Low-temperature flexibility 1.5Ni steel and method of manufacturing the same

A technology of low temperature toughness and manufacturing method, applied in the field of Ni steel, can solve the problems of difficult heating and rolling process, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

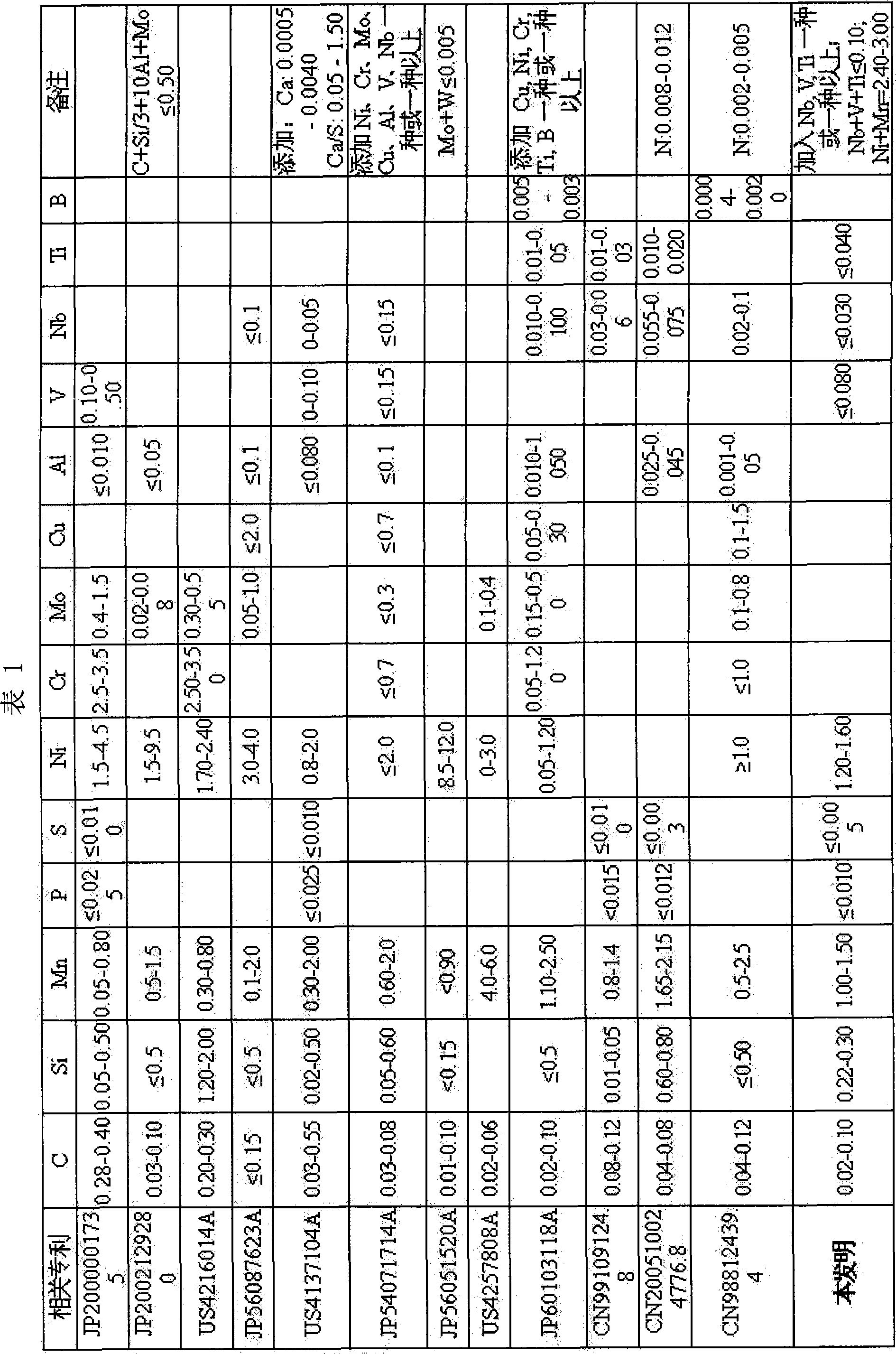

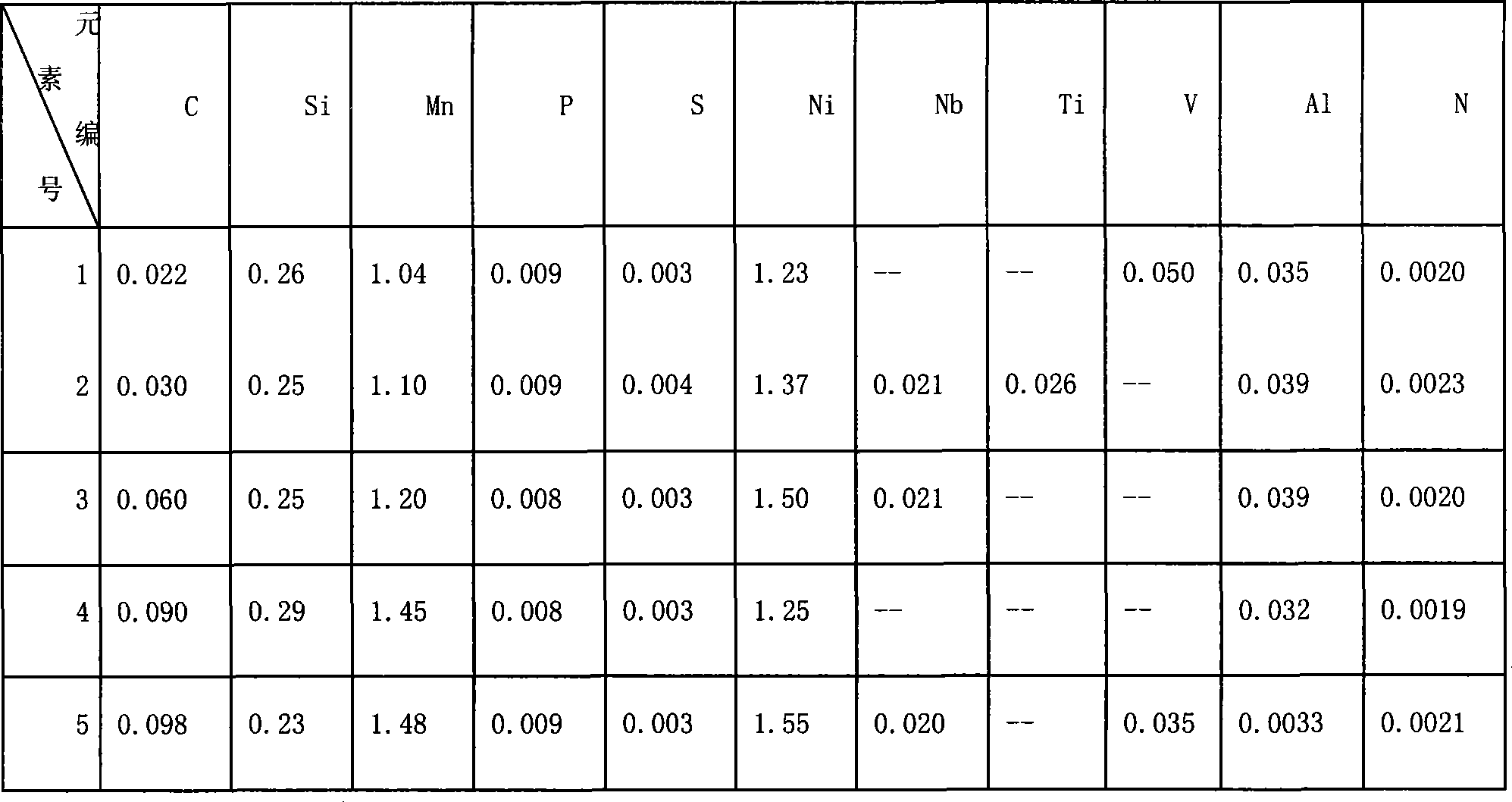

[0037] Table 2 is the chemical composition of embodiment 1-5

[0038] Table 2

[0039]

[0040] According to hot rolling and heat treatment process, embodiment 1-5 rolling (finished steel thickness 20mm) and heat treatment process parameter range are as follows:

[0041] Slab heating temperature: 1150~1250℃; recrystallization controlled rolling temperature: 950~1100℃, accumulative reduction rate≥50%; non-recrystallized controlled rolling temperature: 870~920℃, accumulative reduction rate≥20% ; Two-phase zone controlled rolling temperature: 800-850°C, cumulative reduction rate ≤10%; termination cooling temperature: ≤300°C; quenching temperature: 850-950°C; tempering temperature: 600-660°C.

