Manufacturing method of heating/heat-insulated restricted neck feeding on inner/outer metal mold sand casting manganese steel crushing wall or rolling mortar wall

A technology of sand-covering and manufacturing methods for metal molds, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as easy cracks, low casting process yield, and large riser volume, so as to reduce costs, The effect of improving the casting process yield and good high temperature fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Manufacture Broken wall heating insulation easy-cut riser

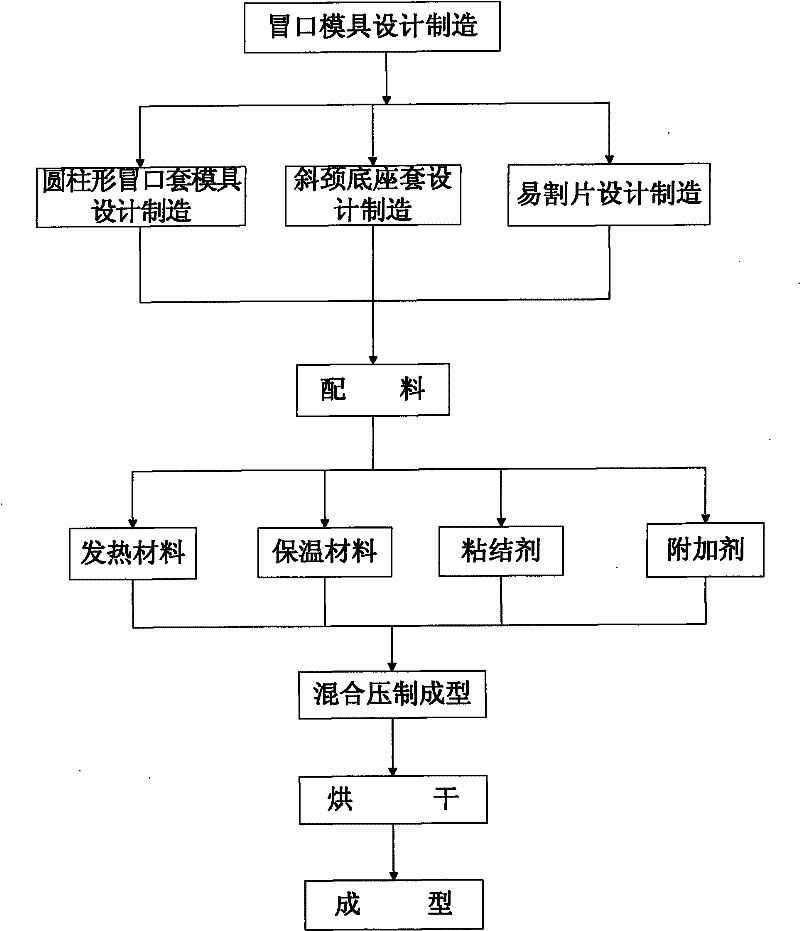

[0036] refer to figure 1 , 2 , 3, its manufacture method step is as follows:

[0037] 1. Design and manufacture Φ1200 broken wall casting heating insulation riser components:

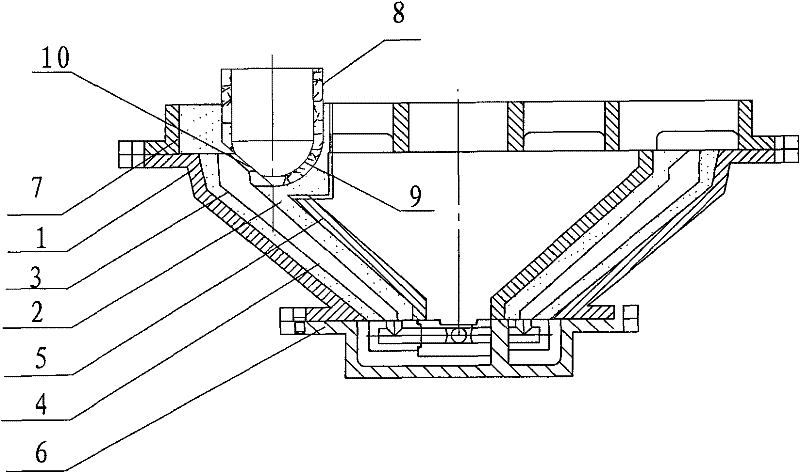

[0038] (1) Design and manufacture cylindrical heating and heat preservation riser sleeve 8 (upper riser), riser sleeve inner diameter d=210mm, outer diameter D=250mm, effective modulus 5cm;

