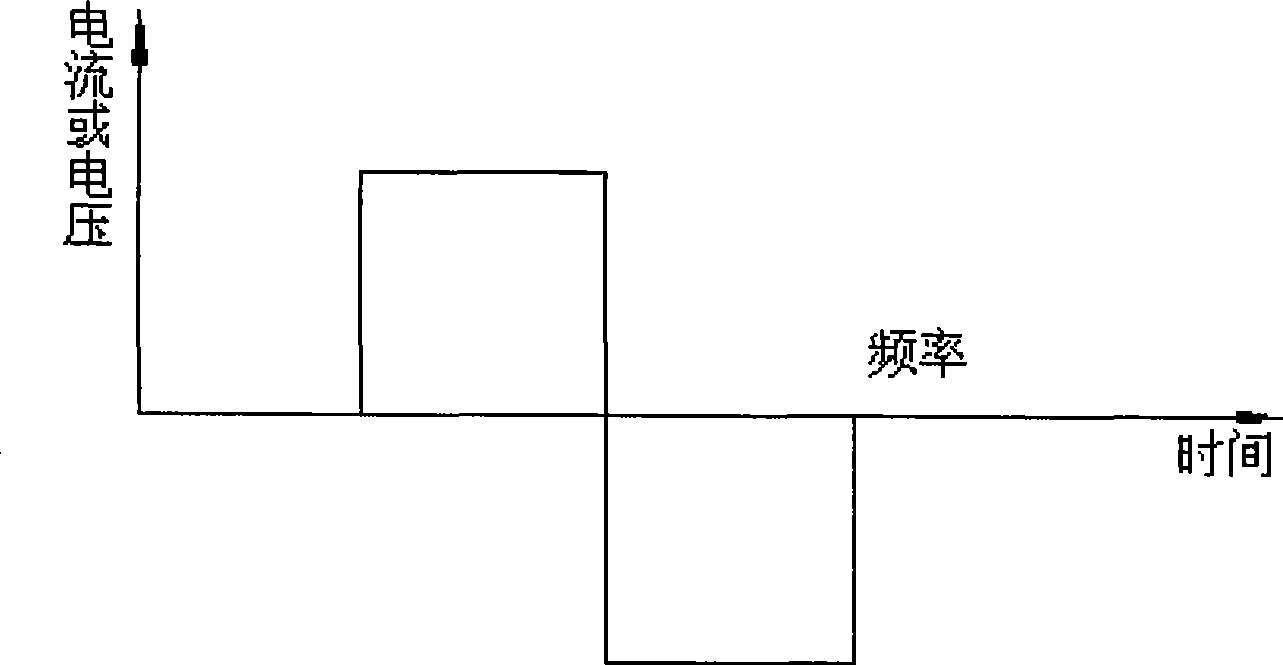

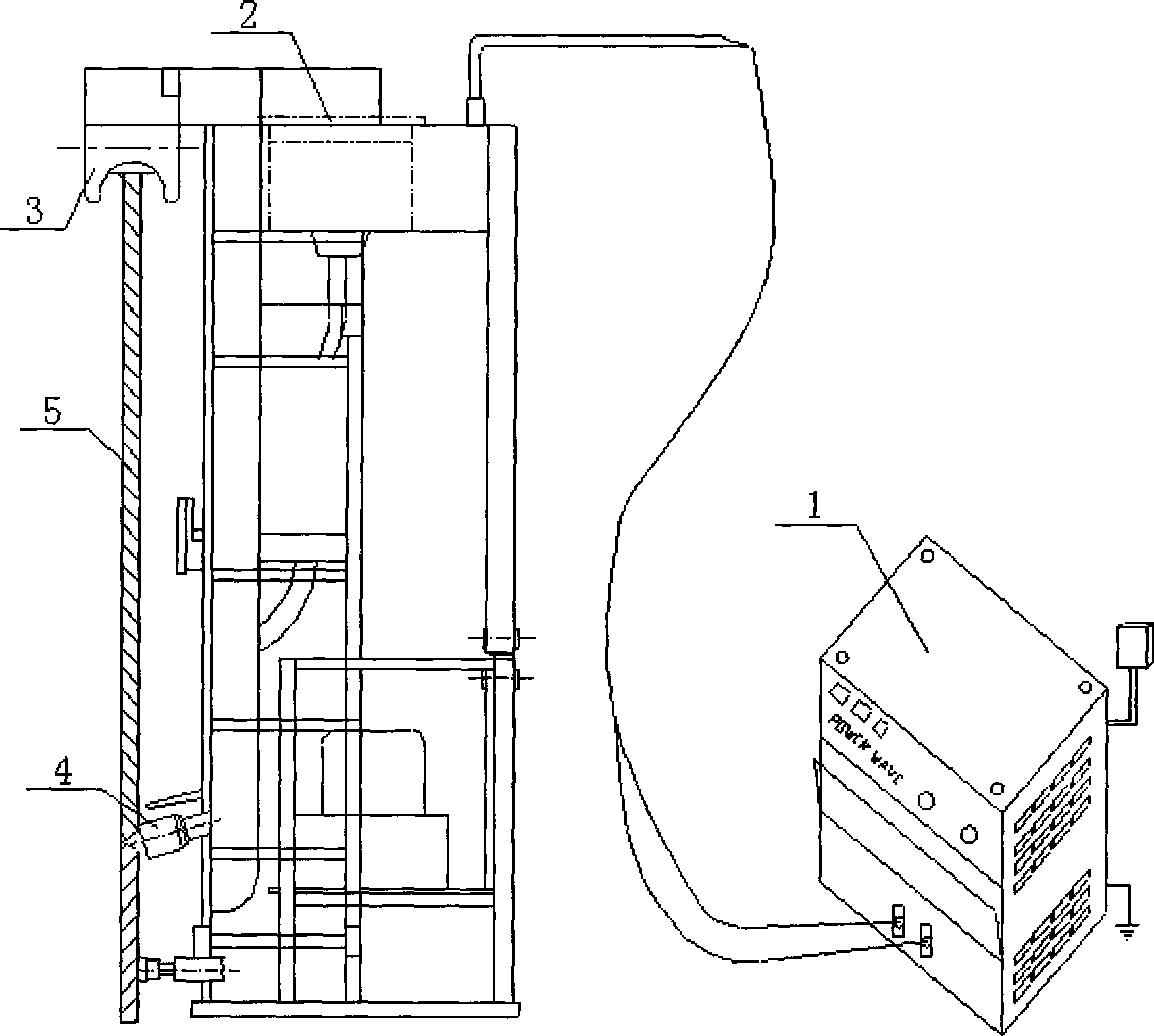

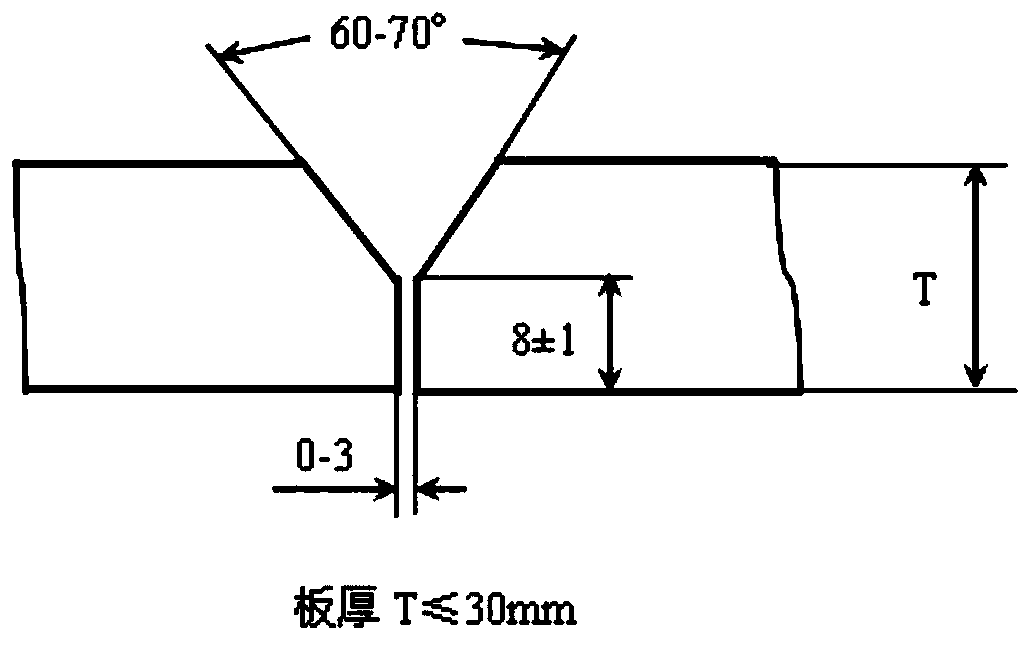

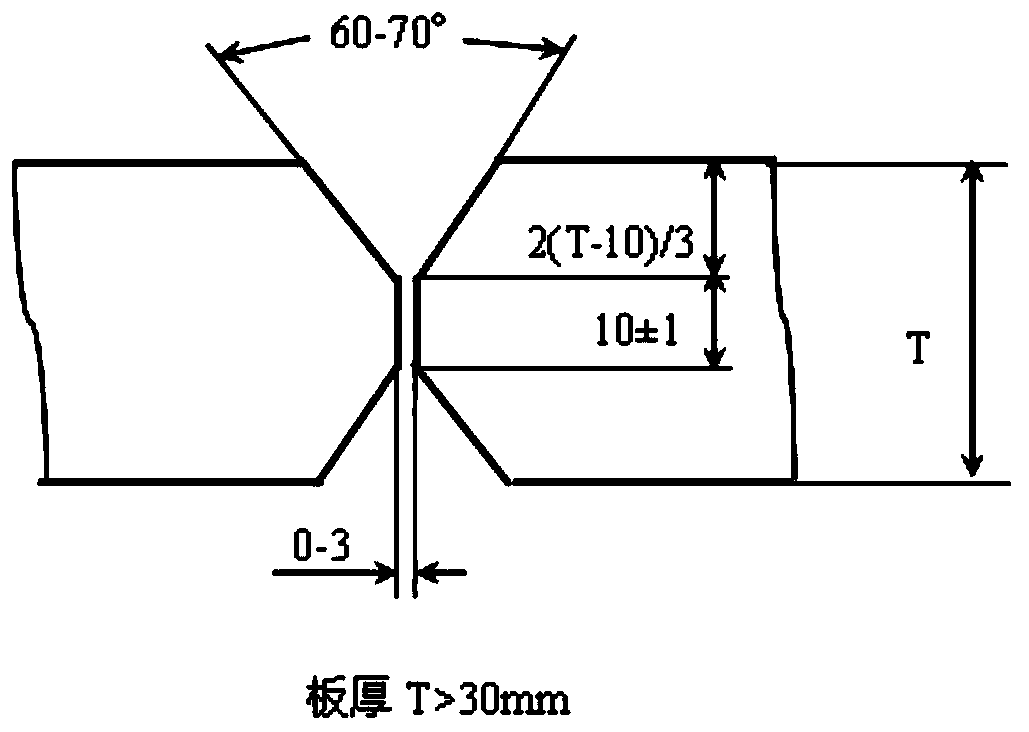

Welding process of large-sized liquefied natural gas storage tank

InactiveCN101412136AEasy to shapeReduce Rooting WorkloadArc welding apparatusDomestic vesselsNatural gas storageEngineering

The invention relates to a method for welding a large liquified natural gas storage tank. The method uses alternating rectangular wave current for welding with a welding parameter of between 8.156 and 24.32 KJ / cm and the interlayer temperature of energy input of between 18.9 and 24.32 KJ / cm of 300 DEG C, and selects low carbon type nickel-based welding wire. The method overcomes the problem of arc blow in welding, not only can avoid impact on 9 percent Ni steel during carbon gouging, but also can save welding materials and manpower so as to accelerate construction process and improve welding efficiency. Welding with the process can improve the cold temperature flexibility of a macrograin area of a welding zone, avoid generation of brittle tissue of a fusion area, avoid generation of cold and heat crack in welding, has excellent quality of weld joint, and effectively ensure the cold temperature flexibility of 9 percent Ni steel welding joints. The method well control the quality of the weld joint, and ensures the overall quality of the natural gas storage tank.

Owner:SHANGHAI INSTALLATION ENG GRP

Stainless steel tube for brake system of rail vehicle and method for producing same

ActiveCN101538684AExtended service lifeReduce manufacturing costFurnace typesHeat treatment furnacesPunchingMolten steel

The invention provides a stainless steel tube for a brake system of a rail vehicle and a method for producing the same. The stainless steel tube comprises the following components in weight percentage: less than 0.030 percent of C, more than 0 percent or less than 1.00 percent of Si, more than 0 percent or less than 1.50 percent of Mn, less than 0.40 percent of P, less than 0.015 percent of S, 10.5 to 12.50 percent of Cr, 0.30 to 1.00 percent of Ni, less than 0.030 percent of N, more than 0 percent or less than 0.10 percent of Cu, 6*(C+N) to 0.75 percent of Ti and Nb, and the balance of Fe and inevitable impurities. The method for producing the stainless steel tube comprises the following steps of: smelting, continuous casting, hot rolling, punching or extruding, and deep processing of the steel tube; the method is characterized in that molten iron is made into molten steel according to the components of the stainless steel tube; at the hot rolling step, the start-rolling temperature is between 1,080 and 1,150 DEG C, and the end-rolling temperature is between 850 and 900 DEG C; and the punching or extruding deformation temperature is controlled to be between 850 and 1,100 DEG C. The stainless steel tube produced by the method has the advantages of good corrosion resistance, good welding, mechanical and cold processing properties, and low price.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

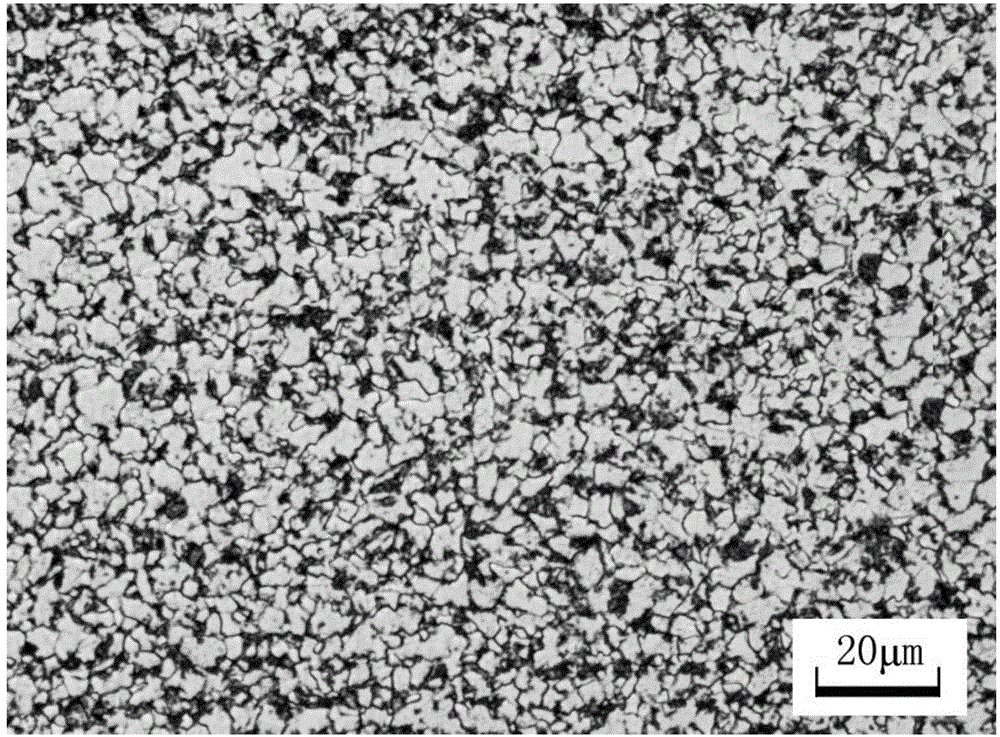

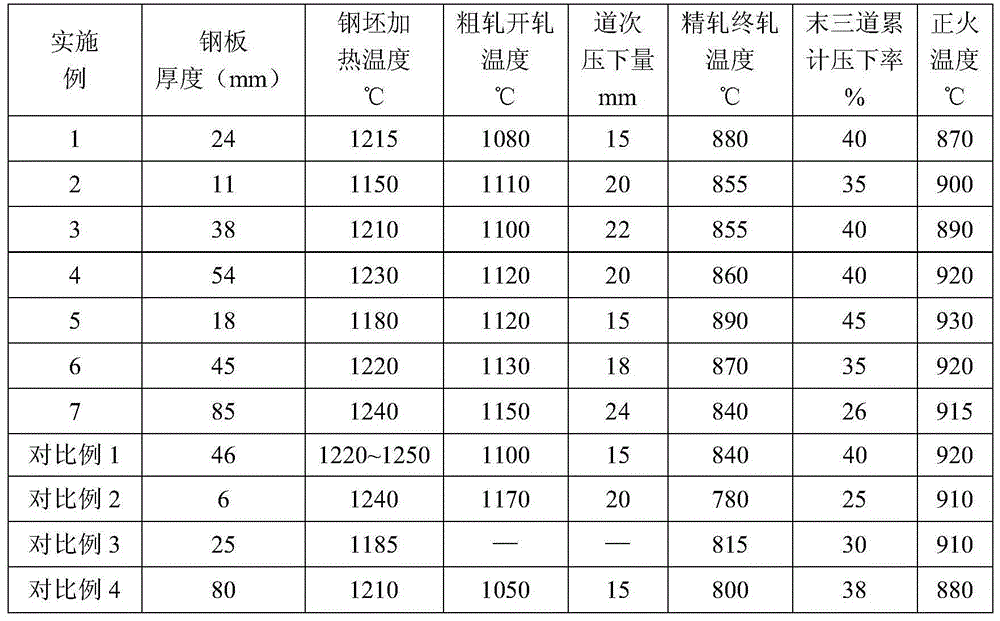

Good low-temperature high-toughness normalizing type high-strength pressure container steel plate and manufacturing method thereof

