Multi-component microalloying section molybdenum-type fire-resistant steel efficient welding process

A micro-alloying and multi-component compounding technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of brittle fracture in the joint area, loss of strengthening effect, deterioration of strength and toughness, etc., and achieve the reduction of phase transition temperature and the amount of solid solution Increase, the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The multi-component composite microalloyed molybdenum-section refractory steel plate Q420FRE is used, and the Q420FRE multiple-component composite micro-alloyed molybdenum-section refractory steel plate of the same plate thickness is used for butt joint, and the plate thickness combination is 16mm+16mm. The size of the test plate is 1200mm×460mm×16mm; the chemical composition and weight percentage of the steel plate are: C: 0.04~0.06%, Mn: 0.70~0.90%, Si: 0.15~0.25%, P: ≤0.010%, S: ≤ 0.003%, Nb: 0.050~0.15%, Ti: ≤0.01~0.025%, V: ≤0.10%, Mo: 0.15~0.20%, Al: 0.20~0.50%, the balance is Fe and unavoidable impurities; carbon equivalent Ceq ≤ 0.37%, cold crack sensitivity index Pcm ≤ 0.18%; the mechanical properties of the steel plate are: room temperature tensile strength Rm is 596MPa, yield strength ReH is 469MPa, 600°C high temperature yield strength is 387MPa, -40°C impact energy KV2 is 308J .

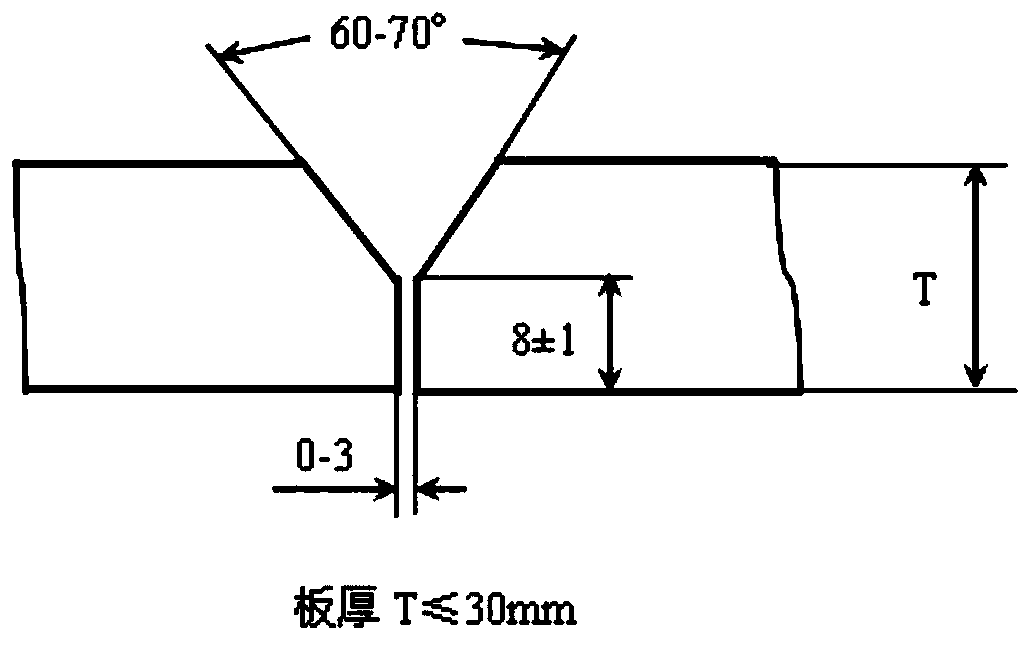

[0023] (2) The groove adopts Y-shaped groove, as attached figure 1 As s...

Embodiment 2

[0029] (1) The multi-component composite microalloyed molybdenum-section refractory steel plate Q420FRE is used, and the Q420FRE multi-component composite micro-alloyed molybdenum-section refractory steel plate of the same plate thickness is combined butt joint, and the plate thickness combination is 80mm+80mm. The size of the test plate is 1200mm×500mm×80mm; the chemical composition and weight percentage of the steel plate are: C: 0.04~0.06%, Mn: 0.70~0.90%, Si: 0.15~0.25%, P: ≤0.010%, S: ≤ 0.003%, Nb: 0.050~0.15%, Ti: ≤0.01~0.025%, V: ≤0.10%, Mo: 0.15~0.20%, Al: 0.20~0.50%, the balance is Fe and unavoidable impurities; carbon equivalent Ceq ≤ 0.37%, cold crack sensitivity index Pcm ≤ 0.18%; the mechanical properties of the steel plate are: the tensile strength Rm at room temperature is 576MPa, the yield strength ReH is 447MPa, the high temperature yield strength at 600°C is 349MPa, and the impact energy KV2 at -40°C is 333J .

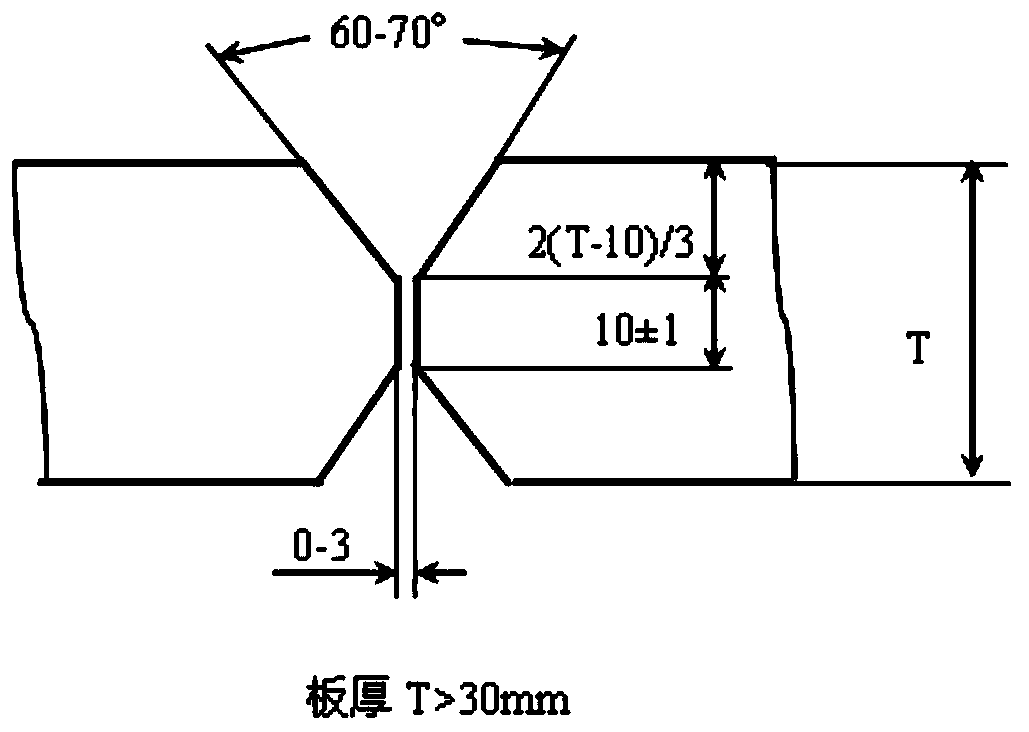

[0030] (2) The groove adopts X-shaped groove, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com