Nickel-free high-strength low-yield ratio medium manganese low-temperature steel and preparing method thereof

A low-yield-ratio, low-temperature steel technology, which is applied in the field of low-temperature steel and its preparation, can solve problems such as difficult to save nickel and reduce costs, high-strength yield ratio, and difficult to guarantee the safety of steel structures, etc., to achieve alloy cost reduction and cost reduction. Reduced, excellent low temperature toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

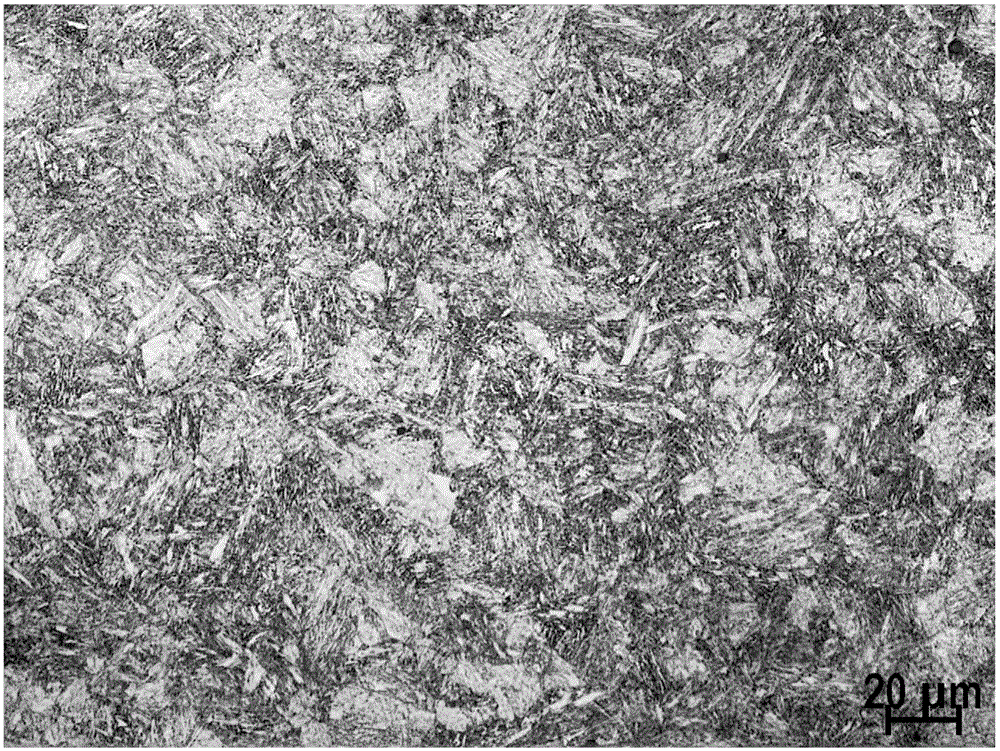

Embodiment 1

[0035] This example 1 is a nickel-free high-strength low-yield-ratio medium-manganese low-temperature steel plate with a thickness of 60mm, and its chemical composition and mass fraction are 0.04%C, 5.1%Mn, 0.23%Si, 0.02%Als, and 0.16% Mo, 0.006%S, 0.007%P, and the balance of Fe and impurity elements, the metallographic structure is a tempered ferrite lath bundle + austenite double phase structure, yield strength 609MPa, yield ratio 0.78, elongation The rate is 37%, and the transverse impact energy absorbed in the Charpy impact test at -110°C is 152J.

[0036] The preparation process of the above-mentioned low-temperature steel plate is carried out according to the following steps:

[0037] Put a 320mm thick blank into a heating furnace and heat it to 1050°C for 180 minutes. The chemical composition and mass fraction of the blank are 0.04%C, 5.1%Mn, 0.22%Si, 0.02%Als, 0.16%Mo, 0.006% S, 0.007%P, and the balance Fe and impurity elements;

[0038] Two-stage rolling is carried ...