The present invention discloses a good low-temperature high-toughness normalizing type high-strength pressure container steel plate, wherein the chemical components comprise, by weight, 0.10-0.22% of C, less than or equal to 0.40% of Si, 1,10-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.40% of Ni, less than or equal to 0.035% of Nb, less than or equal to 0.17% of V, 0.0070-0.0190% of N, 0-0.025% of Als, 0-0.018% of Ti, and the balance of Fe and unavoidable inclusion, wherein (V+Ti+Nb) / N is more than or equal to 3.5 and is less than or equal to 15, and (C+V+2Ti) is more than or equal to Ti+Nb / (3.5N) and is less than or equal to 5V / (C+V+Nb). The good low-temperature high-toughness normalizing type high-strength pressure container steel plate has the following characteristics that: the yield strength is more than or equal to 460 MPa, the tensile strength is 630-725 MPa, the elongation is more than or equal to 25%, the yield ratio is less than or equal to 0.85, the weldability is good, and the production cost is low.

Owner:武汉钢铁有限公司

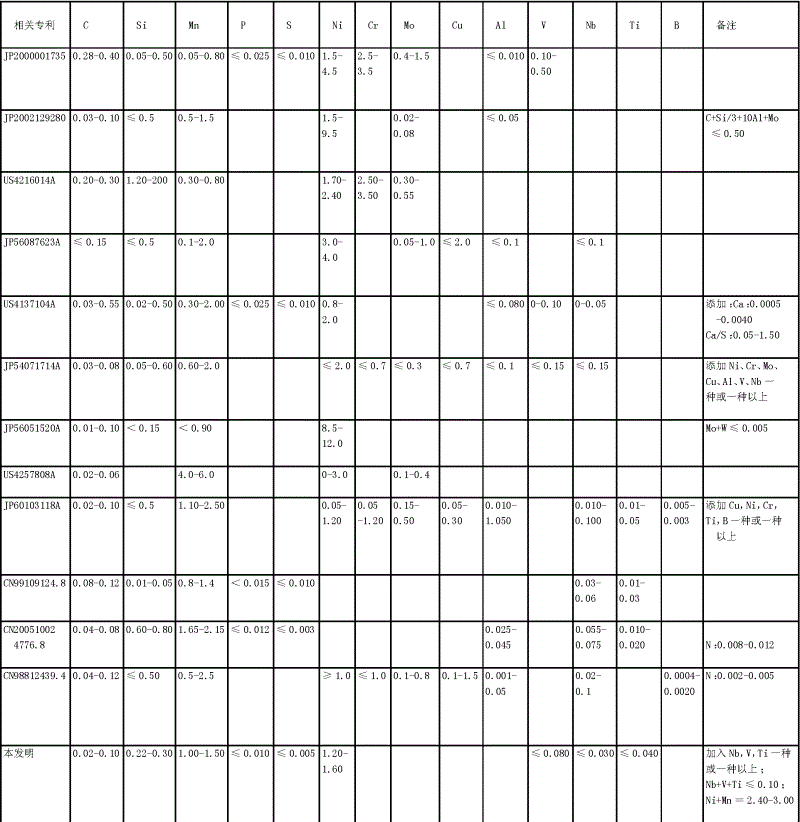

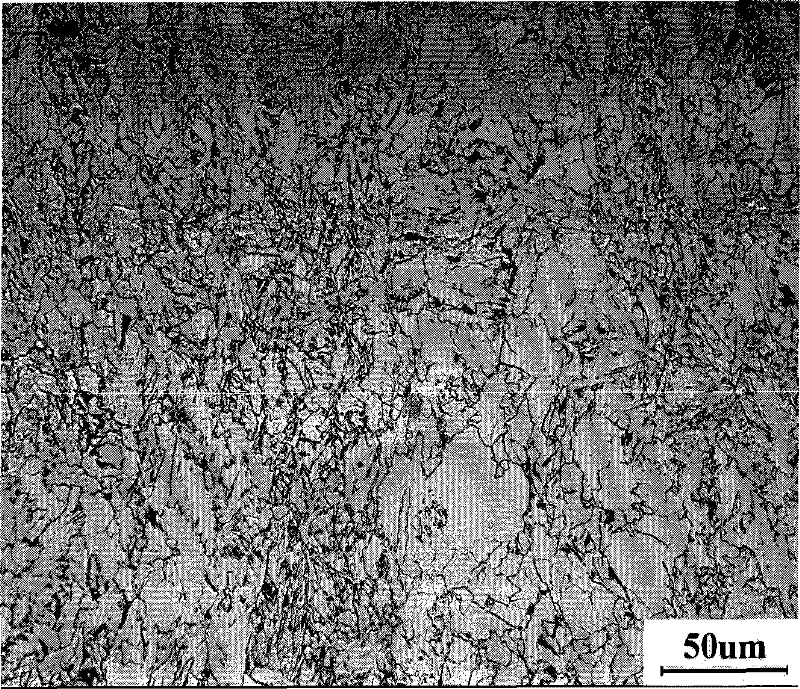

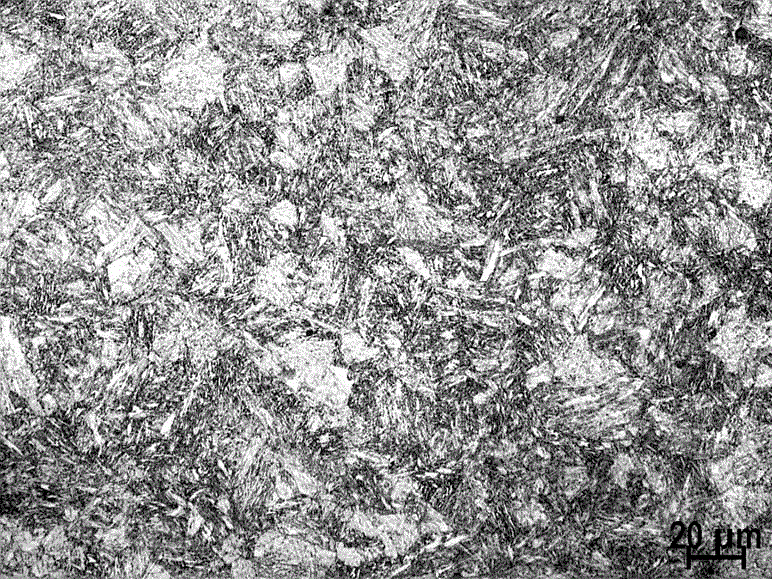

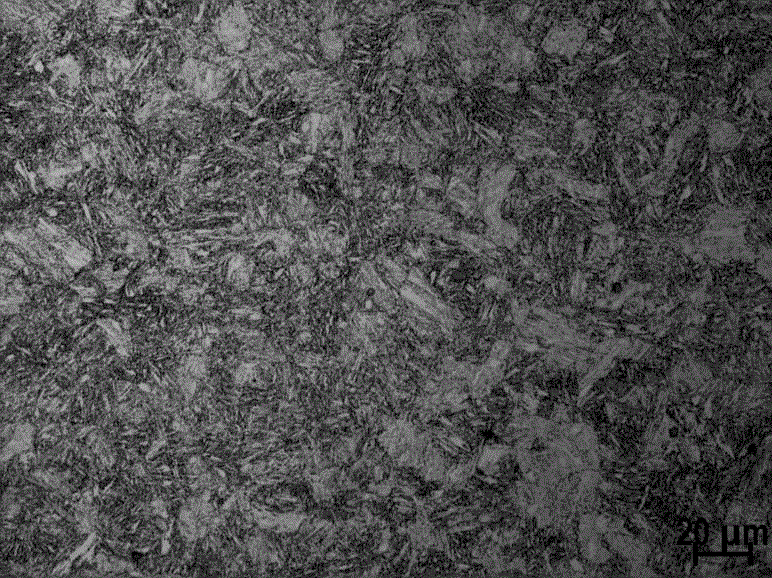

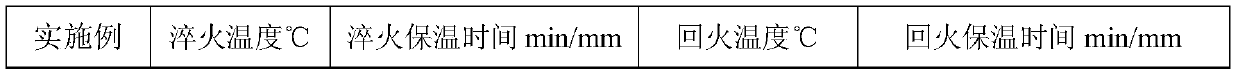

Low-temperature flexibility 1.5Ni steel and method of manufacturing the same

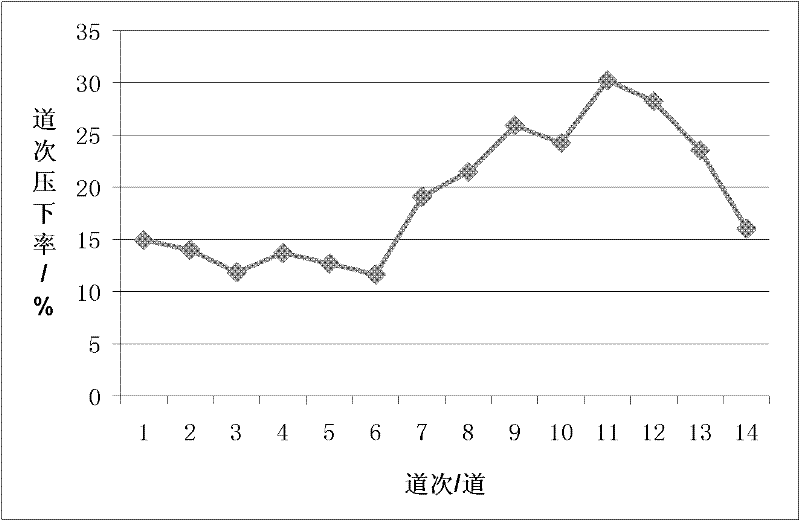

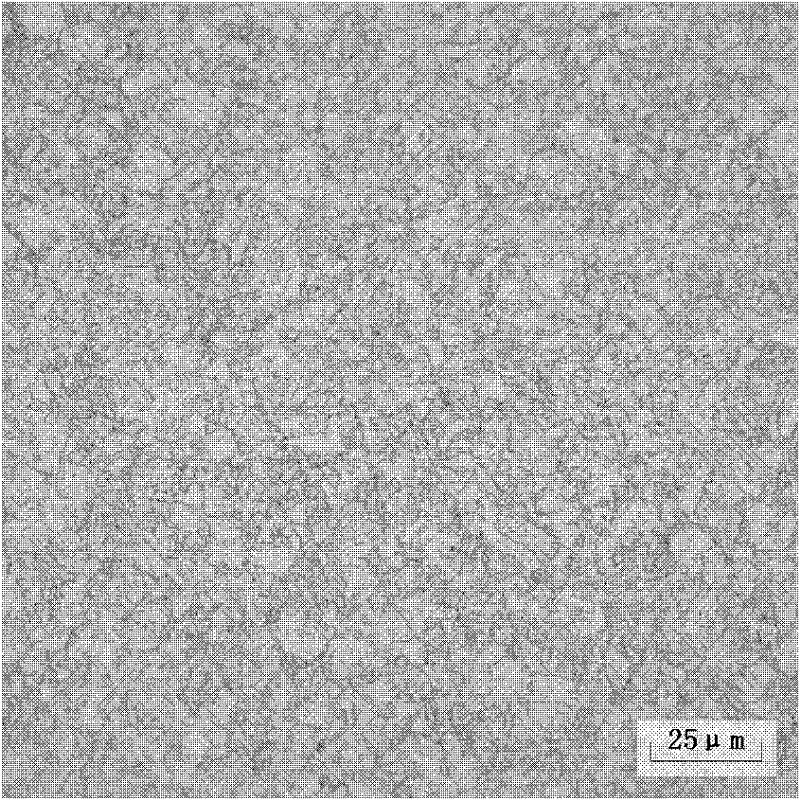

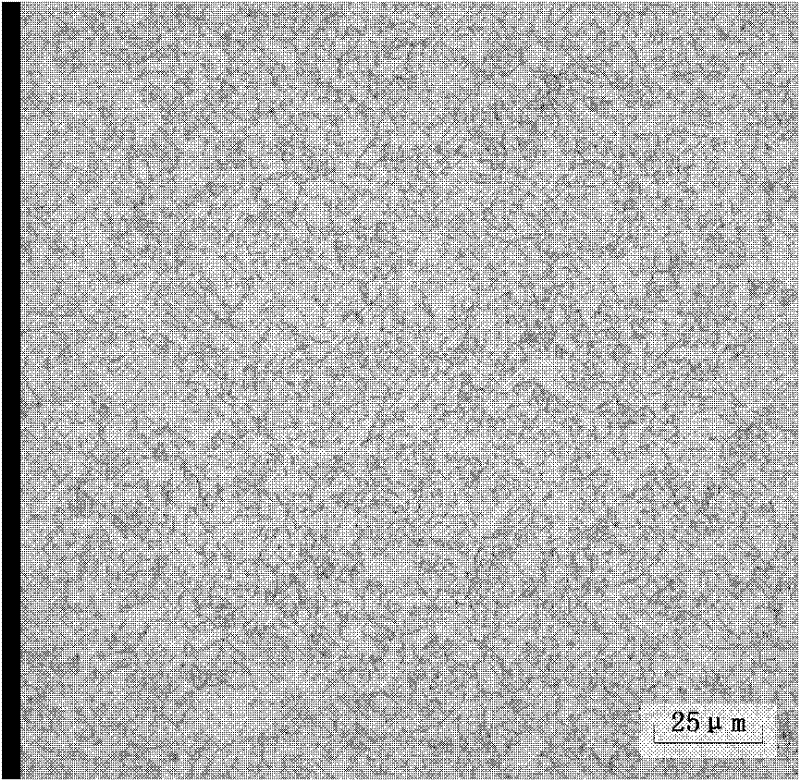

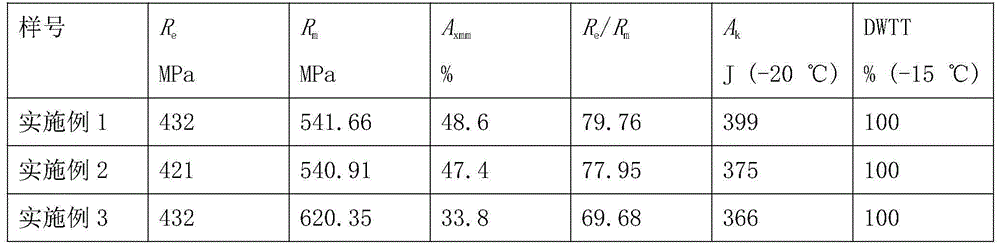

ActiveCN101497961AGuaranteed Low Temperature ToughnessTemperature control deviceLiquefied natural gasHigh intensity

