Anti-shock, corrosion resisting and fire resisting steel and preparing method thereof

A refractory and corrosion-resistant technology, applied in the field of seismic-corrosion-resistant refractory steel and its preparation, can solve problems such as difficult process control, and achieve the effects of simple preparation method, improved yield strength, and improved low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

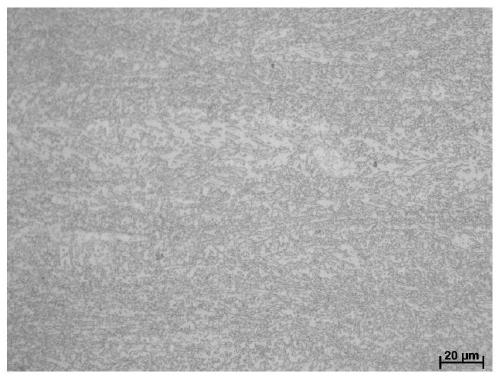

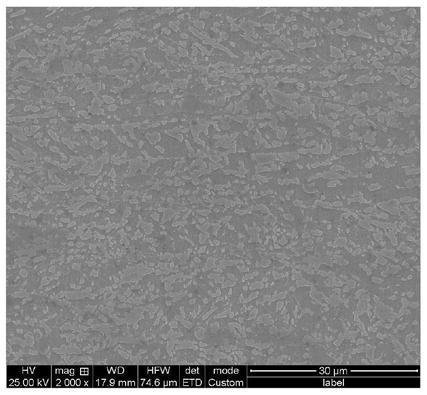

Image

Examples

preparation example Construction

[0048] On the other hand, the present invention also provides a kind of preparation method of anti-shock and corrosion-resistant refractory steel, comprising the following steps:

[0049] Step S1: smelting and casting;

[0050] Step S2: Two-stage controlled rolling of recrystallization and non-recrystallization is carried out by using a plate rolling mill.

[0051] Specifically, in step S1, molten steel is smelted using a converter or an electric furnace, and continuous casting is used for casting.

[0052] Specifically, step S2 includes the following steps:

[0053] S21. After the continuous casting billet or ingot is opened, put it into the heating furnace and heat it to T1, and hold it for t1 time;

[0054] Specifically, in S21, T1 is 1200-1250°C. This is because when T1 is too high, the austenite grains of the slab are too coarse, and energy costs are increased at the same time. When T1 is too low, elements such as Nb and C are difficult to fully dissolve , affecting su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com