[0039] (2) Design and manufacture torticollis heating and heat preservation riser seat cover 9 (the lower part of the riser), torticollis diameter Φ105mm, h=80mm;

[0040] (3) Design and manufacture heating and heat preservation riser sleeves 8 easy-cut pieces 10, the thickness of the easy-cut pieces 10 is 10mm, and the minimum diameter is Φ100mm;

[0041] 2. Assemble the 8 components of the heating and heat preservation riser sleeve:

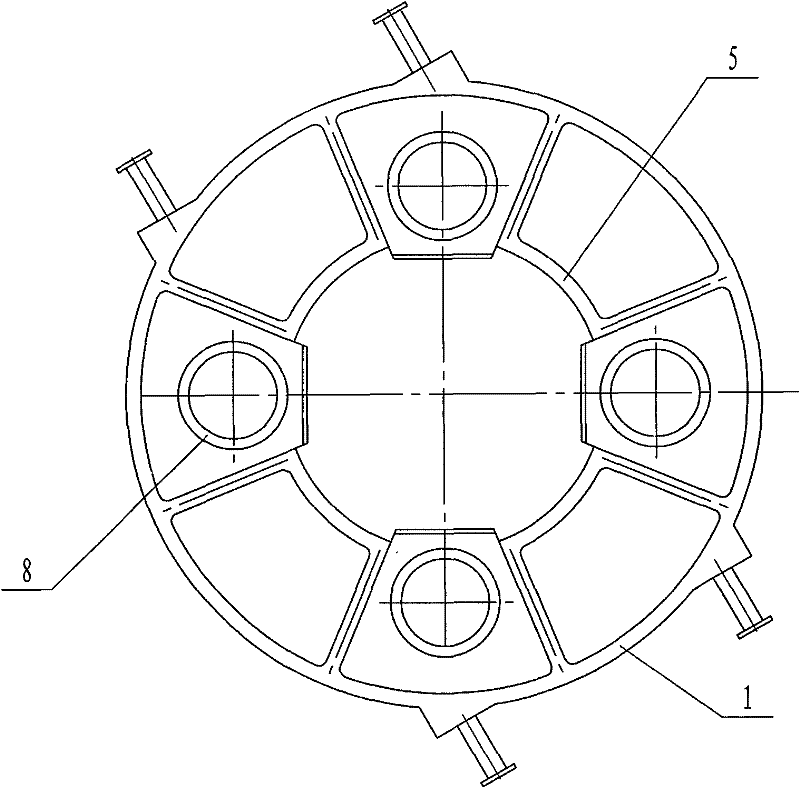

[0042] (1) When manufacturing the inner metal mold 5 and the inner metal mold sand coating layer ...

Embodiment 2

[0047] Example 2 Manufacture Rolling mortar wall heating and heat preservation easy-cut riser

[0048] refer to figure 1 , 4 , 5, its manufacture method step is the same as embodiment 1.

Embodiment 3

[0049] Example 3 Manufacture Broken wall heating insulation easy-cut riser

[0050] refer to figure 1 , 6 , 7, its casting method steps are as follows:

[0051] 1. Design and manufacture of Φ2200 broken wall casting heating insulation riser components:

[0052] (1) Design and manufacture cylindrical heating and heat preservation riser sleeve 8 (the upper part of the riser), the inner diameter of the riser sleeve is d=310mm, the outer diameter is D=360mm, and the effective modulus is 7cm;

[0053] (2) Design and manufacture torticollis heating and thermal insulation riser seat cover 9 (the lower part of the riser), torticollis diameter Φ120mm, h=100mm;

[0054] (3) Design and manufacture heating and heat preservation riser sleeves 8 easy-cut pieces 10, the thickness of the easy-cut pieces 10 is 15mm, and the minimum diameter is Φ115mm;

[0055] 2. Assemble each component of the heating and heat preservation riser sleeve:

[0056] (1) When manufacturing the outer metal mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com