Embodiment 2

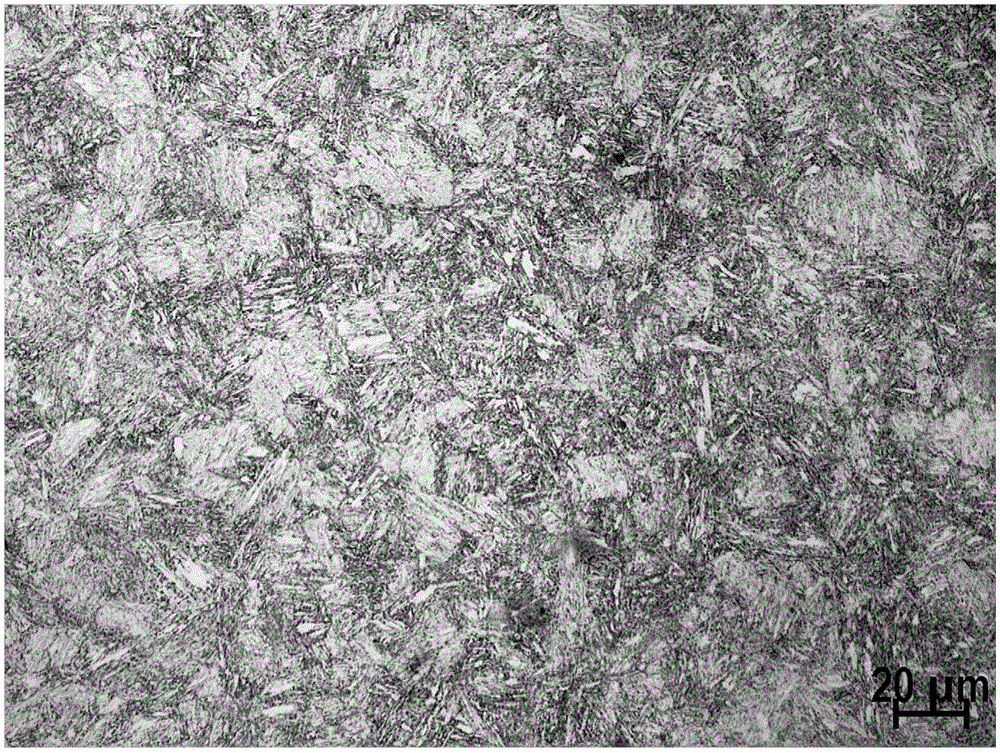

[0042] In this example, the nickel-free high-strength low-yield-ratio medium-manganese low-temperature steel plate with a thickness of 41mm has chemical components and mass fractions of 0.06%C, 4.5%Mn, 0.15%Si, 0.03%Als, and 0.3%Mo, respectively. 0.001%S, 0.009%P, and the balance of Fe and impurity elements, the metallographic structure is a tempered ferrite lath bundle+revolved austenite multiphase structure, the yield strength is 637MPa, the yield ratio is 0.82, and the elongation is 35 %, -110 ℃ Charpy impact test transverse impact energy absorption is 131J.

[0043] The preparation process of the above-mentioned low-temperature steel plate is carried out according to the following steps:

[0044] Put a 280mm thick blank into a heating furnace and heat it to 1120°C and hold it for 120min. The chemical composition and mass fraction of the blank are 0.06%C, 4.5%Mn, 0.15%Si, 0.03%Als, 0.3%Mo, 0.001% S, 0.009%P, and the balance Fe and impurity elements;

[0045] Two-stage rol...

Embodiment 3

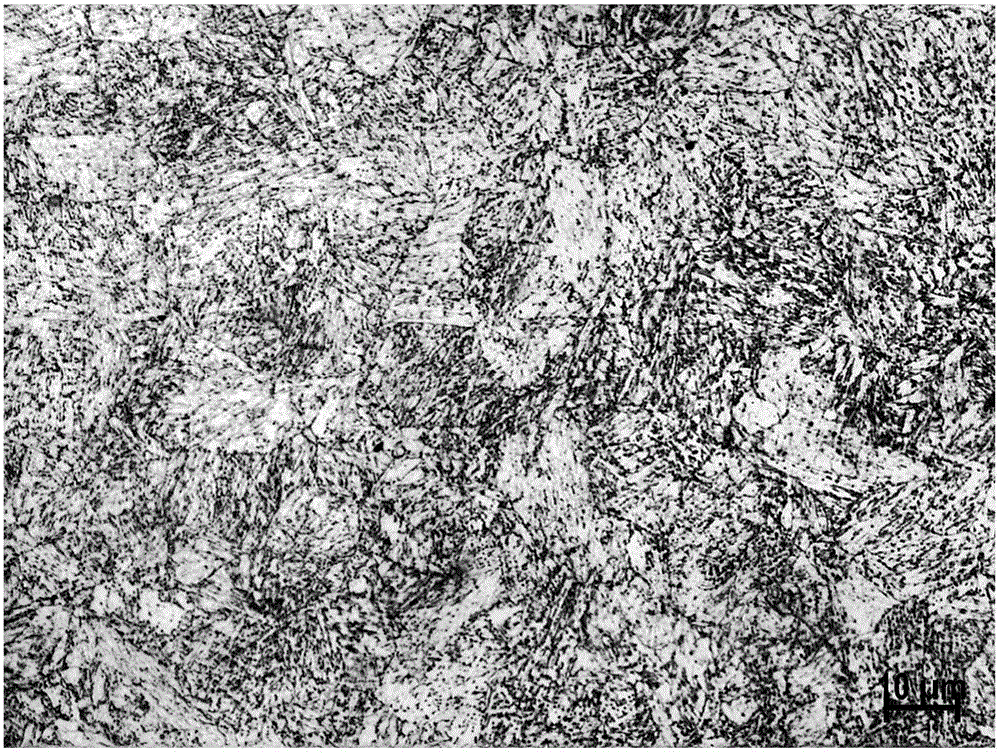

[0049] This example is a nickel-free high-strength low-yield-ratio medium-manganese low-temperature steel plate with a thickness of 17mm, and its chemical composition and mass fraction are 0.03%C, 6.0%Mn, 0.20%Si, 0.015%Als, and 0.1%Mo , 0.003%S, 0.006%P, and the balance of Fe and impurity elements, the metallographic structure is a complex phase structure of tempered ferrite lath bundle + rotative austenite, yield strength 654MPa, yield ratio 0.85, elongation 32%, -110 ℃ Charpy impact test transverse impact absorption energy is 120J.

[0050] The preparation process of the above-mentioned low-temperature steel plate is carried out according to the following steps:

[0051] Put a 180mm thick billet into a heating furnace and heat it to 1150°C for 90 minutes. The chemical composition and mass fraction of the billet are 0.03%C, 6.0%Mn, 0.20%Si, 0.015%Als, 0.1%Mo, 0.003% S, 0.006%P, and the balance Fe and impurity elements;

[0052] The heated billet is rolled in two stages, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com