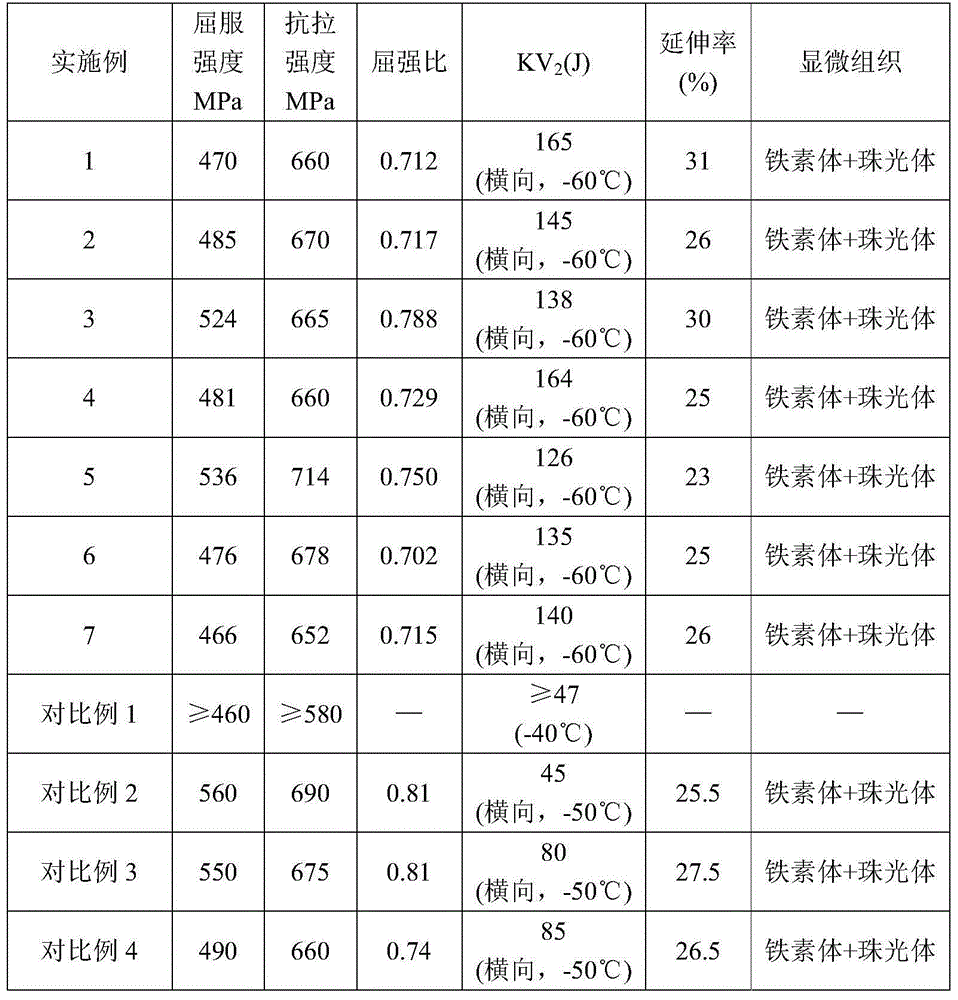

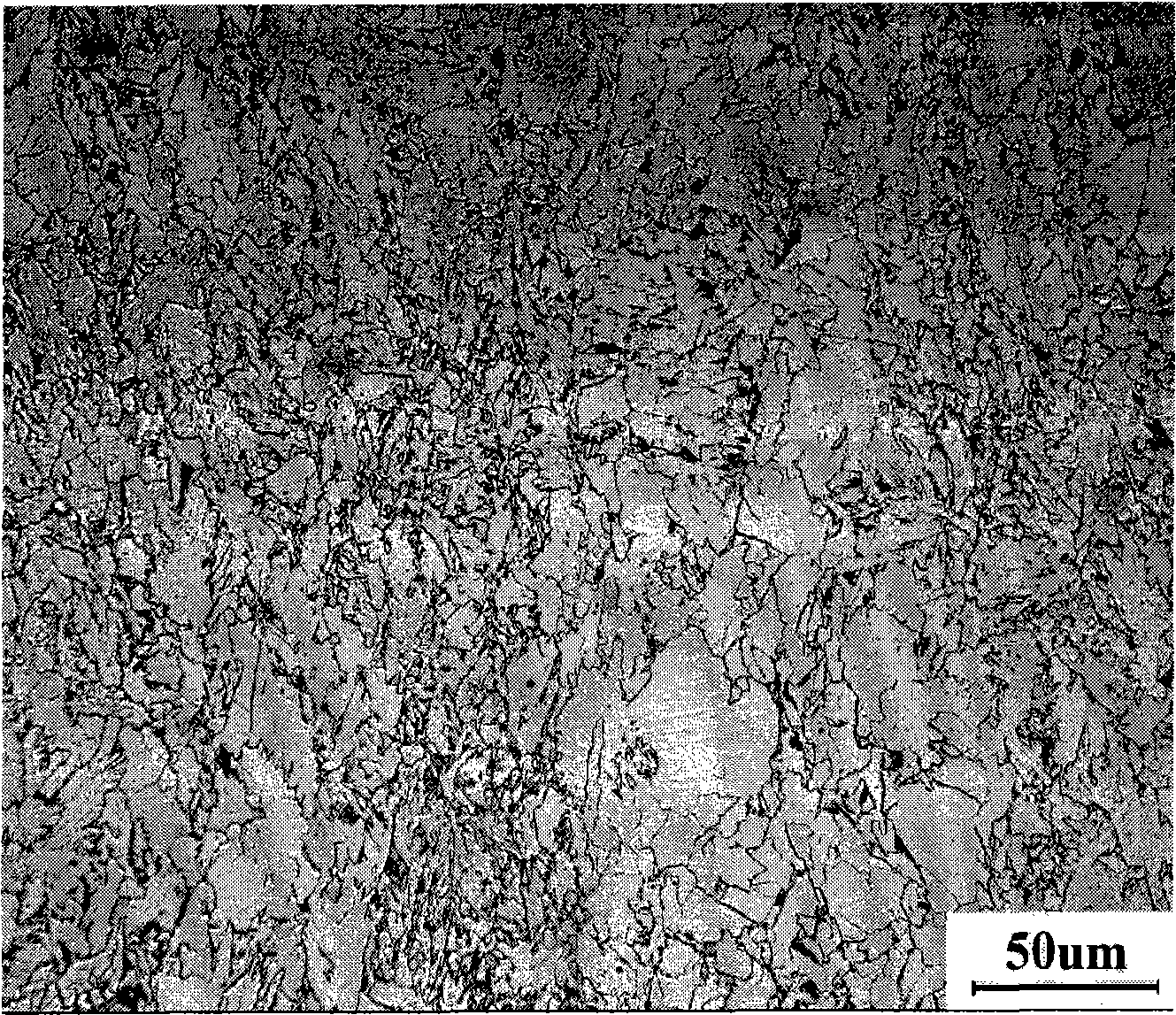

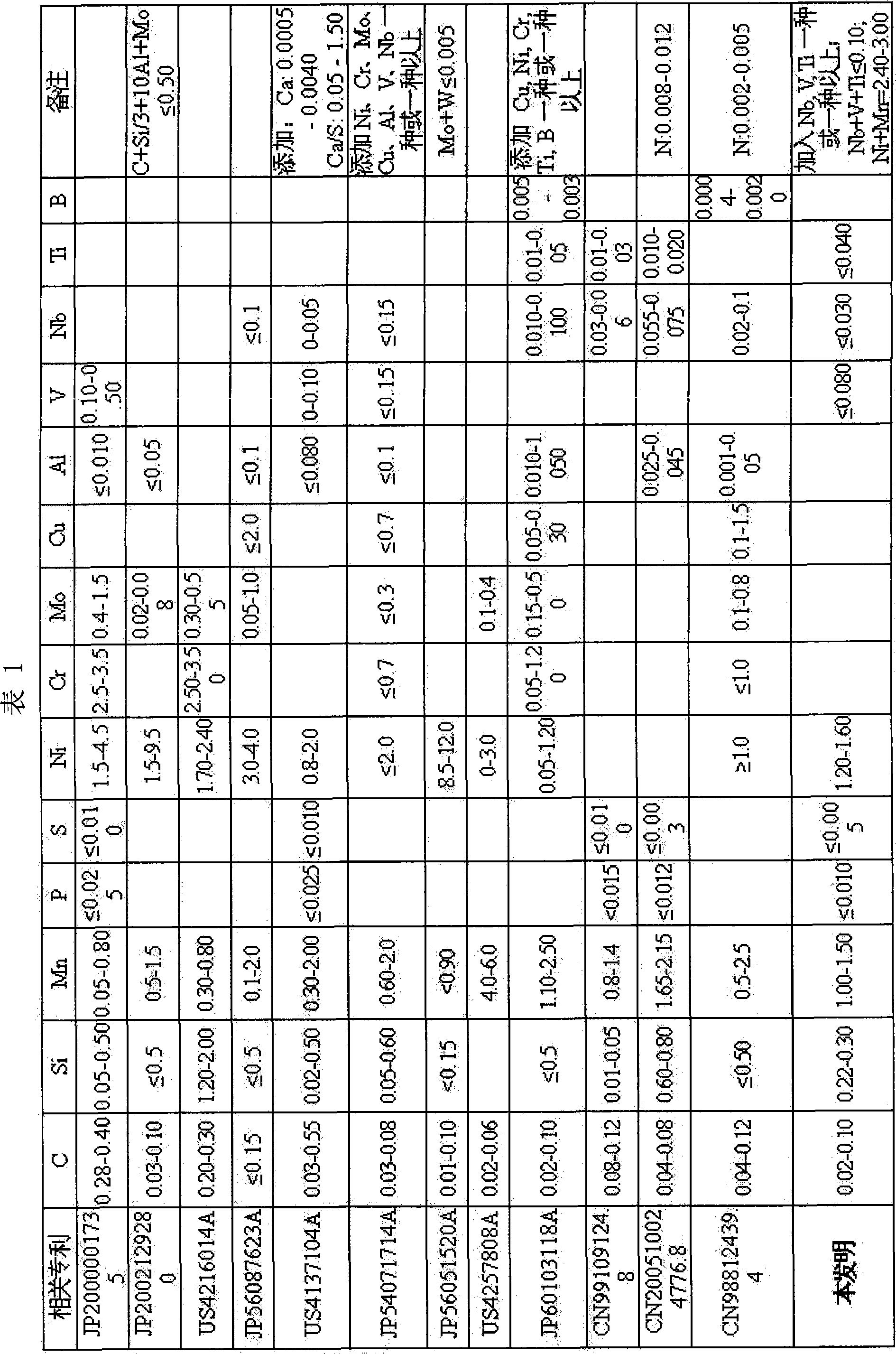

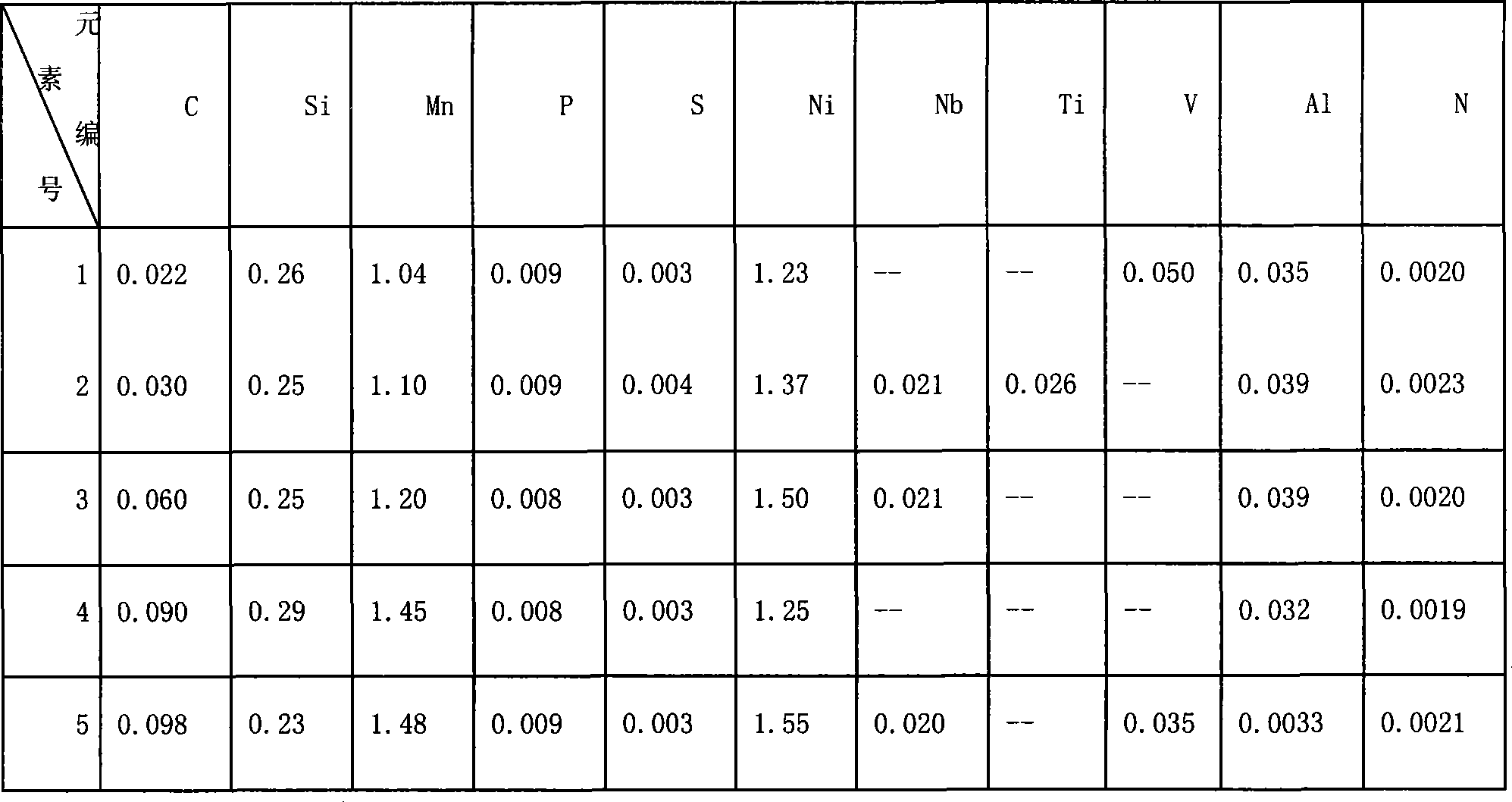

The invention discloses low-temperature ductility 1.5Ni steel and a manufacturing method thereof, wherein the low-temperature ductility 1.5Ni steel comprises the chemical components according to percentages by weight of 0.02-0.10 percent of C, 0.22-0.30 percent of Si, 1.00-1.50 percent of Mn, less than or equal to 0.08 percent of V, 1.20-1.60 percent of Ni, less than or equal to 0.005 percent of S, less than or equal to 0.010 percent of P, less than or equal to 0.03 percent of Nb, less than or equal to 0.04 percent of Ti, less than or equal to 0.04 percent of Al, 0.002-0.005 percent of N and the rest of Fe and unavoidable impurities. The manufacturing method comprises the following steps of smelting and casting into a casting blank, heating the casting blank, controlled rolling and heat treatment. In the invention, after the micro alloy steel finishes the controlled rolling, a high-strength low-temperature pressure vessel steel plate which has yield strength of more than 400MPa, tensile strength of more than 500MPa and satisfies the low-temperature impact ductility requirement of 100 DEG C below is produced through adopting a thermal refining method. The invention is suitable for manufacturing vessels, such as a low-temperature pressure vessel, a liquefied natural gas storage tank, a liquefied petroleum gas storage tank, a petrochemical storage tank, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

X60N normalizing pipeline steel and production method thereof

ActiveCN104862614AGuaranteed Low Temperature ToughnessHigh strengthUltimate tensile strengthImpurity

The invention discloses X60N normalizing pipeline steel and a production method thereof. The X60N normalizing pipeline steel comprises the following elements: 0.07 to 0.15 percent of C, 0.20 to 0.40 percent of Si, 1.55 to 1.7 percent of Mn, greater than or equal to 0.008 percent of P, greater than or equal to 0.015 percent of S, greater than or equal to 0.10 percent of Mo, 0.02 to 0.05 percent of Alt, greater than or equal to 0.30 percent of Ni, greater than or equal to 0.30 percent of Cr, greater than or equal to 0.30 percent of Cu, 0.004 to 0.008 percent of V, 0.03 to 0.06 percent of Nb, 0.005 to 0.025 percent of Ti, and Fe and inevitable impurity elements for the surplus. The production method mainly comprises converter smelting, continuous casting, rolling and normalizing heat treatment. The X60N normalizing pipeline steel with strength and tenacity being properly matched with each other through rolling and normalizing heat treatment, the strength property of the steel is guaranteed by increasing the carbon content, the tenacity of the steel, especially the low-temperature tenacity of the steel, is greatly improved through the added Nb, V and Ti microalloy elements and normalizing heat treatment. The X60N normalizing pipeline steel produced through the method is small and uniform in phase transformation structures, and has not only high strength but also very excellent low-temperature tenacity.