[0042] The holding time of each stage is calculated according to the plate thickness according to 1 ~ 3.5min / mm.

[0043] Table 3 embodiment 1-5 concrete process parameter

[0044] table 3

[0045]

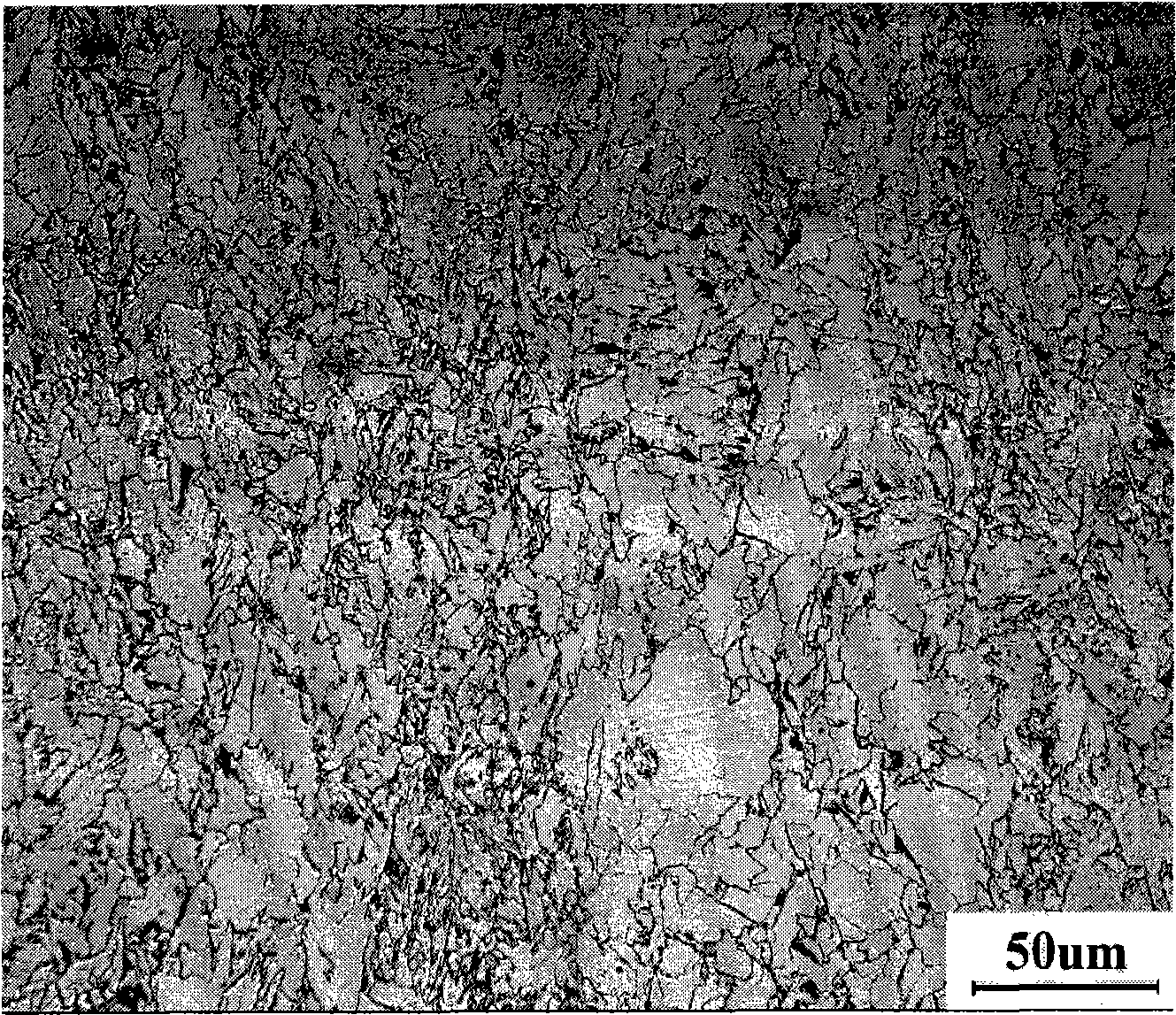

[0046] Such as figure 1 As shown, the embodiment passes through the metallograph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com