Low odor and high toughness modified PC/ABS material for vehicles and preparation method thereof

An ABS material and high toughness technology, applied in the field of polymer materials, can solve the problems of low odor and low impact strength, and achieve the effect of low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

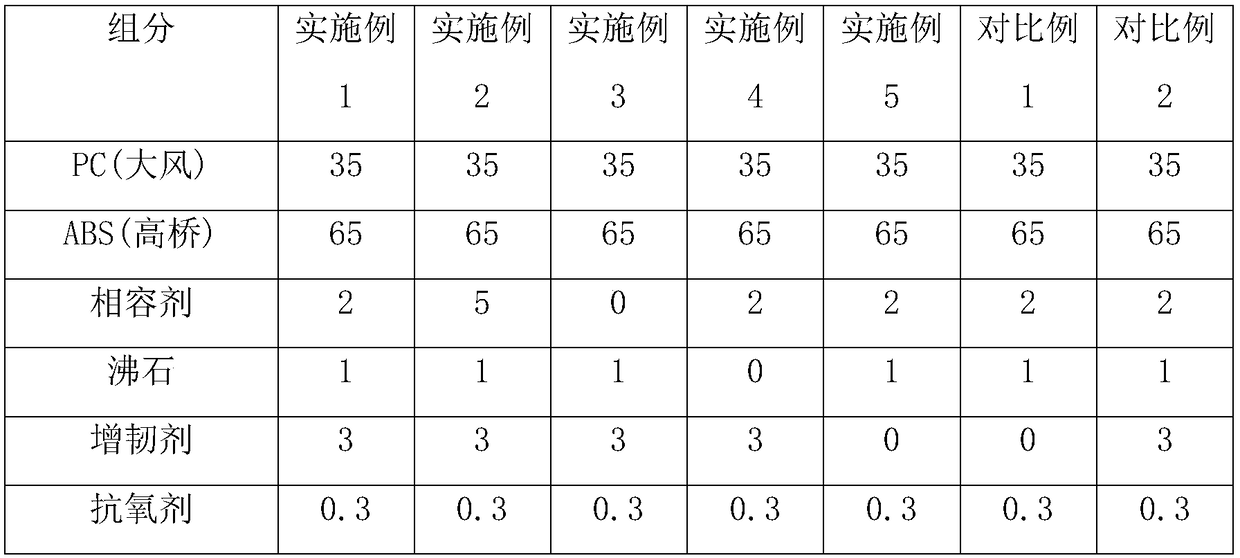

[0029] The present invention will be further described below through specific embodiments. The parts by weight of each component in Examples 1-5 and Comparative Examples 1-2 are shown in Table 1, and the test results are shown in Table 2.

[0030] The parts by weight of raw materials in Table 1 Examples 1-5

[0031]

[0032] The preparation method of Example 1-5 is the same as that of Comparative Example 1-2, that is, the raw materials are weighed according to the ratio of each component shown in Table 1, placed in a high-speed mixer to mix uniformly, and the mixed raw materials are placed in an extruder, and the After extrusion, it was cooled, dried, and pelletized, and then test strips were prepared by an injection molding machine.

[0033] The PC / ABS materials prepared in Examples 1-5 and the PC / ABS materials prepared in Comparative Examples 1-2 are subjected to performance testing and comparative analysis below.

[0034] Test methods for materials:

[0035] Tensile s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com