Owner:NANJING IRON & STEEL CO LTD +1

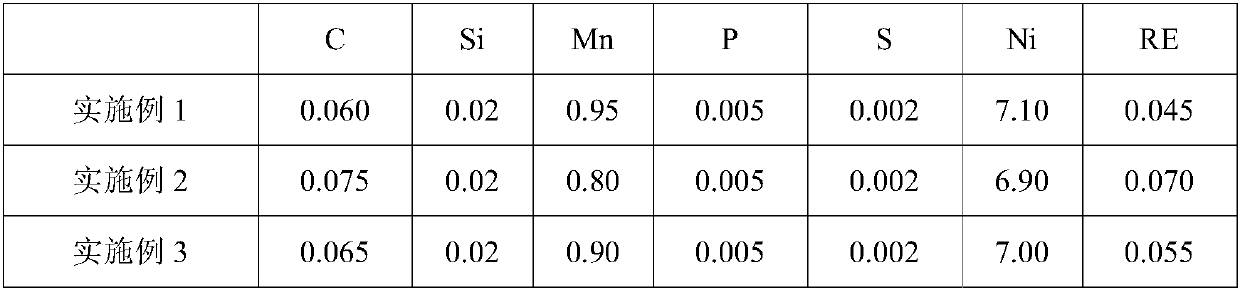

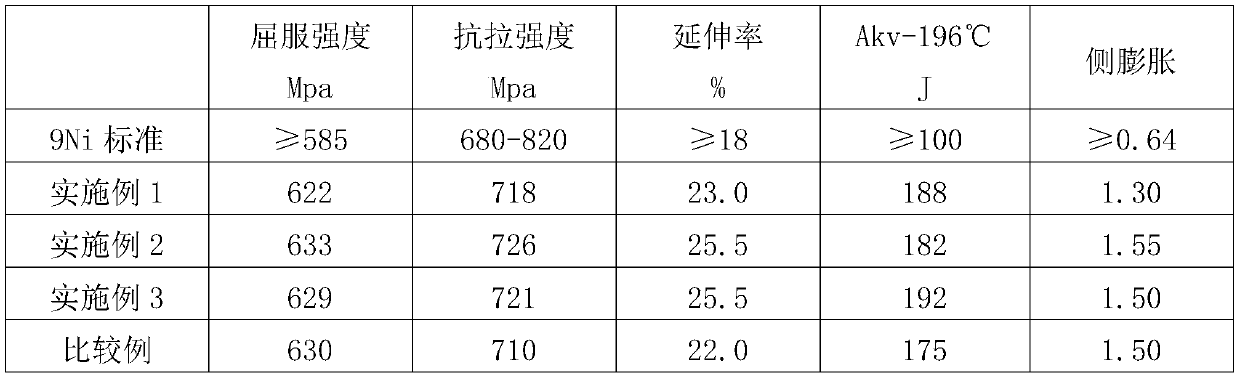

High nickel steel for ultra-low temperature pressure vessel and manufacturing method thereof

The invention provides high nickel steel for an ultra-low temperature pressure vessel and a manufacturing method thereof. The components of a steel plate include, by weight percentage, 0.01-0.10% of C, 0.01-0.10% of Si, 0.50-1.50% of Mn, 6.50-7.50% of Ni, 0.01-0.20% of RE, S which is less than or equal to 0.005%, and P which is less than or equal to 0.008%, with the balance being Fe and inevitableimpurities; and the manufacturing method includes converter smelting, external refining, continuous casting, slow cooling of slabs, rolling and heat treatment. The yield strength of the produced steel plate is greater than or equal to 585 MPa, the tensile strength is greater than or equal to 680 MPa, he elongation rate is greater than or equal to 18%, -196 DEG C V-type impact energy is greater than or equal to 100 J, and the lateral expansion is greater than or equal to 1.0; and therefore, manufacturing costs of the steel for LNG storage tanks can be reduced.

Owner:ANGANG STEEL CO LTD

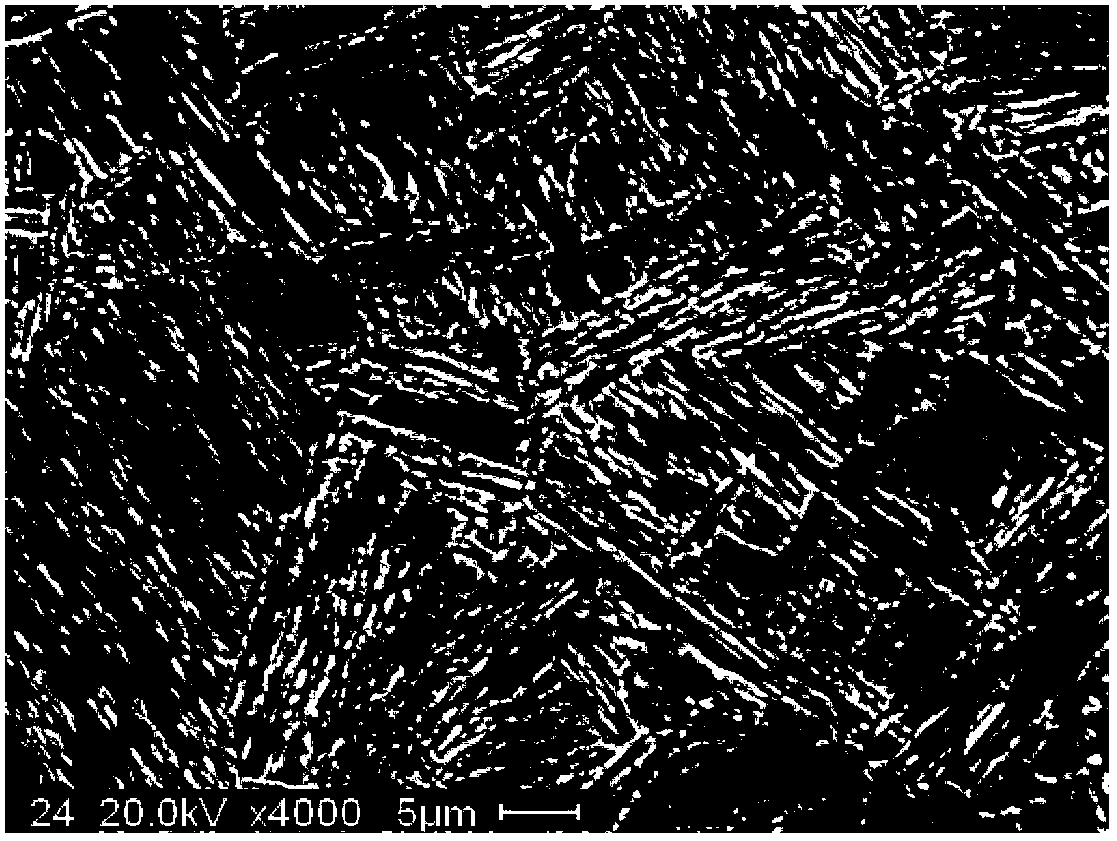

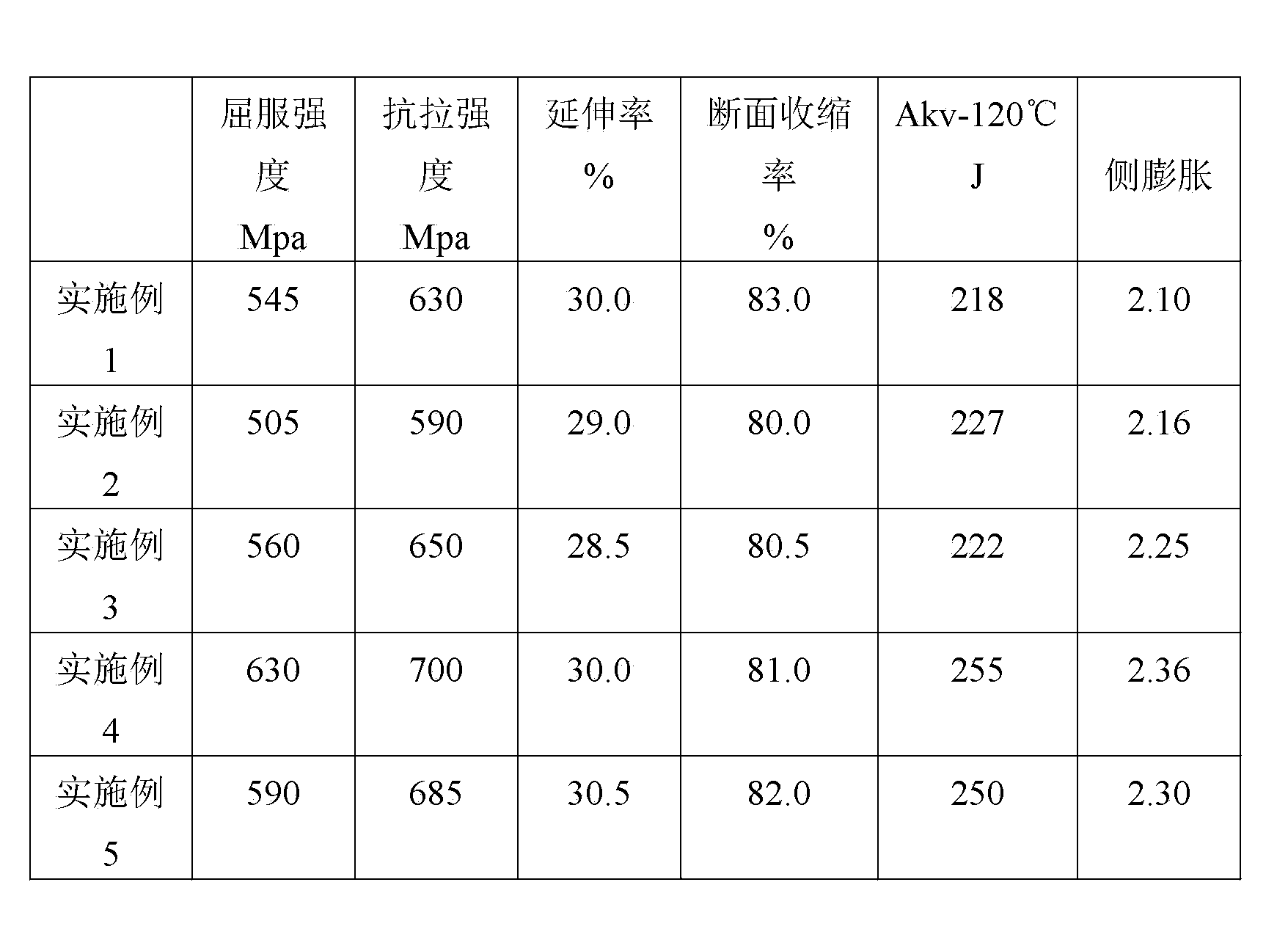

Manufacturing method of high nickel steel used for cryogenic storage tank

The invention provides a manufacturing method of high nickel steel used for a cryogenic storage tank. In a converter smelting process, the carbon temperature is coordinated, and LF-VD compound refining ensures accurate control of the steel components and gas content. Compared with common plate billets, a slow cooling process is added, the gas content in a casting blank is reduced to the utmost, and the internal quality of the casting blank is improved. Plate billet shot blasting and iron sheet packaging treatment are carried out to improve the surface quality of the casting blank, thus ensuring the casting blank a smooth and defect-free surface before rolling, and further improving the surface quality of a steel plate. Controlled rolling and heat treatment processes aim to control the grain size and microstructure of a high nickel steel plate, and guarantee the strength and low temperature toughness of the steel plate. The high nickel steel manufactured by the method provided by the invention has yield strength of greater than or equal to 390MPa, tensile strength of greater than or equal to 530MPa, elongation of greater than or equal to 20%, a section shrinkage rate of greater than or equal to 50%, V type impact energy of greater than or equal to 150J at -120DEG C, and side expansion of greater than or equal to 2.0.

Owner:ANGANG STEEL CO LTD

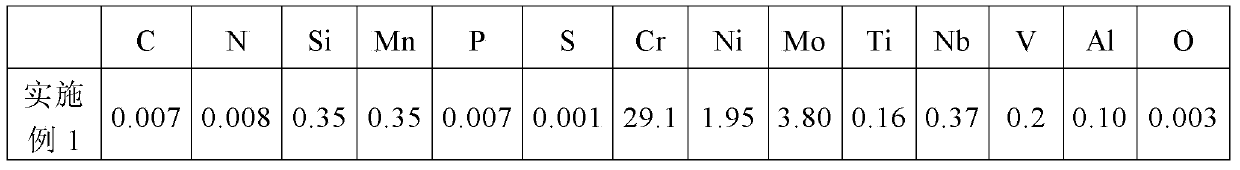

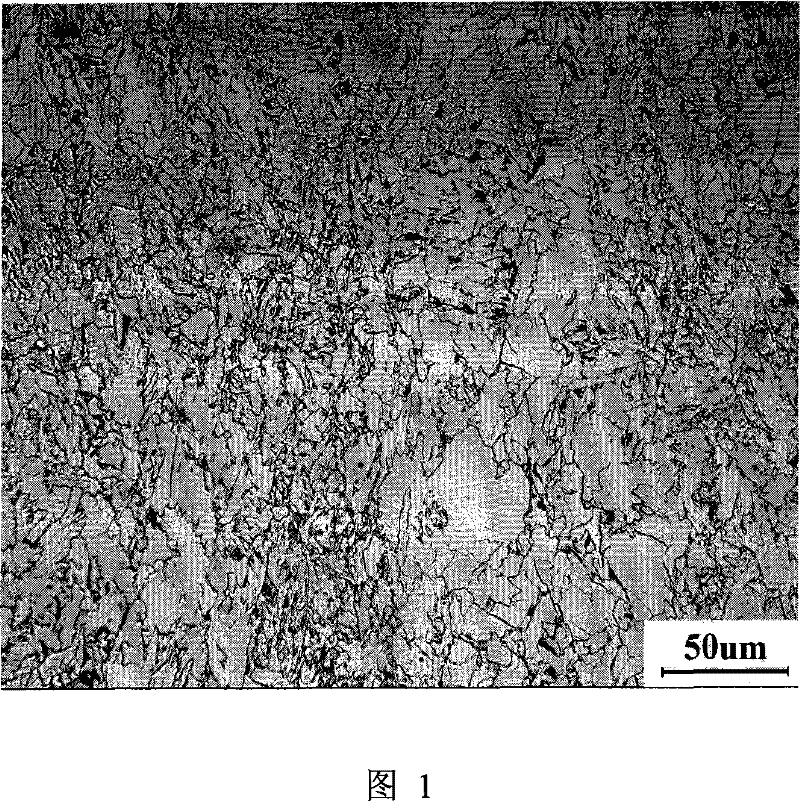

Sulfuric acid resistant ferritic stainless steel and manufacturing method thereof

InactiveCN105506502AHigh sulfuric acid corrosion resistanceImprove low temperature impact toughnessAlloyAustenite

The invention relates to a sulfuric acid resistant ferritic stainless steel and a manufacturing method thereof. The sulfuric acid resistant ferritic stainless steel comprises the following chemical components by weight: 0.002-0.015% of C, 0.002-0.015% of N, 0.2-1.0% of Si, 0.2-0.5% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 28-30% of Cr, 1.5-3% of Ni, 2.0-4.0% of Mo, 0.1-0.3% of V, 0.10-0.30% of Ti, 0.2-0.5% of Nb, 0.05-0.1% of Al, with the sum of Cr+3.3*Mo being greater than or equal to 38%, and Ti+Nb being greater than or equal to 16(C+N), less than or equal to 0.005% of O, and the balance Fe and inevitable impurities. The ferritic stainless steel provided by the invention can tolerate the corrosion of various concentration sulfuric acids at a temperature of less than 60 DEG C and at a concentration of less than or equal to 98wt%, also has good impact toughness and welding performance. With a pitting resistance equivalent PREN of greater than or equal to 38, the ferritic stainless steel has corrosion resistance far superior to conventional ferritic stainless steel, and is equivalent to superaustenitic stainless steel and nickel based alloys.

