X60N normalizing pipeline steel and production method thereof

A production method and pipeline steel technology, applied in the field of pipeline steel production, can solve problems such as abnormal structure, uneven structure, fluctuation of pipeline steel performance, etc., and achieve the effect of uniform structure, stable performance and improved strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

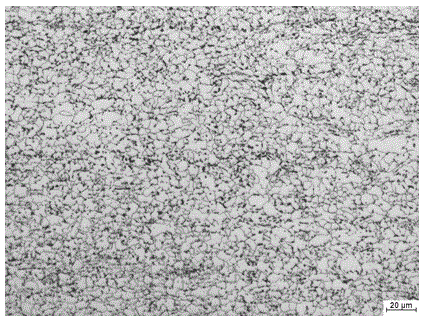

Image

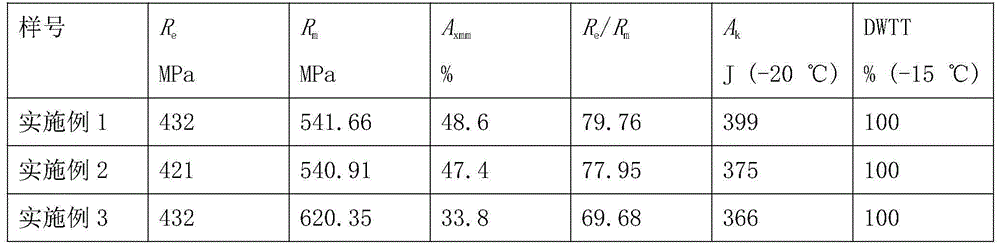

Examples

Embodiment 1

[0027] The product specification is X60N normalizing pipeline steel with a thickness of 16mm, and its chemical composition (wt%) is as follows: C0.083193wt%, Si0.288wt%, Mn1.6113wt%, S0.0014wt%, P0.008wt%, Ni0.0406wt% , Cr0.2259wt%, Cu0.0123wt%, Nb0.0548wt%, V0.0046wt%, Ti0.012wt%, Mo0.0086wt%, Alt0.0308wt%, the rest is Fe and unavoidable impurities.

[0028] Its production process includes converter smelting, continuous casting, rolling, and normalizing heat treatment processes. The molten steel is smelted and poured into a billet with a thickness of 150mm. The billet is first subjected to rough rolling stage: starting rolling temperature: 1030°C, finishing rolling temperature: 1000°C; finishing rolling stage: starting rolling temperature: 940°C, finishing rolling temperature: 800°C; ACC laminar flow cooling, water inlet temperature is 790°C, red return temperature is 460°C,

[0029] After the steel plate is cooled, the stack is slowly cooled, and the stack cooling time is 1...

Embodiment 2

[0031] The product specification is X60N normalizing pipeline steel with a thickness of 16mm, and its chemical composition (wt%) is as follows: C0.083193wt%, Si0.288wt%, Mn1.6113wt%, S0.0014wt%, P0.008wt%, Ni0.0406wt% , Cr0.2259wt%, Cu0.0123wt%, Nb0.0548wt%, V0.0046wt%, Ti0.012wt%, Mo0.0086wt%, Alt0.0308wt%, the rest is Fe and unavoidable impurities.

[0032] After converter smelting, continuous casting, rolling, and normalizing heat treatment processes, the molten steel is smelted and poured into a billet with a thickness of 150mm. The billet is first subjected to rough rolling stage: starting rolling temperature: 1030°C, finishing rolling temperature: 1000; finishing rolling stage: starting rolling temperature : 940°C, final rolling temperature: 800°C; after rolling, the steel plate enters the ACC laminar flow cooling, the water inlet temperature is 790°C, the redness temperature is 460°C, the steel plate is stacked and cooled slowly after cooling, and the stack cooling time ...

Embodiment 3

[0034] The product specification is X60N normalizing pipeline steel with a thickness of 16mm, and its chemical composition (wt%) is as follows: C0.083193wt%, Si0.288wt%, Mn1.6113wt%, S0.0014wt%, P0.008wt%, Ni0.0406wt% , Cr0.2259wt%, Cu0.0123wt%, Nb0.0548wt%, V0.0046wt%, Ti0.012wt%, Mo0.0086wt%, Alt0.0308wt%, the rest is Fe and unavoidable impurities. After converter smelting, continuous casting, rolling, and normalizing heat treatment processes, the molten steel is smelted and poured into a billet with a thickness of 150mm. The billet is first subjected to rough rolling stage: starting rolling temperature: 1030°C, finishing rolling temperature: 1000; finishing rolling stage: starting rolling temperature : 940°C, final rolling temperature: 800°C; after rolling, the steel plate enters the ACC laminar flow cooling, the water inlet temperature is 790°C, the redness temperature is 460°C, the steel plate is stacked and cooled slowly after cooling, and the stack cooling time is 12-24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com