Manufacturing method of high nickel steel used for cryogenic storage tank

A low-temperature storage tank and a manufacturing method technology, applied in the field of high-alloy steel manufacturing, can solve the problem that the chemical composition of the test steel is not listed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

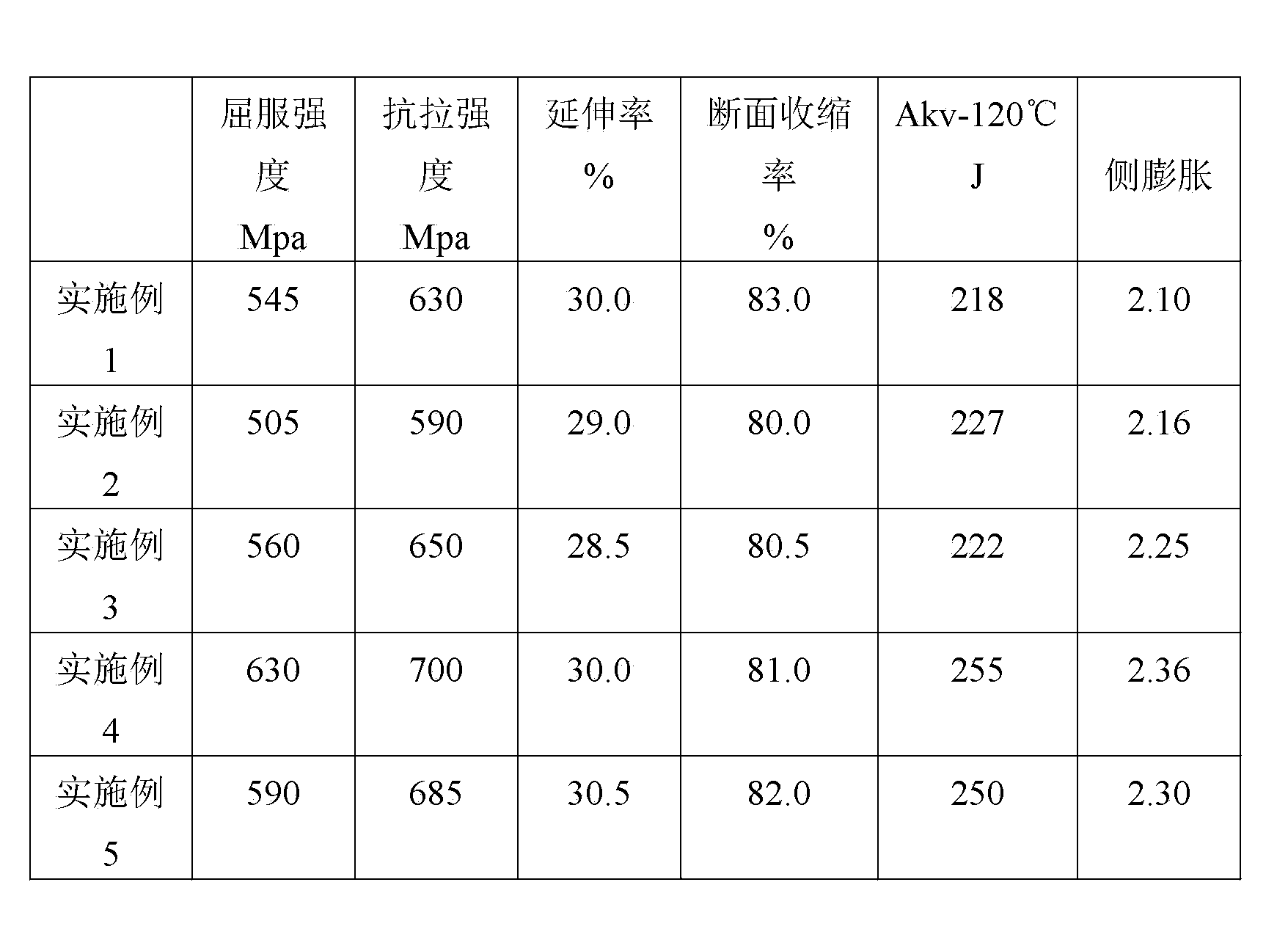

[0021] The chemical composition of high nickel steel is shown in Table 1. The smelting and continuous casting process is as follows: 100 tons of oxygen top-blown converter is used for smelting, the gun position is well controlled during the blowing process, and the carbon temperature is coordinated; the composition is adjusted during the LF refining process, and the ladle is kept blowing argon for 5 minutes; Press for 15 minutes, measure the content of H and O, and ensure that [H]≤2ppm, [O]≤20ppm; the continuous casting slab is slowly cooled, and the slow cooling time is 48 hours.

[0022] Table 1 Chemical composition wt% of high nickel steel

[0023]

C

Si

mn

P

S

Ni

als

H

O

N

Example 1

0.060

0.20

0.65

0.005

0.002

5.00

0.020

0.0001

0.0017

0.0030

Example 2

0.055

0.19

0.70

0.005

0.002

4.52

0.022

0.0001

0.0020

0.0027

Example 3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com