Owner:BAOSTEEL STAINLESS STEEL

Low-temperature flexibility 1.5Ni steel and method of manufacturing the same

ActiveCN101497961BGuaranteed Low Temperature ToughnessTemperature control devicePetrochemicalImpurity

Owner:BAOSHAN IRON & STEEL CO LTD

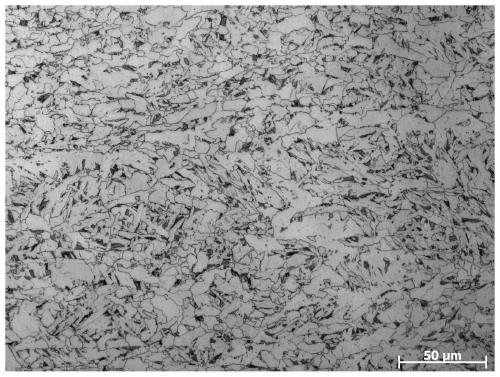

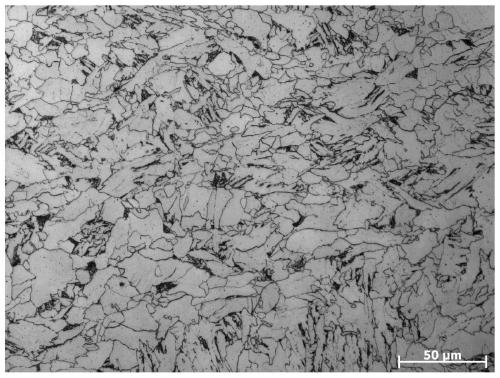

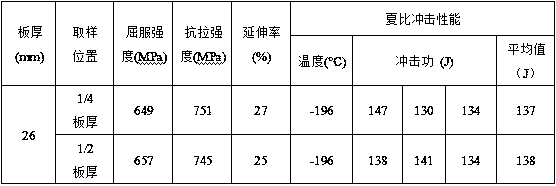

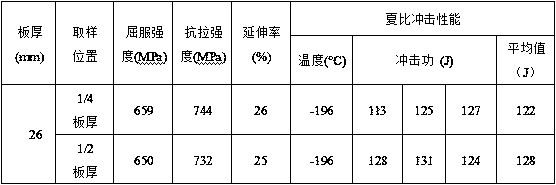

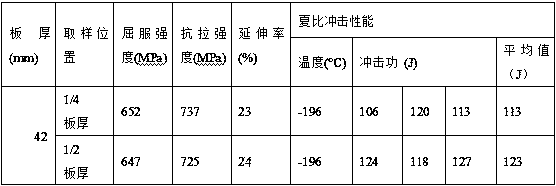

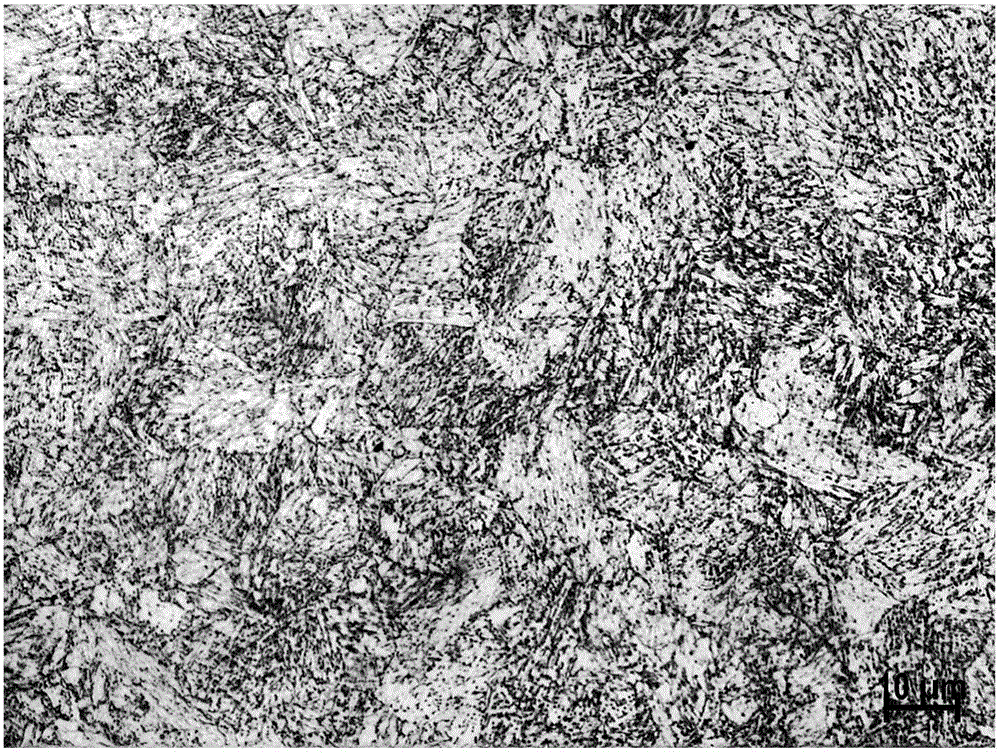

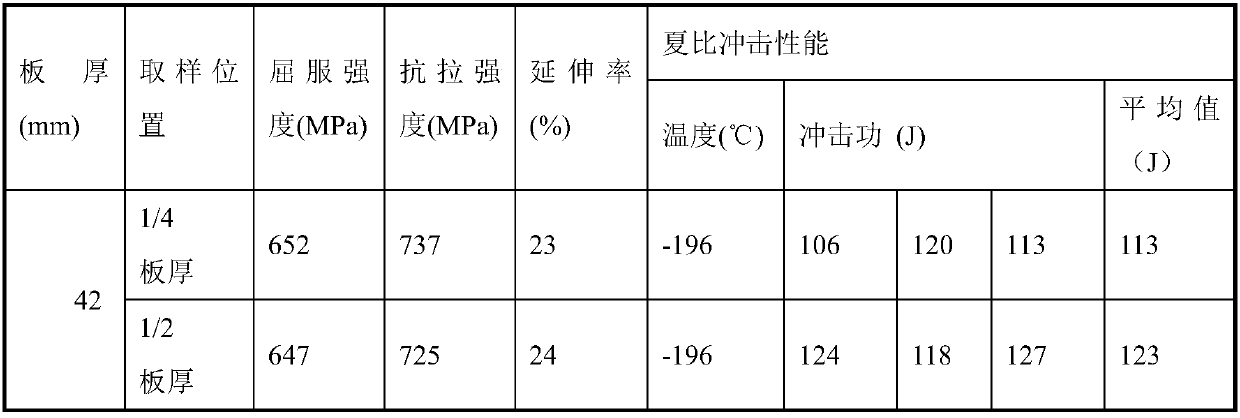

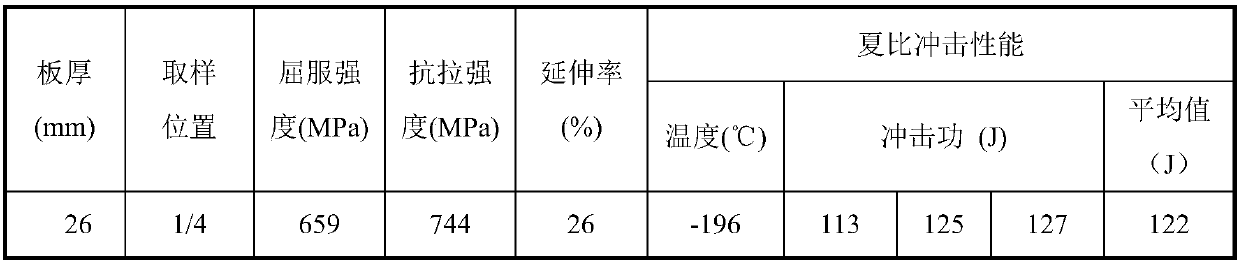

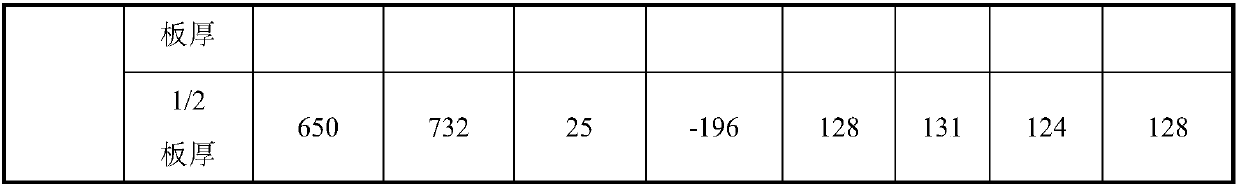

High-hardenability and high-strength ultra-thick marine steel plate and production method thereof

The invention relates to a high-hardenability and high-strength ultra-thick marine steel plate. The high-hardenability and high-strength ultra-thick marine steel plate is 60-150 mm thick and is composed of the chemical components of, by weight percentage, 0.04-0.08% of C, 4-9% of Mn, 0.10-0.25% of Si, 0.01-0.03% of Als, 0.2-0.5% of Mo, 0.025-0.050% of Nb, less than or equal to 0.04% of S, less than or equal to 0.007% of P, and Fe and impurity elements as balance. The high-hardenability and high-strength ultra-thick marine steel plate can solve the phenomenon of non-uniformity of thickness direction texture and performance, expand the thickness specification to 150 mm with low-temperature toughness still meeting the operating requirements at -80 DEG C and obtain low yield ratio under equal yield strength conditions, specifically, the parts of 1 / 4 and 1 / 2 thickness of the steel plate reach a yield strength not lower than 690 MPa, a yield ratio not higher than 0.86, an elongation percentage not lower than 20%, and a -80 DEG C low-temperature impact energy greater than 100 J.

Owner:NANJING IRON & STEEL CO LTD

Large-thickness high-toughness steel plate and production method thereof

The invention relates to a large-thickness high-toughness steel plate and a production method thereof. The large-thickness high-toughness steel plate comprises the chemical composition, by mass: C: 0.03-0.07%, Si <= 0.10%, Mn: 1.40-1.60%, P <= 0.015%, S <= 0.010%, Nb: 0.040- 0.050%, Ti: 0.010-0.020%, Cr: 0.20-0.30%, Ni: 0.05-0.15%, Cu: 0.15-0.25%, Alt: 0.020-0.050%, N <= 0.005% and the balance iron and inevitable impurities, and meanwhile the formulas: Cr*7 <= Mn + Cr <= (Mn + Cr + Ni + Cu) * 0.9 and 1.8 <= Cu / Ni <= 2.8 are met. Through reasonable component design and a TMCP controlled rollingand controlled cooling process in a matched mode, the prepared steel plate is good in mechanical property and welding property and wide in application field.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Low-temperature container steel plate with high flaw detection quality and used for 9Ni ship and manufacturing method thereof

ActiveCN107604255AControl the total amount addedImprove low temperature impact toughnessHigh surfaceUltimate tensile strength

The invention relates to a low-temperature container steel plate with high flaw detection quality and used for a 9Ni ship. The low-temperature container steel plate takes Fe as the basic element and comprises the following chemical components in percentage by mass: 0.03-0.05% of C, 0.10-0.14% of Si, 0.50-0.80% of Mn, 8.7-9.7% of Ni, equal to or less than 0.008% of P, equal to or less than 0.002% of S, equal to or less than 0.25% of Cr, equal to or less than 0.08% of Mo, equal to or less than 0.35% of Cu, 0.020-0.035% of Alt, 0.01-0.02% of Nb, equal to or less than 60 ppm of N, equal to or lessthan 1.2 ppm of H and the balance of unavoidable impurity elements, wherein the carbon equivalent CEV[pound sign] is 0.80. The low-temperature container steel plate has high low temperature toughness, tensile property, strength and the like; and compared with the existing steel plate of the same kind, the low-temperature container steel plate has higher surface and heart flaw detection quality and facilitates follow-up processing of the steel plate.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

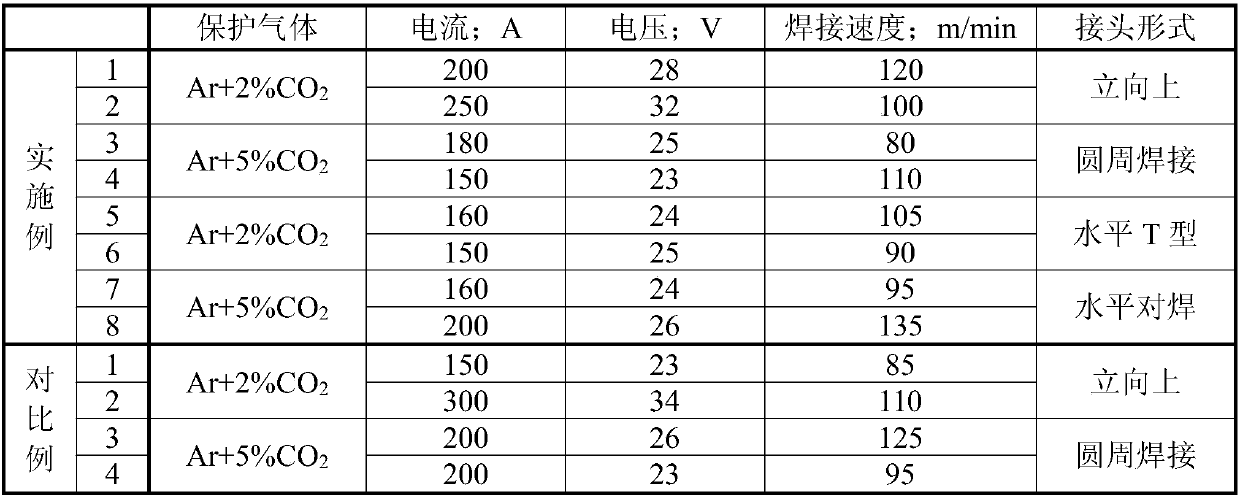

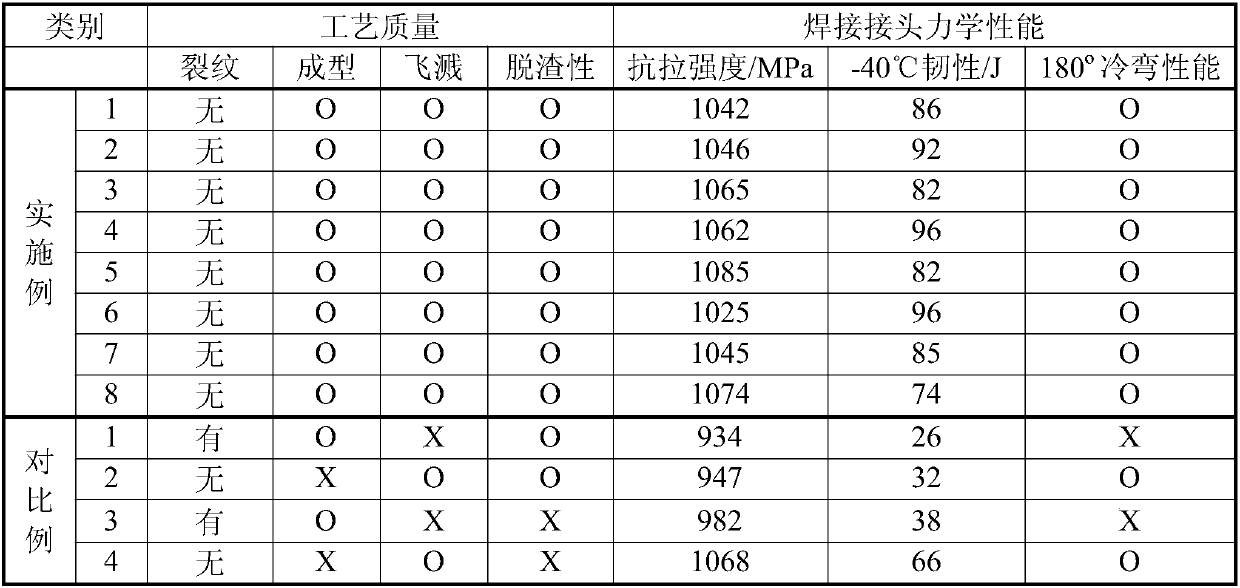

Multi-component microalloying section molybdenum-type fire-resistant steel efficient welding process

