High-nickel steel for low-temperature container and manufacturing method of high-nickel steel

A low-temperature container and manufacturing method technology, applied in the field of metallurgical steelmaking, can solve problems such as the inability to meet the technical requirements of 9Ni steel, and achieve the effects of increasing the quantity, reducing harmful elements, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for manufacturing high-nickel steel for cryogenic vessels, comprising the following steps:

[0047] 1) 100 tons of oxygen top-blown converter is used for smelting, and the carbon temperature is coordinated during the blowing process;

[0048] 2) Desulfurization of reducing slag made in LF furnace, reducing inclusions and adjusting composition. The holding time of VD furnace is 18min. Determination of H, O content, [H] = 1.0ppm, [O] = 15ppm;

[0049] 3) The whole process of continuous casting is protected and poured, and the billet size is 300mm;

[0050] 4) The slab is slowly cooled in a slow cooling pit for 60 hours;

[0051] 5) Two-stage controlled rolling, the first-stage start-rolling temperature is 1100°C, the second-stage start-rolling temperature is 880°C, and the final rolling temperature is 850°C. The temperature is 190°C, the redness temperature is 310°C, and the thickness of the steel plate is 30mm;

[0052] 6) Heat treatment: Put the steel plat...

Embodiment 2

[0054] A method for manufacturing high-nickel steel for cryogenic vessels, comprising the following steps:

[0055] 1) 100 tons of oxygen top-blown converter is used for smelting, and the carbon temperature is coordinated during the blowing process;

[0056] 2) Desulfurization of reducing slag made in LF furnace, reducing inclusions and adjusting composition. The holding time of VD furnace is 18min. Determination of H and O content, [H] = 1.2ppm, [O] = 16ppm;

[0057] 3) The whole process of continuous casting is protected and poured, and the billet size is 300mm;

[0058] 4) The slab is slowly cooled in a slow cooling pit for 60 hours;

[0059] 5) Two-stage controlled rolling, the first-stage start-rolling temperature is 1100°C, the second-stage start-rolling temperature is 860°C, and the final rolling temperature is 830°C. The temperature is 180°C, the redness temperature is 300°C, and the thickness of the steel plate is 30mm;

[0060] 6) Heat treatment: Put the steel p...

Embodiment 3

[0062] A method for manufacturing high-nickel steel for cryogenic vessels, comprising the following steps:

[0063] 1) 100 tons of oxygen top-blown converter is used for smelting, and the carbon temperature is coordinated during the blowing process;

[0064] 2) Desulfurization of reducing slag made in LF furnace, reducing inclusions and adjusting composition. The holding time of the VD furnace is 20min. Determination of H and O content, [H] = 1.2ppm, [O] = 16ppm;

[0065] 3) The whole process of continuous casting is protected and poured, and the billet size is 300mm;

[0066] 4) The slab is slowly cooled in a slow cooling pit for 60 hours;

[0067] 5) Two-stage controlled rolling, the first-stage start-rolling temperature is 1100°C, the second-stage start-rolling temperature is 900°C, and the final rolling temperature is 845°C. The temperature is 190°C, the redness temperature is 320°C, and the thickness of the steel plate is 30mm;

[0068] 6) Heat treatment: Put the ste...

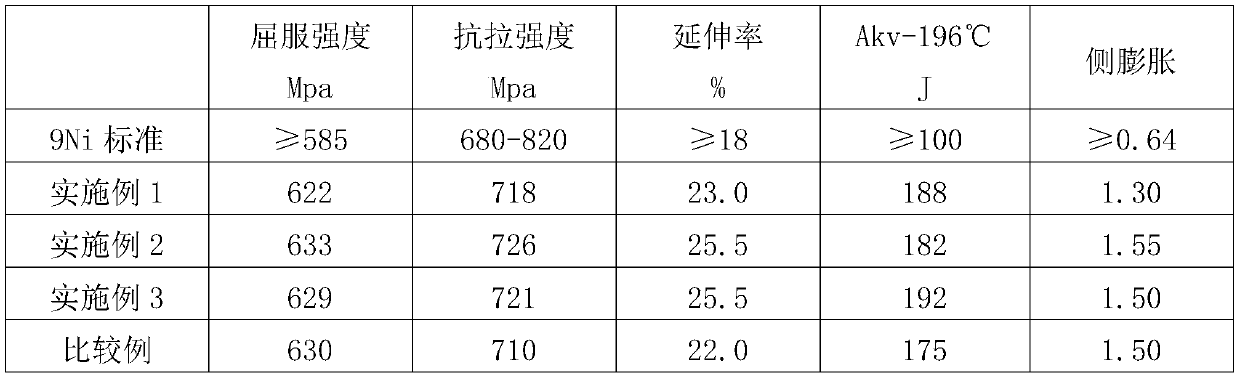

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com