Ocean engineering steel with welded joint CTOD (crack tip opening displacement) greater than 0.5mm and preparation method

A welded joint and marine engineering technology, applied in the field of marine engineering, can solve the problems of reduced steel fracture toughness, poor steel plate quality, and unexplained CTOD performance of welding parts, etc., to ensure low temperature toughness and good lamellar tear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

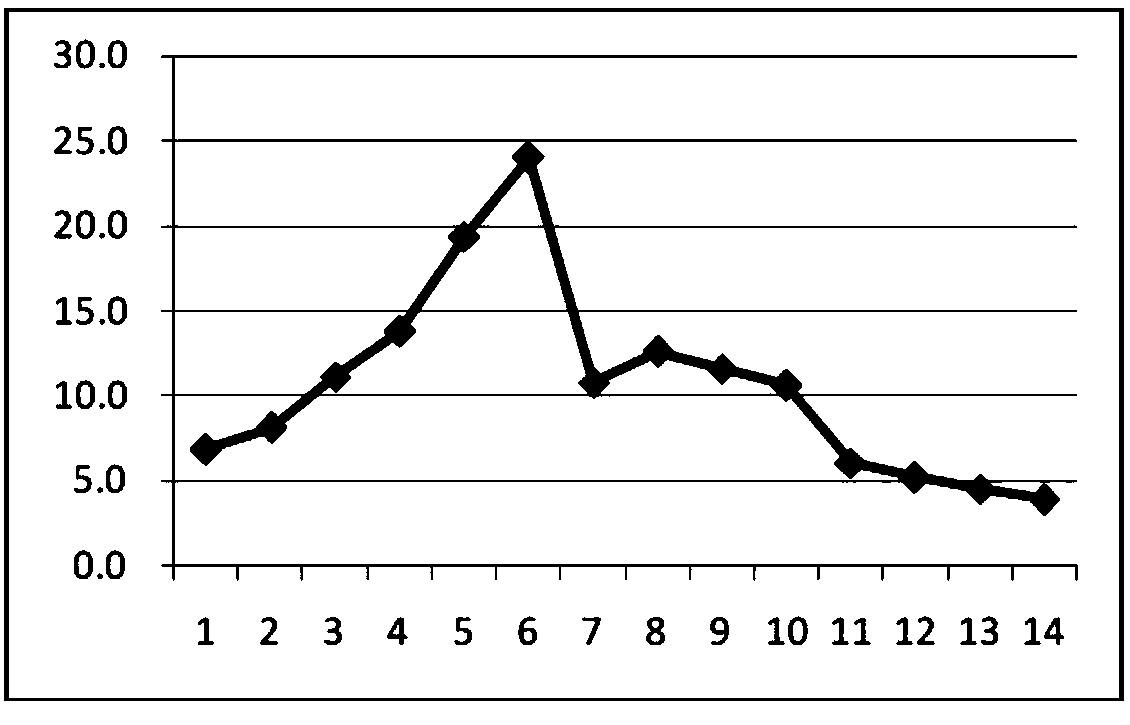

[0018] The thickness of the steel plate for marine engineering is 60mm, and its chemical composition is: C0.07%, Si0.3%, Mn1.45%, Alt0.035%, Nb0.032%, Ti0.015%, Ni0.35%, P0. 01%, S0.003%, and the rest are iron Fe and unavoidable impurities. The size of the billet is 300*2000*2700mm, and the size of the steel plate is 60*2090*12000mm. Table 1 is the controlled rolling and controlled cooling process parameters under this composition, and Table 2 is the mechanical properties obtained under the process parameters. Table 3 is the welding process parameters, Table 4 is the CTOD results, Table 5 is the lamellar tear resistance performance, attached figure 1 Rolling regulations for 60mm thick steel plate, attached figure 2 , attached image 3 And attached Figure 4 It is the microstructure of 60mm thick steel plate. It can be seen that the structure of the steel plate is mainly composed of ferrite and pearlite.

[0019] Table 1 rolling process parameters

[0020] Plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com