InactiveCN110666311AGood high temperature fire resistancePracticalArc welding apparatusWelding/cutting media/materialsMetallurgyWelding process

The invention discloses a multi-component microalloying section molybdenum-type fire-resistant steel efficient welding process. Through the reasonable matching of welding materials and welding processes, under the welding condition of heat input of 120 kJ / cm, a welding joint can still obtain good high-temperature fire-resistant performance and excellent low-temperature impact toughness of -40 DEGC, the using requirements of building steel structures are met, the good comprehensive mechanical properties of the welding joint and the effect of considering the high efficiency of welding are achieved, welding operation is simple and convenient, and the multi-component microalloying section molybdenum-type fire-resistant steel efficient welding process can be applied to the high-rise buildingsin the central and southern regions of China as well as the cold regions.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

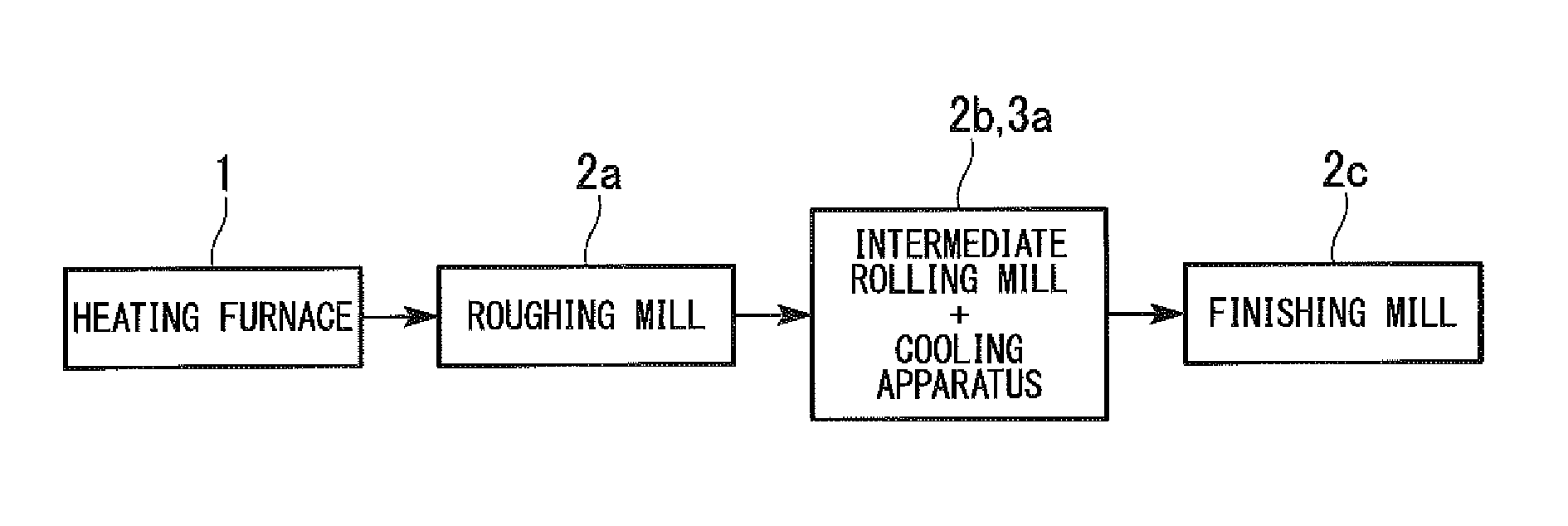

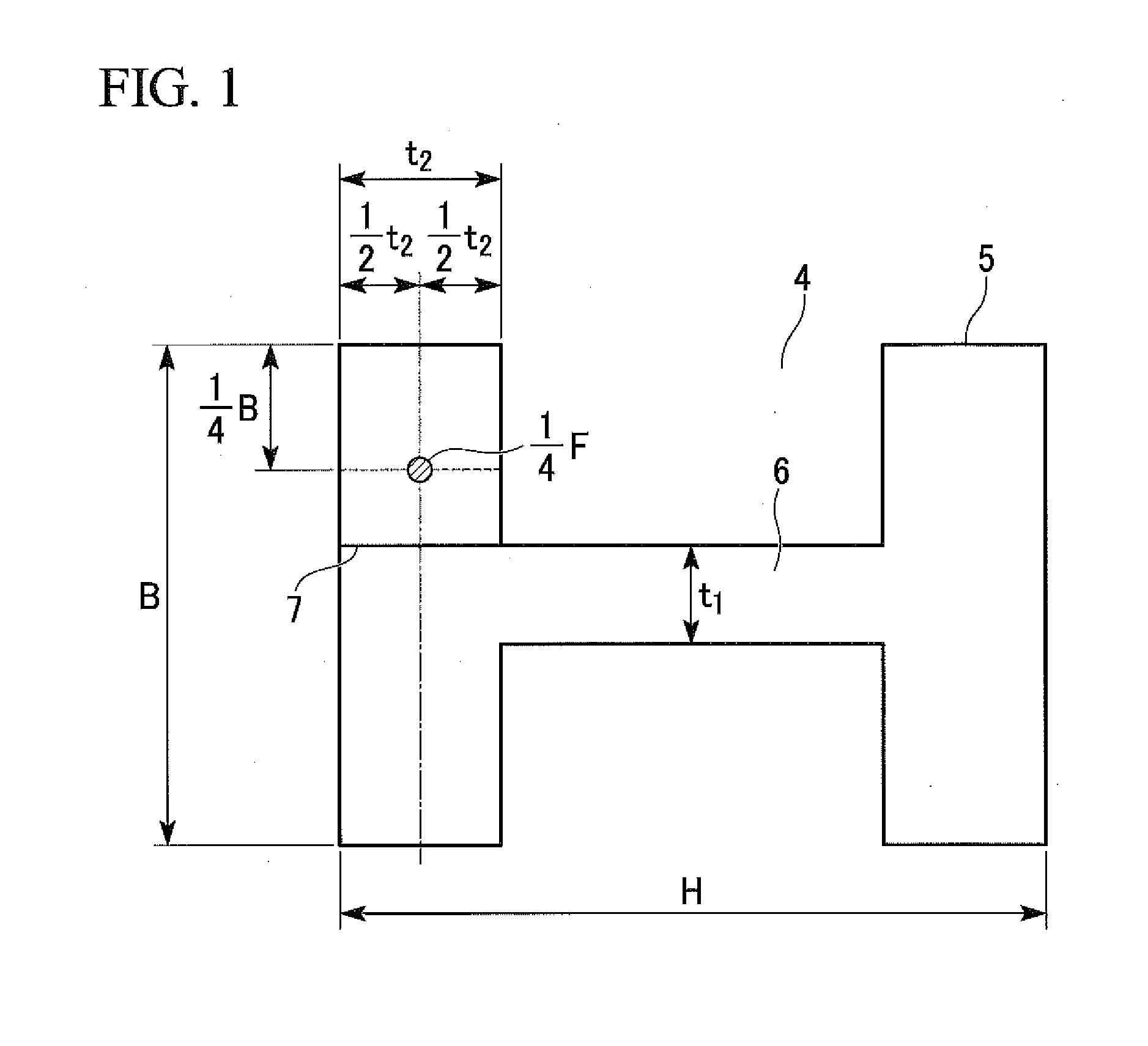

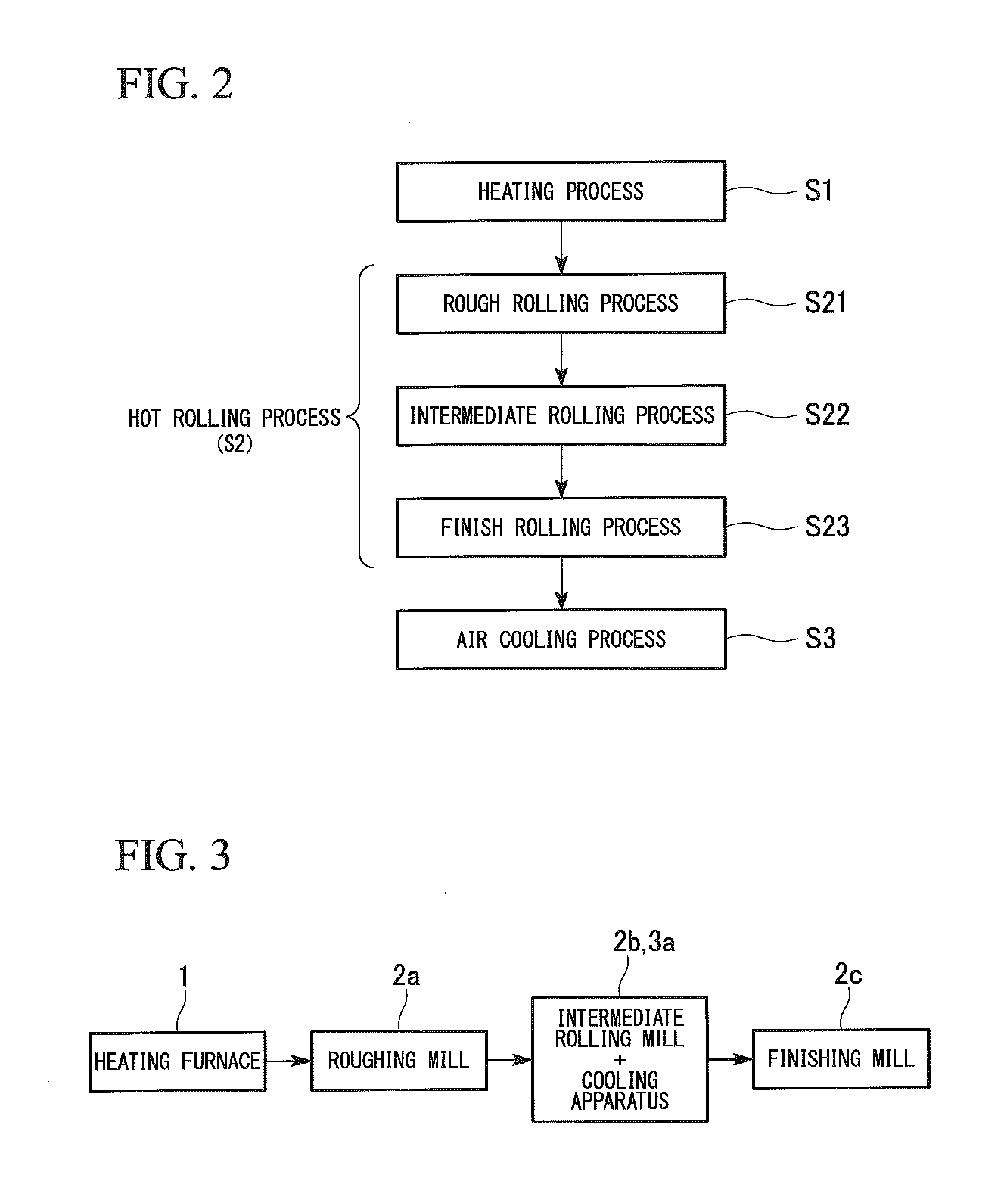

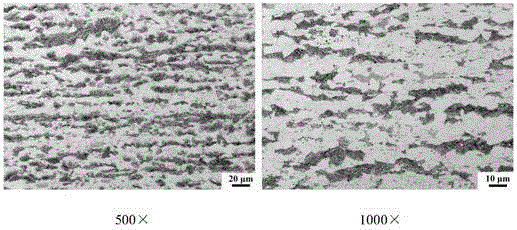

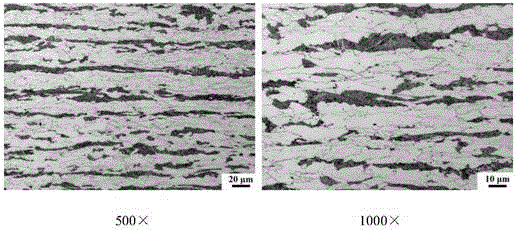

H-section steel and method of producing the same

InactiveUS20150361664A1High strengthImprove low temperature toughnessFurnace typesRollsChemical compositionMetallurgy

An H-section steel has a predetermined chemical composition, an Nb content and a B content satisfy Nb+125×B≧0.075%, a thickness of a flange is 12 mm to 40 mm, and in a thickness center portion and ¼ flange width portion of the flange, a metallographic structure of a cross-section perpendicular to a rolling direction contains pearlite having a distribution density of 3.2×10−3 units / μm2 or lower and the remainder is formed of ferrite and bainite.

Owner:NIPPON STEEL CORP

Material specially used for low-smoke, high flame-retardant and low-odor PC (polycarbonate) alloy board and preparation method of material

The invention relates to the technical field of alloy materials and discloses a material specially used for a low-smoke, high flame-retardant and low-odor PC (polycarbonate) alloy board and a preparation method of the material. The material is prepared from the following ingredients: 60-85 wt% of polycarbonate, 5-20 wt% of ABS (acrylonitrile butadiene styrene) resin, 1-5 wt% of a toughening agent,1-5 wt% of a smoke suppressant, 2-10 wt% of a flame retardant, 0.1-1 wt% of an antioxidant, 0.1-2 wt% of a lubricant and 0.2-0.5% of an anti-dripping agent; when the halogen-free flame retardant andthe anti-dripping agent are added to enhance the flame resistance of a PC alloy material, the silicon toughening agent is added, black smoke generated during combustion is reduced, and the density ofsmoke during the combustion is reduced. Meanwhile, by adding ABS and MBS (methyl methacrylate-butadiene-styrene), the tenacity of the PC alloy material at normal temperature and low temperature is guaranteed. The materials selected for the alloy material are all low-odor products, so that the finally produced material has a relatively low odor and can meet the requirements of manufacturers in thebus industry.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Welding method for plates of ladle turret

ActiveCN103658937AMake sure the welding is successful onceEnsure a successArc welding apparatusMetal working apparatusToughnessNondestructive testing

The invention discloses a welding method for plates of a ladle turret. The technical scheme includes the step 1, plate groove processing, the step 2, weldment assembling, the step 3, preheating before welding, the step 4, welding equipment and material selecting, the step 5, welding of the ladle turret, the step 6, processing after welding, and the step 7, nondestructive detection. All welded joints are subjected to complete ultrasonic detection after the welding is ended for 24 hours. By the welding method for the plates of the ladle turret, the one-step successful welding of the ladle turret can be guaranteed, cold fraction is decreased and even eliminated, certain low-temperature toughness of the ladle turret is guaranteed, welding efficiency of the ladle turret is improved, welding quality of welded joints is also guaranteed, and production cost is lowered.

Owner:ANHUI MASTEEL ENG & TECH GRP

Economic air-cooled dual-phase low yield ratio steel plate and production process thereof

ActiveCN103981452AImprove low temperature toughnessFacilitate phase transitionChemical compositionMetallurgy

The invention relates to an economic air-cooled dual-phase low yield ratio steel plate and a production process thereof. The steel plate comprises the following chemical components in percentage by weight: 0.07-0.09% of C, 0.70-0.90% of Si, 1.90-2.10% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.90-1.10% of Cr, and the balance of Fe and inevitable impurities. By controlling a Mn / C ratio at 21-25, Si+Mn+Cr content is 3.5-3.7%; through a low-temperature rolling process and by air cooling after cooling, a ferrite+martensite dual-phase structure is obtained; according to the prepared steel plate product, thickness is more than or equal to 15mm, yield strength Rp0.2 is less than or equal to 440MPa, tensile strength Rm is more than or equal to 690Mpa, percentage elongation after fracture is more than or equal to 14%, yield ratio (Rp0.2 / Rm) is less than or equal to 0.64 and impact energy at minus 20 DEG C is more than or equal to 60J.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

High-nickel steel for low-temperature container and manufacturing method of high-nickel steel

The invention relates to high-nickel steel for a low-temperature container. The high-nickel steel comprises, by weight, 0.01%-0.10% of C, 0.10%-0.25% of Si, 0.50%-1.50% of Mn, 5.0%-6.0% of Ni, 0.05%-0.30% of Mo, 0.30%-0.90% of Cr, 0.03%-0.20% of RE, less than or equal to 0.005% of S, less than or equal to 0.008% of P, and the balance Fe and impurities. By adding a certain amount of the Cr, the Moand rare earth into the steel, the strength and the low-temperature toughness reach the standard requirements of 9% Ni steel; rare earth elements are added, so that molten steel is purified, and the effect of harmful elements is greatly reduced; the rare earth elements are mainly dissolved in austenite, so that the strength of a matrix and the Ni content of the matrix can be improved, the number of the residual austenite is increased, and the toughness of the steel is improved; and controlled rolling and online quenching and two-phase region quenching and high-temperature tempering heat treatment are adopted by a manufacturing method after smelting. The use amount of nickel is greatly reduced, the production cost of the steel is reduced, and the method is especially suitable for construction of liquefied natural gas (LNG) storage tanks.

