Economic air-cooled dual-phase low yield ratio steel plate and production process thereof

A technology with low yield ratio and production process, which is applied in the field of low yield ratio steel plates, can solve the problems of long production cycle, increased cost, and low production efficiency, and achieve the effect of high production efficiency, low cost, and loose production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

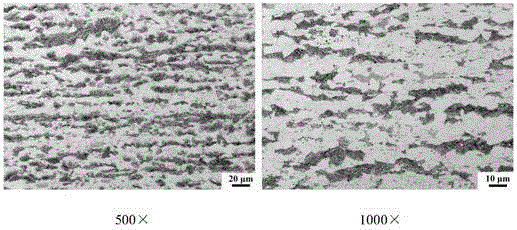

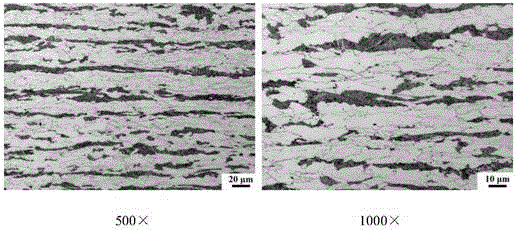

Image

Examples

Embodiment 1

[0026] The steel consists of the following components (wt%): C: 0.08%, Si: 0.80%, Mn: 2.0%, P≤0.015%, S≤0.008%, Cr: 0.90%, the rest is Fe and unavoidable impurities , and the Mn / C ratio is 25, and the Si+Mn+Cr content is 3.7%.

[0027] 1) Smelt and continuously cast slabs according to the above ingredients, and heat the continuous casting slabs at a heating temperature of 1150-1180°C;

[0028] 2) Controlled rolling, rough rolling starting temperature ≤ 990°C, rough rolling finish rolling temperature ≥ 900°C, rough rolling total reduction is 35-65%, then wait for temperature; use intermediate cooling device for watering Cooling, when the temperature is cooled below 800°C, finish rolling is carried out, the finish rolling start temperature is 780-800°C, the finish rolling finish temperature is 700-720°C, the total reduction of finish rolling is 45-75%; the finished plate The thickness is 15mm, and after rolling, it is placed on a cooling bed and air-cooled to room temperature. ...

Embodiment 2

[0031] The steel consists of the following components (wt%): C: 0.08%, Si: 0.80%, Mn: 1.9%, P≤0.015%, S≤0.008%, Cr: 0.9%, the rest is Fe and unavoidable impurities , and satisfy the Mn / C ratio of 23.8, and the Si+Mn+Cr content of 3.6%.

[0032] 1) Smelt and continuously cast slabs according to the above ingredients, and heat the continuous casting slabs at a heating temperature of 1150-1180°C;

[0033] 2) Controlled rolling, rough rolling starting temperature ≤ 990°C, rough rolling finish rolling temperature ≥ 900°C, rough rolling total reduction is 35-65%, then wait for temperature; use intermediate cooling device for watering Cooling, when the temperature is cooled below 800°C, finish rolling is carried out, the finish rolling start temperature is 780-800°C, the finish rolling finish temperature is 700-720°C, the total reduction of finish rolling is 45-75%; the finished plate The thickness is 15mm, and after rolling, it is placed on a cooling bed and air-cooled to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com