Owner:ANGANG STEEL CO LTD

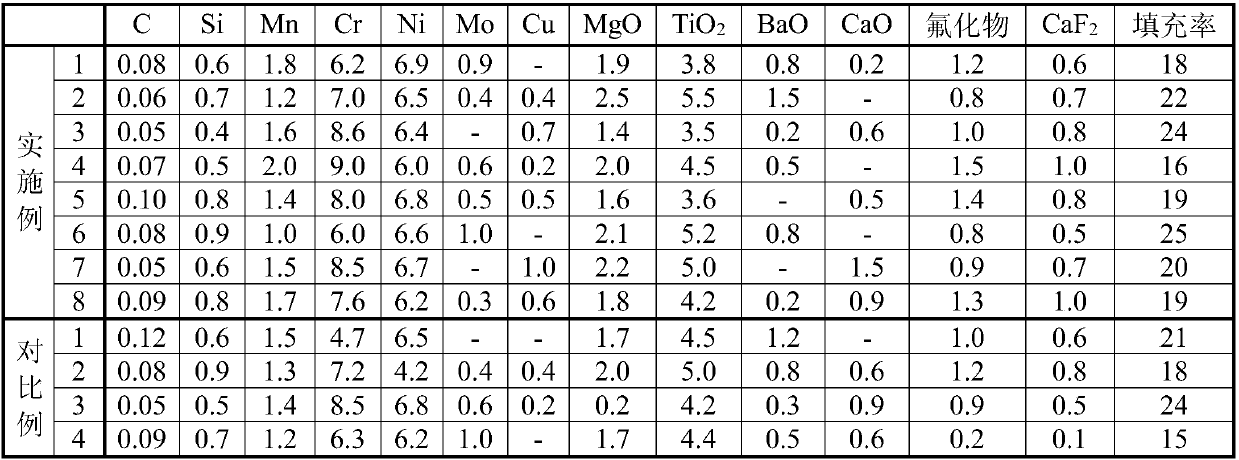

Flux-cored wire for gas shield welding for high-strength steel

InactiveCN107914097AReduce oxygen contentImprove surface qualityWelding/cutting media/materialsSoldering mediaFerricWeld metal

The invention relates to a high-strength steel gas-shielded welding flux-cored wire, which is composed of a steel sheath and a core powder, in terms of total weight percentage, C 0.04-0.10%, Si 0.3-0.9%, Mn 0.5-2.0%, Cr 5-10%, Ni 5.0-8.0%; in the core powder, the conversion value of Mg oxide MgO is 0.5-3.5%, the conversion value of Ti oxide TiO2 is 2-7%, and MgO / TiO2=0.2-0.8, fluorine Compound conversion value 0.5‑1.5, and an appropriate amount of arc stabilizer, the rest is iron. The tensile strength of the prepared weld metal is above 980MPa, which is suitable for all-position welding.

Owner:张宇

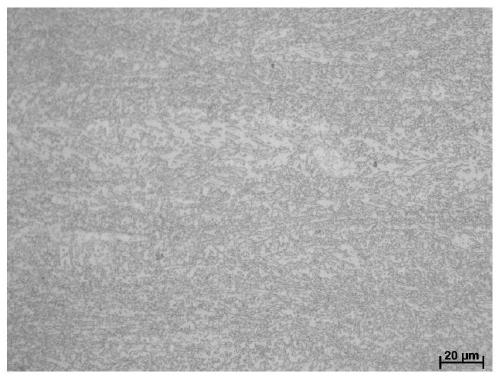

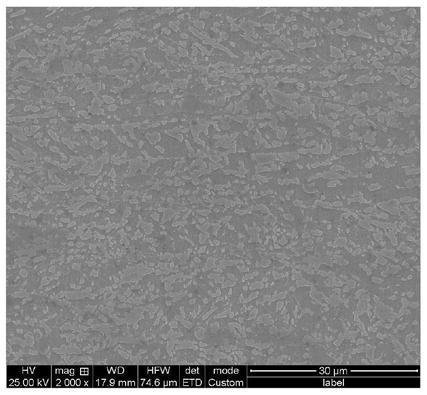

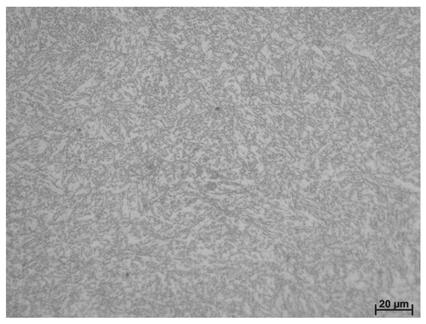

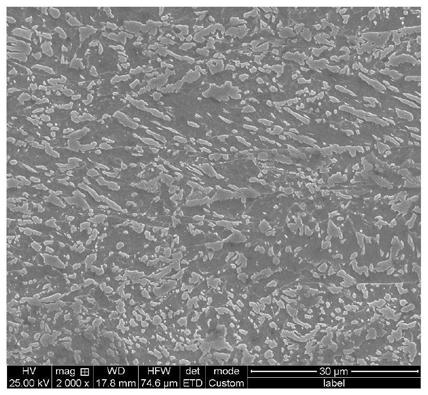

Nickel-free high-strength low-yield ratio medium manganese low-temperature steel and preparing method thereof

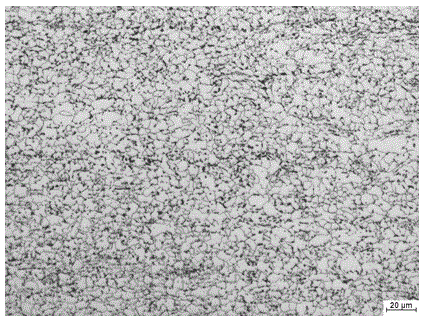

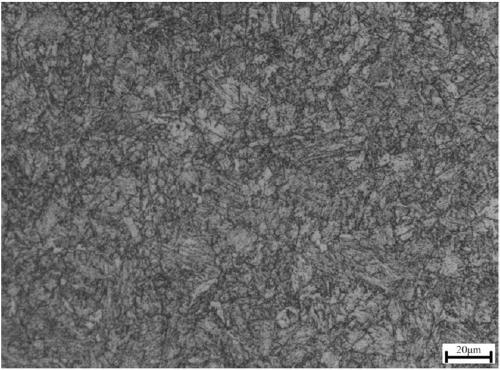

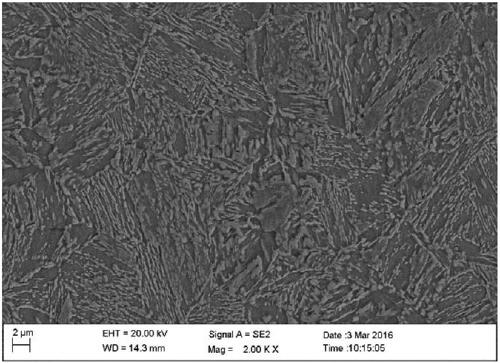

The invention discloses nickel-free high-strength low-yield ratio medium manganese low-temperature steel.The nickel-free high-strength low-yield ratio medium manganese low-temperature steel comprises, by mass, 0.03-0.06% of C, 4.5-6.0% of Mn, 0.15-0.23% of Si, 0.015-0.030% of Als, 0.1-0.3% of Mo, 0.006% or less of S, 0.009% or above of P and the balance Fe and impurity elements.The metallographic structure of the low-temperature steel is a complex-phase structure of tempered ferrite batten beam and a rotation austenite.By means of the alloy design mode that nickel is replaced by manganese and the reasonable rolling and the heating technology, the material acquires superior low-temperature tenacity, and cost is greatly reduced compared with that of other low-temperature steel.Meanwhile, the low-temperature steel further has the remarkable advantages of being high in yield strength and low yield ratio, and therefore the low-temperature steel is wider in application range and higher in structural safety.

Owner:NANJING IRON & STEEL CO LTD

Ocean engineering steel with welded joint CTOD (crack tip opening displacement) greater than 0.5mm and preparation method

ActiveCN103741027AGuaranteed Low Temperature ToughnessImprove low temperature toughnessCrack tip opening displacementEngineering

The invention discloses ocean engineering steel with welded joint CTOD (crack tip opening displacement) greater than 0.5mm and a preparation method, belonging to the technical field of ocean engineering steel. The ocean engineering steel comprises the following chemical components in percentage by weight: 0.05-0.12% of C, 0.10-0.40% of Si, 1.0-1.50% of Mn, 0.03-0.04% of Alt, 0.02-0.06% of Nb, 0.010-0.02% of Ti, 0.1-0.5% of Ni, less than 0.01% of P, less than 0.005% of S and the balance of Fe and unavoidable impurities. The alloy content is adjusted according to the effect of the alloy element in the steel, the parameters of the controlled-rolling and controlled-cooling process are strictly controlled, and the obtained 10-80mm steel plate has comprehensive mechanical properties that the welded joint CTOD is greater than 0.5mm at -10 DEG C under 420MPa and the lamellar tearing resistance is greater than 35% and the like. The ocean engineering steel disclosed by the invention has excellent comprehensive properties and can be widely applied to the key parts of the stationary, semi-submersible and self-elevating platforms.

Owner:SHOUGANG CORPORATION

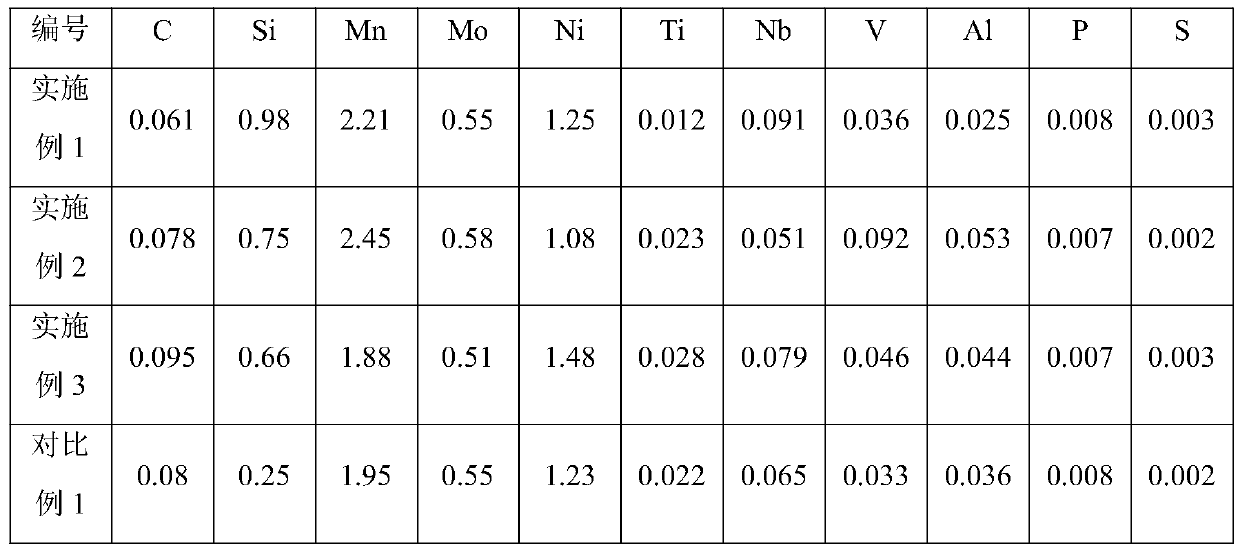

Anti-shock, corrosion resisting and fire resisting steel and preparing method thereof

ActiveCN111154962AHigh yield strengthSufficient yield strengthFurnace typesHeat treatment furnacesMaterials scienceCorrosion

The invention discloses anti-shock, corrosion resisting and fire resisting steel and a preparing method thereof, and belongs to the technical field of building structure steel. The problems that in the prior art, the anti-shock, corrosion resisting and fire resisting steel preparing technology is complex, and technology control difficulty is large are solved. The anti-shock, corrosion resisting and fire resisting steel comprises chemical components including, by mass percent, 0.06%-0.10% of C, 0.65%-1.00% of Si, 0.80%-1.20% of Mn, 0.50%-0.60% of Mo, 1.00%-1.50% of Ni, 0.72%-1.00% of Cr, 0.25%-0.40% of Cu, 0.01%-0.03% of Ti, 0.05%-0.10% of Nb, 0.03%-0.10% of V, 0.015%-0.055% of Al, smaller than 0.015% of P, smaller than 0.005% of S, smaller than 0.003% of O, smaller than 0.005% of N and thebalance Fe and inevitable impurities. The preparing method comprises smelting and casting and two-stage controlled rolling. The preparing method is simple and easy to control, and the comprehensive performance of the prepared anti-shock, corrosion resisting and fire resisting steel is good.

Owner:CENT IRON & STEEL RES INST +1

Anti-aseismic fire-resistant steel and preparation method thereof

ActiveCN111074158AImprove high temperature strengthGuaranteed fire resistanceEarthquake resistantChemical composition

The invention discloses anti-aseismic fire-resistant steel and a preparation method thereof, and belongs to the technical field of steel for a building structure. The anti-aseismic fire-resistant steel consists of the following chemical components in percentage by mass: 0.06%-0.10% of C, 0.65%-1.00% of Si, 1.85%-2.50% of Mn, 0.51%-0.60% of Mo, 1.00%-1.50% of Ni, 0.01%-0.03% of Ti, 0.05%-0.10% of Nb, 0.03%-0.10% of V, 0.015%-0.055% of Al, less than 0.015% of P, less than 0.005% of S, less than 0.003% of O, less than 0.005% of N, and the balance of Fe and inevitable impurities. The preparation method for the anti- aseismic fire-resistant steel comprises the following steps: smelting and casting; and performing two-stage control rolling. The preparation method is simple and easy to control, and the prepared anti-aseismic fire-resistant steel has good combination property.

Owner:CENT IRON & STEEL RES INST +1

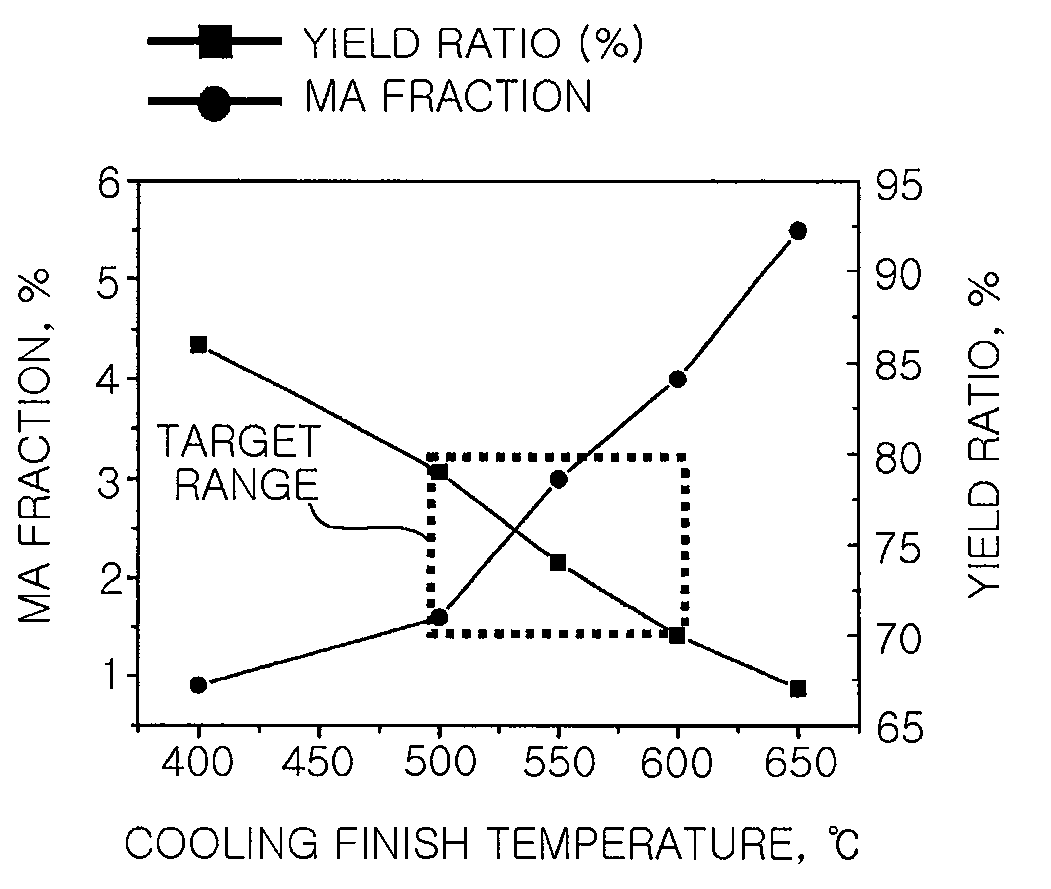

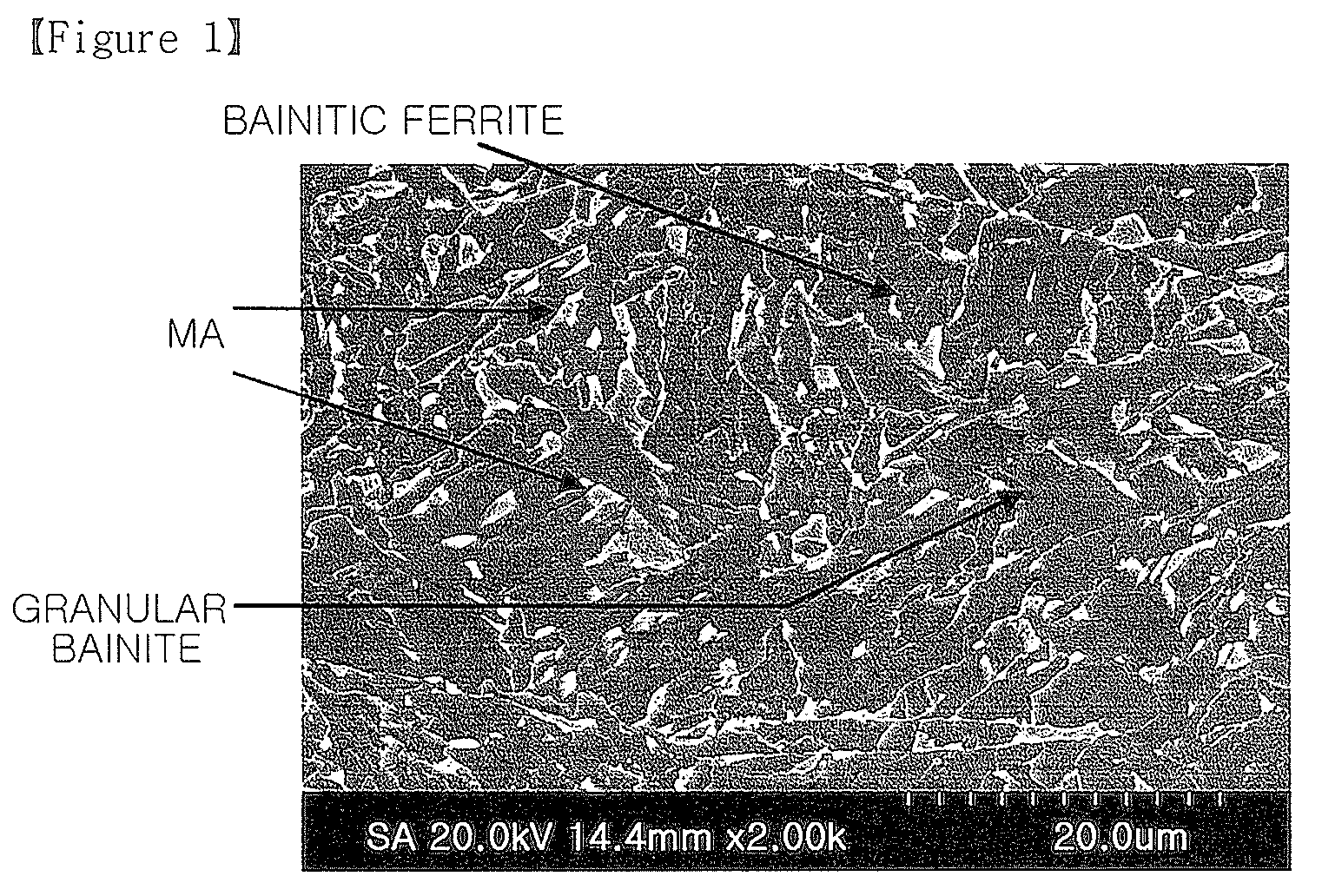

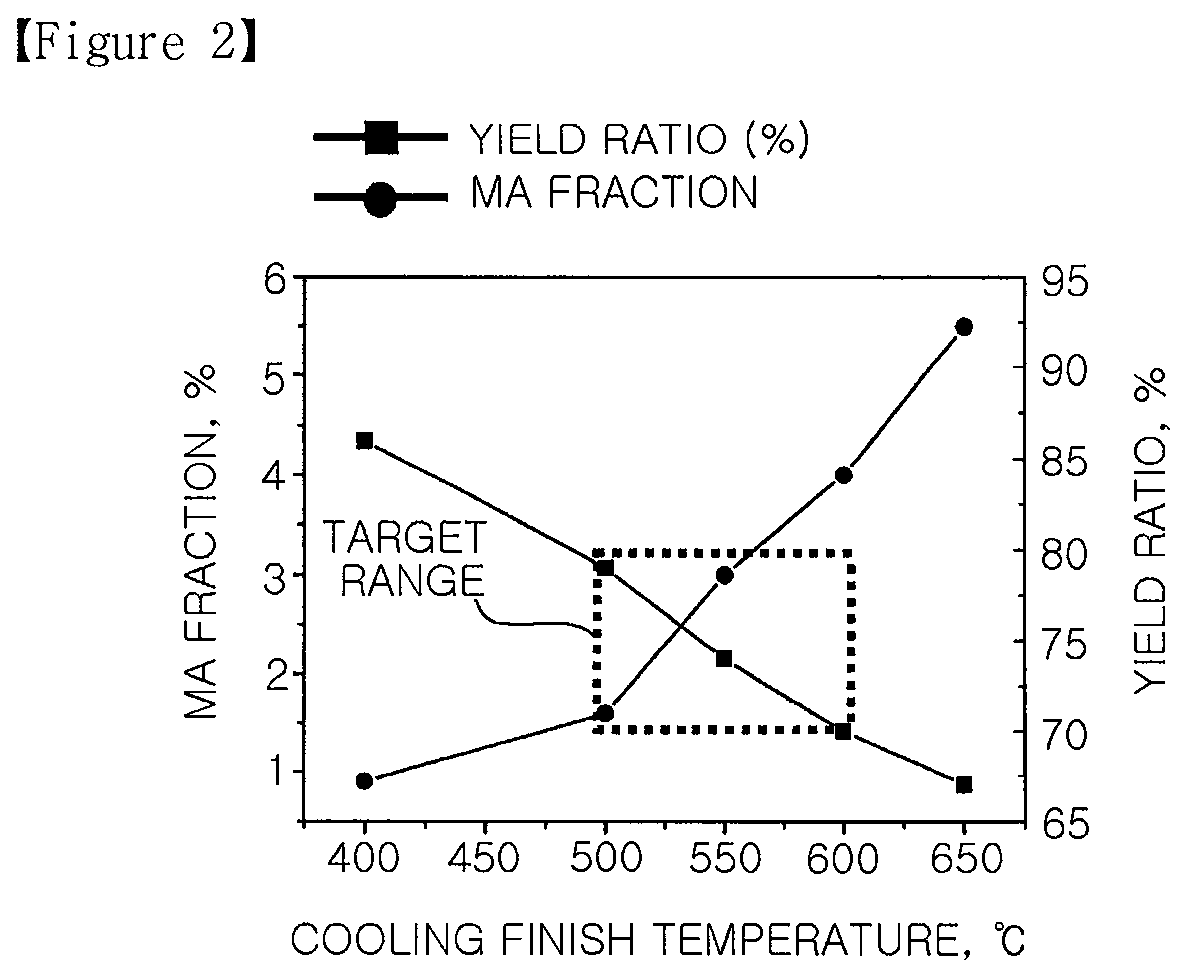

High strength and low yield ratio steel for structure having excellent low temperature toughness

ActiveUS8702880B2High strengthGuaranteed Low Temperature ToughnessRollsMetal rolling arrangementsUltimate tensile strengthToughness

A high strength and low yield ratio steel that has excellent characteristics such as low temperature toughness, a tensile strength of approximately 600 MPa or more and a low yield ratio of 80% or less. The high strength and low yield ratio steel includes, by weight percent: C: 0.02 to 0.12%, Si: 0.01 to 0.8%, Mn: 0.3 to 2.5%, P: 0.02% or less, S: 0.01% or less, Al: 0.005 to 0.5%, Nb: 0.005 to 0.10%, B: 3 to 50 ppm, Ti: 0.005 to 0.1%, N: 15 to 150 ppm, Ca: 60 ppm or less, and the balance of be and inevitable impurities, and further includes at least one component selected from the group consisting of by weight percent: Cr: 0.05 to 1.0%, Mo: 0.01 to 1.0%, Ni: 0.01 to 2.0%, Cu: 0.01 to 1.0% and V: 0.005 to 0.3%, wherein a finish cooling temperature is limited to 500 to 600° C. after the finish-rolling process. The high strength and low yield ratio steel satisfying characteristics such as low temperature toughness, brittle crack arrestability and low yield ratio, and the manufacturing method thereof may be provided.

Owner:POHANG IRON & STEEL CO LTD

Supporting steel for containment vessel of nuclear power station and manufacturing method thereof

InactiveCN111363985AGuaranteed toughness indexGuaranteed performanceNuclear powerProcess engineering

The invention provides supporting steel for a containment vessel of a nuclear power station and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.10%-0.16% of C, 0.25%-0.45% of Si, 1.40%-1.65% of Mn, 0.45%-0.65% of Ni, 0.20%-0.50% of Cr, 0.20%-0.55% of Mo, 0.02%-0.04% of Alt, 0.05%-0.10% of Cu, 0.03-0.05% of V, 0.005-0.020% of Ti, 0.008% or less of P, 0.005% of less of S, 0.010% or less of N, and the balance being Fe and unavoidable impurities. The manufacturing method comprises smelting, continuous casting, heating, rolling and heat treatment. The thickness of a steel plate produced from the steel is 30-80 mm, the steel plate in the quenched and tempered state, simulated post-weld heat treatment state and 200 DEG C high temperature state completely meets the requirements of technical indicators, and meanwhile -40 DEG C impact absorption energy is still remained at a high level.

Owner:ANGANG STEEL CO LTD +1

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

Low odor and high toughness modified PC/ABS material for vehicles and preparation method thereof

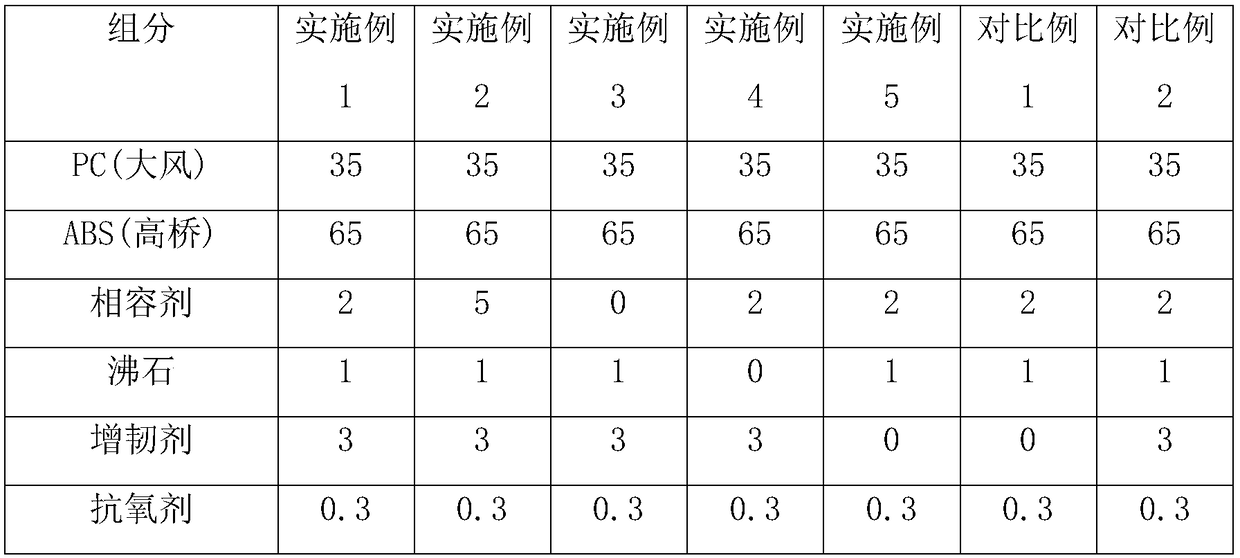

Belonging to the technical field of high polymer materials, the invention relates to a low odor and high toughness modified PC / ABS material for vehicles and a preparation method thereof, and solves the technical problem of low impact strength of low odor PC / ABS materials in the prior art. The material is composed of 30-80% of PC, 15-65% of ABS, 1-3% of a compatilizer, 1-2% of zeolite, 1-3% of a toughening agent, and 0.1-1% of an antioxidant. The invention also provides a preparation method of the above-mentioned low odor and high toughness modified PC / ABS material for vehicles, and the prepared material not only ensures the low odor, but also guarantees the normal temperature and low temperature toughness of the material, and is especially suitable for automobile parts.

Owner:中广核俊尔(上海)新材料有限公司

A kind of 9ni marine cryogenic container steel plate with high flaw detection quality and its manufacturing method

ActiveCN107604255BControl the total amount addedImprove low temperature impact toughnessChemical compositionSheet steel

The invention relates to a low-temperature container steel plate with high flaw detection quality and used for a 9Ni ship. The low-temperature container steel plate takes Fe as the basic element and comprises the following chemical components in percentage by mass: 0.03-0.05% of C, 0.10-0.14% of Si, 0.50-0.80% of Mn, 8.7-9.7% of Ni, equal to or less than 0.008% of P, equal to or less than 0.002% of S, equal to or less than 0.25% of Cr, equal to or less than 0.08% of Mo, equal to or less than 0.35% of Cu, 0.020-0.035% of Alt, 0.01-0.02% of Nb, equal to or less than 60 ppm of N, equal to or lessthan 1.2 ppm of H and the balance of unavoidable impurity elements, wherein the carbon equivalent CEV[pound sign] is 0.80. The low-temperature container steel plate has high low temperature toughness, tensile property, strength and the like; and compared with the existing steel plate of the same kind, the low-temperature container steel plate has higher surface and heart flaw detection quality and facilitates follow-up processing of the steel plate.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Ti-CONTAINING FERRITIC STAINLESS STEEL SHEET, MANUFACTURING METHOD, AND FLANGE

InactiveUS20190093192A1Stably achievedHigh reliability in toughnessSilencing apparatusFurnace typesChemical compositionSS - Stainless steel

A Ti-containing ferritic stainless steel sheet having a large gauge thickness and excellent toughness has a chemical composition containing, in terms of percentage by mass, from 0.003 to 0.030% of C, 2.0% or less of Si, 2.0% or less of Mn, 0.050% or less of P, 0.040% or less of S, from 10.0 to 19.0% of Cr, 0.030% or less of N, from 0.07 to 0.50% of Ti, from 0.010 to 0.20% of Al, from 0 to 1.50% of Mo, and from 0 to 0.0030% of B, the balance of Fe and unavoidable impurities. The steel has a K value defined by the following expression of 150 or more: K value=−0.07′Cr−6790′Free(C+N)−1.44′d+267, and having a sheet thickness of from 5.0 to 11.0 mm. Herein, Free(C+N) corresponds to the solid-dissolved (C+N) concentration (% by mass), and d represents an average crystal grain diameter (μm).

Owner:NIPPON STEEL STAINLESS STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com